文章编号:1004-0609(2015)-07-1773-08

喷射沉积法制备Al-Zn-Mg-Cu-Zr合金的显微组织与性能

刘 斌1,汪明朴1, 2,雷 前1,段雨露1,刘林贤1,虞红春1

(1. 中南大学 材料科学与工程学院,长沙 410083;

2. 中南大学 有色金属材料科学与工程教育部重点实验室,长沙 410083)

摘 要:采用喷射沉积技术制备Al-8.11Zn-2.01Mg-2.36Cu-0.12Zr(质量分数,%)合金,并对其显微组织和性能进行研究。结果表明:喷射沉积的沉积态合金为近等轴状,且晶粒均匀细小,尺寸约为50 μm;对合金进行(470 ℃,24 h)均匀化处理、420 ℃热挤压(挤压比为39)、(470 ℃,1 h)固溶处理、(140 ℃, 8 h)时效处理后合金具有优良的性能,合金的抗拉强度为730 MPa,屈服强度为700 MPa,伸长率为11%。合金在140 ℃时效过程中,时效10 min即形成GP区;时效8 h后,主要强化相为针状的η'-MgZn2和球状的Al3Zr粒子;时效72 h后,针状的η'-MgZn2亚稳相呈现为棒状的η-MgZn2稳定相。该喷射沉积法制备的合金表现出优异的强度和韧性,可广泛应用于航天航空工业、汽车工业、轨道交通、船舶、电子电工等领域。

关键词:Al-Zn-Mg-Cu-Zr合金;喷射沉积;固溶处理;时效处理

中图分类号:TG146.21 文献标志码:A

Microstructure and properties of Al-Zn-Mg-Cu-Zr alloy prepared by spray deposition method

LIU Bin1, WANG Ming-pu1, 2, LEI Qian1, DUAN Yu-lu1, LIU Lin-xian1, YU Hong-chun1

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Key Laboratory of Nonferrous Metal Materials Science and Engineering, Ministry of Education,

Central South University, Changsha 410083, China)

Abstract: Al-8.11Zn-2.01Mg-2.36Cu-0.12Zr (mass fraction, %) alloy was prepared by spray deposition method, and the microstructure and relevant properties were studied in detail. The results show that uniform and fine equiaxed grains with grain size of about 50 μm appears in spray deposition casting ingot. After homogenization treatment at 470 ℃ for 24 h, hot extrusion at 420 ℃ with extrusion ratio 39, solution treatment at 470 ℃ for 1 h, and aging treatment at 140 ℃ for 8 h, the alloy achieves excellent properties: the tensile strength is 723 MPa, yield strength is 700 MPa, elongation is 11%. When the alloy is aged at 140 ℃, GP zones appear in the early state for 10 min, then η'-MgZn2 phase and Al3Zr phase form as aged at 140 ℃ for 8 h and they are the main strengthening phases, as the aging time increases to 72 h, the meta-stable needle-shape η'-MgZn2 phase gradually grows into stable rod-shape η-MgZn2 phase. The studied alloy exhibits excellent strength and toughness, and the alloy can be widely used in aerospace, automotive, rail transportation, marine, electronic, electrical fields.

Key words: Al-Zn-Mg-Cu-Zr alloy; spray deposition; solution treatment; aging treatment

1972年,英国奥斯普瑞(Osprey)金属公司首先开发了喷射沉积技术工艺并应用于金属材料制备[1-3]。与传统的熔炼铸造工艺相比,采用喷射沉积技术所得的材料成分均匀、组织细化、无宏观偏析、含氧量低。这种制备技术流程短、工序简化、沉积效率高,并可以改善材料的综合性能[4-7]。Al-Zn-Mg-Cu合金具有超高的强度及其优良的综合性能,广泛应用于航天航空、汽车运输和电工电子材料等领域[8-10]。但是,熔炼铸造制备的Al-Zn-Mg-Cu合金材料存在枝晶偏析严重、合金元素烧损严重、合金元素固溶度有限等问题,严重影响合金的强度、韧性、抗腐蚀性能和疲劳性能等[11-12]。因此,开发具有高强高韧Al-Zn-Mg-Cu合金已经成为国内外高强铝合金的研究热点[13-16]。目前,关于高强高韧Al-Zn-Mg-Cu合金的研究主要集中在小坯锭实验室制备阶段,而对于大坯锭的研究却鲜见报道。本文作者采用喷射沉积方法制备了大坯锭的Al-Zn-Mg-Cu合金,并分析了喷射沉积工艺参数对大坯件的铸锭性能影响,热挤压等形变热处理对最终性能的影响规律,最后还对沉淀析出过程中强化相的种类、演变及强化机理进行了探讨,获得了制备出高强高韧新型铝合金的重要参数。

