DOI: 10.11817/j.ysxb.1004.0609.2021-36451

复杂高硅白合金硫酸氧化浸出工艺及提铜的动力学研究

吴选高,龚 傲,喻小强,龙海军,徐志峰,田 磊

(江西理工大学 绿色冶金与过程强化研究所,赣州 341000)

摘 要:研究了高硅白合金硫酸氧化体系下铜的浸出工艺与动力学。首先采用可控制变量法,通过单因素实验,系统研究了添加剂、硫酸浓度、反应温度、反应时间和液固比对铜钴浸出率的影响,其次通过X射线衍射(XRD)、电感耦合等离子体(ICP)和扫描电镜-能谱(SEM-EDS)对高硅白合金和浸出渣的物相及化学成分进行了分析对比。结果表明:在次氯酸钠用量5 mL、浸出温度343 K、反应时间5 h、硫酸浓度200 g/L、液固比7:1的工艺条件下,铜的浸出率可达99.42%,钴的浸出率可达到97.57%。最后,通过对高硅白合金硫酸氧化浸出提取铜的动力学模型的分析可知,活化能、硫酸浓度和粒度的反应级数分别为34.64 kJ/mol、2.34和0.18,表明其应遵循化学反应控制的收缩核模型,并建立了相应的动力学方程。

关键词: 高硅白合金;硫酸氧化;浸出动力学;混合控制;收缩核模型

文章编号:1004-0609(2021)-05-1358-11 中图分类号:TF813 文献标志码:A

引文格式:吴选高, 龚 傲, 喻小强, 等. 复杂高硅白合金硫酸氧化浸出工艺及提铜的动力学研究[J]. 中国有色金属学报, 2021, 31(5): 1358-1368. DOI: 10.11817/j.ysxb.1004.0609.2021-36451

WU Xuan-gao, GONG Ao, CHEN Li-jie, et al. Study on process and kinetics of extracting copper from complex high silicon white alloy by sulfuric acid oxidation leaching[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(5): 1358-1368. DOI: 10.11817/j.ysxb.1004.0609.2021-36451

随着科学技术的发展,中国对铜、钴的需求量越来越大,因此,对铜、钴资源的需求也就越来越迫切[1-2]。非洲刚果(金)境内有着世界上最大的铜、钴资源富集区[3]。其中,加丹加铜矿带的铜储量达5500万t,钴储量360万t,大量的品位高达2%~9%的氧化钴矿石就裸露在地表或浅埋于地表中,非常适合开采,目前有多家公司在当地采用电炉还原熔炼方法处理氧化铜钴精矿生产白合金。白合金是国内各大钴业公司向外采购的主要原料之一[4]。

白合金是产生于冶炼过程中的一种中间产品,是一种重要的二次资源,主要元素有钴、铜、铁、硅,其中含铁量较高,还含有少量的铅、锌、钙、镁[5]。白合金一般分为两种:一种是钴精矿和氧化钴矿熔炼时产生的富铜产物,主要是用焦炭在电炉内发生还原反应所得;另一种是镍冶炼过程中产生的副产物,是转炉吹炼时产生的转炉渣经电炉造锍和还原熔炼富集后得到的含铜、钴、铁等元素的合金渣[6-9]。白合金是经过水淬后的产物,金属元素分布复杂,且二氧化硅含量高,导致各金属相之间相互包裹以及二氧化硅和金属相之间包裹的现象较为普遍,尤其是铁硅酸盐相,这使得白合金耐腐蚀、难溶解,铜、钴等有价元素难以浸出[10-17]。针对白合金复杂的包裹结构,铜、钴等有价元素难以浸出的难题,国内外进行了大量的研究,国外多采用硫酸加压浸出工艺,而国内多采用常压预浸和加压浸出工艺,铜浸出率能分别达91%和94%以上。这些方法虽然可达到预期效果,但由于生产时需要加压,对生产设备的要求高,导致运行成本高,因此,需要我们找到更加简单有效,不需要加压的新工艺。

许多研究人员研究了硫酸体系下不同添加剂对白合金浸出效果的影响,LIU等[18]研究了在硫酸体系下添加氢氟酸作为氧化剂,控制电位从白合金中选择性浸出铜钴的方法,结果表明,在H2SO4浓度为3.8 mol/L,氧化剂用量为50 mL/50 g合金,HF浓度为0.04 mol/L,温度为80 ℃,时间为3 h条件下,铁,钴和铜的浸出率可分别达到95%,95%和13.5%,钴和铜在浸出的过程中得到了有效的分离。FENG等[19]研究了Cl-对含高硅白合金在硫酸溶液中电化学溶解的影响,结果表明,添加Cl-可以有效提高钴的电化学溶解,添加NH4Cl明显使钴铁合金相的溶解速率提高了4~6倍,最终钴溶解率可达99%以上。LI等[20]采用铁氧酸硫杆菌破坏白合金中钴铁合金相,从而达到提高白合金中铜钴浸出率的目的,结果表明,经过2~5 d,细菌数量增加到108 cell/mL时,钴的提取率为99.5%,铜的提取率为99%。徐志峰等[21]针对高硅白合金结构复杂、难以直接硫酸浸出问题,采用碱焙烧脱硅预处理的方法以破坏稳定致密的硅铁合金结构,从而达到有效浸出铜钴的目的,结果表明,在温度600 ℃,NaOH用量为硅、铁反应所需理论量 0.64 倍,焙烧时间为2 h的碱焙烧条件下,所得渣经水洗,硅的脱除率达到66.57%;再经常压硫酸浸出,钴、铁浸出率均高达 99%以上,而铜则完全保留在浸出渣中,实现了钴和铜分离。

