文章编号:1004-0609(2007)04-0580-06

机械合金化过程中Fe50Al50二元系的结构演变

任 榕,吴玉程,汤文明,汪峰涛,郑治祥

(合肥工业大学 材料科学与工程学院,合肥 230009)

摘 要:利用高能球磨和后续热处理技术制备纳米晶Fe50Al50(摩尔分数,%)合金粉体。采用X射线衍射、透射电镜和扫描电镜对元素混合粉在机械合金化过程中的结构演变及热处理对合金化粉体结构的影响等进行分析,讨论其机械合金化合成机制。结果表明:球磨过程中Al向Fe中扩散,形成Fe(Al)固溶体。机械合金化合成Fe(Al)遵循连续扩散混合机制;球磨30 h后,粉体主要由纳米晶Fe(Al)构成,晶粒尺寸5.65 nm;热处理导致Fe(Al)纳米晶粉体有序度提高,转变为有序的B2型FeAl金属间化合物,粉体的晶粒尺寸增大,但仍在纳米尺度范围。

关键词:Fe50Al50;机械合金化;结构演变;合金化机制;热处理

中图分类号:TG 156 文献标识码:A

Structure evolution during mechanical alloying of Fe50Al50 binary system

REN Rong, WU Yu-cheng, TANG Wen-ming, WANG Feng-tao, ZHENG Zhi-xiang

(School of Materials Science and Engineering, Hefei University of Technology, Hefei 230009, China)

Abstract: Nanocrystalline Fe50Al50 (mole fraction, %) alloy powder was synthesized by high-energy ball milling and subsequent heat treating. Both the structural evolution of elemental powder during mechanical alloying and the effect of heat treatment on microstructure of as-milled powder were investigated by X-ray diffractometry (XRD), transmission electron microscopy (TEM) and scanning electron microscopy (SEM). The mechanical alloying mechanism of Fe50Al50 powder during ball milling was also discussed. The results show that the diffusion of Al into Fe lattice occurs during milling, leading to the formation of Fe(Al) solid solution. The process was controlled by continuous diffusion mixing mechanism. After milling for 30 h, the powder is composed of Fe(Al) with grain size of 5.65 nm. The transformation from the disordered Fe(Al) solid solution into the ordered B2-FeAl intermetallic compound occurs after heat treating, accompanying with the growth of B2-FeAl grain which is still in nanometer scale.

Key words: Fe50Al50; mechanical alloying; structural evolution; reaction mechanism; heat treatment

Fe-Al金属间化合物(主要是Fe3Al和FeAl),由于强度高、抗氧化和抗硫化腐蚀性能优良,而且其韧性又高于普通的陶瓷材料,因此是航空材料和高温结构材料领域内具有重要应用潜力的新材料[1-2]。随着Al含量的升高,不但Fe-Al金属间化合物密度降低,而且抗氧化和抗硫化性能提高,如FeAl在1 300 K以下的循环条件下的抗氧化性以及在900 K熔融硝酸盐中的耐蚀性与Fe3Al相比都有显著提高[3-5]。然而,与其它金属间化合物一样,室温脆性是影响其工程应用的主要障碍。由于细化晶粒可实现其强韧化,因此关于纳米晶FeAl金属间化合物的研究受到广泛关注。

机械合金化是指在球磨过程中,组元粉末间不断焊合与断裂,并借助于组元的固相扩散实现原子水平的混合,从而达到合金化,并可以细化晶粒尺寸至纳米尺度。目前,机械合金化技术已成为制备纳米晶金属间化合物及其复合材料、非平衡合金及磁性材料等新型材料的主导技术[6]。本文作者采用Fe50Al50二元粉体机械合金化结合后续热处理的方法合成FeAl纳米晶粉体,研究在机械合金化过程中粉体结构的演变以及热处理对合金化粉体结构的影响,并探讨该二元粉体的机械合金化机制。