1 实验

1.1 材料的制备

本实验研究的是Al-8.11Zn-2.01Mg-2.36Cu- 0.12Zr(质量分数,%)合金(牌号7055),合金的大坯锭喷射沉积制坯过程在中国浩然有限公司内进行,采用氮气雾化,雾化温度为820 ℃,接收距离为650 mm。沉积后得到长度为1 800 mm、直径为500 mm的坯锭。大坯锭的热挤压温度为420 ℃、挤压速度为3 mm/s、挤压比为39,对挤压件进行空冷。挤压后的棒材在470 ℃固溶处理1 h后水淬冷地。选取120、140、160和180 ℃ 4个时效温度,以探究不同时效温度对合金的时效行为的影响。

1.2 材料的分析与表征

硬度测试在HV-5型维氏硬度计上进行,载荷为2 kg,加载时间为15 s。室温抗拉强度测试在MTS-810型万能试验机上进行,应变速率为2 mm/min,拉伸后的合金断口形貌在扫描电子显微镜上进行观察。选取不同时效态((140 ℃,20 min),(140 ℃,8 h),(140 ℃,72 h))的典型样品进行了透射电镜分析,操作电压为200 kV。

2 结果与分析

2.1 喷射沉积法制备的坯锭显微组织

为了比较同成分的传统熔炼的铸锭和喷射沉积法制备的坯锭的显微组织,首先采用熔铸法制备了一个坯锭,并对铸态组织进行金相分析。图1所示为传统熔铸法制备的铸锭和喷射沉积法制备的坯锭的光学显微组织。从图1(a)可以看出,熔铸造法制备的合金铸锭组织主要为枝晶组织。这是由于合金熔体在凝固过程中,液相中的原子扩散速度快,而已经凝固的原子扩散速度慢,这样会使得先后凝固的部分的成分不同,从而形成晶内偏析,同时合金的晶粒尺寸较大,约为80~100 μm。而喷射沉积法制备的合金的晶粒尺寸细小,约为30~50 μm,晶粒内部几乎无偏析。

图1 铸造态和沉积态的Al-Zn-Mg-Cu合金的光学显微组织

Fig. 1 Optical micrograph of casted (a) and deposited (b) Al-Zn-Mg-Cu alloys

图2所示为喷射沉积态Al-Zn-Mg-Cu合金坯锭的SEM像。从图2可以看出,晶界和晶内均分布有非平衡凝固相粒子,晶界上凝固相沿着晶界析出,链接连成网状。晶粒内部的凝固相则以棒状、针状和球状分布。坯锭的气孔主要分布在晶界的交叉口处,HU等[17]和GRANT等[18]认为非平衡凝固相与气孔和晶间孔隙度与供液不足的程度有关,在喷射沉积冷却过程中,溶解的气体和未溶的液相滞留在晶界上,容易产生粗大的非平衡凝固相和气孔。

图3所示为喷射沉积法制备的Al-Zn-Mg-Cu合金坯锭的晶内非平衡凝固相、晶界非平衡凝固相和基体的SEM像及EDS能谱分析结果。表1所列为喷射沉积态Al-Zn-Mg-Cu合金析出相和基体组织的合金元素含量。由图3和表1可知,晶界和晶内的第二相粒子主要由Zn、Mg、Cu元素组成,两种析出物中各元素含量基本相同,根据其含量比例确定该析出物可能是Cu(MgZn)2相。同时,在晶界上大块的第二相粒子主要含Cu和Fe元素。

