喷枪结构对底吹炼铜炉流场影响的模拟及实验研究

余跃1,2,温治1,2,刘训良1,2,苏福永1,2,蓝海鹏1,2,郝小红3

(1. 北京科技大学 机械工程学院,北京,100083;

2. 北京科技大学 冶金工业节能减排北京市重点实验室,北京,100083;

3. 中国恩菲工程技术有限公司 冶金事业一部,北京,100083)

摘要:采用水力模型实验的方法对某公司设计的底吹炉内的流动过程进行研究,并利用VOF模型对所建立的水力模型进行数学建模。通过模拟结果和实验结果的对比,发现VOF方法能够描述底吹炉水力模型试验台中气体上升过程中所出现的气泡产生、长大和脱离的过程,为该方法向热态模型的推进提供依据。对比4种喷口结构对炉内流动过程的影响,对比结果显示弥散型结构的氧枪的搅拌面积更大,有利于底吹炉内的搅拌和化学反应过程高效进行,但其喷口处的压力波动更明显,对氧枪的寿命造成一定的影响。

关键词:底吹炉;VOF方法;水力模型实验;喷嘴结构

中图分类号:TF811 文献标志码:A 文章编号:1672-7207(2014)12-4129-09

Simulation and experiment of influence of nozzle structure on bottom-blowing furnace flowing process

YU Yue1, 2, WEN Zhi1, 2, LIU Xunliang1, 2, SU Fuyong1, 2, LAN Haipeng1, 2, HAO Xiaohong3

(1. School of Mechanical Engineering, University of Science and Technology Beijing, Beijing 100083, China;

2. Beijing Key Laboratory of Energy Saving and Emission Reduction for Metallurgical Industry,

University of Science and Technology Beijing, Beijing 100083, China;

3. No. 1 Division of Metallurgy, China Enfi Engineering Corporation, Beijing 100083, China)

Abstract: Water model was utilized to study the flowing process within a bottom-blowing furnace designed by some company, which was simulated by VOF model in the flowing process. The simulation and experimental results were compared. The results show that the VOF method can describe the formation, growing up and separation actions in the rising process, which can be a foundation of using the model to research the thermal process of the bottom-blowing furnace. According to the comparison of the influence on flowing process of four nozzles with different structures, it is indicated that a nozzle with disperse spouts can stir a larger zone. This disperse spouts are benefit to promote the process of stirring and reaction more efficiently, whereas the pressure fluctuation near the nozzle export is more obvious, which may affect the lifetime of the nozzle.

Key words: bottom-blowing furnace; VOF method; water model experiment; structure of nozzle

在有色冶炼过程中,高速喷吹的气体不仅起着提供氧化剂的作用,而且是熔池内熔体流动的动力来源。对于底吹氧枪,枪头处于高温熔体的包围之中,会使得氧枪发生烧损,同时在高速的浸没气体射流中普遍存在回击现象[1-6],该现象的存在使得氧枪的寿命极大的缩短。因此,对于氧枪结构的研究有利于更好地组织炉内的流动以及化学反应过程;同时,合理的氧枪设计可以避免或者减弱回击现象,使得氧枪的寿命增加。底吹熔池炼铜工艺是我国拥有自主知识产权的新型炼铜工艺[7-9],该工艺有着原料适应性强、流程简单、富氧率高和能耗低等方面的优点。底吹炉内的过程包含了流动、传热传质、相变及化学反应等过程,由于其生产工艺十分复杂,目前对于其的研究主要集中在流场、传热过程的模拟及利用水力模型对其内部流动过程进行实验研究。目前对于底吹熔池两相流问题的研究所采用的方法比较多,从大体上分为界面追踪法和界面捕捉法;界面追踪法有着处理界面精度高和技巧性强等优点,发展比较迅速,其代表方法有VOF,Level Set、相域法和CLSVOF方法等。Zhu等[10-12]使用VOF方法对气体微通道内液滴的动力学行为(形成、长大、变形、脱离等)做了系统的模拟研究。Fan等[13-15]模拟研究了高压下气液两相流中单个气泡的形成、上升运动以及气泡形状。Kuipers等[16]研究了不同直径气泡的上升运动以及其最终上升速度,并研究了密度比等物理特性的影响规律。Dilkhuizen等[17]提出了三维VOF方法,分析了大密度比、大黏度比、大表面张力系数的情况下的气泡形状以及同轴、倾斜双气泡的聚并现象。Nguyen等[18]利用数值模拟技术采用VOF模型研究了液体在顶吹射流作用下的熔池气液两相界面的运动情况。张振扬等[19-20]利用三维VOF模型对氧枪喷口压力波动频率和熔池含气率进行了研究。闫红杰等[21]利用三维VOF方法对不同氧枪角度情况下底吹炉内的流动过程进行了研究。邵品等[22]利用欧拉-欧拉模型对底吹炉进行了模拟研究。尽管前人做了许多关于底吹炉氧枪的研究,但是研究过程中都将氧枪简化成一根直管,而目前底吹炉中所使用的氧枪大都呈多孔弥散状,因此对于氧枪出口形状的研究具有非常重要的意义。本文作者采用Fluent软件中的VOF模型对底吹炉内的流动过程进行模拟,在模拟过程中考虑表面张力以及浮升力模型,并通过水力模型实验对所采用的计算模型进行验证。同时,还对4种不同的氧枪结构所对应的熔池流动状况进行了模拟和实验研究,对比各个方案的优缺点,以期为实际的氧枪设计进行指导。

