DOI: 10.11817/j.ysxb.1004.0609.2021-36519

含铅锌难选铁矿石的矿物学及铅锌杂质产出特征

罗立群1,SAYAF Mustafa1, 2,Jean Christophe NIYONZIMA1, 3,郑波涛1,魏晨曦1

(1. 武汉理工大学 资源与环境工程学院,武汉 430070;

2. Department of Mining Engineering, Faculty of Engineering Sciences, Omdurman Islamic University, Omdurman 382, Sudan;

3. Department of Mineralogical and Geological Sciences, Faculty of Sciences, University of Burundi, Bujumbura 1550, Burundi)

摘 要:以新疆某含铁(FeT)47.04%、含Pb 0.39%、含Zn 0.30%的难选铁矿石为试样,采用化学分析、显微镜观察鉴定、EPMA和EDS等手段,考察其化学成分、铁铅锌的物相组成及铅锌杂质矿物的产出特征,探讨影响选矿工艺的矿物学因素与选矿前景。结果表明:含铁矿物中主要组合为赤褐铁矿、高达91.35%,少量磁性铁和硅酸铁;含铅杂质主要为氧化铅和铅铁矾中的铅,分别占49.0%和41.3%(质量分数);而氧化锌中的锌为主要含锌杂质,占比90.6%。试样中可见少量闪锌矿、方铅矿及黄铁矿等杂质矿物,而未发现含铅锌的氧化状态晶质矿物产出。EPMA和EDS分析表明:氧化状态的铅锌杂质呈单独或共同产出形式,且锌的产出更为普遍和广泛;铅含量多为2.89%~3.89%(质量分数)不等,而锌含量多处于0.67%~1.17%(质量分数)之间。预计强常规磁选与浮选工艺均难于取得有效排除铅锌杂质的效果,建议采用高温还原焙烧预处理工艺。

关键词:难选铁矿石;杂质;矿物学;产出特征;电子探针

文章编号:1004-0609(2021)-01-0181-13 中图分类号:TD912;TD925;TD951 文献标志码:A

引文格式:罗立群, SAYAF M, NIYONZIMA J C, 等. 含铅锌难选铁矿石的矿物学及铅锌杂质产出特征[J]. 中国有色金属学报, 2021, 31(1): 181-193. DOI: 10.11817/j.ysxb.1004.0609.2021-36519

LUO Li-qun, SAYAF M, NIYONZIMA J C, et al. Mineralogical characteristics and lead-zinc impurities’ occurrence features of lead-zinc refractory iron ores[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(1): 181-193. DOI: 10.11817/j.ysxb.1004.0609.2021-36519

铅锌是我国重要的有色金属矿产和传统优势资源,也是炼铁原料中常见有害杂质,严重影响高炉寿命与炼铁效益[1-2]。铅锌在高炉中易被还原,导致料层透气性变坏;铅易沉于铁层之下或炉底砖缝[3-4],锌氧化成为ZnO后膨胀,造成炉衬膨胀、破坏[5-7];部分铅锌氧化进入高炉粉尘形成含铅锌尘泥,引发尘泥回用时铅锌恶性循环,易造成铅中毒或引发环境污染问题[8-9]。高炉炼铁中70%以上的铅锌杂质来自炼铁原料,由于炼铁原料精料方针、资源循环技术发展和环保要求,对铁矿中铅锌杂质的要求日益提高,伴随中国新的“环保法”实施而尤为突出[10-11]。

由于地域矿产资源原因,新疆、云南、贵州等西部边远铁矿资源中,虽然矿石中含铁较高,但许多铁矿石含有铅、锌杂质元素,部分矿石中铅锌含量较高,一般为0.2%~1.3%(质量分数)不等,而铁精矿中铅锌含量均要求小于0.1%(质量分数),甚至0.05%(质量分数)以下。通常铁矿石中的铅主要是以铅黄(PbO)、白铅矿(PbCO3)、方铅矿(PbS)和铅矾(PbSO4)等形式存在[7, 12];锌以菱锌矿(ZnCO3)、闪锌矿(ZnS)、锌铁尖晶石(Zn,Mn)Fe2O4、硅锌矿(Zn2SiO4)等形式存在[12-13]。铅锌矿物常以微细粒级与其他矿物共生、穿插,常常浸染于氧化铁矿物的颗粒边缘,或嵌布于石英或碳酸盐矿物中,少量赋存于铁矿物的晶格中[14]。但对铁矿中的铅锌矿物学特性及铅锌矿物的产出特征系统研究较少,本文以新疆某含铅锌的难选铁矿为研究对象,系统研究含铅锌铁矿石的矿物学特性,以及铅锌杂质的赋存状态和产出特征,分析基于矿物学特征的选矿技术,为合理开发该铁矿资源选择适宜的选矿工艺提供技术支持。

