文章编号:1004-0609(2008)04-0637-06

高铼Ni3Al基高温合金的显微组织

范映伟,郑运荣,曾 强

(北京航空材料研究院,北京 100095)

摘 要:用扫描电镜、能谱仪、X射线衍射技术和定量金相技术研究Ni-10Co-7.1W-1.7Mo-0.5Nb-6.9Ta-7.9Re-6.9Al- 0.008CNi3Al基高温合金的显微组织。实验表明:该合金由γ,γ′,γ + γ′共晶和Re3W相组成;Re是强负偏析元素,过量Re促使Re3W相的形成;合金中次生γ′、共晶γ′的固溶温度分别为1 330和1 360 ℃。采用1 290 ℃,2 h+ 1 330 ℃,6 h+1 360 ℃,6 h多级固溶处理实现γ′完全固溶并避免初溶,但该处理不能消除Re3W相,也不能实现Re的完全均匀化,适当降低Al,Ta和Re含量可以消除Re3W相。

关键词:Ni3Al基高温合金;铼;固溶处理;显微组织

中图分类号:TG 113.1;TG 115.21 文献标识码:A

Microstructure of Ni3Al-base superalloy with high content of rhenium

FAN Ying-wei, ZHENG Yun-rong, ZENG Qiang

(Beijing Institute of Aeronautical Materials, Beijing 100095, China)

Abstract: The microstructure of Ni3Al base superalloy with composition of Ni-10Co-7.1W-1.7Mo-0.5Nb-6.9Ta-7.9Re- 6.9Al-0.008C was investigated by SEM, EDS, XRD and quantitative metallographic method. The results show that the alloy consists of γ, γ′, eutectic (γ+γ′) and Re3W phases. Rhenium is a strong negative segregation element and the excessive amount of Re promotes the formation of Re3W phase. The solid solution temperatures of secondary γ′, eutectic γ′ are 1 330 ℃ and 1 360 ℃ respectively. By means of 1 290 ℃, 2 h+1 330 ℃, 6 h+1 360 ℃, 6 h multistep solid solution treatment, the full solid solution of γ′ phase is realized and the incipient melting is avoided. However, the Re3W phase can not be eliminated and the homogenization of Re is not completed by the above mentioned treatment. The proper solution is to modify the alloy composition so as to eliminate Re3W phase.

Key words: Ni3Al base superalloy; rhenium; solid solution treatment; microstructure

由于Ni3Al基金属间化合物强度高及密度小,已广泛应用于制造燃气涡轮叶片[1-3],但其承温能力仍难于满足先进航空发动机日益发展的要求。持续提高这类材料的高温强度是重要的发展方向,添加合金元素Re是实现这一目标的重要手段。尽管Re的价格约为黄金的四分之一,但成品涡轮叶片的价格已达等重黄金的水平,而叶片原材料成本只占叶片价格的20%左右,因此高Re仍是合金发展的重要选择。20世纪90年代以来,定向凝固和单晶合金的含Re量已达3%~6%(质量分数)[4-6],俄罗斯高温合金的含Re量甚至高达10%[7]。深入研究发现,Re是高温合金主量合金元素中偏析最严重的元素,其枝晶干区Re浓度是枝晶间区的5倍[8]。严重的Re偏析造成枝晶干区在高温使用时析出有害的TCP相[9-10]。为解决TCP相析出损害高温蠕变强度,SATO等[11]在含Re高于3%的合金中加入3%Ru,有效抑制TCP相的析出。另外,通过1 310~ 1 370℃多级固溶热处理可以有效地减少Re偏析,也可避免TCP相形成[12]。虽然Re在定向和单晶合金中的作用已有较多的研究[13-18],但Re在定向Ni3Al基高温合金中的影响却鲜见报道。本文作者研究一种含7.9%Re(质量分数)的Ni3Al基高温合金的显微组织,为进一步提高这类材料的高温性能、满足先进航空发动机日益苛刻的要求提供基本依据。

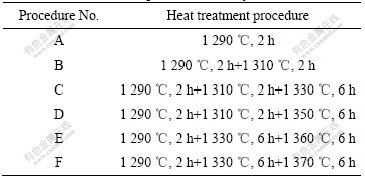

1 实验

实验材料是一炉真空感应熔炼炉3 kg高Re铸造Ni3Al基金属间化合物,其化学成分为Ni-10Co-7.1W- 1.7Mo-0.5Nb-6.9Ta-7.9Re-6.9Al-0.008C(质量分数,%)。合金被铸成多晶棒料,从棒料上切取试块进行高温固溶处理,处理状态列于表1。采用多级固溶处理是为了抑制初熔。用扫描电镜、能谱仪和定量金相技术测定铸态和热处理试样中各种组成相的成分和含量,测定固溶处理前后共晶γ′量的变化以及Re和Ta元素偏析的变化,为材料的均匀化做准备。

