DOI: 10.11817/j.issn.1672-7207.2017.05.008

电弧喷涂铝涂层阳极氧化后表面-截面结构分析

孔德军1, 2,闫保旭1

(1. 常州大学 机械工程学院,江苏 常州,213164;

2. 常州大学 江苏省材料表面科学与技术重点实验室,江苏 常州,213164)

摘要:采用电弧喷涂工艺在S355钢表面制备Al涂层,并对其进行阳极氧化处理,通过SEM,EDS和XRD等技术分析试样表面-截面形貌、化学元素分布和物相组成,探讨氧化膜-Al涂层-基体的结合机理。实验结果表明:阳极氧化膜中Al与O出现富集现象,以Al2O3形式存在;Al与O原子在氧化膜中为高浓度分布,构成氧化膜-Al涂层-基体的复合防腐蚀体系;Al涂层为富Al层,原子含量较高,而基体中Fe原子在界面处发生扩散现象;Al涂层中少量Al原子扩散进入基体,在界面处与Fe反应生成Fe-Al化合物,提高电弧喷涂Al涂层的结合强度。

关键词:S355钢;阳极氧化;氧化膜;面扫描;线扫描;腐蚀性能

中图分类号:TM501+.2;TQ153.6 文献标志码:A 文章编号:1672-7207(2017)05-1175-07

Analysis of arc sprayed Al coating surface-section structure after anodic oxidation

KONG Dejun1, 2, YAN Baoxu1

(1. College of Mechanical Engineering, Changzhou University, Changzhou 213164, China;

2. Jiangsu Key Laboratory of Materials Surface Science and Technology, Changzhou University, Changzhou 213164, China)

Abstract: The Al coatings was prepared on the surface of S355 steel using arc spraying, which was conducted using a anodic oxidation treatment, the surface and section morphologies, chemical element distribution of surface-section and phase of the obtained Al coating were analyzed by using SEM, EDS, and XRD, respectively, and the bonding mechanism of the anodic oxidized film-Al coating-substrate of S355 steel was discussed. The experimental results show that Al and O of the anodic oxidized film appears the enrichment phenomenon, existing in the form of Al2O3. The Al and O atoms in the oxidized film are distributed with high concentration, and the system of oxidized film-Al coating-base composite corrosion resistant is formed. The Al-rich layer of Al coating has the higher concentration of Al, while the Fe atoms of the substrate is diffused at the bonding interface. A small number of Al atoms in the coating are diffused into the substrate to react with Fe atoms and produce the Fe-Al compounds at the interface, improving bonding strength of arc spray Al coating.

Key words: S355 steel; anodic oxidation; oxidized film; plane scan; line scan; corrosion resistance

欧标S355钢是一种新型低合金结构钢,具有强度高、韧性好、塑性强等优点,广泛地应用于海洋平台桩腿的制造[1]。目前,我国对海洋资源的开发力度已经发展到一个前所未有的高度,海洋平台由浅水区逐渐向深海区发展。深海区的海洋环境复杂恶劣,钢材在海洋大气区、海水飞溅区、潮差区和全浸区[2]存在着不同程度的腐蚀,其中海水飞溅区的腐蚀速度最快[3],而且又远离海岸,难以定期地进行保养与维护。因此,腐蚀对海洋平台结构在力学上有严重的影响,对其进行表面防腐蚀改性处理显得十分重要。对于海洋环境而言,铝涂层比锌涂层更具优势[4],其中电弧喷铝涂层具有接合强度高、硬度高、脆性低等优点,可以有效地阻止开裂、起泡、生锈以及脱落的发生[5],但是铝涂层在Cl-浓度较高的环境下,防腐蚀性能会有所降低[6]。因此,在海洋富Cl-环境中,需要对铝涂层进行改性处理,以提高其防腐蚀性能。阳极氧化工艺是一种经济有效的表面处理方法[7],通过阳极氧化处理可以在铝涂层表面制备一层Al2O3氧化膜,其结合性能优异,比自然条件下形成的氧化膜更致密,耐Cl-腐蚀能力较强,从而提高S355钢的服役寿命。本文作者对电弧喷涂Al涂层进行阳极氧化处理,利用SEM,EDS和XRD对阳极氧化膜表面-截面形貌、面扫描与线扫描和物相进行分析,以便为阳极氧化处理在S355钢表面电弧喷涂铝涂层的应用提供实验依据。