1 实验

机械合金化在GN-2型高能球磨机(中科院沈阳金属所研制)上进行,用直径为12 mm的热处理GCr15钢球(硬度HRC60-62)作为球磨介质,将纯Fe粉(质量分数99%,粒度10 μm)、纯Al粉(98%,粒度10 μm)按摩尔比1?1配料,每次投料量15 g。球料比为10?1,球磨机转速为700 r/min。在粉体中加入1%的正庚烷作为过程控制剂,以防止粉体与磨球或球磨罐的内壁发生焊合。球磨气氛为抽真空后充入高纯氩气以防止球磨过程中粉体的氧化。将球磨30 h的粉体在GSL-1600X真空管式高温炉中进行800 ℃保温1 h的热处理。在石英加热管中通入流动的高纯氩气作为保护气氛,以防止热处理过程中粉体氧化。

机械合金化及热处理过程中粉体的结构变化由D∕max-γB型X衍射仪(XRD)分析确定。根据XRD结果,应用Scherrer公式确定粉体的平均晶粒尺寸:

D=0.9λ/(Bcosθ)

式中 λ为入射X射线的波长,λ=0.154 nm;B为衍射峰的半高宽(弧度);θ为衍射角。将球磨粉体经过研磨、超声波分散后用H-800型透射电镜(TEM)观察粉体的形貌,并用选区电子衍射(SAED)分析粉体的结构。采用Sirion 200场发射扫描电镜(SEM)观察球磨粉体形貌。

2 结果与讨论

2.1 球磨过程中Fe50Al50二元粉体的结构演变

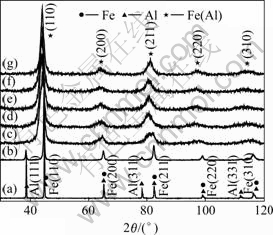

图1所示为Fe50Al50二元粉体经不同球磨时间的XRD谱。如图1中谱线(a)所示,未球磨的元素粉体中Fe、Al的衍射峰非常尖锐。球磨导致各元素衍射峰强度降低,宽度增加,这是由于粉体的晶粒不断细化、结构有序度降低、晶体结构发生形变而产生内应力等原因所致。球磨1 h的粉体中,尽管Fe、Al的衍射峰强度都明显降低,但Al的衍射峰强度相对于Fe降低更多,同时Fe的衍射峰向低衍射角方向移动,晶格常数增大(由球磨前的0.285 5 nm增至0.286 5 nm)(图1谱线(b)),表明借助于Al向Fe晶格的扩散[7-8],部分Al已固溶于Fe中形成固溶体 Fe(Al),导致了晶格膨胀,机械合金化过程已经发生。虽然Al原子半径(0.128 nm)明显小于Fe原子半径(0.140 nm),但在球磨过程中,Al在Fe中的固溶导致Fe的点阵常数发生上述变化。球磨5 h后(图1谱线(c)),Al的特征衍射峰Al(111)、Al(311)和Al(331)均消失。球磨过程中Al衍射峰的消失原因参见文献[9]。

图1 Fe50Al50二元粉体经不同球磨时间的XRD谱

Fig.1 XRD patterns of Fe50Al50 binary powder milltd different time: (a) 0 h; (b) 1 h; (c) 5 h; (d) 10 h; (e) 30 h; (f) 50 h; (g) 80 h

