文章编号: 1004-0609(2006)05-0793-07

旋转盘离心雾化熔滴飞行动力学与凝固进程

李会平1, P. Tsakiropoulos2

(1. 华东理工大学 无机材料系, 上海 200237;

2. School of Mechanical and Materials Engineering, University of Surrey, Guildford Surrey GU2 7XH, UK)

摘 要: 建立了旋转盘离心雾化熔滴飞行与凝固进程的一个数学模型, 并用Runge-Kutta方法进行数值求解, 模拟镍金属熔滴飞行与凝固的基本情况, 探讨过程和材料参数的影响。 结果表明: 在旋转盘离心雾化中熔滴经历了一个大的过冷, 其过冷度约为0.2Tm; 在整个飞行期间, 熔滴的冷却速率并不是常数, 在熔点附近冷却速率约为5×104K/s; 角速度越大, 冷却速率越大, 熔滴开始和完成凝固所需时间越短, 雾化室可小些; 熔滴过热温度对熔滴过冷度和冷却速率影响不明显, 但完成凝固所飞行的距离增大, 从雾化室设计角度, 不宜采用大的过热温度。

关键词: 离心雾化; 旋转盘; 飞行与凝固; 数学模型 中图分类号: TF123.23

文献标识码: A

Droplet dynamic and solidification progress during rotating disk centrifugal atomization

LI Hui-ping1, P. Tsakiropoulos2

(1. Department of Inorganic Materials, East China University of Science and Technology,

Shanghai 200237, China;

2. School of Mechanical and Materials Engineering, University of Surrey,

Guildford Surrey GU2 7XH, UK)

Abstract: A mathematical model of droplet dynamic and solidification progress during rotating disk centrifugal atomization was developed and numerically solved by Runge-Kuttas method. The flight and solidification of a nickel droplet was simulated. The effect of process and materials parameters was studied. The results show that the droplet experiences a large undercooling of about 0.2Tm and the cooling rate is not constant during the flight, about 5×104K/s at the melting point. With increasing disk speed the cooling rate increases, and this leads an early start and completion of solidification. A small atomizing chamber can be used. The droplet superheat has a weak effect on nucleation temperature and cooling rate, but the flight distance at f=1 increases. Therefore, a high droplet superheat is not suitable for the design of atomizing chamber.

Key words: centrifugal atomization; rotating disk; flight and solidification; mathematical model

旋转盘离心雾化是金属粉末制造的一种重要方法, 最初由美国Pratt & Whitney飞机制造公司研制。 由于其独特的粉末尺寸、 形貌的可控性和清洁性以及成本低廉而不断受到人们的重视, 改进的旋转盘离心雾化装置时有报道[1-4]。 近些年来, 人们更是将其与喷射沉积相结合形成离心喷射沉积(CSD)用于航空部件的近终形生产[5]。

旋转盘离心雾化/沉积的基本过程是, 从熔化装置出来的熔化好的金属液经导向装置导流到旋转盘的中心, 而后由于惯性和离心抛甩作用, 金属液沿径向分布开来并在旋转盘上形成一薄的液膜。 当液膜到达旋转盘边缘时, 它被雾化成液滴。 在随后的飞行中, 这些液滴凝固形成粉末或沉积在基质上形成近终形产品。 实际的旋转盘离心雾化/沉积是一个更为复杂的过程, 涉及: 金属液在旋转盘上的分布、 传热和凝固[6], 金属液在旋转盘上、 盘边、 盘外的雾化, 熔滴在旋转盘外的飞行和凝固(对制粉而言)和熔滴在基质上的沉积与凝固(对喷射沉积而言)等。 以前, 旋转盘离心雾化研究主要集中在旋转盘设计和操作参数对粉末尺寸和形貌的影响[3, 4, 7], 缺乏对过程的细致认识。 雾化产生的熔滴在旋转盘外的飞行与凝固情况对雾化器性能的认识和雾化室尺寸的确定具有重要的指导作用。 本文作者旨在这方面做些工作。

1 数学模型

1.1 熔滴飞行动力学

熔滴在旋转盘边形成后, 由于惯性和离心作用, 熔滴被抛离旋转盘。 在飞行过程中, 熔滴传递动量与热量给环境, 其自身速度和温度降低。

熔滴在旋转盘外的运动可用牛顿第二定律描述:

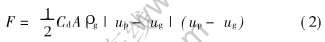

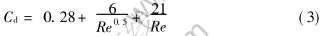

式中 F为作用在熔滴上的力; m为熔滴的质量; up为熔滴的速度; t为时间。 作用在熔滴上的力主要有气体的拖拽力、 重力和浮力。 在旋转盘离心雾化中, 重力和浮力的影响不大。 为简化起见, 暂不考虑这两种力的作用。 假定熔滴是球形的、 彼此之间没有相互作用且在运动过程中熔滴也不进一步破碎, 则拖拽力可表示为[8]

式中 A为熔滴投影面积, A=πd2p/4; ρg为气体密度; ug为气体速度; Cd为拖拽系数, 可表示为[9]

式中 Re为熔滴雷诺数, Re=ρgdp|up-ug|/μg; μg为气体粘度; dp为熔滴直径。 研究表明, 在旋转盘离心雾化中, 熔滴主要按3种模式雾化[10]。 在滴状分裂区, 熔滴尺寸计算式为[11]

式中 D为旋转盘直径; ω为旋转盘角速度; Q为金属液流量; σ、 ρ分别为熔滴表面张力和密度。

将式(2)和(3)代入式(1), 并整理有

上式描述了熔滴在飞行中的运动规律。

当熔滴在旋转盘边形成时, 熔滴具有与旋转盘边液膜同样的速度。 因此, 式(5)的初始条件为

式中 vt, um分别为熔滴在旋转盘边的切向与平均径向速度, 可表示为[12]

式中 υ为熔滴的粘度。

在算得熔滴的速度后, 熔滴的飞行距离ls可按下式计算:

1.2 熔滴的温度

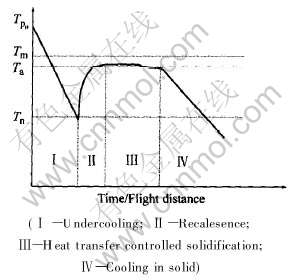

在飞行过程中, 熔滴以辐射和对流方式将热量传给环境, 熔滴温度逐渐降低。 对纯金属而言, 熔滴将经历4个阶段(见图1): 液相冷却; 形核与再辉; 传热控制的冷却; 固相冷却。

图1 纯金属熔滴在飞行中的凝固示意图

Fig.1 Schematic of solidification of pure metal droplet

在液相冷却阶段, 熔滴传递热量给环境, 自身温度降低, 直到达到形核温度Tn。 在这一阶段, 熔滴仍然是液态。 熔滴的热损失为熔滴的焓所补偿。 晶核一旦形成, 凝固进行得非常迅速, 凝固放出的热量远大于熔滴传给环境的热量, 熔滴的温度迅速上升, 熔滴进入形核与再辉阶段。 随着凝固的进行, 熔滴温度逐渐升高, 凝固速率降低, 凝固放出的热量渐渐为熔滴的散热所平衡, 熔滴温度不再上升, 熔滴进入传热控制的冷却阶段, 这一阶段持续到整个熔滴全部凝固成固体。 然后, 随着散热的进行, 熔滴温度再次下降。

1.2.1 液相冷却

在这一阶段, 熔滴的热损失(对流和辐射)为熔滴的焓所补偿。 根据传热学基本原理, 熔滴的温度应满足下式:

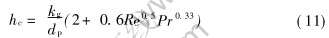

式中 Tp, Tg分别为熔滴和气体的温度; σ为Stefan-Boltzmann 常数; ε为熔滴的黑度; cpl为熔滴的液态比热容; hc为熔滴与气体的对流传热系数, 计算式为[13]

式中 Pr为气体的普朗特数, Pr=μgcpg/kg; μg、 kg、 cpg分别为气体的粘度、 导热系数和比热容。

1.2.2 形核与再辉

在熔滴的温度冷却到金属的熔点时, 熔滴并不马上开始凝固, 而是要过冷到一定的温度, 这一温度要求主要用于形核。 形核速率J可表示如下[14]:

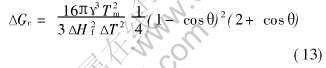

式中 kb、 hp分别为Boltzmann和Planck常数; Vm为分子体积; ΔGam为原子跃迁穿过液固界面的激活能; ΔGc为临界形核自由能势(临界形核功), 可进一步表示如下[9, 14]:

式中 γ为固液界面能; Tm为金属熔点; θ为润湿角; ΔHf为熔化潜热; ΔT=Tm-T为过冷度。

式(12)和(13)描述了非均质形核的形核速率。 当θ=180°时, 上述式子简化为均质形核的形核速率。 为使模拟具有一般性, 选择上述公式。

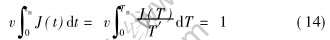

形核温度Tn定义为[14]

式中 v为熔滴体积, v=πd3p/6; tn为形核温度时的飞行时间; T′为冷却速率, T′=dT/dt; J(t)、 J(T)分别为以时间和温度表示的形核速率。 形核温度Tn可用内插法确定。

在算得形核温度后, 凝固速率计算式为[14]

式中 dm为分子有效直径; D0为扩散常数。

对于球形熔滴, 熔滴中的固相分数与凝固速率之间的关系为

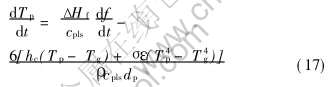

在形核与再辉期, 熔滴是固、 液混合体, 凝固放出的熔化潜热不仅弥补了熔滴的散热而且还导致了熔滴温度快速上升, 熔滴温度应满足下式:

式中 f为固相分数; cpls为固、 液混合体的比热容, 可按下式计算:

cpls=cpl(1-f)+cpsf(18)

式中 cps为熔滴的固态比热容。

1.2.3 传热控制的冷却

随着再辉的进行, 凝固速率逐渐降低。 凝固放出的热量渐渐被散热平衡, 熔滴温度不再上升, 维持在再辉温度Ta。 这一阶段的传热、 凝固规律仍可用式(17)描述或令dTp/dt=0。

1.2.4 固相冷却

在这一阶段, 熔滴已全部变成固体。 熔滴的温度遵循下述规律:

2 计算方法

式(1)~(19)描述了熔滴在整个冷却、 凝固过程中所应遵循的基本规律。 总体上, 上述方程是一阶非线性常微分方程组, 可用四阶Runge-Kutta 方法求解。 计算时, 先输入相关的数据, 然后计算熔滴尺寸, 最后计算熔滴的速度、 固相分数和温度等。

3 结果与讨论

金属镍在旋转盘外的飞行与凝固情况已经进行了模拟。 模拟的基本条件为: 旋转盘直径D=0.1m, 角速度ω=15000r/min, 熔滴过热温度ΔTsuper=50K, 金属液流量Q=2.35×10-6m3/s。 金属镍的热物性数据列于表1[14]。

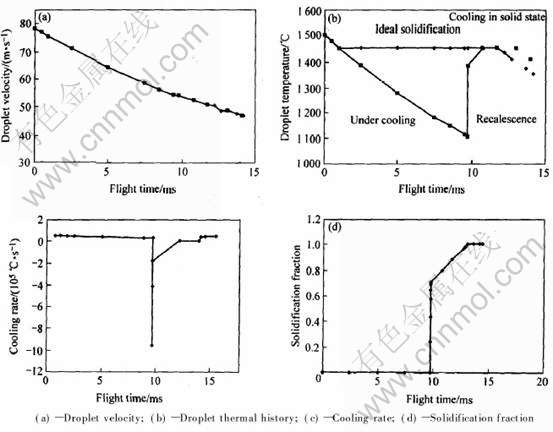

计算表明, 在本模拟条件下, 雾化主要发生在滴状分裂区, 根据文献[10]计算的镍熔滴的直径为107.9μm。 熔滴的速度、 温度、 冷却速率和固相分数随飞行时间的变化如图2所示。