1 模型建立

1.1 物理模型

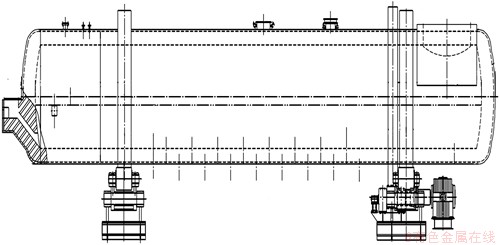

以某公司研发的底吹熔池熔炼炉为研究对象,其结构如图1所示。

图1 底吹熔池吹炼炉示意图

Fig. 1 Sketch map of bottom-blowing bath converting furnace

所研究的吹炼炉内径为3.88 m,长度为21 m,其中沉降段长度为5 m。在沉降段中,布置有放渣口以及虹吸的放铜口。放渣口中心位于炉体转动中心下方0.46 m,在冶炼过程中,炉内熔体高度为1.545 m,基本与放渣口中心平齐。

在熔炼炉的底部布置有18支氧枪,其中两支氧枪位于排烟口附近,其余16支氧枪位于炉体中部的反应区内,反应区内的氧枪呈双排布置,与竖直方向的夹角分别为10°和20°,在每一排中,相邻2支氧枪的间距为1.25 m。

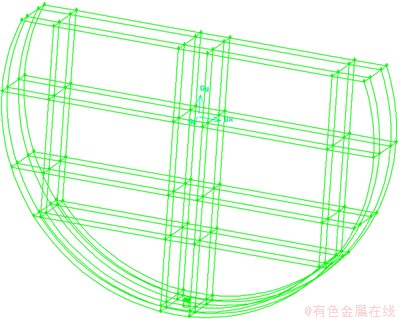

由于底吹炉在轴向上有着一定的周期性,为了减少计算和实验投入的成本,本文对包含1支氧枪的流动区域进行研究。所建立的模型如图2所示,为了生成高质量的计算网格,对所建立的模型进行了精细的分块,共划分57个区域,所有区域都划分结构化网格,总网格数为63万。

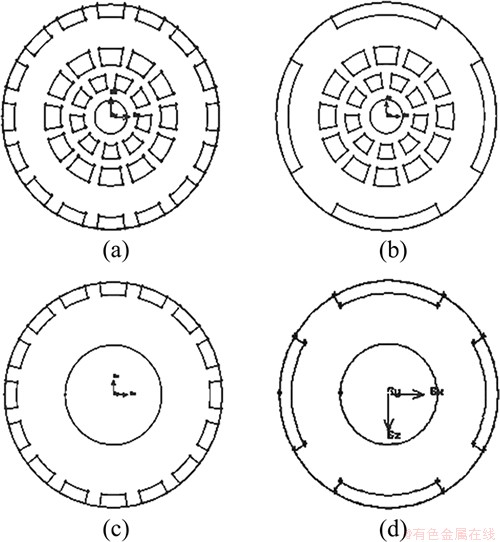

在本文的计算和实验的过程中,研究了4种不同的氧枪结构,氧枪出口的形式见图3。图3中最外层为氮气喷口,其余喷口为氧气喷口。图3(b)~3(d)所示都是针对图3(a)的结构进行简化的图,图3(b)所示为对外层氮气喷口进行简化的图,图3(c)所示为对内层氧气喷口进行简化的图,图3(d)所示为对外层氮气喷口和内层氧气喷口都进行简化的图,在简化的过程中都保证了简化前与简化后的喷口面积不变。