1 实验

实验选材为欧标S355结构钢,化学成分(质量分数,%):C 0.17,Si 0.55,Mn 0.94,P 0.035,Cr 0.065,S 0.035,Ni 0.065,Mo 0.30,Zr 0.15,其余为Fe。电弧喷Al工艺过程:机械打磨抛光→化学洗涤除油→除锈→水洗、烘干→电弧喷Al→冷却→清洁表面。电弧喷Al材料为直径2 mm铝丝,喷涂电压24~34 V,喷涂电流100~300 A,按GB/T 9793—1997“金属和其他无机覆盖层热喷涂Zn,Al及其合金”执行。阳极氧化工艺:喷铝试样→化学洗涤除油→阳极氧化→清洁表面→烘干。电解液:H2SO4 50 g/L,温度:(20±0.5) ℃,氧化电压:16~18 V,电流密度:1.2~1.4 A/dm2,通电时间100 min后,即可获得试验所需的试样。电化学实验采用3.5% NaCl溶液,工作温度为(30±1) ℃,实验设备为PS268A型电化学工作站。采用JSUPRA55型场发射扫描电镜及其配置的能谱仪分析氧化膜表面-截面形貌、面扫描和线扫描,并采用D/max2500 PC型X线衍射仪分析阳极氧化前后试样表面物相组成。

2 结果分析与讨论

2.1 表面-截面形貌

图1所示为电弧喷涂铝涂层表面和截面形貌。由图1(a)可见:电弧喷涂Al涂层表面呈鱼鳞层状,存在少量丝状涂层缺陷,导致表面平整度下降,对其防腐蚀性能影响较小。由图1(b)可见:界面结合良好、紧密,涂层中存在的孔洞是粒子沉积过程中粒子搭接造成所致[7]。同时,在结合界面处Al涂层对基体产生冲击作用,形成了锯齿状机械结合方式。

图1 电弧喷涂铝涂层表面和截面形貌

Fig. 1 Surface and section morphologies of arc sprayed Al coating

图2所示为阳极氧化膜表面形貌。由图2可见:铝涂层在阳极氧化后形成了多孔型氧化膜,呈暗灰色,孔呈随机分布,且形状大小均不规则。这是由于实验采用阳极氧化电解液为H2SO4溶液,其溶解能力较强,未能生成壁垒型氧化膜[8],孔洞分布不均匀。由Debuyck公式可知[9],孔隙的表面密度为

(1)

(1)

式中:J为电流密度;p和 为常数项。

为常数项。

孔径为

(2)

(2)

式中:θ为槽温;g和 为常数项。

为常数项。

式(1)和(2)表明:阳极氧化膜的孔隙率与电流密度有关,孔径与阳极氧化温度相关。阳极氧化形成的蜂窝状氧化膜具有良好的涂料附着性能,可以减少海水冲刷带来的机械腐蚀,在腐蚀现象严重的区域,可涂覆环氧树脂、硅树脂[10]、微波水合[11]、沸水封孔等来提高其防腐蚀性能。

图2 阳极氧化膜表面形貌

Fig. 2 Surface morphologies of anodic oxidized film

图3所示为阳极氧化膜截面形貌。阳极氧化后Al涂层截面形貌如图3(a)所示,由氧化膜、Al涂层和基体组成,阳极氧化后Al涂层有所减薄,这是由于阳极氧化中氧化膜的生成和涂层Al的溶解同时进行[12],氧化膜生成速度略大于Al涂层的溶解速度,出现了氧化膜变厚、Al涂层变薄的现象(图3(b))。氧化膜厚度为4 μm左右,是由Al涂层原位生成所致[13],保证了Al涂层与氧化膜无缝结合,形成了氧化膜随喷涂层形貌变化的分布特征。

2.2 XRD分析

图4所示为铝涂层阳极氧化前后XRD谱。由图4(a)可见:阳极氧化前Al元素在38.40°时出现了1个较高的晶态衍射主峰,说明在涂层中Al原子结晶度较高。在44.64°,65.02°,78.16°和82.38°时出现了3个Al2O3的次峰,说明在喷涂冷却过程中Al涂层由于温度过高,在空气中产生了微量的氧化现象。图4(b)所示为阳极氧化膜的XRD谱,在38.40°时出现的主峰仍为Al,强度明显降低,说明阳极氧化没有破坏Al涂层结构,但少量涂层被溶解,导致Al原子含量与结晶度降低。阳极氧化后形成的氧化膜较为致密,起到了阻挡作用,导致内层物相衍射强度明显降低。

2.3 表面面扫描分析

图5所示为阳极氧化膜表面面扫描分析。氧化膜孔洞随机分布形貌如图5(a)所示,在阳极氧化过程中,阳极处发生下列反应:

4OH--4e=2H2O+O2 (3)