从图2可见, 随飞行时间的增加, 熔滴的飞行速度逐渐降低(图2(a))。 这主要是熔滴与雾化室中气体作用的结果。 熔滴经历了一个大的过冷, 其过冷度ΔT约为0.2Tm, 这与用小液滴法所做的均质形核的实验结果基本一致[15]。 在形核后, 熔滴快速再辉到接近金属的熔点, 并保持在那一温度直到整个熔滴全部凝固。 然后, 熔滴进入固相冷却阶段。 同理想凝固相比, 旋转盘离心雾化快速凝固持续的时间更长(图2(b)), 因而熔滴完全凝固时所飞行的距离也越长。 为防止熔滴在碰到雾化室器壁时进一步破碎和粘附在器壁上, 这就要求更大的雾化室。 在本模拟条件下, 一个直径为1.6m的雾化室是必需的。

表1 金属镍和铝的物理性质

Table 1 Physical properties of pure nickel and aluminum

图2 Ni金属熔滴的飞行与凝固进程

Fig.2 Heat transfer and solidification progress during flight of Ni droplet

从图2(c)可见, 在整个飞行过程中, 熔滴冷却速率并不是常数: 在液相冷却阶段, 随飞行时间的增加, 冷却速率略有降低。 这主要是由于高温辐射散热作用更强和随飞行时间延长熔滴速度降低导致的对流散热下降之故。 在这一区域的冷却速率约为5×104K/s, 这与文献[16]通过测量二次枝晶臂间距估计的冷却速率量级相吻合; 在形核与再辉阶段, 熔滴的温度快速上升, 冷却速率为负值; 在再辉结束时, 熔滴温度维持在金属熔点附近, 冷却速率几乎为零; 在固相冷却阶段, 由于熔滴温度、 速度降低, 冷却速率略小于液相冷却阶段的数值。

3.1 旋转盘角速度的影响

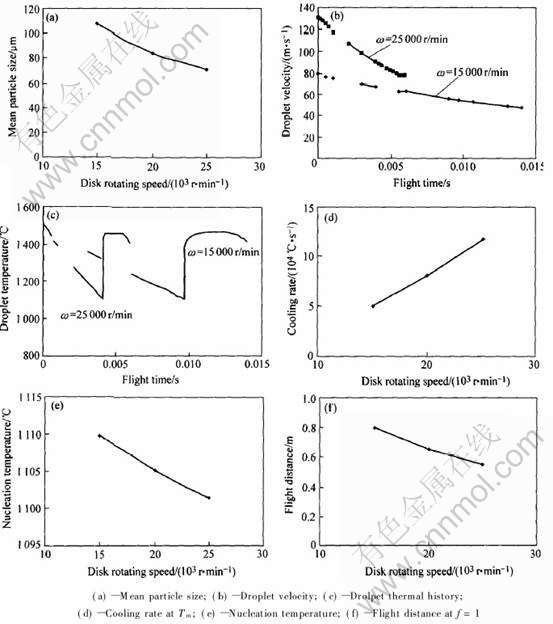

旋转盘角速度对熔滴尺寸、 飞行速度、 热经历、 冷却速度、 形核温度和凝固结束时的飞行距离的影响如图3所示。

图3 旋转盘角速度对熔滴尺寸、 飞行速度、 热经历、 冷却速率、 形核温度和凝固完成时飞行距离的影响

Fig.3 Effects of disk rotating speed on mean particle size, droplet velocity, thermal history,cooling rate, nucleation temperature and flight distance at end of solidification

从图3(a)可见, 角速度越大, 熔滴尺寸越小, 这主要是由于角速度越大, 金属液受到的离心力越大, 因而雾化后的熔滴越细。 由图3(b)可见, 大角速度时(25000r/min)熔滴有大的飞行速度(图3(b), 但大角速度时熔滴的飞行速度衰减得更快。 这主要是由于大角速度时熔滴离开旋转盘的初始速度越大, 因而大角速度时熔滴有大的飞行速度; 大的飞行速度有大的拖拽力, 这导致了大角速度时熔滴飞行速度衰减得更快些。 大角速度时大的飞行速度和小的滴径共同导致了大角速度时熔滴开始凝固和结束凝固更早些(图3(c))。 飞行速度越大, 熔滴与环境的对流传热越强; 熔滴越小, 熔滴自身的焓越少; 因而, 角速度越大, 熔滴的冷却速率越大(图3(d)), 这又导致了大角速度时有大的过冷(图3(e))。 角速度愈大, 冷却速率愈大, 凝固开始得愈早, 凝固结束得也愈早, 因而凝固结束时熔滴飞行距离随之下降(图3(f)), 在保证熔滴在碰到雾化室器壁时不发生粘壁和进一步破碎的前提要求下, 雾化室可设计得小些。 这就为整个雾化装置的设计创造了宽松的环境。