1 实验

1.1 试样及基本性质

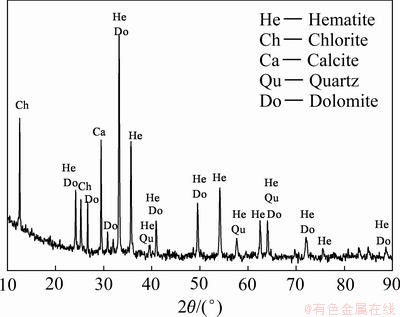

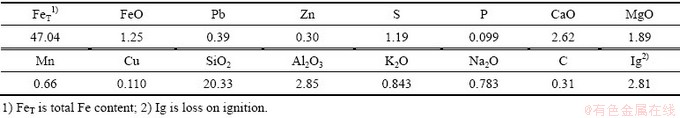

试样取自中国新疆维吾尔自治区某铁矿,试样粒度为粒径小于100 mm,外观为红褐色,采用三段一闭路破碎流程,用颚式破碎机和对辊破碎机将试样破碎至粒径小于2.0 mm,混匀备用。试样化学多元素分析见表1,X射线衍射(XRD)谱见图1。

从表1中可知,试样中FeT品位为47.04%(质量分数),有害杂质Pb、Zn含量为0.39%和0.30%(质量分数),超过炼铁原料要求不大于0.10%(质量分数)的指标,同时,有害杂质硫也较高,为1.19%(质量分数),需要排除或降低;脉石矿物组分SiO2、Al2O3含量分别为20.33%和2.85%(质量分数)。从图1中可以看出,该矿石中主要铁矿物为赤铁矿(Hematite),铅锌杂质矿物因含量较低,并未出现其特征峰;脉石矿物为石英(Quartz)、绿泥石(Chlorite)、方解石(Calcite)和白云石(Dolomite)。

1.2 研究与测试方法

1) 光学显微镜观察 取适量待观察样品,经切割、磨片、抛光后制成光片和薄片在Nikon Lv100pol型偏反光显微镜下进行观察。利用矿物在光学显微镜下的光学性能不同,分析和统计样品中矿物的形态特征和产出形式。

图1 试样XRD谱

Fig. 1 XRD pattern of raw sample

2) X射线衍射分析 通常采用X射线衍射(XRD)来分析样品中的主要物相组成,所用X射线衍射仪为日本理学Rigaku D/max-3c,采用Cu 靶,Kα辐射源,石墨单色滤波器,步进扫描。实验参数为管电压 40 kV,管电流 50 mA,扫描速度3(°)/min,光散狭缝 1°,接收狭缝 0.30 mm,放散射狭缝 1°。

3) 电子探针及EDS能谱分析 分析样品微观结构及微区元素组成,所用电子探针型号为日本电子株式会社厂家生产电子探针显微分析仪+能谱仪,型号为JXA-8230/INCAX-ACT。各种元素具有自己的X射线特征波长,特征波长的大小则取决于能级跃迁过程中释放出的特征能量△E,利用能谱仪确定不同元素X射线光子特征能量不同来进行成分分析,确定微区点的元素组成、含量与矿物种类。

表1 试样多元素分析结果

Table 1 Chemical analysis result of raw sample (mass fraction, %)

2 结果与讨论

2.1 矿区地质及矿石特征

新疆和静地区铁矿位于塔里木板块伊犁微板块之阿吾拉勒-伊什基里克晚古生代裂谷带,处于西天山阿吾拉勒东段,呈火山穹窿构造,矿区地层主要为下石炭统大哈拉军山组和上石炭统伊什基里克组,并且受到环状断裂和辐射状断裂的制约[15-16]。矿区位于阿吾拉勒金、铜、铁、铅、锌成矿区,铁矿产于高铁中性为主的火山岩中,强烈的热液蚀变是铁矿形成和富集的重要标志,受大型古火山机构控制的火山气液交代矿床影响,主要产于呈带状分布的强烈蚀变带中,成矿经历了一个多期、多次、长期和复杂的交代成矿作用过程[17]。矿石构造类型可划分为3 类:浸染状矿石、角砾状矿石-网脉状矿石和块状矿石。矿区的矿石结构类型总体较为简单,以它形-半自形微粒结构和自形-半自形粒状结构为主,交代假象结构,粒状-纤维状变晶结构、碎裂结构次之,本区围岩蚀变具有明显的多样性多梯度特征。

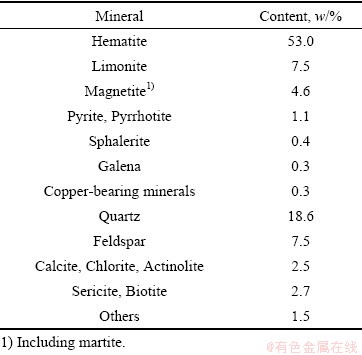

2.2 矿区地质及矿石特征

矿石中主要金属矿物为赤铁矿及褐铁矿、部分磁铁矿与假像磁铁矿,少量黄铁矿、闪锌矿、方铅矿、以及微量磁黄铁矿、黄铜矿、黝铜矿及铜蓝;透明矿物含量约为28%~30%,主要为石英、钠长石及绢云母,少量阳起石、绿泥石、黑云母及方解石,偶见钾长石等,其主要矿物组成及含量如表2所示。

2.3 铁矿物与铅锌矿物的物相性质

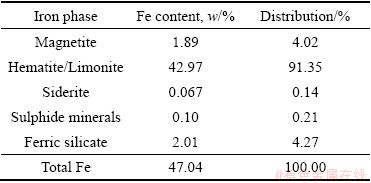

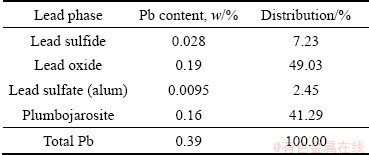

物相是物质中具有特定的物理化学性质的相,矿物的物相状态是影响选矿方法和技术指标的重要因素[14, 18],为此对铁矿物和有害杂质铅锌矿物进行了物相分析如表3~5。