4Al+3O2=2Al2O3+能量 (4)

实验中阳极不断有气泡析出,在气泡、电流、溶液共同作用下,阳极氧化膜表面出现孔洞,且孔洞位置随气泡产生位置随机分布[14]。氧化膜表面出现了少量微裂纹与点蚀坑,主要有以下原因:1) 实验采用H2SO4溶液的腐蚀性较强,在电流作用下,氧化膜孔洞被腐蚀成为点蚀坑;2) 实验采用的电流密度稍大,在局部产生大量热,导致已生成的氧化膜出现疏松,产生少量裂纹[15]。

对图5(a)所示位置进行面扫描分析,其EDS结果如图5(b)所示,各元素含量如表1所示。氧化膜中Al原子分布较为均匀(图5(c)),仅在少量的点蚀坑处出现了缺失。O原子分布特征与Al原子的分布特征相似(图5(d)),进一步说明了喷铝层表面形成的氧化膜为Al2O3。C元素在表面凸起部分出现了富集现象(图5(e)),这是因为多孔膜对空气中CO2有一定的吸附作用,也产生了富集现象。表面存在微量的S,Ca,Fe,Si,Cl,K和Na等为杂质元素(图5(f)~(l)),分布也比较均匀。

图3 阳极氧化膜截面形貌

Fig. 3 Section morphologies of anodic oxidized film

图4 铝涂层阳极氧化前后XRD谱

Fig. 4 XRD patterns of Al coatings before and after anode oxidation

图5 阳极氧化膜表面面扫描分析结果

Fig. 5 Plane scan analysis results of anodic oxidized film surface

表1 Al涂层表面化学元素含量

Table 1 Contents of chemical elements on Al coating surface

2.4 截面面扫描分析

图6所示为阳极氧化膜截面面扫描分析。截面面扫描位置如图6(a)所示,在基体-Al涂层结合界面处出现锯齿状结合,为典型的机械结合形式。这是由于在高温高压的喷涂环境下,雾态Al冲击基体表面,填补了基体不平整孔洞的缘故。Al原子出现了分层富集的现象(图6(b)),Al涂层中Al原子含量最高,在结合界面处发生了Fe和Al的扩散相互与化合现象,提高了其结合强度。O原子也存在富集现象(图6(c)),其中氧化膜中O含量最高,在Al涂层和Al涂层-基体界面处观察到O原子出现少量的块状富集区,主要集中在Al涂层孔洞缺陷和涂层-基体结合缺陷处。这是由于阳极氧化过程中,Al涂层中Al原子与O原子反应,生成Al2O3。在一定反应热作用下,部分区域中Al2O3与阳极氧化溶液接触后,发生水合反应,生成γ-Al2O3·H2O)[16],其反应如下

Al2O3+H2O→2AlO(OH)→Al2O3·H2O (5)

式(5)中反应产物富集在孔洞区域,填补了电弧喷涂Al涂层的缺陷,防腐蚀性能有所增强,同时,提高了涂层-基体的结合性能。Fe原子在基体中含量较高(图6(d)),少量扩散进入Al涂层-基体结合界面处,改善了涂层与基体的结合性能。但在一定程度上破坏了阳极氧化膜,由于其扩散量较小,对氧化膜防腐蚀性能的影响甚微。Si主要集中于基体中(图6(e)),在Al涂层中少量Si来源于喷涂靶材铝丝。

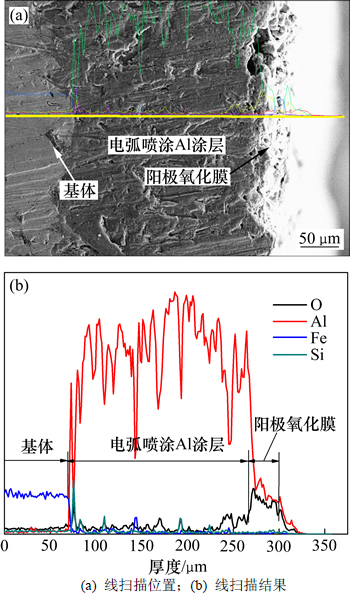

2.5 截面线扫描分析

图7所示为阳极氧化膜截面线扫描分析结果。利用能谱线扫描对截面进行了分析,扫描位置如图7(a)所示,扫描结果如图7(b)所示。由图7可知:1) Al原子出现了明显的梯度分布,在基体-Al涂层结合界面处出现了一个跳跃式的上升,并在Al涂层中达到最大值。而Fe原子在基体中表现为高含量,在Al涂层中其含量为0。这是由于在基体-Al涂层界面处Al原子向基体方向发生了扩散和Al-Fe化合。2) 在Al涂层-氧化膜结合界面处Al原子含量出现了急剧的梯度下降,同时O原子含量呈现急剧上升,此处为阳极氧化膜。由于Al原子与O原子的化合和扩散作用,保证了Al涂层与氧化膜的良好结合。3) Si存在于基材与喷涂靶材中,保持较低含量。