图2 喷射沉积态Al-Zn-Mg-Cu合金的SEM像

Fig. 2 SEM images of spray-deposited Al-Zn-Mg-Cu alloys

图3 喷射沉积态Al-Zn-Mg-Cu合金不同相的SEM像及EDS谱

Fig. 3 SEM images ((a), (c), (e), (g)) and EDS spectrums ((b), (d), (f), (h)) of different spray-deposited Al-Zn-Mg-Cu alloys

表1 喷射沉积态Al-Zn-Mg-Cu合金基体组织和析出相的化学成分

Table 1 Chemical composition of spray-deposited Al-Zn- Mg-Cu alloy matrix and precipitates

为了弄清非平衡凝固相的种类,对喷射沉积法制备的坯锭进行XRD分析。图4所示为喷射沉积态Al-Zn-Mg-Cu合金的XRD谱。由图4可知:非平衡凝固相主要为η-MgZn2相和CuAl2相。这说明合金在喷射沉积凝固过程中,部分合金元素已经以η-MgZn2相和CuAl2相的形式从基体中快速析出。

图4 喷射沉积态Al-Zn-Mg-Cu合金的XRD谱

Fig. 4 XRD pattern of spray-deposited Al-Zn-Mg-Cu alloy

2.2 合金挤压态和固溶态显微组织

图5所示为喷射沉积态Al-Zn-Mg-Cu合金的挤压态和固溶态的显微组织及相应析出相的EDS谱。从图5(a)和(b)中可以看出,合金经过热挤压变形能够有效地消除沉积态中的气孔和缺陷,提高合金的致密度。同时也能够破碎基体中的粗大第二相,沿着挤压方向分布,有利于后续的固溶处理时第二相的回溶,该第二相主要为Cu、Zn、Mg等元素组成的析出相和一些粗大的含Fe相。从图5(c)和(d)可知,挤压态合金经过固溶处理后,大量的第二相回溶到基体中,只留下一些粗大的含Fe相。

图5 挤压态和固溶态喷射沉积Al-Zn-Mg-Cu合金的显微组织及相应析出相的EDS谱

Fig. 5 Microstructures ((a), (c)) and EDS spectrum ((b), (d)) of spray-deposited Al-Zn-Mg-Cu alloys

2.3 时效处理后合金的力学性能

图6所示为喷射沉积法制备的Al-Zn-Mg-Cu合金经过420 ℃热挤压、(470 ℃,1 h)固溶处理后在不同温度下的时效硬化曲线。由图6可见,合金的硬度随着时效时间的延长先迅速增加到峰值,然后缓慢下降,发生过时效。随着时效温度的增加,到达峰值的时间越短。合金在120 ℃时效时,硬度达到峰值(219 HV)约需24 h;在140 ℃下时效达到硬度峰值(225 HV)约需8h;继续增加时效温度至160和180 ℃,硬度在1~3 h内就迅速增加到峰值(218 HV)。

图6 喷射沉积Al-Zn-Mg-Cu合金在不同温度下的时效曲线

Fig. 6 Age-hardening curves of spray-deposited Al-Zn-Mg- Cu alloys aged at different temperatures

图7所示为不同状态喷射沉积法制备的Al-Zn- Mg-Cu合金的力学性能。经过挤压变形后,合金的抗拉强度为401 MPa,屈服强度为280 MPa,伸长率为14.2%。这是由于在合金内,存在一些粗大的第二相,单向拉伸时易在第二相处产生应力集中,成为裂纹源,影响合金的延展性。将合金在470 ℃,固溶1 h,其抗拉强度为684 MPa,屈服强度为533 MPa,伸长率为17.4%,合金性能得到很大的提高。这是因为经过固溶处理合金内部的粗大第二相和易脆第二相溶解在基体中,起到了固溶强化的效果,合金的延展性得到很大的提高。固溶后的合金在140 ℃,时效8 h后达到峰时效,其抗拉强度为723 MPa,屈服强度为700 MPa,伸长率为11%。

图7 不同状态喷射沉积Al-Zn-Mg-Cu合金室温拉伸的应力—应变曲线

Fig. 7 Ambient tensile stress–strain curves of spray-deposited Al-Zn-Mg-Cu alloys after different treatments