试样中铁主要以赤褐铁矿的形式存在,其铁含量为42.97%,分布率占全铁的91.35%,其次含磁性铁1.89%和硅酸铁2.01%,硫化铁和碳酸铁则较少,赤褐铁矿和磁性铁为选别过程中主要铁回收对象,二者占比达95.37%。含铅杂质主要为氧化铅和铅铁矾中的铅,分别占49.03%和41.29%,二者合计为90.32%;而氧化锌中的锌为主要含锌杂质,占比90.60%;硫化铅锌均较少,只占7.23%和5.71%。因铅锌杂质的存在对炼铁过程有害,为选别过程中的主要脱除对象,预计在脱除铅锌杂质的同时,大部分硫可以同步去除[19-20]。

表2 矿石中主要矿物组成及含量

Table 2 Compositions and contents of main minerals for raw sample

表3 试样中铁物相分析结果

Table 3 Iron mineral phase analysis of raw sample

表4 试样中铅物相分析结果

Table 4 Lead phase analysis results in raw sample

表5 试样中锌物相分析结果

Table 5 Zinc phase analysis results in raw sample

2.4 主要铁矿物的产出及特征

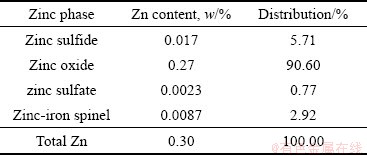

为了查明试样中主要铁矿物的产出特征,将试样经磨片制样后,在光学显微镜下进行观察鉴定,原矿试样的显微镜照片图如图2所示。含铁有用矿物主要为赤铁矿、次为褐铁矿和磁铁矿;赤铁矿(Hem)呈半自形-它形粒状结构,可见其针状晶体形态,如图2(a)和(b)所示。部分颗粒长轴定向分布,呈脉状或条带状,交代磁铁矿(Mt),并被黄铁矿(Py)、黝铜矿、铜蓝及褐铁矿等交代(见图2(a)),呈尖角状或包含结构等,粒径在0.002~0.1 mm之间。褐铁矿(Lm)呈不规则粒状或胶状结构(见图2(a)和(b)),交代磁铁矿、赤铁矿、黄铁矿及磁黄铁矿等强烈(见图2(b)),集合体粒径在0.002~0.5 mm之间。磁铁矿(Mt)呈半自形-它形粒状,可见其八面体自形晶体截面形态(见图2(a)),八面体裂开发育,沿边缘及裂隙被赤铁矿、黄铁矿、黄铜矿、闪锌矿及褐铁矿等交代,多为尖角状、细脉-网脉状或包含结构等,局部被赤铁矿等交代强烈呈交代残余结构(见图2(c)),粒径在0.01~0.2 mm之间。含硫的杂质矿物有少量黄铁矿和微量磁黄铁矿,黄铁矿呈自形-半自形粒状结构,可见立方体及五角十二面体晶体截面形态,被褐铁矿交代,呈尖角状、细脉-网脉状或镶边结构,多数被交代强烈呈残余或假象结构(见图2(d)),部分被交代磁铁矿及赤铁矿等,粒径为0.01~0.4 mm之间。

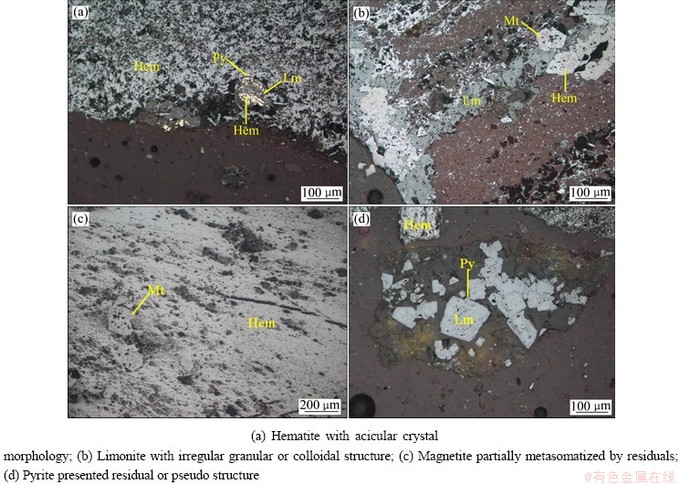

2.5 铅锌杂质矿物的产出特征

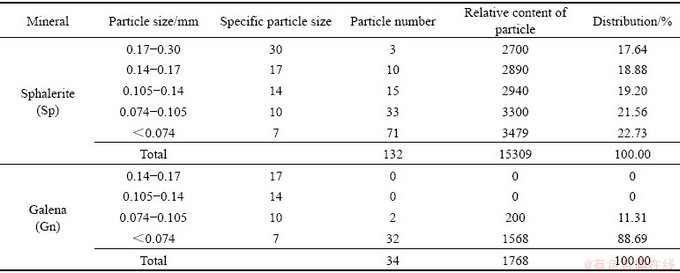

显微镜下可见少量方铅矿(Gn)呈不规则粒状沿岩石裂隙中的透明矿物粒间分布(见图3(a)),呈填隙结构存在;交代褐铁矿、黄铁矿及闪锌矿等(见图3(b)),粒径在0.002~0.05 mm之间。闪锌矿(Sp)呈不规则粒状产出,局部被方铅矿(Gn)及铜蓝(Cov)等尖角状交代(见图3(c)),粒径在0.002~0.2 mm之间;局部可见黄铜矿(Ccp)呈乳浊状分布于闪锌矿(Sp)中(见图3(d)),呈固溶体分解结构,交代磁铁矿及赤铁矿。以点测法在显微镜下测量、计算闪锌矿与方铅矿的嵌布粒度统计结果如表6所示。

