DOI: 10.11817/j.ysxb.1004.0609.2021-35973

电子束焊接工艺参数对Ti2AlNb/TC18接头组织与性能的影响

刘莹莹,李洁洁,张 乐

(西安建筑科技大学 冶金工程学院,西安 710055)

摘 要:采用真空电子束焊研究不同工艺参数时Ti2AlNb/TC18异种合金焊接接头的组织特征和高温拉伸性能。结果表明:当选用合适的焊接工艺参数时,TC18侧热影响区为细小且均匀分布的针状α相组织;焊缝的β晶界明显,在β晶界上分布着晶粒细小的α和α2相;Ti2AlNb侧热影响区与焊缝分界面明显,β晶粒发生粗化。焊接工艺参数对 Ti2AlNb/TC18 合金的高温塑性影响较小,但对其高温强度的影响较大。当焊接速度相同时,焊接电流I=28 mA的高温拉伸强度最高,为807 MPa;当焊接电流相同时,焊接速度 v=6 mm/s的高温拉伸强度最高,达813 MPa。这是由于焊缝组织相对细小,导致晶界面积的增加,位错的滑移受阻,因此使其接头的强度得到提高。当采用焊接工艺参数28 mA、6 mm/s时,试样的高温拉伸断口颈缩明显、韧窝较大且较均匀,表明采用该组焊接工艺参数制备的Ti2AlNb/TC18高温拉伸性能较好,这与其连接界面宽度较窄、组织细小且分布较均匀有关。

关键词:真空电子束焊;焊接工艺参数;Ti2AlNb/TC18合金;焊接界面;高温拉伸性能;显微组织

文章编号:1004-0609(2021)-03-0699-08 中图分类号:TG457.1 文献标志码:A

引文格式:刘莹莹, 李洁洁, 张 乐. 电子束焊接工艺参数对Ti2AlNb/TC18接头组织与性能的影响[J]. 中国有色金属学报, 2021, 31(3): 699-706. DOI: 10.11817/j.ysxb.1004.0609.2021-35973

LIU Ying-ying, LI Jie-jie, ZHANG Le. Effects of electron beam welding processing parameters on microstructure and properties of Ti2AlNb/TC18 joint[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(3): 699-706. DOI: 10.11817/j.ysxb.1004.0609.2021-35973

TC18(Ti-5Al-5Mo-5V-1Cr-1Fe(质量分数,%)) 是一种近β型钛合金[1-2],它具有强韧性高、塑性好以及焊接性能优良等特点,可用于飞机机翼、机身等紧固件,还可用于制造低于350 ℃工作的发动机的叶片和风扇盘等[3-5]。Ti2AlNb(Ti-22Al-25Nb (摩尔分数,%)) 合金的高温性能优异,可在 700 ℃的高温下稳定使用,且具有较高的比强度、室温塑性、断裂韧性和蠕变抗力等优点[6],能够满足航空航天结构件对轻质高温结构材料的迫切需求,具有广阔的应用前景。因此,本文作者采用真空电子束焊将TC18 钛合金和Ti2AlNb 合金连接起来,制备成应用在航空发动机上不同部位对性能具有不同要求的异种合金件,不仅能充分利用两种合金各自的性能优势,还能够降低成本。

一些学者对异种钛合金电子束焊进行了研究[7-14]。其中,CHENG等 [7]、LI等 [8]和CHEN等[9]分别研究Ti60/TC17、TC4/TA7、Ti-6Al-4V/ Ti-43Al-9V- 0.3Y合金电子束焊接接头组织和力学性能。罗鑫等[10]、申景园等[11]和谭立军等[12]分别研究了热处理、热暴露和热变形温度对 TC11/Ti2AlNb 合金电子束焊接界面组织和性能的影响。WANG 等[13]研究电子束流对Ti-22Al-25Nb/TC4 合金电子束焊接接头组织和性能的影响。本课题组也曾研究了焊接电流对Ti3Al/TC11连接界面组织及拉伸性能的影响[14],结果表明,当焊接电流为 18~21 mA 时,连接界面的组织细小且高温拉伸性能较好。

对异种合金的连接而言,焊接界面性能的优劣与其工艺参数的选择合适与否密切相关。因此,本文研究了不同焊接工艺参数时,Ti2AlNb/TC18 异种合金真空电子束焊接接头组织特征、高温拉伸性能及断口形貌特征,研究结果为航空发动机用异种合金件的制备提供可靠的工艺技术及参数。