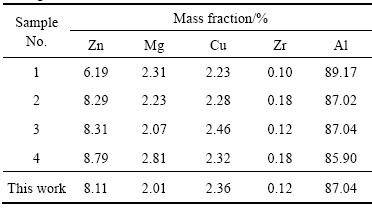

表2和3所示分别为喷射沉积法和熔炼铸造法制备的Al-Zn-Mg-Cu合金成分和主要力学性能。样品1、2和3的抗拉强度明显偏低[13, 19, 21]。与样品4相比,本实验中研究的合金中元素含量低,抗拉强度略低于样品4的,但是伸长率较高,合金的强塑积明显大于样品4的[20]。因此通过对比可见,与熔炼铸造法相比,采用喷射沉积法可以制备性能更加优异的Al-Zn-Mg- Cu合金。

表2 喷射沉积法和熔炼铸造法制备的化学成分

Table 2 Chemical composition of main compositions of Al-Zn-Mg-Cu alloys prepared by spray deposition and melting casting method

表3 喷射沉积法和熔炼铸造法制备的Al-Zn-Mg-Cu合金的性能参数

Table 3 Property parameters of Al-Zn-Mg-Cu alloys prepared by spray deposition and melting casting methods

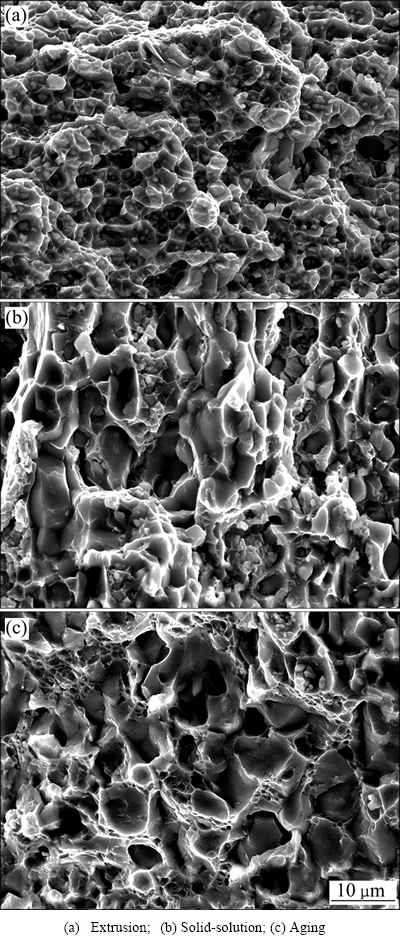

2.4 合金的拉伸断口形貌

图8所示为喷射沉积法制备的Al-Zn-Mg-Cu合金的挤压态、固溶态和峰时效态的拉伸断口形貌。样品经过热挤压后,合金的晶粒得到细化,第二相粒子分布更加均匀且与基体的塑性变形能力存在着差异,在变形过程中,粒子周围堆积的位错环在切应力的作用下往两相界面迁移形成微孔,易在此处形成裂纹并发生断裂(见图8(a))。挤压态的样品经过固溶和时效处理后,基体中第二相的有所长大,而且基体软化、变形塑性增加,形成的韧窝较大(见图8(b)和(c))。同时可以看出韧窝的尺寸明显增大,且在韧窝源处并没有观察到第二相粒子,断裂基本沿着晶界进行。这表明合金经过固溶、时效处理后,合金的断裂方式以沿晶断裂为主。

2.5 合金时效不同时间的显微组织

图9所示为喷射沉积技术制备的Al-Zn-Mg-Cu合金在挤压变形和固溶处理后,140 ℃下时效不同时间的TEM像及其选区电子衍射花样。合金在140 ℃时效10 min后,合金的硬度上升了很多,可能是由于溶质原子形成了团簇或GP区(见图9(a))。但在Al基体[110]Al带轴下的选区电子衍射花样中,除了Al基体的主衍射斑点,还可以观察到一些微弱的第二相衍射斑点(见图9(b))。合金在140 ℃时效8 h后,合金的硬度达到峰值。从图9(c)可以看出,主要析出了两种不同形貌衬度的析出相:一类为针状的η'-MgZn2相,长度大约为5~10 nm,沿着Al基体的[100]Al和[010]Al方向分布;另一类为球状的Al3Zr相,直径约为2~5 nm。其中η'-MgZn2相是主要的强化相。根据选区电子衍射花样分析结果可知,合金中主要有铝基体、针状的η'-MgZn2相、Al3Zr相和少量其他相(见图9(d))。合金在140 ℃时效72 h后,合金中针状η'-MgZn2相为棒状,长度约为30 nm,宽度约为12 nm。同时,合金中的Al3Zr相粒子也长大。