图2所示为球磨5 h后的Fe50Al50二元粉体的SEM形貌。从图2可以看到,球磨5 h后的Fe50Al50二元粉体塑性变形明显,出现层状精细(亚)结构,导致缺陷密度急剧增加,颗粒和亚结构不断细化。高密度的缺陷为原子的固态扩散提供了顺畅的通道,而精细的亚结构则缩短了原子扩散路径(短路扩散)。另外,球磨过程中的温度升高对合金化过程也起到促进作用[10]。继续球磨(<10 h),Fe(Al)衍射峰持续左移,Fe(Al)的晶格常数仍较快增大,合金化过程持续进行。在球磨的后期(>10 h),Fe(Al)的晶格常数增加缓慢(图3),合金化过程固溶和脱溶过程趋于平衡。本研究中,Fe50Al50二元粉体球磨30 h后,Fe(Al)的晶格常数为0.291 3 nm,比球磨前的晶格常数要大2.03%。根据PDF(ICDD)卡片(#45-983),二元Fe50Al50(110)面的晶面间距为0.206 2 nm,其对应的晶格常数为0.291 5 nm。比较可知,此时Fe(Al)的晶格常数略低于等原子比FeAl,说明Al没有完全固溶于Fe中。也就是说,在球磨Fe50Al50二元粉体中,Al原子除了形成Fe(Al)外,可能还有其它的存在形式。Mazzone等[11]球磨不同成分的FexAl1-x时发现,当x=0.50时,Fe、Al两者相互扩散,形成Fe(Al)和Al(Fe)固溶体。但在本研究中并没有发现在球磨粉体中存在Al(Fe)固溶体。由于球磨Fe晶粒内部蕴涵着高密度的缺陷和精细亚结构,一部分Al原子可以进入这些缺陷位置,从而丧失其衍射特性,但却未真正溶入Fe的晶格中,处于一种“亚互溶”状态[12],使得在Fe(Al)中实际的Al含量低于50%(摩尔分数)。另外,考虑到Al为塑性相,球磨时可能由于粘壁造成少量损耗。总之,球磨30 h后的粉体主要由BCC结构的Fe(Al)固溶体所构成,这与Huang等[13]的研究结果一致。

图2 球磨5 h后的Fe50Al50二元粉体的SEM形貌

Fig.2 SEM micrograph of Fe50Al50 binary powder milled for 5 h

图3 Fe(Al)晶格常数与球磨时间的关系

Fig.3 Relationship between lattice parameter of Fe(Al) and milling time

值得注意的是,继续球磨时(30~80 h),Fe(Al)衍射峰的强度反而出现缓慢增加,其晶格有序度增加,如图1中谱线(e)~(g)所示。这说明过长时间的球磨还会促进结晶,即发生了所谓的机械合金化诱发结晶过程,这种现象在二元Mo-Si系的机械合金化过程中也有报道[14]。Enayati等[15]将Fe50Al50粉体放入转速为390 r/min的行星式球磨机中进行机械合金化,在球磨过程中没有形成Fe(Al),而是直接得到FeAl相。本研究将Fe50Al50二元粉体球磨直至80 h后,对应的XRD谱中仍没有出现超点阵衍射峰[16],即没有FeAl有序金属间化合物生成。造成这种差异的原因是多方面的,可能与实验采用的球磨条件有关。对于机械合金化,即使是相同的原始粉末组成,球磨后也可能得到不同结构的产物,具体还要取决于工艺参数如球磨装置的类型、球料比、球磨温度、球磨时间、球磨强度等[17]。球磨过程中Al原子固溶进入Fe的晶格中,并且Al在Fe中的固溶量随着Fe中缺陷浓度的增加而增加。相比较而言,本研究中球磨机转速明显高于Enayati所用的行星式球磨机,球磨速度增加,粉体获得的球磨能量增加,缺陷密度剧烈增加,导致球磨粉体晶格严重畸变,从而抑制B2有序金属间化合物的形成,球磨粉体仍为有序度低的Fe(Al)固溶体。

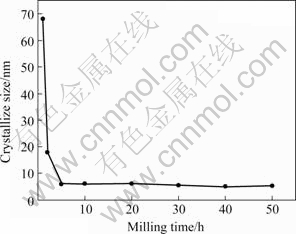

机械合金化过程中,球磨粉体中Fe(Al)的平均晶粒尺寸与球磨时间的关系如图4所示。在球磨初期(<5 h),Fe(Al)的平均晶粒尺寸急剧下降,球磨1 h后粉体的平均晶粒尺寸为68.12 nm,达到了纳米尺度。继续球磨(>5 h),Fe(Al)的晶粒尺寸未见明显降低,表明此时机械合金化过程中焊合和断裂过程趋于平衡,粉体的晶粒细化趋于稳定。球磨30 h后,Fe(Al)的平均晶粒尺寸为5.65 nm。