表1 合金的固溶处理规范

Table 1 Heat treatment procedure of alloy

为了鉴定合金中相的结构,对铸态和热处理试样还做了X射线衍射分析(阳极采用Cu Kα)。

2 结果及讨论

2.1 铸态组织

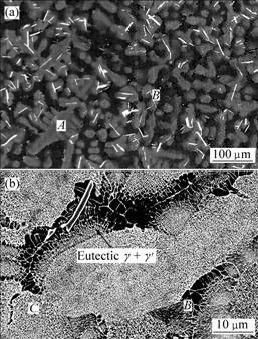

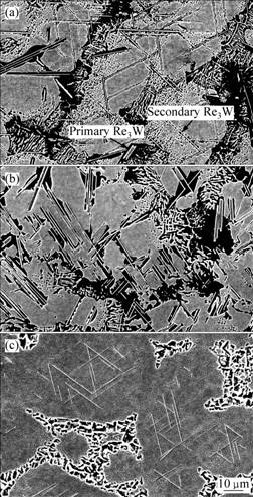

合金的铸态组织如图1所示。在扫描电镜背散射像中,铸态枝晶组织清晰可见,枝晶干区A是γ和γ′两相组成,枝晶间区B是γ+γ′共晶,还有白亮的片状和块状相(图1(a))。在更高放大倍率下(图1(b)),枝晶干A区γ基体上析出粒状γ′,受显微偏析影响,枝晶间区Al、Ta等γ′形成元素较多,析出的γ′相比枝晶干区更粗大,甚至析出花状的γ+γ′共晶,在扫描电镜下,它由丝状灰白色γ和黑色块状γ′(共晶γ′)组成,共晶γ+γ′中γ′的最大尺寸高达8 μm,可用EDS测定其含量。

图1 合金的铸态显微组织

Fig.1 Microstructures of as-cast alloy

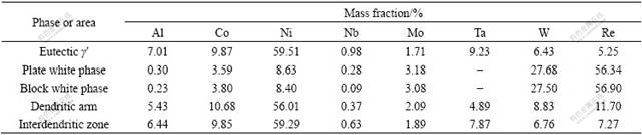

为了测定Re在合金中的分配,用能谱测定图1中共晶γ′、白亮片状相和块状相、枝晶干中心区和共晶γ′边缘的枝晶间C区(图1(b))的成分,结果如表2所列。表中所列数据是2次以上测定结果的平均值。

从表2可知,共晶γ′主要富Al、Ta和Nb,Re在共晶γ′中的溶解度较在基体γ +γ′中低。白色的片状和块状相的成分非常相似,都含有很高的W和Re,还溶解较多的Ni和Co,实际上都是富W和Re相。从表2还可以看出,Re和W是负偏析元素,主要富集 在枝晶干区,尤其是Re显微偏析更严重,其偏析比 (cseg=cden/cinterden,其中cden是其在枝干中的浓度,cinterden是其在枝间的浓度)高达1.61。Ta、Nb和Al是正偏析元素,主要富集在枝晶间区,而Nb是偏析最严重的正偏析元素。正是由于铸态合金中难熔元素Re、W、Mo、Nb和Ta的严重偏析,使合金的高温强度得不到充分发挥,需要通过高温固溶处理使合金均匀化。

表2 合金中相的成分与枝晶偏析

Table 2 Composition of phases and dendritic segregation in alloy

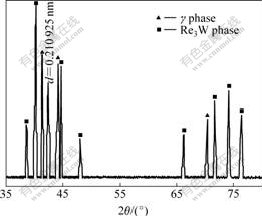

为了鉴定合金中的富W和Re相,用10%盐酸-甲醇溶液,在电流密度0.2 A/cm2下,电解萃取富W和Re相,溶解掉γ+γ′基体相以后,对收集到的少量萃取残余物用X射线衍射仪进行相鉴定,结果如图2所示。由图可知,萃取粉末中除残留的基体γ相外,另一组衍射谱线与Re3W相标准谱线很相符,该相为体心立方(BCC)结构,点阵常数为0.958 8 nm。衍射谱中还有一条d = 0.210 925 nm的未知谱线,可能是电解萃取过程中出现的未知产物。