图2 原矿试样中主要铁矿物的显微镜照片图(反光)

Fig. 2 Microscopic photos of main iron minerals in raw ore samples (Reflect light)

图3 原矿试样铅锌杂质矿物的显微镜照片图(反光)

Fig. 3 Microscopic photos of lead and zinc impurity minerals in raw ore samples (Reflect light)

表6 铅锌杂质矿物的嵌布粒度测量计算(点测法)

Table 6 Measurement of dissemination particle sizes of lead and zinc impurity minerals

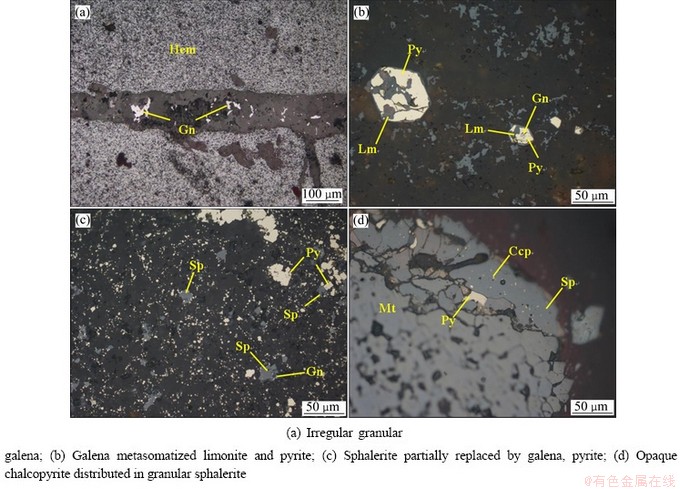

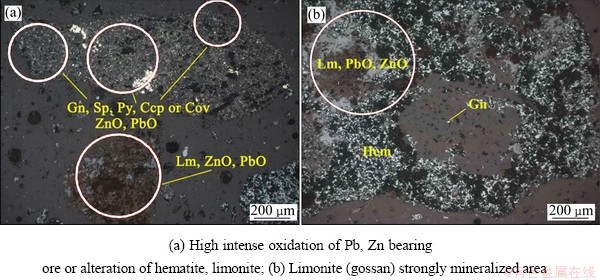

尽管铅、锌的物相分析表明,铅、锌杂质90%以上均为氧化状态的形式存在,但显微镜下并未发现有含铅锌的氧化状态晶质矿物产出,因含铅、锌矿物的后期强烈氧化作用,或与部分氧化矿的强烈矿化作用,可能产生氧化状态的铅锌矿物,部分疑似氧化状态的铅、锌产出区域如图4所示。显微镜下鉴定结果表明,矿石后期氧化作用较强烈(见图4(a)),褐铁矿(铁帽)矿化强烈(见图4(b)),疑似氧化状态的铅、锌可能零星分布于褐铁矿(如铁帽)等氧化带中,呈交代或淋滤残余特征,在显微镜下将对疑似含氧化铅锌区域进行圈定,后续用EMPA与EDS进行扫描和微区成分分析与鉴定。

2.6 铅锌杂质与铁矿物的共生特性

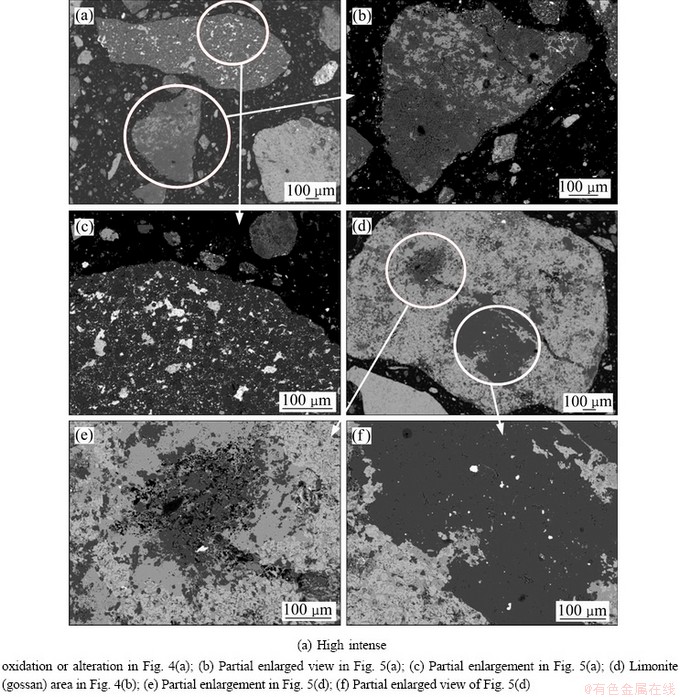

鉴于显微镜下观察未发现氧化状态铅锌的晶质矿物产出,结合铁矿石的成因及与氧化铁矿物的氧化蚀变,对疑似氧化状态区域进行电子探针分析和微区能谱分析,以查明和确定呈氧化状态的铅锌杂质共生产出特征。以显微镜下观察标出的疑似氧化状态的铅、锌产出区域进行电子探针二次电子像及局部放大图如图5所示。