白合金中的铜钴浸出属于电化学溶解,对于氧化还原浸出反应最主要阻碍是阳极的钝化,而对于高硅白合金的浸出而言,破坏铁硅合金相与有价金属之间的包裹是关键步骤。本文利用次氯酸根的氧化性和氯离子的高电导性,采用硫酸氧化浸出的方法来处理高硅白合金,并考察了高硅白合金硫酸浸出动力学的研究,找到了限制高硅白合金硫酸浸出速率的控制步骤,最终建立了相应的宏观动力学方程进行表征,研究结果有助于实现合金在常压条件硫酸介质中顺利浸出,并为实现高硅白合金中铜、钴比较理想的浸出提供基础数据。

1 实验

1.1 实验原料

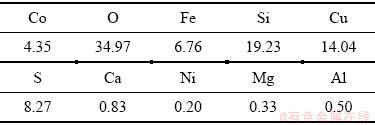

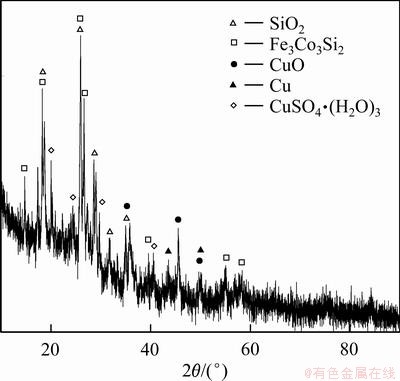

本研究所使用的原料,是由赣州某钴冶炼企业提供,为确定物料的物相及化学成分组成,采用XRD、ICP对白合金原料分析,其中高硅白合金化学成分如表1所示。

表1 高硅白合金主要化学成分分析

Table 1 Analysis of main chemical components of white cobalt alloy samples (mass fraction, %)

由表1可知,高硅白合金中主要元素为钴、铁、硅、铜、硫和氧,其中铜含量达14.04%,接着进一步对高硅白合金进行了XRD分析,如图1所示。

由图1可知,高硅白合金的主要物相为SiO2、Fe3Co3Si2、Cu、CuO和CuSO4·(H2O)3。

图1 高硅白合金的XRD谱

Fig. 1 XRD pattern of high silicon white alloy

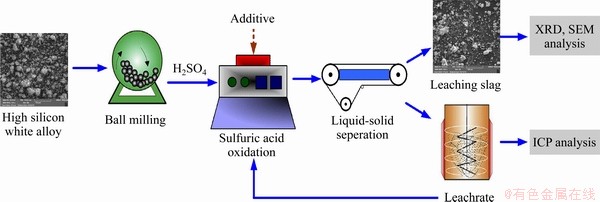

1.2 实验步骤

单因素实验:首先,将高硅白合金进行球磨筛分,得到不同粒度级数的高硅白合金颗粒,然后将一定浓度的硫酸溶液和适量的高硅白合金混合加入到水浴锅中加入至设定温度,接着加入适量的添加剂,当达到反应时间时,停止加热并进行料液的液固分离,最后得到的浸出渣和浸出液送物相和元素成分分析。

动力学实验:将500 mL硫酸溶液,10.0 g高硅白合金和适量的添加剂加入到水浴锅中并加热至设定温度。然后,以适当的时间间隔取出5 mL浸出溶液,并使用电感耦合等离子体(ICP)发射光谱仪(Leeman,USA)分析元素离子的浓度,最终进行拟合,得到相关的动力学参数和方程。 实验流程图如图2所示。

有价值元素的浸出率计算如下:

(1)

(1)

式中:c1是通过ICP检测到的滤液中有价值元素的浓度,g/L;V1是滤液的体积,L;m0是实验中使用的样品的质量,g;x0是样品中有价元素的含量(质量分数,%)。

2 结果与讨论

2.1 高硅白合金硫酸浸出实验

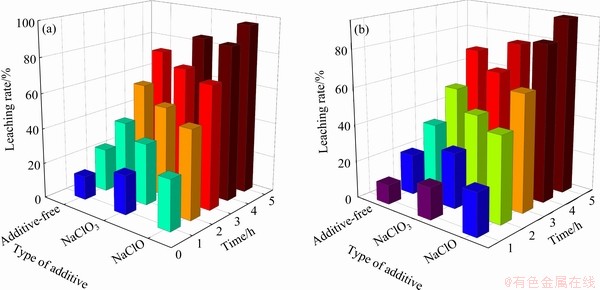

2.1.1. 不同氧化剂对铜钴浸出率的影响

以高硅白合金为原料,在温度为343 K,硫酸浓度为200 g/L,液固比为7:1,搅拌速率为400 r/min,粒度范围为45~75 μm,反应5 h的条件下,考察了无添加剂、添加0.4 g的氯酸钠和5 mL的次氯酸钠(Cl-的摩尔数相等)对铜钴浸出率的影响,结果如图3所示。