1 实验

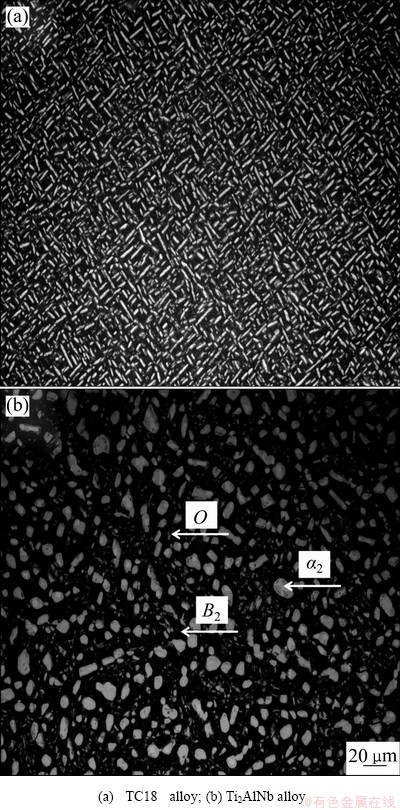

实验所用材料为Ti2AlNb合金和TC18钛合金。采用线切割分别将Ti2AlNb合金和TC18合金切割成尺寸为18 mm×18 mm×35 mm和18 mm×18 mm×40 mm的试样。两种合金的化学成分和显微组织如表1、表2和图1所示。由图1可知,TC18 合金是由针状α相和β相组成的网篮组织(见图1(a)),Ti2AlNb合金组织主要由α2相、O相与B2相组成(见图1(b))。

图1 合金的显微组织

Fig. 1 Microstructures of alloys

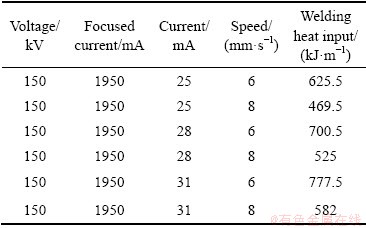

在焊接试验之前,将待焊面磨平后用丙酮清洗干净。焊接是在德国制造的EBOCAM-KS555-G150- CNC真空电子束焊机上进行的,采用的工艺参数及对应的焊接热输入见表3(E=U·I/v,其中E为热输入(kJ·m);U为焊接电压(kV);I为焊接电流(mA);v为焊接速度(mm/s))。

高温拉伸实验是在Zwick-150电子万能试验机上按照GB/T 4338—2006进行;采用OLYMPUS GX51型金相显微镜和VEGAⅡ扫描电子显微镜分别对试样的显微组织及断口形貌进行观察,其中所用腐蚀剂的体积配比为V(HF):V(HNO3):V(H2O2): V(H2O)=1:2:7:20。

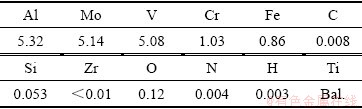

表1 TC18 合金的化学成分

Table 1 Chemical composition of TC18 titanium alloy (mass fraction, %)

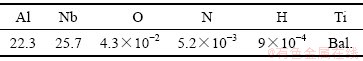

表2 Ti2AlNb 合金的化学成分

Table 2 Chemical composition of Ti2AlNb alloy (mass fraction, %)

表3 焊接工艺参数

Table 3 Welding process parameters

2 结果与讨论

2.1 Ti2AlNb/TC18高温拉伸性能

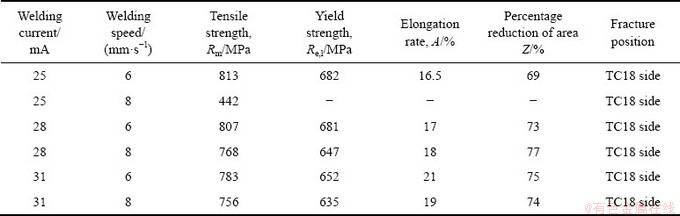

表4所列为Ti2AlNb/TC18合金试样的高温拉伸性能结果。由表4可以看出,焊接工艺参数对Ti2AlNb/TC18合金的高温塑性影响较小,但对其高温强度影响较大。当焊接速度相同时,高温强度随着焊接电流的降低而增大,如当v=6 mm/s时,I=25 mA的抗拉强度(Rm)和屈服强度(Re,l)最大,分别为813 MPa和682 MPa;而 I=31 mA的抗拉强度(Rm)和屈服强度(Re,l)最小,分别为783 MPa和652 MPa。当焊接电流一定时,随着焊接速度的降低,高温拉伸强度不断增大,如I=28 mA 时,v=6 mm/s的抗拉强度(Rm)和屈服强度(Re,l)最大,分别为807 MPa和681 MPa;v=8 mm/s的抗拉强度(Rm)和屈服强度(Re,l)最小,分别为768 MPa和647 MPa。