图2 单氧枪计算区域模型图

Fig. 2 Sketch of computational domain with single nozzle

图3 4种氧枪结构示意图

Fig. 3 Sketch maps of structures of four different oxygen nozzles

1.2 数学模型

吹炼炉内的过程是一个包含流动、传热传质、相变及化学反应的非常复杂的过程,本文的研究工作为不同氧枪结构对炉内流动过程的影响,暂不考虑其他复杂过程,研究过程中所进行的简化如下。

1) 假设初始状态时熔体为静止状态。

2) 假设熔池内的高温熔体为不可压缩流体,忽略喷溅造成的熔体损失。

3) 熔体内流体流动的主要驱动力为表面张力和浮升力,浮升力采用Boussinesq假设。

4) 不考虑炉内化学反应过程。

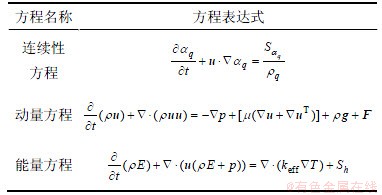

根据前面的假设,本文可以得到如下控制方程组:

对于两相过程,本文采用VOF方法进行描述,对于相界面的跟踪是通过求解两相的容积比率的连续性方程来完成的。对于第q相,该方程的形式表1中所示,式中的αq为第q相在单元体中所占的比例,当0<αq<1时,认为在单元体中包含两相的交界面。

出现在表1中输运方程中的属性是由每一控制容积中的分相决定的,容积比率平均密度用下式进行描述:

(1)

(1)

对于湍流,本文采用标准的k-ε模型进行描述,湍动能方程k和扩散方程ε分别如式(2)和(3)所示:

(2)

(2)

(3)

(3)

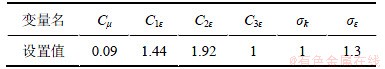

式中:Gk为由于平均速度梯度引起的湍动能k的产生项;Gb为由于浮力引起的湍动能k的产生项;YM为可压湍流中脉动扩张的贡献;C1ε,C2ε和C3ε为湍流经验常数;σk和σε分别为湍动能k和耗散率ε对应的prandtl数;Sk和Sε为源项。关于模型常数的设置值见表2。

表1 控制方程组

Table 1 Governing conservation equations

湍流黏度μt为k和ε的函数,表达式为

(4)

(4)

式中:Cμ为经验常数,设置值见表2。

表2 k-ε模型湍流常数

Table 2 Model constants of k-ε models

1.3 定解条件

1) 入口条件。入口采用速度边界入口,外层气体的速度为63.75 m/s,湍流强度为5.137%,当量直径为2.44 mm;内层气体的速度为30 m/s,湍流强度为5.308%,当量直径为4 mm。

2) 出口条件。出口采用压力出口边界条件,出口压力设置为-10 Pa,回流湍动能为0.01 m2/s2,回流耗散率为0.01 m2/s3。

3) 壁面边界条件。无滑移边界条件,认为在壁面处的流体速度为0,近壁面区域采用标准壁面函数处理。

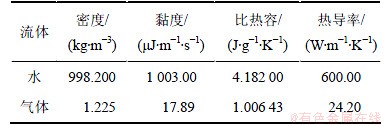

4) 物性参数。由于本文是对所做的水力模型实验过程进行数值模拟,所以不需要采用底吹炉中铜锍的物性参数进行计算,而是采用水的参数。具体的参数设置见表3。

表3 底吹炉水力模型实验流体的物性参数

Table 3 Property parameters of fluids in experimental water model of bottom-blowing furnace

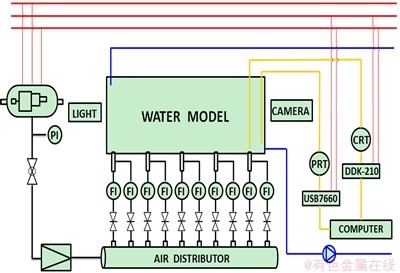

2 实验装置的建立

水力模型试验台的原理图如图4所示。在水力模型的底部接5支喷枪,每支喷枪有2个通道,分别对应底吹炉原型中的内层氧气通道和外层氮气通道。每个通道通过单独的阀门和流量计控制其流量,10个单独的通道分别与气体分配器的出口相连。气体分配器的进口端通过管道与压缩机相连,为了保证管道中压力及流量的稳定,在压缩机与气体分配器之间安装1个稳压阀。对实验结果的记录包括气体喷吹状态的影像资料记录、喷枪出口平面压力波动记录和水力模型内电导率变化曲线记录,分别通过相机、压力变送器和电导率变送器来实现上述功能。