图2 高硅白合金硫酸氧化浸出的流程图

Fig. 2 Flow chart of sulfuric acid oxidation leaching of high silicon white alloy

图3 不同氧化剂对铜和钴浸出率的影响

Fig. 3 Effect of different oxidants on leaching rate of copper(a) and cobalt(b)

在硫酸浸出高硅白合金过程中,随着浸出的不断进行,无添加剂一组的铜钴的浸出率明显要低于有添加剂的两组,而在其他条件相同的情况下,相对于添加氯化钠,加入次氯酸钠后铜钴的浸出率得到明显地提高,这是由于其强氧化性使得铁硅包裹相被打开,且次氯酸钠经过硫酸加热后分解,氯离子提高了溶液的电导率,增强了高硅白合金的电化学腐蚀,使得铜钴浸出率大幅度提高。因此,从氧化效果及浸出率综合考虑拟选择用次氯酸钠作为酸浸体系的氧化剂。

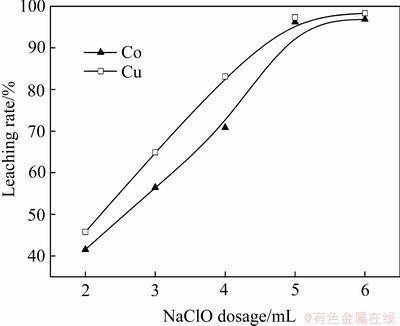

2.1.2 次氯酸钠的用量对铜钴浸出率的影响

在温度为343 K,硫酸浓度为200 g/L,液固比为7:1,搅拌速率为400 r/min,粒度范围为45~75 μm,反应5 h的条件下,考察了次氯酸钠添加量对铜钴浸出率的影响,结果如图4所示。

图4 次氯酸钠的用量对铜钴浸出率的影响

Fig. 4 Effect of amount of sodium hypochlorite on leaching rate of copper and cobalt

由图4可知,钴白合金中铜钴的浸出率随着次氯酸钠用量的增加而增加,当添加次氯酸钠5 mL时,铜钴的浸出率分别达到99.42%和97.57%;继续增加次氯酸钠的用量,可以看出对铜钴的浸出率影响不大,反应还是趋于平衡,所以次氯酸钠的最佳用量为5 mL左右。

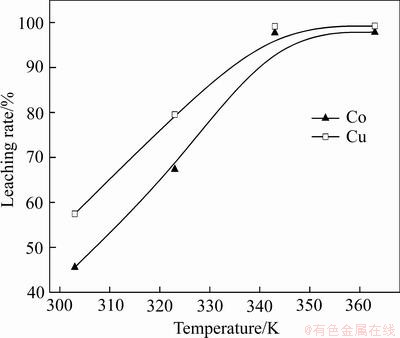

2.1.3 温度对铜钴浸出率的影响

在添加次氯酸钠5 mL,硫酸浓度为200 g/L,液固比为7:1,搅拌速率为400 r/min,粒度范围为45~75 μm,反应5 h的条件下,考察了温度对铜钴浸出率的影响,结果如图5所示。

图5 温度对铜钴浸出率的影响

Fig. 5 Effect of temperature on copper and cobalt leaching rates

由图5可知,反应温度在小于343 K时,铜和钴的浸出率并不是很高,当温度升高343 K左右时,铜和钴的浸出率达到99.42%和97.57%,进一步升高温度,反应趋向平衡。因此,反应温度控制在343 K较宜。

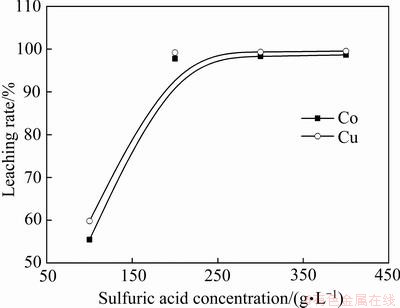

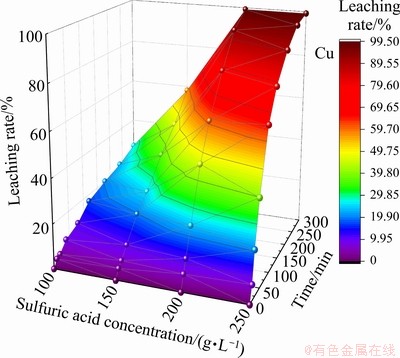

2.1.4 硫酸浓度对铜钴浸出率的影响

在温度为343 K,添加次氯酸钠5 mL,液固比为7:1,搅拌速率为400 r/min,粒度范围为45~75 μm,反应5 h的条件下,考察了硫酸浓度对铜钴浸出率的影响,结果如图6所示。

由图6可知,在硫酸浓度小于200 g/L时,铜钴金属的浸出率随着硫酸浓度的增大而增大,当硫酸浓度达到200 g/L时,钴的浸出率达到了97.57%,同时,铜的浸出率也达到了99.42%,当继续增大硫酸浓度后,铜和钴的浸出率并不会增大,这是由于当硫酸浓度达到200 g/L后,高硅白合金中铜和钴的浸出反应已经非常充分,当继续增加硫酸的用量时,并不会对浸出有明显的影响,对于铜和钴的浸出也相对不大。因此,硫酸浓度控制在200 g/L较宜。

