文章编号:1004-0609(2014)10-2530-09

废弃锂离子电池富钴破碎产物的可浮性

李 红1,何亚群1, 2,张 涛1,黄亚军1,朱向楠1

(1. 中国矿业大学 化工学院,徐州 221006;

2. 中国矿业大学 现代分析与计算中心,徐州 221006)

摘 要:对比研究废弃锂离子电池富钴破碎产物与商品化电极材料的浮选行为,并分析不同浮选行为的机理。结果表明:商品化钴酸锂和石墨的天然可浮性差异较大,将以质量比1:1混合后的模拟物料进行浮选,钴品位由15.66%富集到50.71%;手工拆解废弃锂离子电池得到的钴酸锂颗粒和石墨颗粒表面粗糙,有杂质附着,使得电极材料表面相关元素的含量降低,该杂质为以C、F、P和O元素为主的有机物,使回收的钴酸锂和石墨颗粒表面化学组成相近,造成材料表面润湿性发生改变;富钴破碎产物经浮选后,钴品位由24.21%仅提高到28.08%。因此,浮选前必须对回收的富钴破碎产物进行表面改性,以增大钴酸锂和石墨表面润湿性差异,从而使浮选获得有效的分离。

关键词:废弃锂离子电池;浮选;钴酸锂;石墨;资源化

中图分类号:X705 文献标志码:A

Floatability of Co-enriched crushed products of spent lithium-ion batteries

LI Hong1, HE Ya-qun1, 2, ZHANG Tao1, HUANG Ya-jun1, ZHU Xiang-nan1

(1. School of Chemical Engineering and Technology, China University of Mining and Technology, Xuzhou 221006, China;

2. Advanced Analysis and Computation Center, China University of Mining and Technology, Xuzhou 221006, China)

Abstract: The floatation behaviors of Co-enriched crushed products and commercialized electrode materials were compared, and the mechanism caused different floatation behavior was analyzed. The results show that, because of a huge floatability difference between commercialized electrode materials, the flotation of simulation material, a mixture of LiCoO2 and graphite, achieve good enrichment, the product grade of Co increases from 15.66% to 50.71%. The organic impurity containing C, F, P and O covers on rough surface of recovered material obtained from disassembled spent lithium-ion batteries. The impurity leads to different surface properties including the content decrease of related elements, similar surface chemical composition of LiCoO2 with graphite, and cause the change of materials surface wettability. After the flotation of Co-enriched crushed products, the grade of Co increases from 24.21% to 28.08%. Therefore, the surface modification must be conducted to the recovered Co-enriched crushed products to enlarge the wettability differences before floatation. As a result, the efficient effect of floatation separation can be achieved.

Key words: spent lithium-ion batteries; floatation; LiCoO2; graphite; recycling

锂离子电池(Lithium-ion batteries, LiBs)具有质量轻、体积小、电压高等优点,是手机、数码相机和手提电脑等便携式设备的主要能源[1]。据统计,2013年,国内LiBs产量为47.68亿只,同比增长16.9%。随着LiBs在数码商品和能源汽车方面的运用,LiBs产业将会有更大的发展空间[2]。与此同时,由于LiBs使用寿命的限制,废弃LiBs的数量逐年递增。废弃LiBs中含有很多贵重金属,如钴(5%~20%)、镍(5%~10%)、锂(5%~7%)等[3],具有显著的经济效益。另外,LiBs含有易燃、有毒成分,会对环境产生潜在的污染威胁。废弃LiBs兼具资源性和危害性,因此,对其进行科学的回收利用,对于环境保护和资源再利用具有重要意义。

现有研究方法侧重于贵重金属钴的回收[4],且多采用化学浸出和生物浸出的方法。化学浸出方法普遍存在处理成本高、工艺繁杂和易污染环境等问题[5-9],而生物浸出方法存在细菌选培、处理周期长和效率低等问题[10-13]。对于LiBs的资源化回收,探索更加直接有效、经济适用的处理工艺是近年来的研究方向,如采用机械物理法,即通过破碎、分选等工艺,使目标产品得到有效富集。张涛等[14]和ZHANG等[15-16]对废弃LiBs的机械破碎特性以及化学和工艺矿物学进行了研究,结果表明,LiBs具有明显的选择性破碎行为,钴酸锂和石墨的粒径小于0.25 mm,故称粒径小于0.25 mm的破碎物料为富钴破碎产物。富钴破碎产物中的钴酸锂和石墨均具回收价值,钴酸锂为层状结构的过渡金属氧化物[17-18],亲水性较好,而非极性矿物石墨,表面键合能很低,具有很好的疏水性[19]。表面润湿性性质差异较大,且分选物料粒度较细,浮选回收钴酸锂和石墨在理论上是较为理想的方法。金泳勋等[20]对浮选钴酸锂做出了初步探索,认为粘结剂PVDF会对浮选效果产生影响,经773 K焙烧处理后,钴酸锂浮选取得了较好的效果,但并未就富钴破碎产物的浮选特性进行深入详细的研究,尤其是缺乏对钴酸锂和石墨表面组分的探讨。而国内对浮选回收钴酸锂的研究还尚属空白。