图6 阳极氧化膜截面面扫描分析结果

Fig. 6 Plane scan analysis results of anodic oxidized film section

图7 阳极氧化膜截面线扫描分析结果

Fig. 7 Line scan analysis results of anodic oxidized film section

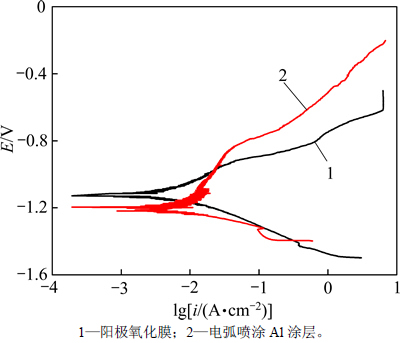

2.6 腐蚀性能

图8所示为试样阳极氧化前后在3.5%NaCl溶液中动电位极化曲线,电弧喷涂试样腐蚀电位ECorr=-1.200 V,阳极氧化试样的腐蚀电位ECorr=-1.120 V,经过阳极氧化处理后试样的腐蚀电位正向移动,试样的耐腐蚀性能有所增强。

经过720 h海水浸泡腐蚀后氧化膜表面形貌如图 9(a)所示,表面孔隙率有所下降,这是由于氧化膜中少量Al原子与腐蚀液中OH-反应生成了Al(OH)3,填补了氧化膜孔洞。同时,表面也出现了腐蚀坑,这是因为腐蚀液中Cl-吸附在Al(OH)3表面发生了二次反应,即[17]

Al(OH)3+ 3Cl-→AlCl3+ 3OH- (6)

式(4)中腐蚀产物AlCl3易溶于水,局部氧化膜被破坏,在表面形成了腐蚀蚀坑。氧化膜表现出良好的耐腐蚀性能,这是由于受Cl-影响较小的区域,Al(OH)3发生了下列脱水反应[17]:

2Al(OH)3→Al2O3+3H2O (7)

腐蚀后截面形貌如图9(b)所示,结构上保持了氧化膜-喷涂Al层-基体的复合防腐蚀形式。

图8 动电位极化曲线

Fig. 8 Curves of potentiodynamic polarization

图9 氧化膜表面和截面腐蚀后形貌

Fig. 9 Surface and section morphologies of anodic oxidized film after corrosion

3 结论

1) 电弧喷涂Al涂层经阳极氧化后表面形成了氧化膜,构成了氧化膜-电弧喷涂Al层-基体的复合防腐蚀体系。

2) Al和O原子含量在氧化膜界面为梯度分布,产生了分层富集现象,在结合界面处形成了扩散和化合作用,提高了电弧喷涂Al涂层界面结合强度。

3) 经过海水浸泡720 h后,阳极氧化后试样自腐蚀电位正向移动,证实了其良好的防腐蚀性能。

参考文献:

[1]  M P de Jesus, RUI Matos, BRUNO F C Fontoura, et al. A comparison of the fatigue behavior between S355 and S690 steel grades[J]. Journal of Constructional Steel Research, 2012, 79: 140-150.

M P de Jesus, RUI Matos, BRUNO F C Fontoura, et al. A comparison of the fatigue behavior between S355 and S690 steel grades[J]. Journal of Constructional Steel Research, 2012, 79: 140-150.

[2] CUI Lei, YANG Xinqi, WANG Dongpo, et al. Friction taper plug welding for S355 steel in underwater wet conditions: welding performance, microstructures and mechanical properties[J]. Materials Science & Engineering A, 2014, 611: 15-28.

[3] 刘艳洁, 王振尧, 柯伟. 2024-T3 铝合金在模拟海洋大气环境中的腐蚀行为[J]. 中国有色金属学报, 2013, 23(5): 1208-1216.

LIU Yanjie, WANG Zhenyao, KE Wei. Corrosion behavior of 2024-T3 aluminum alloy in simulated marine atmospheric environment[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(5): 1208-1216.

[4] 郑传波, 益帼, 高延敏, 等. 海洋环境中 7075-T6 铝合金的氢渗透及应力腐蚀破裂[J]. 中国有色金属学报, 2013, 23(8): 2118-2124.