图6 硫酸浓度对铜钴浸出率的影响

Fig. 6 Effect of sulfuric acid concentration on copper and cobalt leaching rates

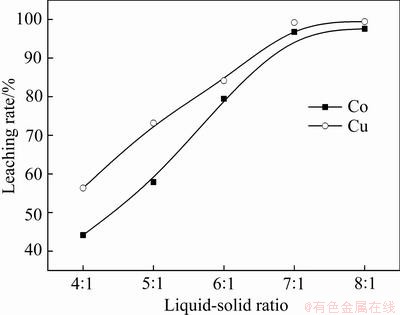

2.1.5 液固比对铜钴浸出率的影响

在温度为343 K,硫酸浓度为200 g/L,添加次氯酸钠5 mL,搅拌速率为400 r/min,粒度范围为45~75 μm,反应5 h的条件下,考察了液固比对铜钴浸出率的影响,结果如图7所示。

由图7可知,铜钴浸出率均随液固比的增大而增大。当液固比为7:1时,反应达到平衡,铜钴浸出率分别为99.42%和97.57%。继续增大液固比,铜钴浸出率变化不大,故液固比取7:1为宜。

图7 液固比对铜钴浸出率的影响

Fig. 7 Effect of liquid-solid ratio on copper and cobalt leaching rates

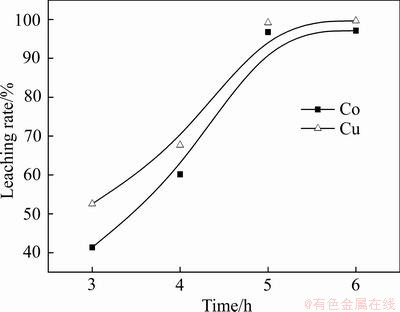

2.1.6 时间对铜钴浸出率的影响

在温度为343 K,硫酸浓度为200 g/L,添加次氯酸钠5 mL,液固比为7:1,搅拌速率为400 r/min,粒度范围为45~75 μm的条件下,考察了时间对铜钴浸出率的影响,结果如图8所示。

由图8可知,随着实验时间从3 h延长至5 h,铜钴浸出率慢慢增大,反应5 h后达到相对平衡,所以反应时间在5 h最宜。

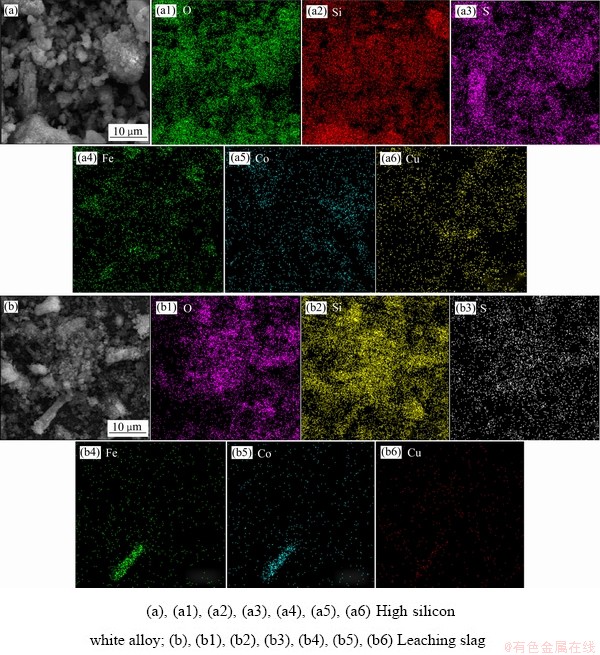

2.2 氧化酸浸过程中高硅白合金浸出渣的性质变化特征

图9所示为高硅白合金和浸出渣的SEM-EDS图谱,由图9(a)所示,高硅白合金颗粒相对比较均一,有少量的絮状物存在,EDS显示高硅白合金各元素分布比较均匀,硅与氧分布区域较为重合,说明高硅白合金中Si主要是以SiO2形式存在,硫和氧的分布比较也较为集中,说明其中含有大量的硫酸盐存在。由图9(b)可知,浸出渣颗粒大部分呈絮状物存在,这说明经过硫酸氧化浸出原有的颗粒已经被破坏,EDS显示其中主要元素为氧和硅,而铁、铜和钴的含量很低,仍有少量铁钴合金相存在。

图8 时间对铜钴浸出率的影响

Fig. 8 Effect of time on copper and cobalt leaching rates

2.3 高硅白合金硫酸氧化浸出动力学方程

关于不同物料的液固反应模型,其反应速度往往与液固的接触面积、物料在液中的扩散速度、反应中生成物的扩散速度等紧密相关。物料的液固反应最为典型的一种模型是收缩核模型(Shrinking core model,SCM)。在高硅白合金酸浸过程中,其实质是在两相之间的界面处发生的固-液发生反应。在浸出铜钴过程中,其高硅白合金中的铁相可能会包裹在钴铜颗粒周围。所以在经过加入氧化剂后,破坏了钴白合金渣中的铁相,使得液中铜钴进一步浸出。

图9 高硅白合金和浸出渣的SEM-EDS图谱

Fig. 9 SEM-EDS pattern of high silicon white alloy and leaching residue

白合金酸浸过程符合收缩核模型,其浸出反应的总动力学方程见于式(2):

(2)

(2)