本文作者应用浮选方法从富钴破碎产物中回收钴酸锂和石墨为出发点,通过接触角测量、SEM、XPS、XRD等手段,以商品化钴酸锂和石墨作为对比材料,详细分析废弃LiBs富钴破碎产物中钴酸锂和石墨颗粒的表面组成,深入研究富钴破碎产物的浮选特性和分选可行性,探讨商品化电极材料和富钴破碎产物可浮性差异存在的原因,为浮选回收富钴破碎产物中的钴酸锂和石墨奠定基础。

1 实验

1.1 实验材料

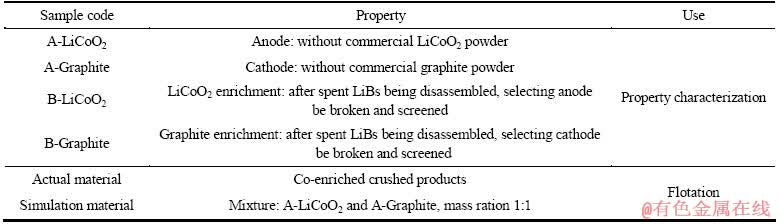

浮选实验材料为经过破碎筛分回收的废弃LiBs富钴产物,采用未使用过的商品化电极材料组成模拟物料进行同样的实验。通过手工拆解的方式,分别获取废弃LiBs的正极和负极,采用相同的破碎筛分方法,分别获得单一的正极钴酸锂富集体和负极石墨富集体,用来比较其表面性质的异同。实验材料代号、性质和用途说明如表1所列。

1.2 实验方法

1.2.1 浮选实验

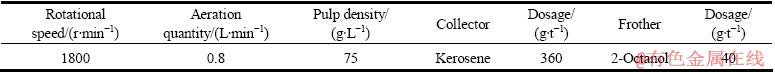

浮选实验采用40mL XFG型挂槽式浮选机,浮选参数列于表2中。

表1 实验材料及性质

Table 1 Experimental materials

表2 浮选实验参数

Table 2 Parameters of floatation

实验流程如图1所示。每次实验称取3 g样品,置于浮选槽内,加入去离子水并搅拌2 min,使颗粒充分润湿,分散在水中。添加捕收剂经5 min搅拌,再加入起泡剂,搅拌3 min后开启充气开关,浮选刮泡5 min,浮选过程采取手工刮泡。泡沫产品为石墨尾矿,槽内产品为LiCoO2精矿,将精矿和尾矿分别过滤、烘干、称取质量,测定品位。

图1 矿样浮选流程

Fig. 1 Mineral floatation flowsheet

1.2.2 接触角测量

首先将物料压成片,采用接触角测量仪(DSA100, KRUSS, 德国生产)随机选取样片上6点,滴加蒸馏水在待测固体表面,快速测量,读取6次接触角,计算平均值作为接触角值。

1.2.3 扫描电镜和元素品位测量

在低真空模式下,应用SEM(Quanta 250, FEI, 美国生产)和 EDX(QUANTAX400-10, BRUKER, 德国生产)相结合分析物料的微观形态和元素组成。

1.2.4 X射线光电子能谱(XPS)测定

XPS分析仪器为ESCALAB 250Xi型数字化多功能光电子能谱仪,采用单色化Al靶作为激发源,束斑尺寸为900μm,系统工作真空优于3×10-7 Pa,扫描模式为CAE。宽扫PE为100 eV,步长1 eV,停留时间50 ms;窄扫PE为20 eV,步长0.05 eV,停留时间100 ms。采用C1s 284.8 eV对谱峰进行荷电校正。

1.2.5 X射线衍射仪(XRD)检测

XRD分析仪器为德国布鲁克(BRUKER)公司D8 ADVANCE X射线衍射仪,X射线管电压40kV,电流30mA,Cu靶,Ka辐射。采样扫描速度0.1 s/步,间隔为0.019450°(步宽)。