图2 铸态合金萃取粉末的XRD谱

Fig.2 XRD pattern of as-cast alloy

根据表2数据,将富W和Re相中体心立方结构元素W、Mo和Nb归为一组,将具有面心立方和密排六方结构元素Al、Ni、Co、Re归为另一组,计算Al+Ni+Co+Re与W+Mo+Nb的摩尔比约等于2.9,从成分上也证明富W和Re相应为Re3W相。

2.2 固溶热处理组织

合金固溶处理的目的是使共晶γ′和从γ基体析出的次生γ′全部固溶,并减轻Re和W等难熔元素的显微偏析。温度越高越易达到上述目的,但要受到合金初熔的制约。因此,首先要探明γ′的固溶温度和合金的初熔温度。

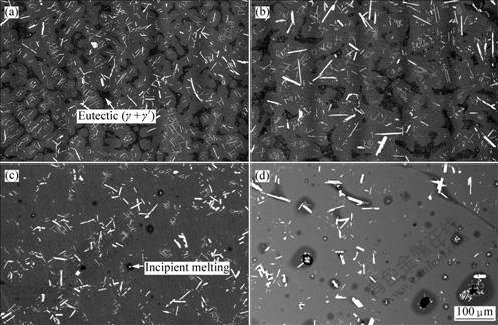

次生γ′的固溶比共晶γ′的固溶容易,经1 290 ℃,2 h处理后,枝晶干区的次生γ′就已经明显回溶,而共晶γ′却没有明显的变化,同时,枝晶间区的γ′反而粗化。组织中除铸态粗片状初生Re3W相外,还析出薄片状相(图3(a))。由于片太薄,用能谱不能准确测定其成分,但能确定该相富W和Re。对该试样做X射线衍射分析后,也证明其组成相与铸态相同,没有新相析出,证明该相仍为Re3W相。经1 290 ℃,2 h+1 310 ℃,2 h处理后,次生γ′的回溶更加明显,共晶γ′此时也开始固溶,同时补充析出更多的次生Re3W相(图3(b))。1 330 ℃,6 h处理后,仍有少量次生γ′(图3(c))。再经1 350 ℃,6 h处理后,次生γ′固溶完毕。

图3 次生γ′的固溶显微组织

Fig.3 Microstructures of solid solution for secondary γ′: (a) 1 290 ℃, 2 h; (b) 1 290 ℃, 2 h+1 310 ℃, 2 h; (c) 1 290 ℃, 2 h+1 310 ℃, 2 h+1 330 ℃, 6 h

经固溶处理后,共晶γ′的固溶组织如图4所示。与图1(a)的铸态组织相比,图4(a)中,合金经1 330 ℃,6 h处理后共晶γ′明显减少。经过1 360 ℃,6 h处理,共晶γ′已完全固溶,同时出现微量的初熔区(图4(c)中箭头所指)。固溶温度进一步升高至1 370 ℃时,初熔进一步扩大(图4(d))。图4还表明,高于1 330 ℃固溶处理时,随着固溶温度的升高,薄片状的次生Re3W相渐渐减少,到1 370 ℃时,该相基本溶解(图4(d))。次生Re3W的析出,是由于在偏析区,Re浓度超出其在γ中的极限溶解度,且Re的扩散极为困难,要达到完全均匀化很困难,使浓度超过极限溶解度的Re以次生Re3W形式析出。要消除Re3W相,需要从调低合金饱和度的角度加以解决。

图4 不同固溶处理后共晶γ′的固溶组织

Fig.4 Solid solution treated microstructures of eutectic γ′ after different treatments: (a) 1 290 ℃, 2 h+1 310 ℃, 2 h+1 330 ℃, 6 h; (b) 1 290 ℃, 2 h+1 310 ℃, 2 h+1 350 ℃, 6 h; (c) 1 290 ℃, 2 h+1 330 ℃, 6 h+1 360 ℃, 6 h; (d) 1 290 ℃, 2 h+1 330 ℃, 6 h+ 1 370 ℃, 6 h