ZHENG Chuanbo, YI Guo, GAO Yanmin, et al. Hydrogen permeation and stress corrosion cracking sensitivity of 7075-T6 Al alloy in marine environment[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(8): 2118-2124.

[5] JIANG Qiong, MIAO Qiang, TONG Fei, et al. Electrochemical corrosion behavior of arc sprayed Al-Zn-Si-RE coatings on mild steel in 3.5% NaCl solution[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(8): 2713-2722

[6] 李言涛, 刘建国, 侯保荣. 喷涂铝覆盖层在实海浪花飞溅区的腐蚀行为[J]. 中南大学学报(自然科学版), 2011, 42(5): 1243-1247.

LI Yantao, LIU Jianguo, HOU Baorong. Corrosion behavior of sprayed aluminum coatings at splash zone[J]. Journal of Central South University (Science and Technology), 2011, 42(5): 1243-1247.

[7] WANG Chenguang, XU Zhude, LIU Run. Fabrication and optical property of Cu7S4 hollow nanoparticles formed through kirkendall effect[J]. Chemical Research in Chinese Universities, 2008, 24(2): 249-250.

[8] 徐荣正, 宋刚, 刘黎明. 铝合金表面电弧喷涂铝涂层工艺与性能[J]. 焊接学报, 2008, 29(6): 109-112.

XU Rongzheng, SONG Gang, LIU Liming. Microstructure and properties of aluminum coatings on Al alloy surface by arc spraying[J]. Transactions of the China Welding Institution, 2008, 29(6): 109-112.

[9] DEBUYCK F, MOORS M. The Influence of the anodization temperature and voltage on the porosity of the anodization layer on aluminum[J]. Materials Chemistry and Physics, 1993, 36(1/2): 146-149.

[10] YI Chunlong, AN Yunqi, SHEN Yatan. Three years corrosion tests of nanocomposite epoxy sealer for metalized coatings on the east China sea[C]// Proceeding of International Thermal Spray Conference. OH: ASM International, Materials Park, 2009: 1090-1093.

[11] WEI Xiaowei, CHEN Chaoyin. Influence of oxidation heat on hard anodic film of aluminum alloy[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(11): 2707-2712.

[12] LAN Dongyun, WANG Qiang, XUAN Zhaozhi. Interfacial microstructure and characterization of double-layer coatings on cast iron by arc spraying and sintering[J]. Materials Science and Engineering A, 2008, 473(1): 312-316.

[13] SAEEDIKHANI M, JAVIDI M, YAZDANI A. Anodizing of 2024-T3 aluminum alloy in sulfuric-boric-phosphoric acids and its corrosion behavior[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(9): 2551-2559.

[14] NASIRPOURI F, ABDOLLAHZADEH M, ALMASI M J, et al. A comparison between self-ordering of nanopores in aluminium oxide films achieved by two and three-step anodic oxidation[J]. Current Applied Physics, 2009, 9(S1) S91-S94.

[15] 王文昌, 张垒, 孔德军, 等. YL113铝合金阳极氧化膜表面-界面形貌与能谱分析[J]. 材料热处理学报, 2014, 35(3): 180-186.

WANG Wenchang, ZHANG Lei, KONG Dejun, et al. Surface-interface morphologies and energy spectrum analysis of anodic oxide film on the surface of aluminum alloy YL113[J]. Transactions Journal of Materials and Heat Treatment, 2014, 35(3): 180-186.

[16] TOUGERTI A, M THIVIER C, CRISTOL S. Structure of clean and hydrated α-Al2O3 (1102) surfaces: implication on surface charge[J]. Physical Chemistry Chemical Physics. 2011, 13(14): 6531-6543.

THIVIER C, CRISTOL S. Structure of clean and hydrated α-Al2O3 (1102) surfaces: implication on surface charge[J]. Physical Chemistry Chemical Physics. 2011, 13(14): 6531-6543.

[17] LEE Y J, KANG S W. Growth of aluminum nitride thin films prepared by plasma-enhanced atomic layer deposition[J]. Thin Solid Films, 2004, 446(2): 227-231.

(编辑 陈爱华)

收稿日期:2016-08-12;修回日期:2016-10-22

基金项目(Foundation item):江苏省科协首席专家(工程师)项目(2013-216);江苏省重点研发计划项目(BE2016052) (Project(2013-216) supported by Jiangsu Province CAST Chief Expert (Engineer); Project(BE2016052) supported by Key Research and Development Project of Jiangsu Province)

通信作者:孔德军,博士,教授,从事材料表面改性处理研究;E-mail: kong-dejun@163.com