2 结果与讨论

2.1 浮选实验

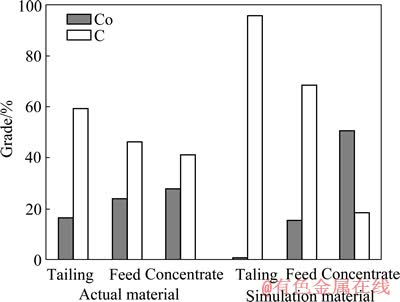

采用EDX测量浮选矿样和产品中Co、C元素的品位。图2所示为实际物料和模拟物料两组浮选实验结果。由图2可看出,Co含量为 24.21%(质量分数)的实际物料经浮选后,精矿中Co 的品位提高到28.08%;尾矿中含Co 16.64%。Co品位增幅小,富矿比为1.16,分选效果不佳,实验结果与表面性质理论分析差异较大。模拟物料浮选对比实验,入料含Co 和C分别为15.66%和 68.68%(质量分数)。浮选后,精矿中Co的品位提高到50.71%,富矿比为3.24,C品位减少到18.49%;尾矿中C品位提高到95.72%,Co仅占0.86%。结果表明模拟物料经浮选,Co的品位与石墨分别有效富集在精矿和尾矿中,品位增幅明显,分选效果较好。实验结果与钴酸锂和石墨矿物的表面性质差异分析一致。

图2 实际物料和模拟物料的浮选结果

Fig. 2 Floatation results of actual and simulation materials

实际物料经浮选,富矿效果不理想,而浮选模拟物料可获得明显分离富集效果,两组物料的浮选行为存在显著的差异。为探究造成差异存在的内外部原因,采用接触角测量仪、SEM、XPS和XRD对LiBs电极材料A-LiCoO2、A-石墨与回收材料B-LiCoO2、B-石墨的表面性质和晶体结构进行对比分析。

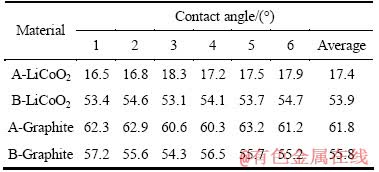

2.2 接触角测量

接触角是矿物表面润湿性质最直接的表征,矿物的疏水性随着接触角的增加而增加。实验分别测定A-LiCoO2、A-石墨、B-LiCoO2和B-石墨的接触角,结果列于表3。

由表3可看出,A-LiCoO2的接触角为17.4°,具有较强的亲水性。A-石墨的接触角为61.8°,疏水性较强。接触角测量结果与前文理论分析相一致,也证明了A-LiCoO2和A-石墨矿物的表面润湿性差异的确较大,所以模拟物料的浮选可获得较好的分选效果。B-LiCoO2的接触角为53.9°,表现较强的疏水性,B-石墨的接触角为55.8°,相较A-石墨,疏水性略微减弱,B-LiCoO2和B-石墨的接触角相差约2°,二者表面润湿性相近。

表3 实验材料的接触角

Table 3 Contact angle of experimental materials

由以上分析可知,作为电极材料的钴酸锂和石墨,表面润湿性在使用前后均发生变化:使用前二者表面润湿性相差较大,而使用后二者表面润湿性非常接近,其差距缩小到可以忽略的范围,导致不能通过浮选有效回收B-LiCoO2。采用SEM观察矿物的微观形貌,以探究导致该结果的原因。

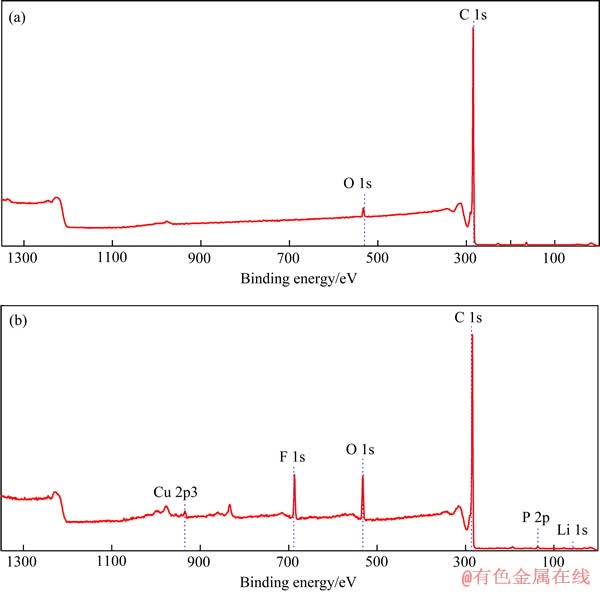

2.3 SEM结果分析

图3所示为A-LiCoO2、A-石墨、B-LiCoO2 和B-石墨的表面形貌。由图3可看出,A-LiCoO2矿物棱角分明,表面平整光滑,粒度分布较分散,且小颗粒居多。呈球状的A-石墨曲线圆滑,表面光洁,粒度分布均匀。在B-LiCoO2中,出现了较多的粗糙颗粒,表面平整光滑的颗粒较少,且明显看出部分LiCoO2颗粒表面附着另种物质,并且多颗粒LiCoO2粉末和该物质由于解离程度较差,形成了大粒度聚团物。同样的颗粒状况在B-石墨的SEM像中也可观察到,且大部分颗粒表面粗糙,聚团物粒度较大。