图4 显微镜下疑似氧化状态的铅、锌产出区域

Fig. 4 Oxidized lead and zinc producing regions suspected under microscope

图5 疑似氧化状态的铅、锌区域的二次电子像

Fig. 5 Secondary-electron images on oxidized lead and zinc producing regions suspected under EPMA

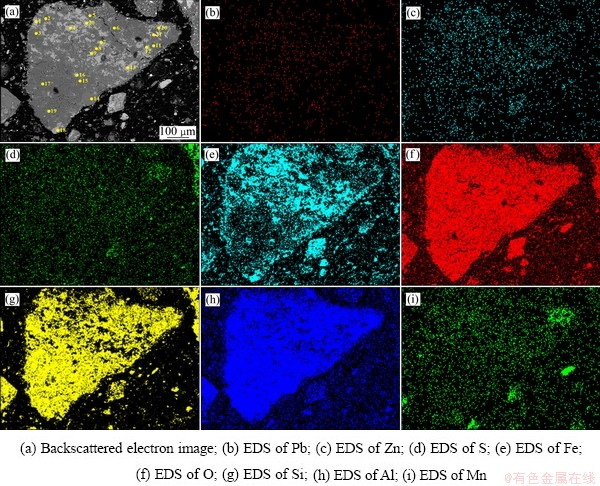

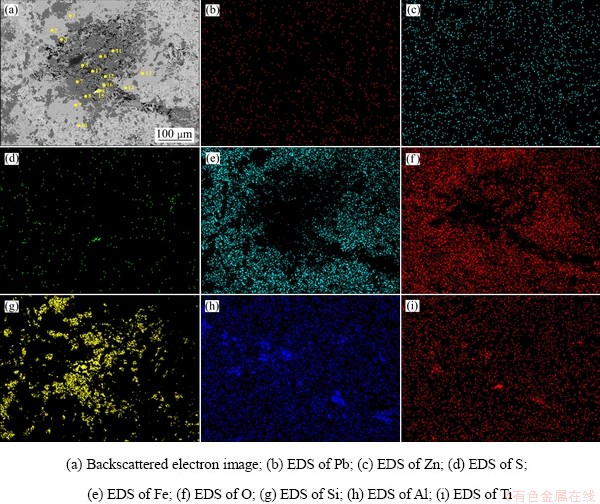

选择试样中疑似铅锌杂质与铁矿物共生的区域,对应电子像中的图5(b)和(e)中的电子探针元素面扫描与相应的微区能谱图如图6和7所示。

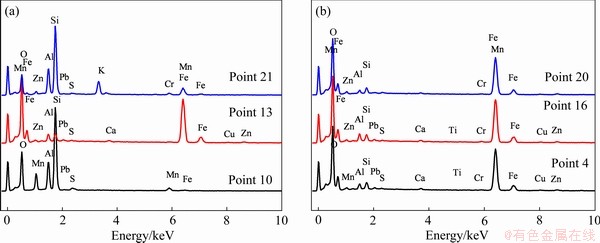

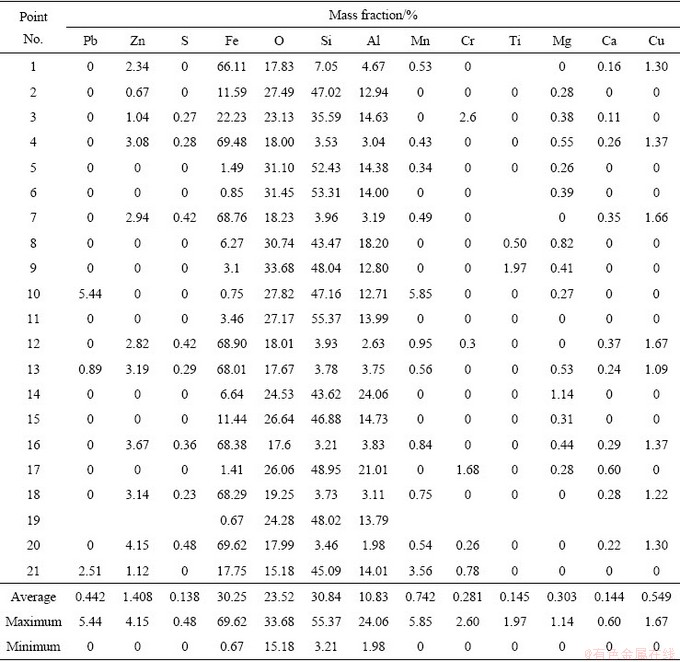

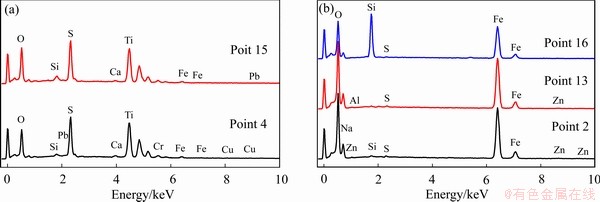

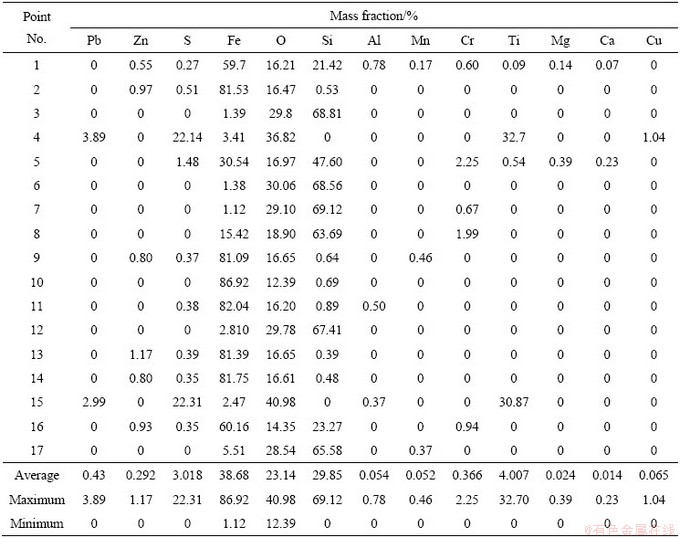

鉴于铅锌杂质或其杂质矿物在铁矿物或其他矿物中的含量不高,图6和7中疑似区域的Pb、Zn元素面扫描并不能清晰确认Pb、Zn杂质元素有无的差异。为进一步确认Pb、Zn杂质元素的共生与产出,采用EMPA-EDS对其进行能谱微区成分分析,以确定疑似区域化学成分的组成特点。图6和7中各微区点的X 射线能谱成分结果见表7和8,含铅锌杂质典型微区的X 射线能谱成分图如图8和9所示。

由图6和7中选定的微区点和表7和8各微区点的X 射线能谱成分结果可知(见图9),显微镜所圈定试样的疑似区域中,存在有铅锌杂质元素,其杂质状态通过硫元素的含量配比计算,因硫元素含量不高,从而可以确定铅锌杂质必然含有氧化物的状态存在。若考虑铅锌的硫酸盐等氧化物状态,则所选微区的铅锌硫化物更少。从表7中褐铁矿(铁帽)强烈矿化区域的铅锌杂质含量可知,所含铅锌杂质的微区中,铅含量为0.89%~5.44%不等,而锌含量处于0.67%~4.15%之间。从表8中赤褐铁矿蚀变作用区域的铅锌杂质含量可知,所含铅锌杂质的微区中,铅含量为2.89%~3.89%不等,而锌含量处于0.55%~1.17%之间。

疑似区域中铅锌杂质元素的产出呈现多种形式:既有氧化状态的铅锌杂质伴生在铁矿物及脉石矿物共同产出,也有含铅或锌杂质单独产出的形式存在,特别是含锌杂质的产出更为普遍和广泛,参阅表7和8中的结果。进一步分析发现,含铅杂质多与脉石矿物的嵌布关系更为密切,有时伴生有少量铜、铬等其它金属元素;而含锌杂质多与含铁矿物的嵌布关系密切,且产出的频度较高、分布更为普遍。同时,含锌杂质均与褐铁矿物共生产出,赤铁矿中未发现含锌杂质的存在。