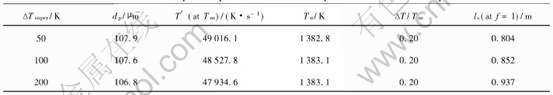

3.2 熔滴过热温度的影响

由表2可见, 熔滴过热温度对熔滴滴径、 冷却速率和形核温度影响不明显; 随熔滴过热温度增大, 熔滴滴径和在熔点时的冷却速率略有降低, 而形核温度略有升高。 熔滴温度高, 金属液表面张力小, 这可能是雾化后熔滴滴径变小的一个原因。 熔滴温度高, 熔滴冷却到金属熔点所需时间长, 在其他条件不变的情况下, 熔滴飞行速度就小, 因而对流散热少, 在熔点时的冷却速率也就小。 而这又导致了形核温度的升高。

从表2也可看出, 过热温度对熔滴凝固结束时的飞行距离有较大影响。 过热温度越大, 凝固结束时的飞行距离越大, 要保证熔滴在碰到器壁前完全凝固, 这就要求更大的雾化室。 过热200K, 雾化室直径需达1.9m。 因此, 大的过热温度对雾化室设计是不利的。 3.3 金属种类的影响

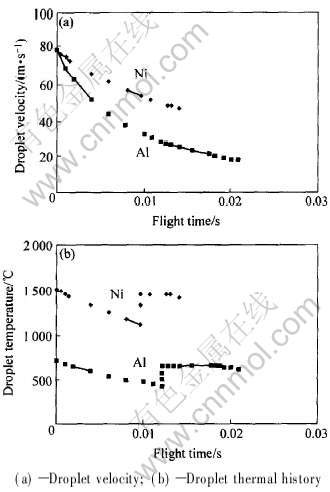

图4 比较了金属镍和铝的凝固情况。 不同的金属有不同的热物理性质, 因此在相同的操作条件下, 它们的表现是不一样的。 铝比较轻, 雾化后的颗粒比较大, 因而飞行速度下降得更快些(图4(a))。 而熔滴在飞行中的冷却情况则同时取决于气固之间的传热情况和熔滴的热物理性质。 在旋转盘离心雾化中, 辐射和对流同时起作用。 在高温下, 辐射起主要作用, 因而熔点高的金属冷却速率更大些, 开始凝固和凝固结束也更早些(图4(b))。 因此, 雾化Al的雾化室要设计得更大些。

图4 金属种类对熔滴飞行与凝固进程的影响

Fig.4 Effects of different metals on droplet velocity and temperature

表2 熔滴过热温度对一些凝固参数的影响

Table 2 Effects of droplet superheat on some important solidification parameters

4 结论

1) 建立了旋转盘离心雾化熔滴飞行与凝固进程的一个数学模型, 并用数值方法进行了模拟。 模拟计算表明: 在飞行过程中, 熔滴经历了一个大的过冷, 其过冷度约为0.2Tm; 在整个飞行期间, 熔滴的冷却速率并不是常数, 在熔点附近冷却速率约为5×104K/s。

2) 角速度越大, 熔滴尺寸越小, 冷却速率越大, 熔滴开始和完成凝固所需时间越短, 因而所要求的雾化室越小。 随角速度增大, 熔滴过冷度也增大, 这就为材料的快速凝固加工创造了更好的条件。

3) 熔滴过热温度对熔滴过冷度和冷却速率影响不明显, 而大的过热温度要求更大的雾化室。 从雾化室设计角度, 不宜采用大的过热温度。

REFERENCES

[1]李荣德, 刘金民, 向青春. 两种新型快凝雾化制粉技术的研究[J]. 机械设计与制造, 2003, 6: 98-99.