比较图3(a)和(c)可知,经破碎得到的B-LiCoO2,部分LiCoO2发生解离,其粒度比A-LiCoO2的小,表面粘有杂质的LiCoO2颗粒和团状物解离较差,数量较多,导致LiCoO2的表面性质发生变化。比较图3(b)和(d)可知,经破碎得到的B-石墨,石墨与杂质的解离较完整,解离出的石墨表面干净光滑,其粒度比原料的小,分布也较分散,与杂质粘成的团状物多且粒度较大,使石墨的表面性质发生一定的变化。对比图3(c)和(d)可看出,B-石墨团状物比B-LiCoO2团状物的粒度大,数量多。

图3 LiBs商品化电极材料和回收材料的SEM像

Fig. 3 SEM images of commercialized electrode and recovered materials of LIBs

结合接触角变化的结果,分析对比4种物料的扫描电镜图,推测B-LiCoO2和B-石墨物料中,由于颗粒表面粘附杂质以及混杂着杂质碎屑,使得LiCoO2和石墨的表面性质发生一定改变。

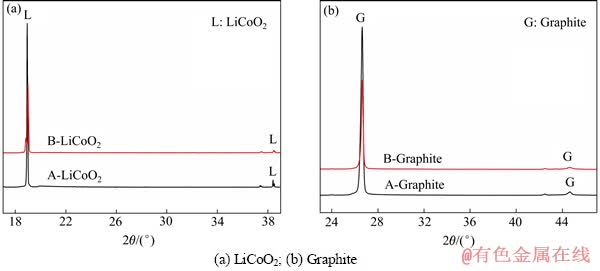

2.4 XPS结果分析

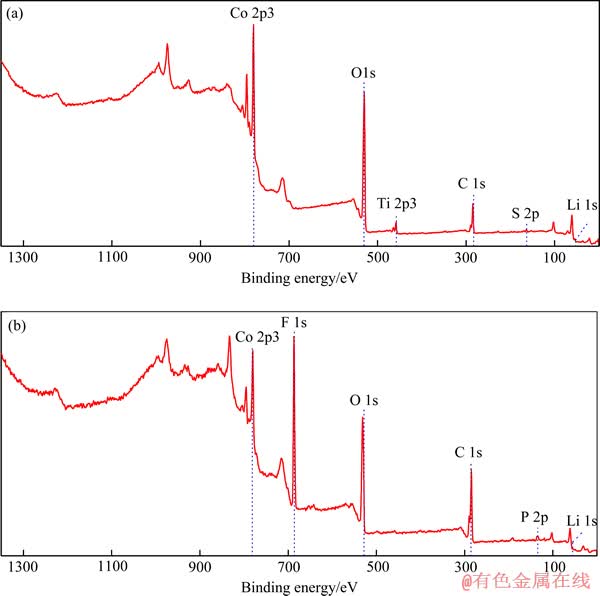

为了验证推测的正确性,采用XPS测定A-LiCoO2、A-石墨、B-LiCoO2 和B-石墨的表面化学组成。其中A-LiCoO2和B-LiCoO2的宽扫谱如图4所示,其表面组成元素的相对含量列于表4中。

由图4和表4可以发现,B-LiCoO2的表面检出了C、F和P元素,C元素来源于炭黑,在LiBs中P元素来源于电解质LiPF6,F元素除来源于LiPF6之外,另一个来源是粘结剂聚偏氟乙烯(PVDF);而A-LiCoO2表面检出的C、Ti和S元素则为外来污染。

对比其含量发现,B-LiCoO2表面的C元素含量较高,而Co、O和Li这些与钴酸锂关联的元素含量较低。是因为含有C、F和P等元素的物质覆盖了钴酸锂颗粒的大部分表面,从而减少了与钴酸锂相关元素在表面的相对含量。

图4 A-LiCoO2和B-LiCoO2的XPS宽扫谱

Fig. 4 XPS survey spectra of A-LiCoO2(a) and B-LiCoO2(b)