表4 Ti2AlNb/TC18 的高温拉伸性能(400 ℃)

Table 4 Elevated temperature tensile properties of Ti2AlNb/TC18 (400 ℃)

此外,由表4可知,拉伸时均断裂在TC18 侧,表明焊接接头具有良好的性能。当焊接工艺参数为28 mA、6 mm/s时,可获得连接界面具有较好高温拉伸性能的Ti2AlNb/TC18异种合金件。

2.2 焊缝的宏观形貌

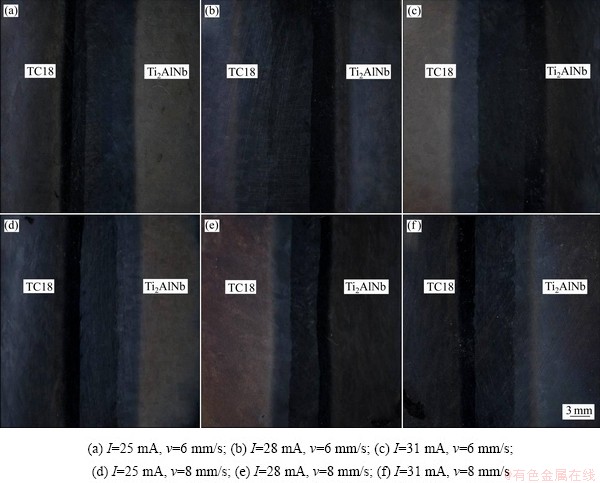

图2所示为焊缝的宏观形貌。由图2可以看出,无论采用何种焊接工艺参数,焊缝均为不对称漏斗形状,下端为细长而狭窄的条柱状[15],深宽比约为4:1以上。其中漏斗状是因为两种合金的比热容、热导率等存在差异。焊缝组织呈现“水波纹”状形貌,是由于电子束流对焊缝液态金属的热搅动所形成的。

图3所示为Ti2AlNb/TC18焊缝下端的宏观形貌。由图3可以看出,无论采用何种焊接工艺参数,其焊接界面的宏观形貌比较相似,均为条柱状,只是随着焊接电流的增大或焊接速度降低,焊缝宽度相对较大,这是由于焊接电流的增加或焊接速度的减小,使得电子束向四周母材的热输入增大,同时高温停留时间越长,导致焊缝宽度增大[14]。

图2 Ti2AlNb/TC18焊缝宏观形貌

Fig. 2 Macromorphology of welding for Ti2AlNb/TC18

2.3 焊接界面的显微组织

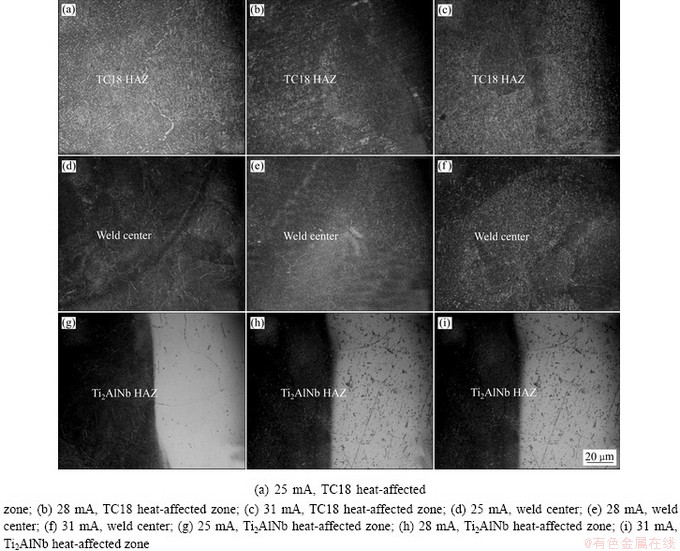

图4所示为焊接电流为25 mA、28 mA和31 mA时焊接界面的显微组织。由图4可以看出,当焊接电流从 25 mA增大到28 mA时,TC18侧热影响区为细小且均匀分布的针状α相组织(见图4(b));焊缝的β晶界明显,且在β晶界上分布着晶粒细小的α和α2相(见图4(e));Ti2AlNb侧热影响区与焊缝分界面明显,且β晶粒发生了粗化(见图4(h))。这是由于随着焊接电流增大至28 mA时,焊接热输入增大,TC18侧针状α相向β转变的量增多,使得针状α相含量减少且宽长比增大;由于焊接热输入的增大使得焊缝金属熔化和元素扩散充分,达到完全的冶金结合,此时晶粒尺寸也相对细小;Ti2AlNb侧的α2相向β转变,β晶粒明显长大。