图4 水力模型试验台原理图

Fig. 4 Schematic diagram of experimental water model

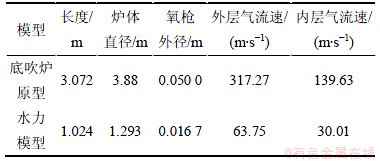

为了保证动力相似,水力模型试验台的搭建按照修正的弗雷德准数相等的原则进行,取模型与原型的比例为1:3。因为底吹炉原型在轴线方向具有一定的周期性,取其中的一段区域进行实验研究,所取的区域包含4支氧枪,原型与模型的各部分尺寸及操作参数见表4。

表4 底吹炉与水力模型尺寸及操作参数对比

Table 4 Comparison of size and operation parameters between bottom-blowing furnace and water model

3 结果及分析

3.1 模拟结果与实验结果对比

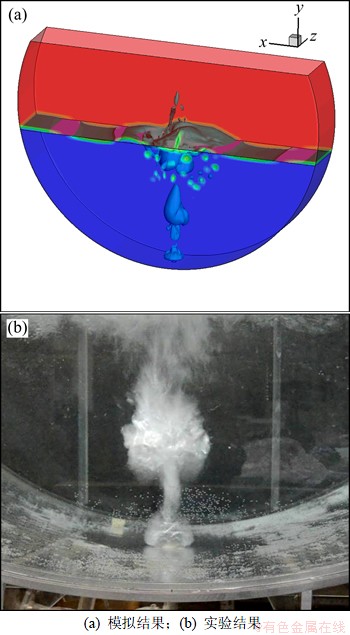

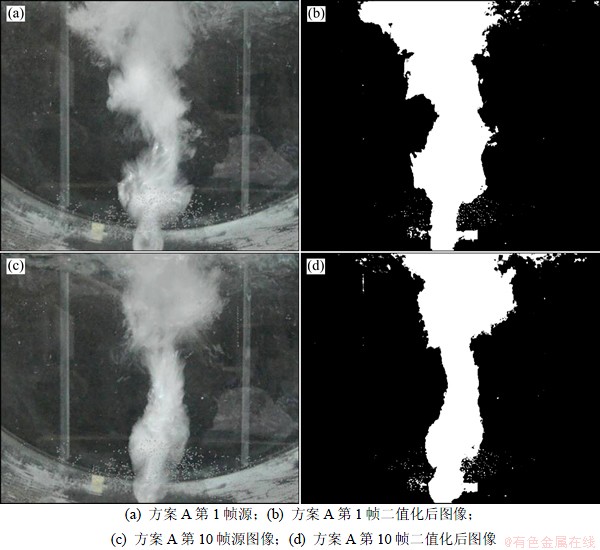

方案A模拟和实验的结果如图5所示。由于浮力以及表面张力的作用,气泡在上升的过程中会受到1个与运动方向相反的切应力,这个切应力会导致气泡的变形以及破碎。从图5(a)可以看到:模拟结果能够很好的捕捉到气泡上升过程中的变形以及破碎的过程。对比图5(a)与图5(b)可以发现:目前所采用的计算模型能够比较准确描述高速气体从水下喷出时气体的形貌。另外,在陈帅等[23-24]的研究中指出,水下高速气体喷吹的时候,在喷口端口附近容易形成射流回击以及射流鼓胀的现象。在本文所进行的模拟和实验研究中,都很好地捕捉到了射流回击现象的存在,由于射流回击现象的存在,使得喷口端面不断受到回击气体的冲刷,使得氧枪磨损并损坏,这也是底吹炼铜炉及底吹炼铅炉中氧枪寿命短的主要原因之一。