图4 Fe50Al50粉体的平均晶粒尺寸与球磨时间的关系

Fig.4 Relationship between aver-age grain size of Fe50Al50 powder and milling time

图5所示是不同球磨时间的Fe50Al50粉体形貌及其电子衍射图谱。由图5(a)可见,球磨5 h的粉体颗粒趋于球型,大多数颗粒尺寸在0.5 μm以下,每一个颗粒都是多个小晶粒的团聚体,大颗粒的旁边依附着若干纳米级的小颗粒。该粉体的SAED图谱呈现不连续多晶衍射环的特征(图5(b)),经标定为BCC结构的α-Fe (Al)固溶体,得到环状斑点是因为多晶的衍射斑点取向分布较广。球磨30 h后,Fe50Al50粉体的颗粒球化更加明显,部分粉体团聚形成大颗粒,粉体的平均颗粒尺寸仍维持在亚微米范围内(图5(c))。此时,粉体的SAED图谱呈现多晶环的特征,衍射结果仍为BCC结构的α-Fe(Al)(图5(d))。这与图1所示的XRD结果是一致的。

图5 经不同时间球磨的Fe50Al50粉体的TEM照片及其SAED花样

Fig.5 TEM photographs and SAED patterns of Fe50Al50 binary powder milled for different time: (a) 5 h; (b) SAED pattern of Fig.5(a); (c) 30 h; (d) SAED pattern of Fig.5(c)

2.2 Fe50Al50二元系统的机械合金化机制

机械合金化合成的机理分为两种类型[17-18]:以Ni-Al二元粉体的机械合金化过程为例,在Ni75Al25二元粉体的机械合金化过程中,发生Al向Ni中扩散,直至Al完全固溶于Ni中形成一种非平衡过饱和固溶体Ni(Al),Ni3Al不能直接通过机械合金化获得。但对该过饱和固溶体进行600 ℃热处理,可使之转化为长程有序L12型Ni3Al金属间化合物[19]。机械合金化不能获得相应的有序金属间化合物,而只能形成无序的固溶体合金,这一过程称为“连续扩散混合”机制。而Ni50Al50、Ni25Al75二元粉体的机械合金化过程与Ni75Al25二元粉体的机械合金化过程显著不同,可以直接合成有序的NiAl、NiAl3金属间化合物[20-21]。在这种情况下,在组成元素(Ni,Al)粉末的尺寸达到纳米尺度之前,不会发生组元间的明显扩散。一旦粉末的尺寸细化到一定程度,金属间化合物通过一个与自蔓延高温合成(SHS)近似的反应过程——爆炸反应形成,此时,反应形成的NiAl、NiAl3金属间化合物的晶粒尺寸为反应前粉末尺寸之和,称为“不连续叠加混合”机制。

在Fe50Al50二元粉体球磨过程中,球磨初期(<5 h)粉体经历反复的断裂、冷焊过程,形成精细的层状结构;伴随着晶粒的细化,Al原子向Fe晶格快速扩散,形成纳米结构的Fe(Al)固溶体。球磨5 h后,焊合和断裂过程趋于平衡,粉体的晶粒细化趋于稳定。球磨10 h后Fe(Al)的晶格常数增加缓慢,并于球磨30 h后趋于稳定,Al原子在Fe中的扩散和均化基本完成,机械合金化完成。继续球磨时(>30 h),尽管粉体内部储存的能量足够高,也发生了机械合金化诱发结晶的现象,但并没有形成FeAl有序金属间化合物。Fe50Al50二元粉体粉机械合金化过程呈现如下特征:Fe+Al→精细Fe/Al层状组织→Fe(Al)纳米晶。显然这一过程遵循“连续扩散混合”机制,而非“不连续叠加混合”机制。