式中:δ为边界层厚度,m;D1为边界层中的传质系数,m/s; 为铜的浸出率,%;r0为钴白合金渣颗粒的平均半径,m;Ds为固体产物层的传质系数,m/s;kr为界面反应速率常数;cA0为初始反应物浓度,kg/m3;ρ为钴白合金原料的密度,kg/m3;t为反应时间,min。

为铜的浸出率,%;r0为钴白合金渣颗粒的平均半径,m;Ds为固体产物层的传质系数,m/s;kr为界面反应速率常数;cA0为初始反应物浓度,kg/m3;ρ为钴白合金原料的密度,kg/m3;t为反应时间,min。

当 >>

>>  和

和 >>

>>  时,总浸出过程受边界层扩散的控制,方程简化为式(3)所示:

时,总浸出过程受边界层扩散的控制,方程简化为式(3)所示:

(3)

(3)

当 >>

>> 和

和 >>

>> 时,总浸出过程由固体产物层扩散控制,方程简化为式(4)所示:

时,总浸出过程由固体产物层扩散控制,方程简化为式(4)所示:

(4)

(4)

当 >>

>> 和

和 >>

>> 时,总浸出过程由界面化学反应控制,方程简化为式(5):

时,总浸出过程由界面化学反应控制,方程简化为式(5):

(5)

(5)

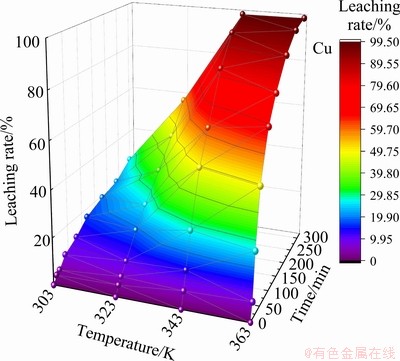

2.3.1 温度影响及活化能的求解

以高硅白合金为原料,在硫酸浓度200 g/L、次氯酸钠5 mL、液固比50:1、搅拌速率400 r/min、粒度范围53~75 μm的条件下,探究了在不同温度下(T=303, 323, 343, 363 K),浸出300 min内铜的浸出率,如图10所示。

图10 反应温度对铜的浸出率的影响

Fig. 10 Effect of reaction temperature on leaching rate of Cu

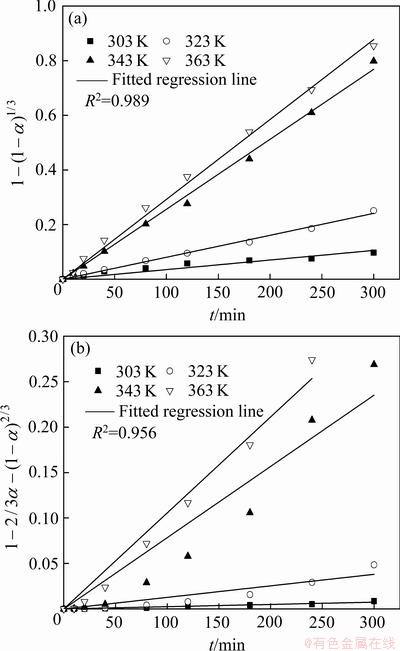

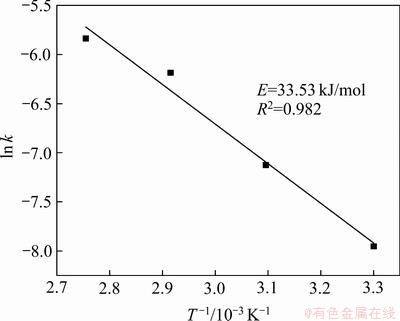

为了确定动力学方程,将不同温度下铜的浸出率代入式(4)和(5)中,其拟合的相关系数结果见图11。

拟合直线结果表明,在303~363 K温度范围内, 与t的拟合动力学直线呈现良好的线性关系。故进一步由图11(a)所示的铜浸出表观速率常数(k)来求得对应不同浸出温度时的自然对数

与t的拟合动力学直线呈现良好的线性关系。故进一步由图11(a)所示的铜浸出表观速率常数(k)来求得对应不同浸出温度时的自然对数 ,以

,以 对1/T作图,结果如图12所示。

对1/T作图,结果如图12所示。

由图12可知,钴白合金酸浸过程中,铜的浸出系数 与1/T之间呈良好的线性关系,相关系数R2≥0.98。根据阿伦尼乌斯公式(见式(6))计算可知,铜浸出的活化能E为33.53 kJ/mol,所得表观活化能大于30 kJ/mol。由此可见,高硅白合金浸出过程处于化学反应控制阶段。

与1/T之间呈良好的线性关系,相关系数R2≥0.98。根据阿伦尼乌斯公式(见式(6))计算可知,铜浸出的活化能E为33.53 kJ/mol,所得表观活化能大于30 kJ/mol。由此可见,高硅白合金浸出过程处于化学反应控制阶段。

(6)

(6)

式中:kT为化学反应速率常数;A0为指前因子;E为活化能,kJ/mol;T为反应温度,K;R为理想气体常数,8.314 J/(mol·K)。

图11 不同温度下铜浸出短流程方程 和

和 与t的拟合直线

与t的拟合直线

Fig. 11 Plot of  (a) and

(a) and  (b) versus t for Cu leaching rate at different temperatures (data from Fig. 10)