图6 图5(b)中颗粒元素面扫描及能谱分析微区点

Fig. 6 Micro-area scanning of particle element surface and X-ray energy dispersive spectra analysis in Fig. 5(b)

图7 图5(e)中颗粒元素面扫描及能谱分析微区点

Fig. 7 Micro-area scanning of particle element surface and energy spectrum analysis in Fig. 5(e)

图8 褐铁矿(铁帽)强烈矿化区域中含铅锌典型微区的EDS能谱图(参见图6和表7)

Fig. 8 EDS spectra of typical micro areas in strongly mineralized area of limonite (gossan) (Referring to Fig. 6 and Table 7)

表7 褐铁矿(铁帽)强烈矿化区域的微区能谱成分分析结果

Table 7 Results of energy spectrum analysis of micro regions on strongly mineralized areas of limonite (gossan)

图9 赤褐铁矿蚀变作用区域中含铅锌典型微区的EDS能谱图(参见图7和表8)

Fig. 9 EDS spectra of typical micro areas on alteration areas of hematite or limonite (Referring to Fig. 7 and Table 8)

表8 赤褐铁矿蚀变作用区域的微区能谱成分分析结果

Table 8 Results of energy spectrum analysis of micro regions on alteration areas of hematite or limonite

2.7 基于矿物学特征的选矿技术分析

掌握和分析试样中有用矿物与伴生杂质矿物和脉石矿物的矿物学特征,可为制定和优化有用矿物的回收与杂质矿物的排除提供矿物学依据[2]。

1) 新疆赤褐铁矿试样中虽然含铁(FeT) 47.04%,可以产出产率较大的铁精矿,但因赤褐铁矿为42.97%、磁性铁仅为1.89%,表明选择磁选工艺时,必须采用强磁选工艺,此时则需要着重关注易于泥化的褐铁矿的回收。

2) 由于试样中占有率高达90.3%和90.6%的呈氧化状态的铅、锌杂质矿物,呈现单独与共同产出的多元化特征,且因铅锌矿物后期强烈氧化,或与褐铁矿的强烈矿化作用,磨矿分级时难于获得选矿所需的充分解离,采用选矿分离时,恐将混入精矿产品中而不能有效排除。