但当焊接电流继续增大至31 mA,TC18侧热影响区组织为较粗大的β晶粒,在其内部分布着针状α相(见图4(c));焊缝晶粒尺寸有一定程度的粗化(见图4(f));Ti2AlNb侧热影响区的晶粒粗化明显(见图4(i))。这是由于当焊接电流继续增大到31 mA时,焊接热输入过大(777.5 kJ/m),使得TC18侧α相向β相转变的数量过多,β晶粒进一步粗化;焊缝金属由于焊接热输入过大在高温下停留时间过长,晶粒尺寸变大;Ti2AlNb侧的α2相完全转变为β相,晶粒长大的阻碍降低,晶粒长大更为明显。

图5所示为焊接速度为6 mm/s和8 mm/s时焊接界面的显微组织。由图5可以看出,随着焊接速度的降低,TC18侧热影响区为细小且均匀分布的针状α相组织(见图5(b));焊缝的β晶界明显,且在β晶界上分布着晶粒细小的α相和α2相(见图5(d));Ti2AlNb侧热影响区晶粒粗化(见图5(f))。表明焊接接头组织形貌的变化与其在焊接时热输入值的大小选择合适与否有关。

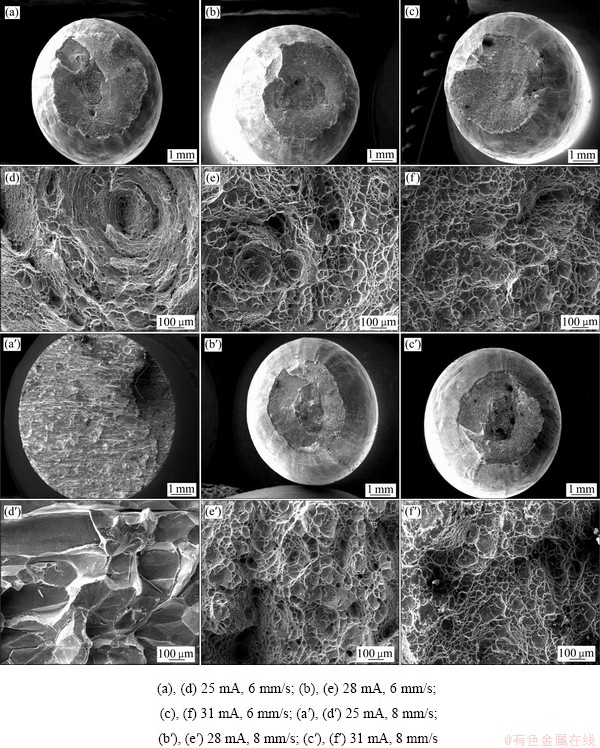

图6所示为不同焊接工艺参数时的高温拉伸断口形貌。由图6(a)和(d)可以看出,宏观断口呈现出明显的脆性断裂特征,微观断口有明显的解理小刻面。这是由于焊接电流小或焊接速度大,使得焊接热输入比较小(469.5 kJ/m),不足以熔化焊缝金属,出现未焊透现象,导致试样在高温拉伸时异常断裂(故抗拉强度仅为 442 MPa)。除图6(a′)和(d′)外,其他焊接工艺参数的断口形貌较相似,均为韧性断裂,宏观断口颈缩明显;微观断口存在较大、较深的韧窝。

由图6(b)和(e)可知,宏观断口颈缩现象较明显,微观断口存在较多均匀分布的等轴韧窝,表现出较好的韧性断裂特征,这与其高温拉伸性能较好一致,说明采用该组焊接工艺参数(28 mA、6 mm/s)进行焊接时能获得拉伸性能较好的焊接接头。

图3 焊缝下端的宏观形貌

Fig. 3 Macromorphologies of lower end of weld

图4 焊接界面在不同电流下的显微组织(v=6 mm/s)