LI Rong-de, LIU Jin-min, XIANG Qing-chun. Study on two new techniques of rapid solidification atomization for metal powder production[J]. Machinery Design & Manufacture, 2003, 6: 98-99.

[2]Folio F, Lacour A. Centrifugal atomization of metallic alloys in inductive plasma onto cooled disc[J]. Powder Metallurgy, 2000, 43(2): 245-252.

[3]Ozturk S, Arslan F. Production of rapidly solidified metal powders by water cooled rotating disc atomization[J]. Powder Metallurgy, 2001, 44(2): 171-176.

[4]Labrecque C, Angers R, Tremblay R. Inverted disk centrifugal atomization of AZ91 Magnesium alloy[J]. Canadian Metallurgical Quarterly, 1997, 36(3): 169-175.

[5]Zhao Y Y. Modelling deposit growth on tilted rotating cylindrical substrate in centrifugal spray deposition[J]. Powder Metallurgy, 2000, 43(2): 117-122.

[6]Ho K H, Zhao Y Y. Modelling thermal development of liquid metal flow on rotating disc in centrifugal atomisation[J]. Materials Science and Engineering, 2004, A365: 336-340.

[7]Angers R, Tremblay R, Dube D. Formation of irregular particles during centrifugal atomization of AZ91 alloy[J]. Materials Letters, 1997, 33: 13-18.

[8]袁武华, 陈振华, 徐海洋, 等. 多层喷射沉积耐热铝合金管坯热流分析(Ⅰ)[J]. 湖南大学学报(自然科学版), 2004, 31(1): 7-11.

YUAN Wu-hua, CHEN Zhen-hua, XU Hai-yang, et al. Heat flow of multi-layer spray deposited heat-resistant Al alloy pipe blank(Ⅰ)[J]. J Hunan University (Natural Sciences), 2004, 31(1): 7-11.

[9]Grant P S, Cantor B, Katgerman L. Modelling of droplet dynamic and thermal histories during spray forming (Ⅰ) individual droplet behaviour[J]. Acta Metall Mater, 1993, 41(11): 3097-3108.

[10]Li H, Tsakiropoulos P. Calculation of powder size in centrifugal atomization and spray forming[J]. J Materials Synthesis and Processing, 1997, 5(1): 117-121.

[11]Angers R. Powder production and spray forming[A]. Advances in Powder Metallurgy & Particulate Materials[C]. New Jersey: MPIF, 1992. 79-88.

[12]李会平. 应用波理论预测旋转盘离心雾化膜状分裂区的粉末尺寸[J]. 粉末冶金工业, 2006(1): 17-21.

LI Hui-ping. Application of wave theories to predict the powder particle size in film formation regime during centrifugal atomization by rotating disk[J]. Powder Metallurgy Industry, 2006(1): 17-21.

[13]傅晓伟, 张济山, 孙祖庆. 喷射沉积过程的计算模型及优化软件[J]. 金属学报, 1999, 35(2): 147-151.

FU Xiao-wei, ZHANG Ji-shan, SUN Zu-qing. Modeling and optimizing software of spray deposition process[J]. Acta Metallurgica Sinica, 1999, 35(2): 147-151.

[14]Clyne T W. Numerical treatment of rapid solidification[J]. Metall Trans B, 1984, 15: 369-381.

[15]陈光, 傅恒志. 非平衡凝固新型金属材料[M]. 北京: 科学出版社, 2004. 71.

CHEN Guang, FU Heng-zhi. Advanced Metallic Materials by Non-equilibrium Solidification[M]. Beijing: Science Press, 2004. 71.

[16]曹阳, 李国俊, 杨贤金. 离心雾化工艺参数对快速凝固LY12硬铝粉末特性影响的研究[J]. 机械工程学报, 1990, 26(4): 45-49.

CAO Yang, LI Guo-jun, YANG Xian-jin. The effect of centrifugal atomisation processing on characteristic of rapidly solidified LY12 alloy powders[J]. Chinese Journal of Mechanical Engineering, 1990, 26(4): 45-49.

收稿日期: 2005-01-26; 修订日期: 2006-02-21

通讯作者: 李会平, 副教授; 电话: 021-64761458; E-mail: lihuipingecust@sina.com

(编辑陈爱华)