3) 铅锌杂质矿物中的方铅矿和闪锌矿,粒度细小、形态变化较大,多呈填隙结构存在或尖角交错状交代,或与嵌连矿物之间多为不平直的锯齿状或港湾状,很难将其单体解离,即使细磨也将呈连生体产出,且因方铅矿和闪锌矿等硫化矿物占有率较低,若采用浮选工艺脱除预计收效甚微。

4) 基于铅锌杂质易于高温还原挥发的特征,可以从高温还原焙烧预处理探讨其可选性[3, 21];或随着化学与生物预处理选矿技术的发展,预计未来也可以从湿法浸出预处理考察排除铅锌杂质的可能性[17, 22]。

3 结论

1) 新疆赤褐铁矿试样中含铁(FeT)47.04%,有害杂质铅、锌含量为0.39%和0.30%,含铁矿物中主要组份为赤褐铁矿,高达91.35%;90.32%含铅杂质以氧化铅和铅铁矾中的铅存在,90.60%含锌杂质以氧化锌中的锌存在,为含铅锌难选赤褐铁矿。

2) 物相分析表明:试样中赤褐铁矿含量为42.97%、磁性铁含量仅为1.89%,另有少量菱铁矿、硫化物中铁和硅酸铁;含铅杂质主要为氧化铅和铅铁矾中的铅,分别占49.03%和41.29%;而氧化锌中的锌为主要含锌杂质,硫化铅锌均较少,只占7.2%和5.7%,表明该赤褐铁矿中的铅锌杂质主要以氧化态的铅锌矿物为主。

3) 显微镜下可见试样中存在少量闪锌矿、方铅矿及黄铁矿等杂质矿物,多为不规则粒状产出,局部被其他矿物呈多种形态交代,粒径多为0.002~0.05 mm之间。显微镜下未发现有含铅锌的氧化状态晶质矿物产出,由于含铅、锌矿物的后期强烈氧化作用,或与部分氧化矿的强烈矿化作用,经过电子探针与能谱微区分析确认,铅锌杂质与铁矿物呈现密切的共生特性,铅锌杂质呈单独或共同产出形式,且锌的产出更为普遍和广泛,铅含量多为2.89%~3.89%不等,而锌含量多处于0.67%~ 1.17%%之间。

4) 结合试样的矿物学特征,预计针对该试样的选矿工艺,由于难于获得铁矿物与铅锌杂质的有效单体解离度,强常规磁选与浮选工艺均难于取得有效排除铅锌杂质矿物的效果;若要获得铅锌杂质较低的铁精矿产品,预计需要进行高温还原焙烧、或者化学及生物预处理工艺排除铅锌杂质后,才能得到合格的铁精矿。

REFERENCES

[1] JIAO K X, ZHANG J L, LIU Z J, et al. Circulation and accumulation of harmful elements in blast furnace and their impact on the fuel consumption[J]. Ironmaking & Steelmaking, 2017, 44(5): 344-350.

[2] FISHER V L, BARRON R A. The recycling and reuse of steelmaking slags—A review[J]. Resources, Conservation and Recycling, 2019, 146: 244-255.

[3] LI Yan-chun, LIU Zhi-lou, LIU Hui, et al. Clean strengthening reduction of lead and zinc from smelting waste slag by iron oxide[J]. Journal of Cleaner Production, 2017, 143: 311-318.

[4] MORADI S, MONHEMIUS A J. Mixed sulphide-oxide lead and zinc ores: Problems and solutions[J]. Minerals Engineering, 2011, 24(10): 1062-1076.

[5] WANG W, WANG J, XU R S, et al. Influence mechanism of zinc on the solution loss reaction of coke used in blast furnace[J]. Fuel Processing Technology, 2017, 159: 118-127.

[6] YIN Hui-chao, ZHANG Jian-liang. Study on the law of zinc absorption and change of metallurgical property of sinter and pellet[J]. Iron and Steel, 2010, 45(2): 15-18.

[7] YANG Xue-feng, CHU Man-sheng, SHEN Feng-man, et al. Mechanism of zinc damaging to blast furnace tuyere refractory[J]. Acta Metallurgica Sinica (English Letters), 2009, 22(6): 454-460.

[8] ZHANG Du-chao, ZHANG Xin-wang, YANG Tian-zu, et al. Selective leaching of zinc from blast furnace dust with mono-ligand and mixed-ligand complex leaching systems[J]. Hydrometallurgy, 2017, 169: 219-228.

[9] VAN H P, VANDECASTEELEA C, SWENNEN R, et al. Zinc and lead removal from blast furnace sludge with a hydrometallurgical process[J]. Environmental Science & Technology, 2000, 34(17): 3802-3808.

[10] RODGERS K J, HURSTHOUSE A, CUTHBERT S. The potential of sequential extraction in the characterisation and management of wastes from steel processing: A prospective review[J]. International Journal of Environmental Research and Public Health, 2015, 12(9): 11724-11755.

[11] LUO Li-qun, NGUYEN A V. A review of principles and applications of magnetic flocculation to separate ultrafine magnetic particles[J]. Separation and Purification Technology, 2017, 172: 85-99.

[12] GUPTA S, FRENCH D, SAKUROVS R, et al. Minerals and iron-making reactions in blast furnaces[J]. Progress in Energy and Combustion Science, 2008, 34(2): 155-197.