Fig. 4 Microstructures of welding interface under different electric currents (v=6 mm/s)

图5 焊接界面在不同速度下的显微组织(I=28 mA)

Fig. 5 Microstructures of welding interface under different welding speeds (I=28 mA)

图6 不同速度下试样的断口形貌

Fig. 6 Fracture morphologies of specimen under different welding speeds

3 结论

1) 采用真空电子束焊将 Ti2AlNb和TC18合金进行连接时,焊接界面的宏观形貌都较相似:焊缝上端为不对称漏斗状,下端为深宽比大于4:1的细长、狭窄的条柱状。随着焊接电流的增大或焊接速度的降低,焊缝的宽度逐渐增大,这与其热输入的增大有关。

2) 焊接工艺参数对Ti2AlNb/TC18合金的高温塑性影响较小,但对其高温强度影响较大。

3) 当采用焊接工艺参数为28 mA、6 mm/s时,高温拉伸宏观断口存在明显颈缩、微观断口韧窝较大且较均匀,表明Ti2AlNb/TC18合金的高温拉伸性能相对较好,这与其连接界面宽度较窄、组织细小且均匀分布有关。

REFERENCES

[1] 韩 栋, 张鹏省, 毛小南, 等. BT22 钛合金及其大型锻件的研究进展[J]. 材料导报, 2010, 24(3): 46-50.

HAN Dong, ZHANG Peng-sheng, MAO Xiao-nan, et al. Research progress of BT22 titanium alloy and its large forgings[J]. Materials Review, 2010, 24(3): 46-50.

[2] 张 乐, 刘莹莹, 孙宇幸, 等. 缺口和平均应力对TC18棒材疲劳强度的影响[J]. 中国有色金属学报, 2018, 28(12): 2450-2456.

ZHANG Le, LIU Ying-ying, SUN Yu-xing, et al. Effect of notch and mean stress on fatigue strength of TC18 alloy bars[J]. The Chinese Journal of Nonferrous Metals, 2018, 28(12): 2450-2456.

[3] HAN W, FU L, CHEN H Y. Effect of strain rate on microstructure and mechanical properties of TC18 thick plate by electron beam welding[J]. Rare Metal Materials and Engineering, 2018, 47(7): 2005-2010.

[4] 张 乐, 刘莹莹, 薛希豪, 等. 显微组织对TC18合金裂纹扩展速率的影响[J]. 稀有金属, 2018, 42(6): 594-600.

ZHANG Le, LIU Ying-ying, XUE Xi-hao, et al. Crack growth rate of TC18 alloy with different microstructure[J]. Rare Metals, 2018, 42(6): 594-600.

[5] LIU Y Y, ZHANG L, SHI X N, et al. High cycle fatigue properties and fracture behavior of Ti-5Al-5Mo-5V-1Cr-1Fe titanium alloy[J]. Rare Metal Materials and Engineering, 2018, 47(12): 3666-3671.

[6] 张建伟, 李世琼, 梁晓波. Ti3Al和Ti2AlNb基合金的研究与应用[J]. 中国有色金属学报, 2010, 20(S1): s336-s341.

ZHANG Jian-wei, LI Shi-qiong, LIANG Xiao-bo. Research and application of Ti3Al and Ti2AlNb based alloys[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(S1): s336-s341.

[7] CHENG C, YU B B, CHEN Z Y, et al. Mechanical properties of electron beam welded dissimilar joints of TC17 and Ti60 alloys[J]. Journal of Materials Science & Technology, 2018, 10: 149-156.

[8] LI L Z, WANG S G, HUANG W, et al. Microstructure and mechanical properties of electron beam welded TC4/TA7 dissimilar titanium alloy joint[J]. Journal of Manufacturing Processes, 2020, 50: 295-304.

[9] CHEN G Q, ZHANG G, YIN Q X, et al. Microstructure evolution of electron beam welded joints of Ti-43Al-9V-0.3Y and Ti-6Al-4V alloys[J]. Materials Letters, 2018, 233: 336-339.

[10] 罗 鑫, 姚泽坤, 秦 春, 等. 热处理对Ti-22Al-25Nb/ TC11双合金焊接接头组织与性能的影响[J]. 金属热处理, 2015, 40(7): 20-24.