图8 不同状态的喷射沉积Al-Zn-Mg-Cu合金的拉伸断口SEM像

Fig. 8 Tensile fracture morphologies of spray-deposited Al-Zn-Mg-Cu alloys with different states

图9 喷射沉积Al-Zn-Mg-Cu合金不同时效状态的TEM像及其选区电子衍射花样

Fig. 9 TEM images and selected area electron diffraction patterns of spray-deposited Al-Zn-Mg-Cu alloys under different aging conditions

3 结论

1) 喷射沉积法制备的合金晶粒为近等轴状,晶粒内部几乎无偏析,晶粒尺寸约为30~50 μm,基体中的非平衡凝固相主要为η-MgZn2相和CuAl2相。

2) 合金通过热挤压变形、(470 ℃, 1 h)固溶处理、(140 ℃, 8 h)时效处理后的抗拉强度为723 MPa、屈服强度为700 MPa、伸长率为11%。

3) 合金在140 ℃时效处理过程中,时效初期析出与基体共格的GP区,随后GP区转变成针状的η'-MgZn2相和球状Al3Zr相,在时效72 h后,析出的强化相η-MgZn2呈棒状。

REFERENCES

[1] BROOKS R G, LEATHAM A G, MOORE C, COOMBS J S. The osprey process: A novel method of the production of forming[J]. Metallurgy and Metals Forming, 1977, 44(4): 157-160, 162-163.

[2] SPIEGELHAUER C, SHAW L, OVERGAARD J, OAKES G. Spray-forming of large diameter steel products by osprey process [J]. Advances in Powder Metallurgy and Particulate Materials, 1995, 2 (7): 41-46.

[3] LEATHAM A G, LAWLEY A. The osprey process: Principles and applications[J]. International Journal of Powder Metallurgy, 1993, 29(4): 321-329.

[4] 熊柏青, 张永安, 石力开. 喷射沉积技术制备高性能铝合金材料[J]. 材料导报, 2000, 14(12): 50-55.

XIONG Bai-qing, ZHANG Yong-an, SHI Li-kai. High-property aluminum alloys prepared by spray-forming process[J]. Materials Review, 2000, 14(12): 50-55.

[5] WEI Qiang, XIONG Bei-qing, ZHANG Yong-an, ZHU Bao-hong, SHI Li-kai. Production of high strength Al-Zn-Mg-Cu alloys by spray forming process[J]. Transactions of Nonferrous Metals Society of China, 2001, 11(2): 258-261.

[6] GRANT P S. Spray forming[J]. Progress in Materials Science, 1995, 39(4/5): 497-545.

[7] 王洪斌, 黄进峰, 杨 滨, 张济山, 张永安, 熊柏青. Al-Zn-Mg-Cu系超高强度铝合金的研究现状与发展趋势[J]. 材料导报, 2003, 17(9): 1-4.

WANG Hong-bin, HUANG Jin-feng, YANG Bin, ZHANG Ji-shan, ZHANG Yong-an, XIONG Bai-qing. Current status and future directions of ultrahigh strength Al-Zn-Mg-Cu aluminum alloys[J]. Materials Review, 2003, 17(9): 1-4.

[8] 潘志军, 黎文献, 马正青, 谭敦强. 高强铝合金的研究现状及展望[J]. 铝加工, 2001, 24(4): 39-41.

PAN Zhi-jun, LI Wen-xian, MA Zheng-qing, TAN Dun-qiang. Development and present states of researching high strength aluminium alloys[J]. Aluminium Fabrication, 2001, 24(4): 39- 41.

[9] SRIANTSAN T S, SRIRAM S, VEERARAGHAVAN D, VASUDEVAN V K. Microstructure, tensile deformation and fracture behavior of aluminium alloy 7055[J]. Journal of Materials Science,1997, 32(11): 2883-2894.