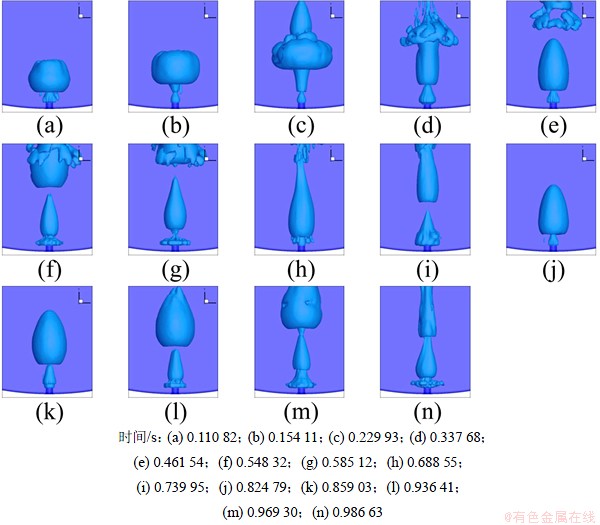

图6所示为0~1 s之间的模拟结果。从图6可以看到:气体从喷口喷出后逐渐形成气泡并长大的过程,当气泡长大到一定程度后,会与喷口端面发生脱离。当前1个气泡离开喷口端面之后,喷口附近会形成2种不同形式的气泡:一种为锥形,另一种为圆盘形。1个气泡从生成到脱离的时间为0.04~0.11 s,气泡生成的频率为14 Hz左右。

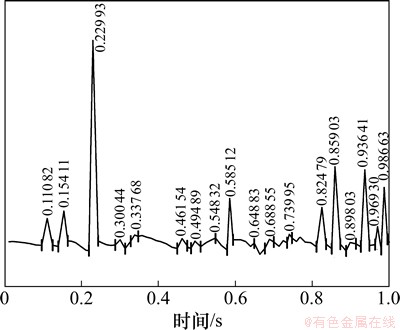

由于气泡的不连续性,会导致喷口附近的压力也不是稳定值,而是存在一定频率的波动。在模拟的过程中,通过监测氧枪平面附近压力波动值可以发现:喷口附近的压力波动与气泡的生成、长大和脱离的过程有着直接的联系。图7所示为0~1 s之间喷口压力的波动情况。从图7可以看到:压力波动频率为18 Hz。从与图7中时间轴的对比可以发现,压力的峰值出现的时刻正好与前一个气泡离开喷嘴、喷嘴附近气体形成小的锥形气泡或圆盘形气泡的时刻相吻合。这是因为当前一个气泡离开喷嘴后,喷嘴附近的液体很快填充到喷嘴附近,填充过来的气体会对新形成的气泡进行压迫;在新形成的小气泡空间内,从喷嘴出来的气体并未完全进行膨胀,所以,该狭小空间内的压力在短时间内会呈现1个较高值。

图5 方案A模拟结果与实验结果对比

Fig. 5 Comparison of simulation result and experimental result

图6 从0~1 s之间喷口附近气泡形成过程

Fig. 6 Bubble formation process near nozzle within period from 0 to 1 s

图7 从0~1 s之间喷口附近压力波动

Fig. 7 Pressure fluctuation near nozzle within period from 0 to 1 s

3.2 4种结构氧枪性能对比

氧枪的搅拌面积和氧枪的寿命是衡量底吹炉所使用的氧枪优劣的2个重要参数,在模拟和水力实验的过程中,没有办法对氧枪的寿命进行直接研究,但可以通过氧枪喷口附近的压力波动情况来间接反映氧枪寿命。本文针对图3中所示的4种结构的氧枪进行了数值模拟和实验研究,并对其搅拌面积和氧枪端面的压力波动情况进行对比。