(b) versus t for Cu leaching rate at different temperatures (data from Fig. 10)

图12 高硅白合金酸浸过程中铜浸出率的阿仑尼乌斯拟合直线

Fig. 12 Arrhenius fitting straight line of Cu leaching rate during acid leaching of high silicon white alloy

不同反应温度条件下高硅白合金浸出过程中铜浸出速率(kCu)的动力学方程为:

(7)

(7)

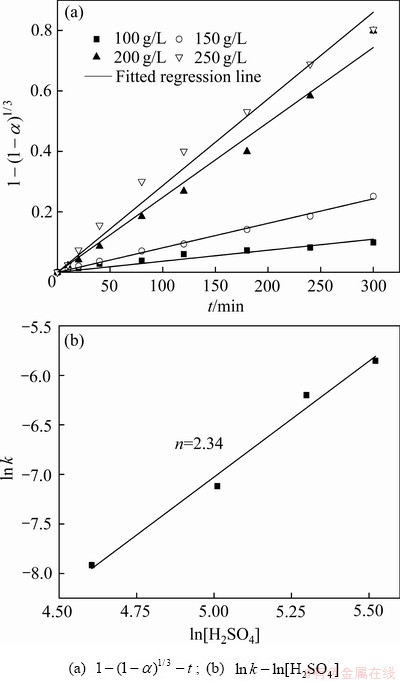

2.3.2 硫酸浓度影响及硫酸反应级数的求解

以高硅白合金为原料,在温度为343 K,添加次氯酸钠5 mL,液固比为50:1,搅拌速率为400 r/min,粒度范围为53~75 μm的条件下,探究了在不同硫酸浓度下(c=100, 150, 200, 250 g/L),浸出300 min内铜的浸出率,如图13所示。

图13 硫酸浓度对铜浸出率的影响

Fig. 13 Effect of sulfuric acid concentration on Cu leaching ratio

为了确定硫酸浓度反应级数,将不同硫酸浓度下的铜浸出率代入式(5)中,其拟合的相关系数结果见图14。

由图14(b)可得到不同酸度条件下高硅白合金浸出过程中铜的浸出速率方程为:

(8)

(8)

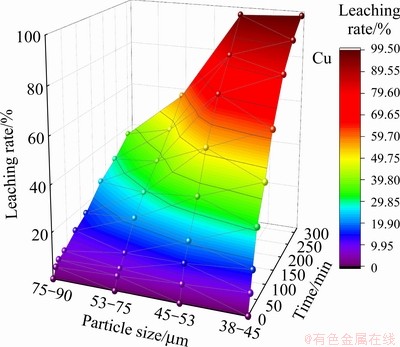

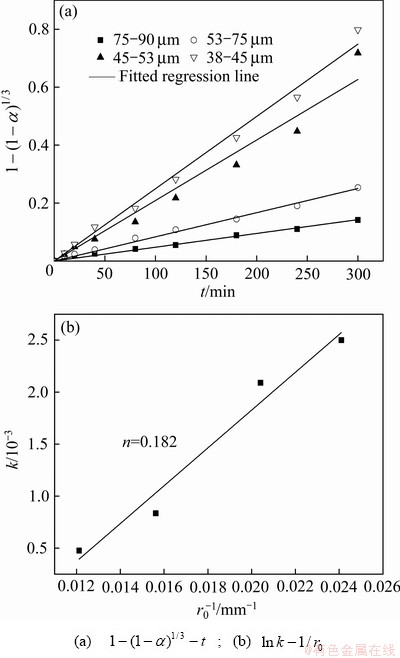

2.3.3 粒度影响及粒度的反应级数求解

以高硅白合金为原料,在温度为343 K,硫酸浓度为200 g/L,添加次氯酸钠5 mL,液固比为50:1,搅拌速率为400 r/min的条件下,探究了在不同粒度下(r0=38~45, 45~53, 53~75, 75~90 μm),浸出300 min内铜浸出率,如图15所示。

为了确定粒度反应级数,将不同粒度下的铜浸出率代入式(5)中,其拟合的相关系数结果见图16。

图14 不同硫酸浓度下铜浸出率的拟合关系

Fig. 14 Fitting relationship of Cu leaching rate under different sulfuric acid concentrations

图15 粒度范围对铜的浸出率的影响

Fig. 15 Effect of particle size ranges on leaching rate of Cu

图16 不同粒度范围下铜浸出率的拟合关系

Fig. 16 Fitting relationship of Cu leaching rate under different particle size ranges

由图16(b)可得到不同粒度范围下高硅白合金浸出过程中铜浸出速率的方程为:

(9)

(9)

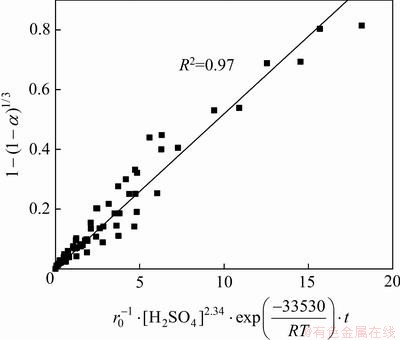

2.3.4 动力学方程的建立

综合上述不同条件下的高硅白合金硫酸氧化浸出数据,可以发现,随着温度和酸度的增大、粒度的减小,相应的铜浸出速率及浸出率均有较大的提高。最终,通过高硅白合金硫酸氧化浸出动力学模型的分析,该体系下的动力学方程可以表达为:

(10)

(10)

然后作出 与

与

的拟合关系,结果见图17。虽然在图中的点有些分散,但是拟合直线的相关系数已超过0.97。因此,从图17中可以得出,K0为5.19×10-2。

的拟合关系,结果见图17。虽然在图中的点有些分散,但是拟合直线的相关系数已超过0.97。因此,从图17中可以得出,K0为5.19×10-2。

图17  和

和 之间的关系

之间的关系

Fig. 17 Relationships between  and

and

最终,可得到高硅白合金硫酸氧化浸出铜的动力学方程为:

(11)

(11)

3 结论

1) 在硫酸浸出高硅白合金过程中,随着浸出的不断进行,无添加剂一组的铜钴的浸出率明显要低于有添加剂的两组;而在其他条件相同的情况下,相对于添加氯化钠,加入次氯酸钠后铜钴的浸出率得到明显地提高,这是由于其强氧化性使得铁硅包裹相被打开,且次氯酸钠经过硫酸加热后分解,氯离子提高了溶液的电导率,增强了高硅白合金的电化学腐蚀,使得铜钴浸出率大幅度提高。

2) 在温度343 K、硫酸浓度200 g/L、添加次氯酸钠5 mL、液固比7:1、搅拌速率400 r/min、粒度范围45~75 μm、浸出5 h的条件下,铜浸出率和钴浸出率分别达到99.42%和97.57%。

3) 随着温度和酸度的增大、粒度的减小,相应的铜浸出速率及浸出率均有较大的提高。最终,通过高硅白合金硫酸氧化浸出动力学模型的分析,活化能、硫酸浓度和粒度的反应级数分别为33.53 kJ/mol、2.34和0.18,表明高硅白合金浸出过程中铜浸出处于化学反应控制阶段,给出了其在本研究条件下的氧化浸出动力学模型方程为:

REFERENCES

[1] AYMAN E, GRAEDEL T E, CIACCI L, et al. Copper demand, supply, and associated energy use to 2050[J]. Global Environmental Change-Human and Policy Dimensions, 2016, 39: 305-315.

[2] GULLEY A L, MCCULOUGH E A, SHEDD K B. China's domestic and foreign influence in the global cobalt supply chain[J]. Resources Policy, 2019, 62: 317-323.

[3] 万方良, 陈爱清, 徐质彬. 刚果(金)加丹加省5208铜钴矿区地质特征及找矿潜力分析[J]. 世界有色金属, 2017(17): 121-124.

WAN Fang-liang, CHEN Ai-qing, XU Zhi-bin. Geological features and prospecting potential of the 5208 copper and cobalt deposit in Katanga province in Congo(DRC)[J]. World Nonferrous Metals, 2017(17): 121-124.

[4] HAYES S M, MCCULOUGH E A, Critical minerals: A review of elemental trends in comprehensive criticality studies[J]. Resources Policy, 2018, 59: 192-199.

[5] 刘卓君, 刘 欣, 李林艳, 等. 钴白合金的常压浸出工艺研究[J]. 有色金属科学与工程, 2015, 6(1): 24-28.

LIU Zhuo-jun, LIU Xin, LI Lin-yan, et al. Atmospheric leaching of Co white alloy[J]. Nonferrous Metals Science and Engineering, 2015, 6(1): 24-28.

[6] 白永生. 白合金的工艺性能研究[J]. 中国矿山工程, 2007, 36(4): 41-45.

BAI Yong-sheng, Research on process property of Cu-Co alloy[J]. China Mine Engineering, 2007, 36(4): 41-45.

[7] 熊以俊, 刘东辉. 机械活化强化钴白合金酸浸钴试验研究[J]. 湿法冶金, 2015, 34(4): 292-295.

XIONG Yi-jun, LIU Dong-hui. Research on leaching of cobalt from white cobalt alloy by mechanical activation[J]. Hydrometallurgy of China, 2015, 34(4): 292-295.

[8] FREITAS M B J G, CELANTE V G, PIETRE M K. Electrochemical recovery of cobalt and copper from spent Li-ion batteries as multilayer deposits[J]. Journal of Power Sources, 2010, 195: 3309-3315.

[9] 杨 坤, 张春生. 加压浸出脱除钴白合金中金属铜和钴的研究[J]. 有色金属设计, 2014, 41(2): 37-41.

YANG Kun, ZHANG Chun-sheng. Research on copper and cobalt removal from cobalt white alloy by using pressure leaching[J]. Nonferrous Metals Design, 2014, 41(2): 37-41.

[10] 焦翠燕, 郭学益. 钴白合金处理工艺进展及研究方向[J]. 金属材料与冶金工程, 2011, 39(2): 58-62.

JIAO Cui-yan, GUO Xue-yi. Progress and research direction of treatment technique for cobalt white alloy[J]. Metal Materials and Metallurgy Engineering, 2011, 39(2): 58-62.

[11] 陈 亮, 代 云. 两矿法浸出钴白合金工艺及机制研究[J]. 湿法冶金, 2017, 36(1): 24-27.

CHEN Liang, DAI Yun. Leaching process and mechanism of Co-white alloy by two-ores method[J]. Hydrometallurgy of China, 2017, 36(1): 24-27.