[10] WAGNER J A, SHENOY R N. Effect of copper, chromium, and zirconium on the microstructure and mechanical properties of Al-Zn-Mg-Cu alloys[J]. Metallurgical Transactions A, 1991, 22A(11): 2809-2818.

[11] OSAMURA K, KOHNO K, OKUDA H, OCHIAI S, KUSUI J, FUJII K, YOKOE K, YOKOTE K, YOKOTE T, HONO K. Mesoscopic structure of super-high strength P/M Al-Zn-Mg-Cu alloys[J]. Materials Science Forum, 1996, 217: 1829-1834.

[12] LI L, ZHOU T T, LI H T, CHEN C Q, XIONG B Q, SHI L K. Effect of additional elements on aging behavior of Al-Zn- Mg-Cu alloys by spray forming[J]. Transactions of Nonferrous Metals Society of China, 2006, 16: 532-538.

[13] YU H C, WANG M P, SHENG X F, LI Z, CHEN L B, LEI Q, CHEN C, JIA Y L, XIAO Z, CHEN W, WEI H G, ZHANG H, FAN X, WANG Y G. Microstructure and tensile properties of large-size 7055 aluminum billets fabricated by spray forming rapid solidification technology[J]. Journal of Alloys and Compounds, 2013, 578: 208-214.

[14] YU H C, WANG M P, JIA Y L, XIAO Z, CHEN C, LEI Q, LI Z, CHEN W, ZHANG H, WANG Y G, CAI C Y. High strength and large ductility in spray-deposited Al-Zn-Mg-Cu alloys[J]. Journal of Alloys and Compounds, 2014, 601: 120-125.

[15] JIA Y D, CAO F Y, NING Z L, GUO S, MA P, SUN J F. Influence of second phases on mechanical properties of spray-deposited Al-Zn-Mg-Cu alloy[J]. Materials and Design, 2012, 40: 536-540.

[16] SANCTIS M D. Structure and properties of rapidly solidified ultrahigh strength Al-Zn-Mg-Cu alloys produced by spray deposition[J]. Materials Science and Engineering A, 1991, 141(1): 103-121.

[17] HU H, LEE Z H, WHITE R D, LAVERNIA E J. On the evolution of porosity in spray-deposited tool steels[J]. Metallurgical and Materials Transactions A, 2000, 31(3): 723-733.

[18] GRANT P S, KIM W T, CANTOR B. Spray forming of aluminium-copper alloys[J]. Materials Science and Engineering A, 1991, 134: 1111-1114.

[19] 陈康华, 方华婵, 陈 祥. 复合添加Zr、Cr和Pr对Al-Zn-Mg-Cu合金组织和性能的影响[J]. 中国有色金属学报, 2010, 20(2): 195-201.

CHEN Kang-hua, FANG Hua-chan, CHEN Xiang. Effects of Zr, Cr and Pr additions on microstructure and properties of Al-Zn-Mg-Cu alloys[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(2): 195-201.

[20] CHEN L, YAN A, LIU H S, LI X Q. Strength and fatigue fracture behavior of Al-Zn-Mg-Cu-Zr(-Sn) alloys[J]. Transactions of Nonferrous Metals Society of China, 2013, 23: 2817-2825.

[21] 何小青, 熊柏青, 孙泽明, 张永安, 王 锋, 朱宝宏. 喷射沉积Al-Zn-Mg-Cu合金在挤压和热处理后的组织演变[J]. 稀有金属材料与工程, 2008, 37(3): 534-537.

HE Xiao-qing, XIONG Bai-qing, SUN Ze-ming, ZHANG Yong-an, WANG Feng, ZHU Bao-hong. Microstructural evolution of the spray formed Al-Zn-Mg-Cu alloy during extrusion and heat treatment[J]. Rare Metal Materials and Engineering, 2008, 37(3): 534-537.

(编辑 王 超)

基金项目:国家自然科学基金资助项目(51271203)

收稿日期:2014-08-04;修订日期:2015-04-12

通信作者:汪明朴,教授;电话:0731-88830264; E-mail: wangmp@csu.edu.cn