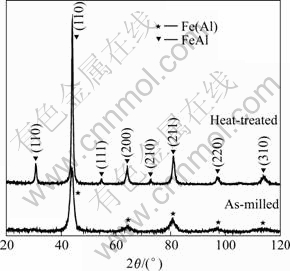

2.3 热处理对球磨Fe-Al粉体结构的影响

球磨30 h的Fe50Al50二元粉体经过800 ℃保温1 h热处理后的XRD谱(图6)证实了Fe-Al合金粉在保温过程中的结构转变。与球磨30 h粉体的 XRD谱相比,除了(110)、(200)、(211)、(220)和(310)晶面衍射峰外,还出现了(100)、(111)B2-FeAl超点阵衍射峰[16],说明热处理后的球磨粉体主要由B2-FeAl构成。热处理后粉体的衍射峰强度显著增加。这是由于热处理过程中粉体的晶格畸变程度降低、内应力释放、晶界应变逐渐消失,伴随着Fe(Al)固溶体向B2-FeAl金属间化合物的转变,粉体结构有序度明显提高。此外,与球磨30 h粉体的XRD谱相比,热处理后粉体的衍射峰的宽度变窄,这主要是因为机械合金化合成的纳米晶粉体有着巨大的比表面积,活性很高,热处理促进了粉体的晶粒生长,晶粒尺寸增大。热处理后B2-FeAl粉体的平均晶粒尺寸为15.11 nm。

图6 球磨30 h的Fe50Al50二元粉体在800 ℃热处理1 h前后的XRD谱

Fig.6 XRD patterns of 30 h milled Fe50Al50 powder before and after heat treated at 800 ℃ for 1 h

3 结论

1) Fe50Al50元素混合粉末在机械合金化过程中形成主要由BCC结构的α-Fe(Al)固溶体构成的纳米晶粉体。

2) Fe50Al50二元粉体的机械合金化主要通过Al原子向Fe晶格中扩散来实现,其合成的反应机制归结为“连续扩散混合”机制。

3) Fe50Al50二元粉体的晶粒尺寸取决于球磨时间,初期球磨对粉体晶粒度影响较大,进一步球磨对它的影响逐渐减弱,球磨30 h的平均晶粒尺寸为5.65 nm。

4) 球磨30 h的Fe50Al50二元粉体在800 ℃热处理1 h过程中发生了相结构有序化转变,形成了有序的B2型FeAl金属间化合物,同时发生晶粒的长大。热处理后粉体的平均晶粒尺寸为15.11 nm。

REFERENCES

[1] Stoloff N S. Ordered alloys-physical metallurgy and structural application[J]. Int Met Rev, 1984, 29(3): 125-135.

[2] 林栋梁. 高温有序金属间化合物研究的新进展[J]. 上海交通大学学报, 1998, 32(2): 95-108.

LIN Dong-liang. Recent advances in high-temperature ordered intermetallics[J]. Journal of Shanghai Jiaotong University, 1998, 32(2): 95-108.

[3] Schneibel J H, Grahle P, R?sler J. Mechanical alloying of FeAl with Y2O3[J]. Mater Sci Eng A, 1992, A153: 684-690.

[4] Varin R A, Bystrzycki J, Calka A. Characterization of nanocrystalline Fe-45%Al intermetallic powders obtained by controlled ball milling and the influence of annealing[J]. Intermetallics, 1999, 7: 917-930.

[5] Deevi S C, Sikka V K, Liu C T. Processing, properties, and applications of nickel and iron aluminides[J]. Prog Mater Sci, 1997, 42: 177-192.

[6] Benjamin J S. Fundamental of mechanical alloying[J]. Mater Sci Forum, 1992, 88: 1-10.

[7] Enzo S, Frattini R, Gupra R, et al. X-ray powder diffraction and mossbauer study of nanocrystalline Fe-Al prepared by mechanical alloying[J]. Acta Mater, 1996, 40(8): 3105-3113.

[8] Bonetti E, Scipione G, Enzo S, et al. Anelastic properties and solid state reactivity of Fe-Al nanostructured intermetallic compounds[J]. Nanostruct Mater, 1995(6): 397-400.