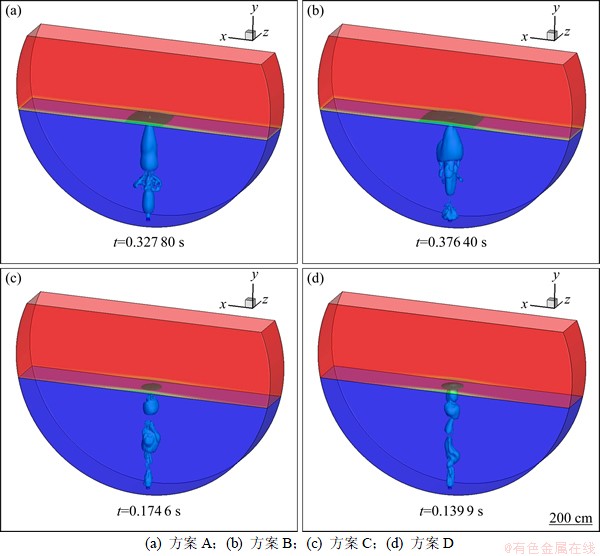

1) 搅拌区域对比。图8所示为4种氧枪模拟结果的对比。从图8可以看到:方案A和方案B中气体在液体中所占的比例较大,说明这2种方案的搅拌能力较强。从另外一个方面看,图中的数字表示从喷口开始喷吹开始,第1个气泡到达液面的时间。对于这4种方案,第1个气泡到达液面的时间分别为0.327 8,0.376 4,0.174 6和0.139 9 s;方案A和方案B的第1个气泡到达液面的时间较长。在第1个气泡达到液面时,4种方案所对应的液体中气体体积分别为1.188×10-3,1.364×10-3,0.633×10-3和0.507×10-3 m3,这说明这2种方案中,有更多的气体分布在液体中,间接说明搅拌的能力较强。

这一点在水力实验中也得到了较好验证。为了更加直观地对比这4种方案的搅拌区域大小,本文将所采集的影像资料进行了二值化。图9所示为二值化过程中随机抽取的2组图像进行对比,其中图9(a)和图9(b)所示分别为方案A第1帧二值化之前和之后的图像,图9(c)和图9(d)所示分别为方案A第10帧二值化之前和之后的图像。从图9可以看到:所采用的二值化过程能够比较准确地描述原来图像中的两相特征。

图8 4种方案搅拌状况对比

Fig. 8 Comparisons of stirring condition for 4 different plans

图9 源图像和二值化后图像对比

Fig. 9 Comparisons of source images and after binarization

本文利用同样的方法,对B,C和D方案的实验结果也进行二值化处理,并对二值化后的影像资料的黑色像素值和白色像素值所占的比例进行统计,统计结果如表5所示。从统计结果可以看出:方案A和方案B中,搅拌区域较大,方案C和方案D相对较小,这与之前的模拟结果能够较好吻合。但在实验结果中,4种方案搅拌区所占比例的差别并没有模拟结果中的差别大,这是由于4次实验中现场的光源条件的存在一定的差异导性,会引入一定的实验误差。

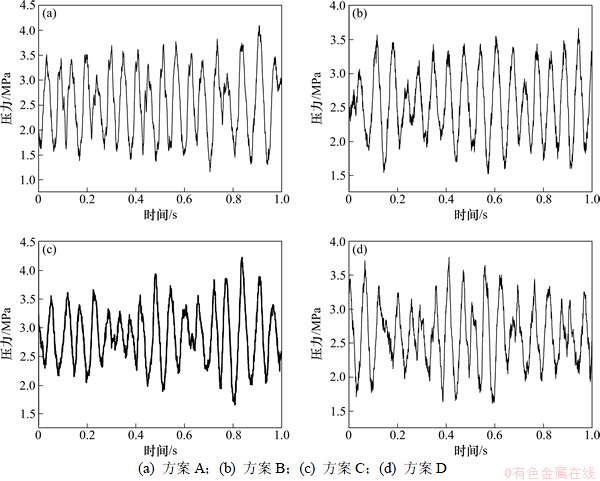

2) 喷口附近压力波动对比。根据郭强等[25]的研究,氧枪喷口压力波动是氧枪磨损的主要原因之一,本文利用压力传感器对喷口附近的压力波动进行了测量,测量结果如图10所示。因为实验中对压力的测量是在流动稳定之后才开始进行的,而3.1节中的模拟是针对喷射初期进行的,所以,这两者的压力波动状况有着一定的差别。

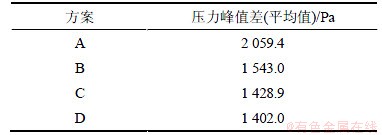

从图10可以看出:4种方案在流动稳定的状态下的压力波动非常类似,压力的波动频率在16~18 Hz之间,所以,从频率的角度并不能完全说明4种方案对氧枪寿命的影响。因此,本文还对1次波动中波峰和波谷压力的差值进行了统计,统计的结果如表6所示。从表6可以看到:4种方案的峰值差依次降低,对峰值差较大的方案,氧枪附近的压力波动的幅值大,氧枪更易磨损。

表5 4种方案搅拌区域所占比例

Table 5 Percentages of stirring zone for four different plans

图10 4种方案喷嘴附近压力波动

Fig. 10 Pressure fluctuation of four different plans near nozzle

表6 4种方案压力峰值差对比

Table 6 Comparisons of average difference of peak and trough pressure of four different plans