LUO Xin, YAO Ze-kun, QIN Chun, et al. Effect of heat treatment on microstructure and properties of Ti-22Al-25Nb/TC11 douplx alloy welded joint[J]. Metal Heat Treatment, 2015, 40(7): 20-24.

[11] 申景园, 姚泽坤, 宁永权, 等. 热暴露对TC11/Ti-22Al- 25Nb双合金盘力学性能的影响[J]. 稀有金属材料与工程, 2018, 47(8): 2511-2517.

SHEN Jing-yuan, YAO Ze-kun, NING Yong-quan, et al. Effect of thermal exposure on mechanical properties in welding seam of TC11/Ti-22Al-25Nb dual alloy[J]. Rare Metal Materials and Engineering, 2018, 47(8): 2511-2517.

[12] 谭立军, 姚泽坤, 秦 春, 等. 变形温度对异种钛合金电子束焊件显微组织与力学性能的影响[J]. 中国有色金属学报, 2010, 20(8): 92-97.

TAN Li-jun, YAO Ze-kun, QIN Chun, et al. Effect of deformation temperature on microstructure and mechanical properties of dissimilar titanium alloy by electron beam welding[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(8): 92-97.

[13] WANG S G, CHEN Y, LI L Z. Effect of beam deviation on electron beam welded Ti-22Al-25Nb/TC4 dissimilar[J]. Welding in the World, 2020, 64: 661-670.

[14] 刘莹莹, 程晓峰, 张勇召. 焊接电流对Ti3Al/TC11连接界面拉伸性能及组织的影响[J]. 稀有金属材料与工程, 2014, 43(1): 184-188.

LIU Ying-ying, CHENG Xiao-feng, ZHANG Yong-zhao. Effect of welding current on the tensile properties and the microstructure of the joining interface for Ti3Al/TC11 alloy[J]. Rare Metal Materials and Engineering, 2014, 43(1): 184-188.

[15] HAN W, FU L, CHEN H Y. Effect of welding speed on fatigue properties of TC18 thick plate by electron beam welding[J]. Rare Metal Materials and Engineering, 2018, 47(8): 2335-2340.

Effects of electron beam welding processing parameters on microstructure and properties of Ti2AlNb/TC18 joint

LIU Ying-ying, LI Jie-jie, ZHANG Le

(School of Metallurgical Engineering, Xi’an University of Architecture &Technology, Xi’an 710055, China)

Abstract: The microstructure and elevated temperature tensile properties of Ti2AlNb/TC18 dissimilar alloy welded joints were investigated by vacuum electron beam welding. The results show that, as the welding processing parameters are adopted properly, the fine acicular α phases are distributed homogenously on the HAZ of the TC18 alloy side. β grain boundary of the weld is obvious, and the fine α phase and α2 phase are distributed on the β grain boundary. Moreover, the HAZ on the Ti2AlNb alloy side and the weld are separated obviously, and the β grains are coarsened. Furthermore, the welding processing parameters have little effect on the elevated temperature plasticity of the Ti2AlNb/TC18 alloy, but they have an obvious influence on its elevated temperature strength. When the welding speed is the same, the elevated temperature tensile strength of welding current of 28 mA is the highest (807 MPa). As the welding current is the same, the elevated temperature tensile strength of welding speed of 6 mm/s is the highest (813 MPa). The reason is that the microstructure of the weld is relatively fine, which leads to the increase of the grain boundary area and the obstruction from the dislocation slip. Therefore, the strength of the joint is improved. When the welding parameters are 28 mA and 6 mm/s, the tensile fracture necking is more obvious, and the dimple is larger and more uniform. All of these are demonstrated that the elevated temperature tensile properties of Ti2AlNb/TC18 prepared by the welding parameters are better, which is related to the narrow width of the interface and the fine microstructure as well as its uniform distribution.

Key words: vacuum electron beam welding; welding processing parameters; Ti2AlNb/TC18 alloy; welding interface; elevated temperature tensile properties; microstructure

Foundation item: Project(2020KW-033) supported by the Key Research and Development of Shaanxi Province, China

Received date: 2020-04-18; Accepted date: 2020-09-07

Corresponding author: LIU Ying-ying; Tel: +86-29-82205097; E-mail: wfllyy7779@163.com

(编辑 李艳红)

基金项目:陕西省重点研发计划资助项目(2020KW-033)

收稿日期:2020-04-18;修订日期:2020-09-07

通信作者:刘莹莹,副教授,博士;电话:029-82205097;E-mail:wfllyy7779@163.com