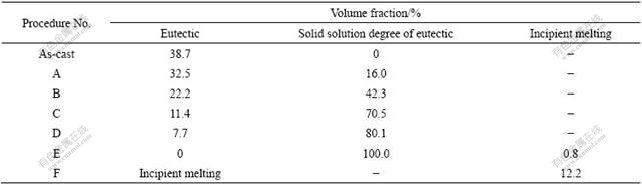

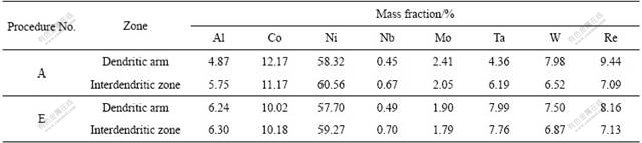

对不同温度固溶处理试样的共晶γ′体积百分含量作了定量分析,结果示于表3中。从表3可以看出,共晶γ′大量回溶温度为1 330 ℃,最终固溶处理为 1 360 ℃,6 h时,保证了合金中全部γ′ 固溶而又不出现明显的初熔,经此处理后,材料的均匀化效果较好,Al达到了完全均匀化,难熔元素Cr、Mo、W、Ta也获得了较好的均匀化效果,但Re仍然保留了较高的偏析度(表4),需要更高温度和更长时间的均匀化处 理[12]。

表3 不同状态试样的共晶γ′和初熔量

Table 3 Volume percent of eutectic γ′ and incipient melting of specimens treated by different conditions

表4 固溶处理状态E对合金枝晶偏析的影响

Table 4 Influence of solid solution E on dendritic segregation

综上所述,热处理状态E,即1 290 ℃,2 h+1 330 ℃,6 h+1 360 ℃,6 h是较合适的固溶处理规范,但受初熔制约未能完全解决Re的均匀化问题。另一方面,合金的含Re量处于过饱和状态,过量的Re以Re3W相形式析出,弱化了合金,而且初生的Re3W相极其稳定,不能通过热处理使其溶解。因为Re在γ中的溶解度远高于在共晶γ′中的溶解度,因此降低合金共晶γ′含量是抑制Re3W相析出的重要措施,对合金中Al和Ta含量作进一步调整避免Re3W相的析出,获得组织稳定性好的高Re Ni3Al基高温合金,进一步的研究工作正在进行中。

3 结论

1) 成分为Ni-10Co-7.1W-1.7Mo-0.5Nb-6.9Ta-7.9Re- 6.9Al-0.008C(质量分数,%)的Ni3Al基高温合金由γ、γ′和γ+γ′共晶和Re3W相组成。

2) Re是强负偏析元素,它的偏析比cseg= cden/cinterden高达 1.61。过饱和的Re以初生和次生Re3W形式析出。

3) 次生γ′和共晶γ′的完全固溶温度分别为1 330 ℃和1 360 ℃,合金明显的初熔温度为1 370 ℃。在 1 290~1 370 ℃温度范围,初生Re3W相没有明显的固溶;在低于1 330 ℃时,次生Re3W相不断以薄片形式析出,温度高于1 350 ℃后又明显回溶,1 370 ℃时基本溶解完毕。

4) Re是最难均匀化元素,经1 360 ℃,6 h处理后,Re的偏析比仍高达1.15。

REFERENCES

[1] HAN Y F, XING Z P, CHATURVEDI M C. Development and engineering applications of a DS cast Ni3Al alloy IC6[C]// NATHAL M V, DAROLIA R, LIU C T, MARTIN P L, MIRACLE D B, WANGER R, YAMAGUCHI M. Structural Intermetallics 1997. Pennsylvania: TMS, 1997: 713-720.

[2] HAN Y F, CHATURVEDI M C. A high performance DS Ni3Al base alloy for advanced gas turbine blades and vanes[J]. Acta Metall Sinica, 1995, 8(8): 497-502.

[3] 李树索, 韩雅芳, 肖程波, 宋尽霞. Ni3Al基合金IC6及MCrAlY包覆涂层的抗腐蚀性能[J]. 中国有色金属学报, 2003, 13(6): 1451-1455.

LI Shu-suo, HAN Ya-fang, XIAO Cheng-bo, SONG Jin-xia. Corrosion resistances of Ni3Al based alloy IC6 and MCrAlY overlay coatings[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(6): 1451-1455.

[4] GIAMEI A F, ANTON D L. Rhenium additions to a Ni-base superalloy: effect on microstructure[J]. Metal Trans A, 1985, 16A: 1997-2005.

[5] HARRIS K, ERICKSON G L, SIKKENGA S L, BRENTNALL W D, AURRECOECHEA J M, KUBARYCH K G. Development of the rhenium containing superalloys CMSX-4 and CMSX186LC for single crystal blade and directionally solidified vane applications in advanced turbine engines[C]// ANTOLOVICH S D, STUSRUD R A, MACKAY R A, ANTON D L, KHAN T, KISSINGER R D, KLARSTRON D L. Superalloys 1992. Pennsylvania: TMS, 1992: 297-306

[6] WALSTON W S, OHARA K S, ROSS E W, POLLOCK T M, MURPHY W H. Rene N6: third generation single crystal superalloy[C]//KISSINGER R D, DEYE D J, ANTON D L, CETEL A D, NATHAL M V, POLLOCK T M, WOODFORD D A. Superalloys 1996. Pennsylvania: TMS, 1996: 27-34.