4 结论

1) 所采用的计算模型能够描述气泡在水中上升过程中的形成、长大与破碎的过程,模拟得到的气体射流的形貌与实验结果吻合良好。

2) 喷口附近的压力波动与喷口附近的气泡形貌有着密切的关系,前一个气泡脱离喷口平面后,会在喷口处形成新的锥形或者圆盘形气泡,新形成的气泡体积狭小,气泡内会在短时间内维持比较高的压力。

3) 通过对实验结果进行二值化,得到4种形式的喷口所对应的搅拌区的比例分别为18.78%,18.97%,17.57%和17.07%,A和B方案的搅拌区域面积相对较大,C和D方案的搅拌区域面积较小。

4) 4种方案的喷口附近压力波动频率为16~18 Hz,压力峰值差分别为2059.4,1 543.0,1 428.9和1 402.0 Pa,A方案的压力波动幅值较大,会影响氧枪寿命。

参考文献:

[1] Taylor I F, Wright J K, Philp D K. Transient pressure and vibration events resulting from high speed gas injection into liquids[J]. Canadian Metallurgical Quarterly, 1988, 27(4): 293-301.

[2] Wei J H, Ma J C, Fan Y Y, et al. Back-attack phenomena of gas jets with submerged horizontally blowing and effects on erosion and wear of refractory lining[J]. ISIJ International, 1999, 39(2): 779-786.

[3] Martin M, Diaz M. Gas-liquid and gas-liquid-liquid reactors with top and bottom blowing (Ⅰ): Fluid dynamic regimes[J]. Chemical Engineering Communications, 2002, 189(4): 543-570.

[4] Fabritius T M J, Mure P T,  J J. The determination of the minimum and operational gas flow rates for sidewall blowing in the AOD-Converter[J]. ISIJ International, 2003, 43(8): 1177-1184.

J J. The determination of the minimum and operational gas flow rates for sidewall blowing in the AOD-Converter[J]. ISIJ International, 2003, 43(8): 1177-1184.

[5] Tang J N, Wang N F, Shyy W. Flow structures of gaseous jets injected into water for underwater propulsion[J]. Acta Mechanica Sinica, 2011, 27(4): 461-472.

[6] Shi H H, Guo Q, Wang C, et al. Oscillation flow induced by underwater supersonic gas jets[J]. Shock Waves, 2010, 20(4): 347-352.

[7] 胡立琼. 氧气底吹炼铜炉的设计[J]. 中国有色冶金, 2010, 39(1): 17-18.

HU Liqiong. Design of oxygen bottom-blowing copper-smelting furnace[J]. China Nonferrous Metallurgy, 2010, 39(1): 17-18.

[8] 曲胜利, 李天刚, 董准勤, 等. 铜富氧底吹生产实践及设计探讨[J]. 有色金属(冶炼部分), 2012(3): 10-13.

QU Shengli, LI Tiangang, DONG Zhunqin, et al. Plant practice of and design discussion on oxygen enriched bottom blowing smelting[J]. Nonferrous Metals (Extractive Metallurgy), 2012(3): 10-13.

[9] 陈知若. 底吹熔池炼铜技术的应用[J]. 中国有色冶金, 2009, 10(5): 16-22.

CHEN Zhiruo. The application of oxygen bottom-blown bath smelting of copper[J]. China Nonferrous Metallurgy, 2009, 10(5): 16-22.

[10] Zhu X, Sui P C, Djilali N. Dynamic behaviour of liquid water emerging from a GDL pore into a PEMFC gas flow channel[J]. Journal of Power Sources, 2007, 172(1): 287-295.

[11] Zhu X, Sui P C, Djilali N. Three-dimensional numerical simulations of water droplet dynamics in a PEMFC gas channel[J]. Journal of Power Sources.2008, 181(1): 101-115.

[12] Zhu X, Liao Q, Sui P C, et al. Numerical investigation of water droplet dynamics in a low-temperature fuel cell micro channel: Effect of channel geometry[J]. Journal of Power Sources.2010, 195(3): 801-812.

[13] Yang G Q, Du B, Fan L S. Bubble formation and dynamics in gas-liquid-solid fluidization-a review[J]. Chemistry Engineering Science. 2007, 62(1): 2-27.