[9] 汤文明,郑治祥,吴玉程,等. 机械合金化过程中Fe75Al25二元系统的结构演变[J]. 材料热处理学报,2004, 25(3): 18-21.

TANG Wen-ming, ZHENG Zhi-xiang, WU Yu-cheng, et al. Structural evolution of Fe75Al25 binary system during mechanical alloying[J]. Transactions of Materials and Heat Treatment, 2004, 25(3): 18-21.

[10] Murty B S, Ranganathan S. Novel materials synthesis by mechanical alloying/milling[J]. Int Mater Rev, 1998, 43: 101-141.

[11] Mazzone G, Curdellini F. Microstructural evolution of Al-Fe powder mixtures during high-energy ball milling[J]. J Mater Sci, 1998, 33(10): 2519-2527.

[12] 齐 民,朱 敏,杨大智. Fe-Cu超饱和固溶体的机械合金化合成[J]. 材料科学进展, 1993, 7(1): 31-34.

QI Min, ZHU Min, YANG Da-zhi. Synthesis at Fe-Cu supersaturated solid solution by mechanical alloying[J]. Materials Science Progress, 1993, 7(1): 31-34.

[13] Huang B, Ishihara K N, Shingu P H. Metastable phases of Al-Fe system by mechanical alloying[J]. Mater Sci Eng A, 1997, A231: 72-79.

[14] 刘邵军,曲选辉,刘志坚,等. Mo-Si系机械合金化过程中的相结构变化[J]. 中南工业大学学报:自然科学版,1998, 29(3): 255-258.

LIU Shao-jun, QU Xuan-hui, LIU Zhi-jian, et al. Structural evolution phase transformation of elemental Mo and Si powders in mechanical alloying[J]. Journal of Central South University of Technology: Nature Science, 1998, 29(3): 255-258.

[15] Enayati M H, Salehi M. Formation mechanism of Fe3Al and FeAl intermetallic compounds during mechanical alloying[J]. J Mater Sci, 2005, 40(15): 3933-3941.

[16] 范润华,孙康宁,尹衍升,等. Fe3Al金属间化合物的机械合金化[J]. 机械工程学报,2000, 36(8): 55-58.

FAN Run-hua, SUN Kang-ning, YIN Yan-sheng, et al. Synthesis of iron aluminides from elemental powders by mechanical alloying[J]. Chinese Journal of Mechanical Engineering, 2000, 36(8): 55-58.

[17] Suryanarayana C. Mechanical alloying and milling[J]. Prog Mater Sci, 2001, 46: 1-184.

[18] Takacs L. Self-sustaining reactions induced by ball milling[J]. Prog Mater Sci, 2002, 47: 355-414.

[19] 郭建亭,周兰章,李谷松. 纳米金属间化合物NiAl的机械合金化合成及性能[J]. 金属学报, 1999, 35(8): 846-850.

GUO Jian-ting, ZHOU Lan-zhang, LI Gu-song. Mechanically synthesis and mechanical properties of nanocrystalline intermetallics NiAl[J]. Acta Metallurgica Sinica, 1999, 35(8): 846-850.

[20] Pabi S K. Mechanism of mechanical alloying in Ni-Al and Cu-Zn systems[J]. Mater Sci Eng A, 1996, A214: 146-152.

[21] 李谷松,丁炳哲,苗卫方,等. 用机械合金化方法制备Ni-Al系金属间化合物[J]. 金属学报,1994, 30(2): B91-B96.

LI Gu-song, DING Bing-zhe, MIAO Wei-fang. Preparation of Ni-Al intermetallic compounds by mechanical alloying[J]. Acta Metallurgica Sinica, 1994, 30(2): B91-B96.

基金项目:安徽省自然科学基金资助项目(050440704);合肥工业大学科技创新基金资助项目(103-037016)

收稿日期:2006-09-11;修订日期:2006-12-12

通讯作者:吴玉程,教授;电话及传真:0551-2905085; E-mail: ycwu@hfut.edu.cn

(编辑 何学锋)