[13] ZHU De-qing, LI Si-wei, PAN Jian, et al. Migration and distributions of zinc, lead and arsenic within sinter bed during updraft pre-reductive sintering of iron-bearing wastes[J]. Powder Technology, 2019, 342: 864-872.

[14] ESEZOBOR D E, BALOGUN S A. Zinc accumulation during recycling of iron oxide wastes in the blast furnace[J]. Ironmaking & Steelmaking, 2006, 33(5): 419-425.

[15] 田光昊, 钱建平, 华克强. 新疆和静县查岗诺尔铁矿矿床成因及意义[J]. 云南地质, 2016, 35(1): 18-23.

TIAN Guang-hao, QIAN Jian-ping, HUA Ke-qiang. The genesis and significance of chagang noel Fe deposit in hejing xinjiang[J]. Yunnan Geology, 2016, 35(1): 18-23.

[16] 张宗欣. 新疆和静县伊开哈仁郭铁矿床地质特征及成因浅析[J]. 新疆有色金属, 2015, 38(6): 33-35.

ZHANG Zong-xin. Geological characteristics and genesis of Yikaiherenguo iron deposit in Hejing County, Xinjiang[J]. Xinjiang Nonferrous Metals, 2015, 38(6): 33-35.

[17] 邵青红, 刘铭峰, 刘兴忠, 等. 新疆和静县查岗诺尔铁矿矿床形成的控矿因素[J]. 西部探矿工程, 2010, 22(11): 184-188.

SHAO Qing-hong, LIU Ming-feng, LIU Xing-zhong, et al. Ore controlling factors for the formation of chagangnuoer iron deposit in Hejing County, Xinjiang[J]. West-China Exploration Engineering, 2010, 22(11): 184-188.

[18] LUO Li-qun, ZHANG Han-quan. Process mineralogy and characteristic associations of iron and phosphorus-based minerals on oolitic hematite[J]. Journal of Central South University, 2017, 24(9): 1959-1967.

[19] LIN Xiao-long, PENG Zhi-wei, YAN Jia-xing, et al. Pyrometallurgical recycling of electric arc furnace dust[J]. Journal of Cleaner Production, 2017, 149: 1079-1100.

[20] MA Nai-yang. Recycling of basic oxygen furnace steelmaking dust by in-process separation of zinc from the dust[J]. Journal of Cleaner Production, 2016, 112: 4497-4504.

[21] OMRAN M, FABRITIUS T. Improved removal of zinc from blast furnace sludge by particle size separation and microwave heating[J]. Minerals Engineering, 2018, 127: 265-276.

[22] CHANG Jun, ZHANG Li-bo, YANG Chang-jiang, et al. Kinetics of microwave roasting of zinc slag oxidation dust with concentrated sulfuric acid and water leaching[J]. Chemical Engineering and Processing: Process Intensification, 2015, 97: 75-83.

Mineralogical characteristics and lead-zinc impurities occurrence features of lead-zinc refractory iron ores

LUO Li-qun1, Sayaf Mustafa1, 2, Jean Christophe Niyonzima1, 3, ZHENG Bo-tao1, WEI Cheng-xi1

(1. School of Resources and Environmental Engineering, Wuhan University of Technology, Wuhan 430070, China;

2. Department of Mining Engineering, Faculty of Engineering Sciences, Omdurman Islamic University, Omdurman 382, Sudan;

3. Department of Mineralogical and Geological Sciences, Faculty of Sciences, University of Burundi, Bujumbura 1550, Burundi)

Abstract: A refractory iron ore containing 47.04% iron (total Fe content), 0.39% Pb and 0.30% Zn was used as a sample in Xinjiang Uygur Autonomous Region, China. The chemical analysis, microscopic observation and identification, EPMA with EDS were used to investigate the chemical composition, phase composition of iron, lead and zinc, and the occurrence and output characteristics of lead and zinc impurity minerals. The mineralogical factors and mineral process prospects affecting the beneficiation process were discussed in proper order. The results show that the iron-bearing minerals are mainly hematite, with content up to 91.35%, and a small amount of magnetic iron and iron silicate. The lead-containing impurities are mainly lead oxide and lead in plumbojarosite, accounting for 49.0% and 41.3%, respectively. While zinc in zinc oxide is the main zinc-containing impurity, accounting for 90.6%. A small amount of impurity minerals, such as sphalerite, galena, and pyrite are found in the sample, but no crystalline minerals in the oxidation state containing lead and zinc are found. EPMA and EDS analysis indicates that the lead and zinc impurities in the oxidized state are in the form of separate or common output, and the output of zinc is more general and extensive. The lead content ranges from 2.89% to 3.89%, while the zinc content is in the range of 0.67% to 1.17%. It is expected that strong conventional magnetic separation and flotation processes are difficult to achieve the effect of effectively eliminating lead and zinc impurities, and high temperature reduction roasting is recommended as a pre-treatment process before separation.

Key words: refractory iron ore; impurities; mineralogy; occurrence characteristics; electron probe micro analysis

Foundation item: Project(51874219) supported by the National Natural Science Foundation of China

Received date: 2020-02-19; Accepted date: 2020-06-22

Corresponding author: LUO Li-qun; Tel: +86-15827624975; E-mail: lqluollq@hotmail.com

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51874219)

收稿日期:2002-02-19;修订日期:2020-06-22

通信作者:罗立群,高级工程师,博士;电话:15827624975;E-mail:lqluollq@hotmail.com