[14] Li Y, Zhang J P, Fan L S. Discrete-phase simulation of single bubble rise behavior at elevated pressures in a bubble column[J]. Chemistry Engineering Science. 2000, 55(20): 4597-4609.

[15] Li Y, Yang G Q, Zhang J P, et al. Numerical studies of bubble formation dynamics in gas- liquid-solid fluidization at high pressures[J]. Powder Technology, 2001, 116(2): 246-260.

[16] van Sint Annaland M, Deen N G, Kuipers J A M. Numerical simulation of gas bubbles behaviour using a three-dimensional volume of fluid method[J]. Chemistry Engineering Science, 2005, 60(11): 2999-3011.

[17] Dijkhuizen W, Van den Hengel E I V, Deen N G, et al. Numerical investigation of closures for interface forces acting on single air-bubbles in water using Volume of Fluid and Front Tracking models[J]. Chemistry Engineering Science. 2005, 60(22): 6169-6175.

[18] Nguyen A V, Evans G M. Computational fluid dynamics modeling of gas jets impinging onto liquid pools[J]. Applied Mathematical Modelling, 2006, 30(5): 1472-1484.

[19] 张振扬, 陈卓, 闫红杰, 等. 富氧底吹熔炼炉内气液两相流动的数值模拟[J]. 中国有色金属学报, 2012, 22(6): 1826-1834.

ZHANG Zhenyang, CHEN Zuo, YAN Hongjie, et al. Numerical simulation of gas-liquid multi-phase flows in oxygen enriched bottom-blown furnace[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(6): 1826-1834.

[20] 张振扬, 闫红杰, 刘方侃, 等. 富氧底吹熔炼炉内氧枪结构参数的优化分析[J]. 中国有色金属学报, 2013, 23(5): 1471-1478.

ZHANG Zhenyang, YAN Hongjie, LIU Fangkan, et al. Optimization analysis of lance structure parameters in oxygen enriched bottom-blown furnace[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(5): 1471-1478.

[21] 邵品, 张廷安, 刘燕, 等. 底吹冰铜吹炼炉中气-液流动状况的数学模拟[J]. 东北大学学报(自然科学版), 2012, 33(9): 22.

SHAO Pin, ZHANG Yanan, LIU Yan, et al. Numerical simulation of gas liquid flow behavior in a copper matte bottom blowing converter[J]. Journal of Northeastern University (Natural Science), 2012, 33(9): 22.

[22] 闫红杰, 刘方侃, 张振扬, 等. 氧枪布置方式对底吹熔池熔炼过程的影响[J]. 中国有色金属学报, 2012, 22(8): 2393-2400.

YAN Hongjie, LIU Fangkan, ZHANG Zhenyang, et al. Influence of lance arrangement on bottom-blowing bath smelting process[J]. The Chinese Journal of Nonferrous Metals, 22(8): 2393-2400.

[23] 陈帅. 三维水下超声速气体射流的实验研究[D]. 杭州: 浙江理工大学机械与自动控制学院, 2012: 25-37.

CHEN Shuai. Experimental study on three-dimensional underwater supersonic gas jets[D]. Hangzhou: Zhejiang Sci-Tech University. School of Mechanical Engineering and Automation, 2012: 25-37.

[24] 施红辉, 郭强, 王超, 等. 水下超音速气体射流胀鼓和回击的关联性研究[J]. 力学学报, 2010, 42(6): 1206-1210.

SHI Honghui, GUO Qiang, WANG Chao, et al. Experiments on the relationship between bulging and back-attack of submerged supersonic gas jets[J]. Chinese Journal of Theoretical and Applied Mechanics, 2010, 42(6): 1206-1210.

[25] 郭强, 施红辉, 王超, 等. 水下超声速气体射流气液两相复杂流动研究[J]. 工程热物理学报, 2012, 33(5): 809-812.

GUO Qiang, SHI Honghui, WANG Chao, et al. Study on gas-liquid complex flow induced by submerged supersonic gas jets[J]. Journal of Engineering Thermophysics, 2012, 33(5): 809-812.

(编辑 陈爱华)

收稿日期:2014-02-17;修回日期:2014-04-24

基金项目(Foundation item):国家自然科学基金资助项目(51276015)(Project (51276015) supported by the National Natural Science Foundation of China)

通信作者:刘训良(1973-),山东兖州人,副教授,博士,从事数值仿真研究;电话:13146788586;E-mail:liuxl@me.ustb.edu.cn