[7] 郑运荣, 韩雅芳. 燃气涡轮用单晶高温合金的成本因素[J]. 金属学报, 2002, 38(11): 1203-1209.

ZHENG Yun-rong, HANB Ya-fang. Cost considerations of single crystal superalloys for gas turbine[J]. Acta Metallurgical Sinia, 2002, 38(11): 1203-1209.

[8] KEARSEY R M, BEDDOES J C, JAANSALU K M, THOMPSON W T, AU P. The effects of Re, W and Ru on microsegregation behavior in single crystal superalloy systems[C]//GREEN K A, POLLOCK T M, HARADA H, HOWSON T E, REED R C, SCHIRRA J J, WALSTON S. Superalloys 2004. Pennsylvania: TMS, 2004: 801-810.

[9] RAE C M F, KARUNARATNE M S A, SMALL C J. Topolgically close packed phases in an experimental rheium containing single crystal superalloy[C]//POLLOCK T M, KISSINGER R D, BOWMAN R R, GREEN K A, MCLEAN M, OLSON S L, SCHIRRA J J. Superalloys 2000. Pennsylvania: TMS, 2000: 777-784.

[10] DAROLIA R, LAHRMAN D F, FIELD R D, SISSON R. Formation of topologically closed packed phases in nickel base single crystal superalloys[C]//SEICHMAN S, DUH D N, MAURES G, ANTDOVICH S, LUND C. Superalloys 1988. Pennsylvania: AIME, 1988: 255-264.

[11] SATO A, HARADA H, YOKOKAWA T, MURAKUMO T, KOIZUMI Y, KOBAYASHI T, IMAI H. The effects of ruthenium on the phase stability of fourth generation Ni-base single crystal superalloys[J]. Scripta Materialia, 2006, 54(9): 1679-1684.

[12] FUCHS G E. Improvement of creep strength of a third generation, single-crystal Ni-base superalloy by solution heat treatment[J]. Journal of Materials Engineering and Performance, 2002, 11(1): 19-25.

[13] 骆宇时, 李嘉荣, 刘世忠, 孙凤礼, 韩 梅, 曹春晓. Re对单晶高温合金高温高应力持久性能的影响[J]. 中国有色金属学报, 2005, 15(11): 1655-1659.

LUO Yu-shi, LI Jia-rong, LIU Shi-zhong, SUN Feng-li, HAN Mei, CAO Chun-xiao . Effects of Re on stress rupture properties of single crystal superalloys at elevated temperature and high stress[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(11): 1655-1659.

[14] LIU C T, SUN X F, GUAN H R, HU Z Q. Oxidation of the single-crystal Ni-base superalloy DD32 containing rhenium in air at 900 and 1 000 ℃[J]. Surface and Coatings Technology, 2005, 197(1): 39-44.

[15] 曾 强, 马书伟, 郑运荣. Re对Al在Ni中扩散的影响[J]. 中国有色金属学报, 2003, 13(4): 899-902.

ZENG Qiang, MA Shu-wei, ZHENG Yun-rong. Influence of rhenium on diffusion behavior of aluminium in nickel[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(4): 899-902.

[16] VOLEK A, PYCZAK F, SINGER R F, MUGHRABI H. Partitioning of Re between γ and γ′ phase in nickel-base superalloys[J]. Scripta Materialia, 2005, 52(2): 141-145.

[17] 刑占平, 黄朝晖, 谭永宁, 余 乾. 第二代定向凝固镍基高温合金的微观结构研究[J]. 中国有色金属学报, 2004, 14(S3): 20-23.

XING Zhan-ping, HUANG Zhao-hui, TAN Yong-ning, YU Qian. Microstructure of second generation DS superalloy[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(S3): 20-23.

[18] PYCZAK F, DEVRIENT B, NEUNER F C, MUGHRABI H. The influence of different alloying elements on the development of the γ/γ′ microstructure of nickel-base superalloys during high-temperature annealing and deformation[J]. Acta Materialia, 2005, 53(14): 3879-3891

收稿日期:2007-07-27;修订日期:2007-11-04

通讯作者:范映伟,工程师;电话:010-62496667;E-mail: fanywbeijing@yahoo.com.cn.

(编辑 龙怀中)