[12] NAN J, HAN D, ZUO X. Recovery of metal values from spent lithium-ion batteries with chemical deposition and solvent extraction[J]. Journal of Power Sources, 2005, 152: 278-284.

[13] LANDOLT D. Corrosion and surface chemistry of metals[M]. Lausanne, Switzerland: EPFL Press, 2007.

[14] AHMED L M, NAYL A A, DAOUD J A. Leaching and recovery of zinc and copper from brass slag by sulfuric acid[J]. Journal of Saudi Chemical Society, 2016, 20: s280-s285.

[15] KHAWAM A, FLANAGAN D R. Solid-State kinetic models: Basics and mathematical fundamentals[J]. Journal of Physical Chemistry B, 2006, 110: 17315-17328.

[16] 张志华, 王 东, 薛生晖. 钴白合金在弱酸溶液中选择性浸出工艺研究[J]. 矿冶工程, 2012, 32(4): 90-92.

ZHANG Zhi-hua, WANG Dong, XUE Sheng-hui. Research on selective leaching of cobalt white alloy from weakly acidic solution[J]. Mining and Metallurgical Engineering, 2012, 32(4): 90-92.

[17] ZHOU X J, CHEN Y L, YIN J G, et al. Leaching kinetics of cobalt from the scraps of spent aerospace magnetic materials[J]. Waste Management, 2018, 76: 663-670.

[18] LIU W F, RAO S, WANG W Y, et al. Selective leaching of cobalt and iron from cobalt white alloy in sulfuric acid solution with catalyst[J]. International Journal of Mineral Processing, 2015, 141: 8-14.

[19] FENG R S, XU S M, LIU J, et al. The influence of Cl- on the electrochemical dissolution of cobalt white alloy containing high silicon in a sulfuric acid solution[J]. Hydrometallurgy, 2014, 142: 12-22.

[20] XIAO L, CHEN B, ZHONG H, et al. Bioleaching of cobalt white alloy in the presence of acidithiobacillus ferrooxidans[J]. Trans Tech Publications, Switzerland, 2013, 373/375: 2042-2045.

[21] 徐志峰, 月日辉, 严 康, 等. 复杂高硅钴白合金碱焙烧脱硅预处理[J]. 中国有色金属学报, 2012, 22(10): 2916-2923.

XU Zhi-feng, YUE Ri-hui, YAN Kang, et al. Alkali-roasting and desilication pretreatment of refractory high-silicon cobalt white alloy[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(10): 2916-2923.

Study on process and kinetics of extracting copper from complex high silicon white alloy by sulfuric acid oxidation leaching

WU Xuan-gao, GONG Ao, CHEN Li-jie, LONG Hai-jun, XU Zhi-feng, TIAN Lei

(Institute of Green Metallurgy and Process Intensification, Jiangxi University of Science and Technology, Ganzhou 341000, China)

Abstract: The leaching process and kinetics of copper in high silicon white alloy sulfuric acid oxidation system were studied. Firstly, the effects of additives, sulfuric acid concentration, reaction temperature, reaction time and liquid-solid ratio on the leaching rate of copper and cobalt were systematically studied by single factor experiment. Secondly, the phase and chemical composition of high silicon white alloy and leaching slag were analyzed by X-ray diffraction (XRD), inductively coupled plasma (ICP) and scanning electron microscopy (SEM-EDS). The results show that the copper and cobalt leaching rate reach 99.42% and 97.57%, respectively, under the conditions of 5 mL in sodium hypochlorite, 343 K in leaching temperature, 5 h in reaction time, 200 g/L in sulfuric acid concentration and 7:1 in liquid-solid ratio. Finally, by analyzing the kinetic model of copper extraction from high silicon white alloy by sulfuric acid oxidation leaching, the activation energy, sulfuric acid concentration and particle size reaction order are 34.64 kJ/mol, 2.34 and 0.18, respectively, indicating that it should follow the chemical reaction control of shrinking core model, and establish the corresponding kinetic equation finally.

Key words: high silicon white alloy; sulfuric acid oxidation; leaching kinetics; hybrid control; shrinking core model

Foundation item: Projects(51804136, 51764016) supported by the National Natural Science Foundation of China; Projects(2019T120625, 2019M652276) supported by the China Postdoctoral Science Foundation; Project(20181BAB216017) supported by the Natural Science Foundation of Jiangxi Province, China; Project(GK-201803) supported by the Open Fund Project of the State Key Laboratory of Rare Metal Separation and Comprehensive Utilization, China; Project(20192ACB70017) supported by the Key Research and Development of Jiangxi Province, China

Received date: 2019-10-08; Accepted date: 2021-04-06

Corresponding author: TIAN Lei; Tel: +86-797-8312047; E-mail: tianleijx@163.com

(编辑 何学锋)

基金项目:国家自然科学基金资助项目(51804136,51764016);中国博士后科学基金资助项目(2019T120625,2019M652276);江西省自然科学基金资助项目(20181BAB216017);稀有金属分离与综合利用国家重点实验室开放基金资助项目(GK-201803);江西省重点研发计划重点项目(20192ACB70017)

收稿日期:2019-10-08;修订日期:2021-04-06

通信作者:田 磊,副教授,博士;电话:0797-8312047;E-mail:tianleijx@163.com