表4 A-LiCoO2和B-LiCoO2的表面元素组成

Table 4 Surface elements component of A-LiCoO2 and B-LiCoO2

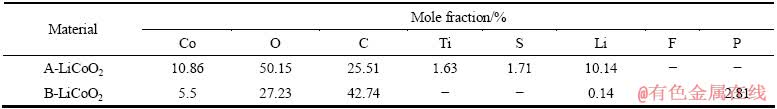

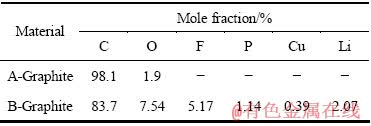

图5 A-石墨和B-石墨的XPS宽扫谱

Fig. 5 XPS survey spectra of A-Graphite(a) and B-Graphite(b)

A-石墨和B-石墨的宽扫图谱如图5所示,其表面组成元素的相对含量列于表5中。由图5和表5可以发现,A-石墨的表面检出了C和O两种元素,O元素可能来源于外界污染。而B-石墨除了检出以上元素外,还有Li、P、F和Cu元素。其中Li和P元素来源于电解质LiPF6;与正极材料一样,负极材料中F的来源依然是电解质LiPF6和粘结剂PVDF;由于石墨是通过粘结剂附着于铜箔上的,Cu则来源于破碎产生的细小铜粉末。

对比A-石墨和B-石墨表面元素的相对含量发现,B-石墨中C元素含量有所下降,而O含量较高。因而可以推断,是含有O、F和P等元素的物质覆盖了石墨颗粒的表面,造成了C元素含量的降低。

表5 A-石墨和B-石墨的表面元素组成

Table 5 Surface element components of A-Graphite and B-Graphite

通过以上分析可以发现,造成钴酸锂和石墨相关元素表面含量降低的原因是存在含有C、F、P和O等元素的物质覆盖了电极材料颗粒的部分表面。推测该物质为炭黑、粘结剂和有机溶剂的混合物,因此,钴酸锂和石墨表面呈疏水性。

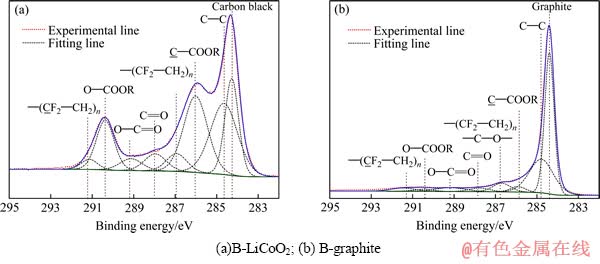

为了进一步分析钴酸锂和石墨表面润湿性相近的原因,对样品中含量较高的C元素进行高分辨的XPS扫描,其分峰拟合后的XPS能谱如图6所示,C 1s峰相关信息列于表6中。

图6所示为B-LiCoO2、B-石墨中C 1s的XPS谱,两图中均分为8个峰,其分峰位置相同。不同之处在于,在结合能为284.27 eV处,钴酸锂表面为炭黑 (C1sA)官能团,而在结合能为284.40 eV处;石墨表面为石墨(C1sA)官能团,且各分峰峰值不同。但由于石墨和炭黑的结构性质类似,导致钴酸锂和石墨表面润湿性相近。从表6可知,B-LiCoO2表面C 1s主导官能团为C—C(C1sB)和炭黑(C1sA),合计所占比例45.67%(摩尔分数),二者疏水性较强。B-石墨中C 1s主导官能团为石墨(C1sA′)和C—C(C1sB′)合计79.83%(摩尔分数),石墨表面润湿性质变化不大。

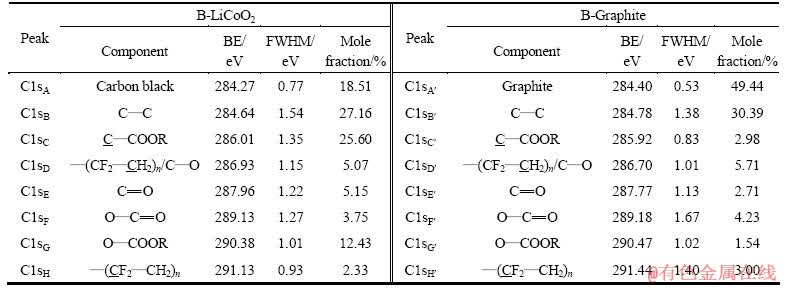

2.5 XRD结果分析

影响矿物表面润湿性的因素,一个是外在表面杂质,另一个则是内在矿物自身晶体结构。为了探究矿物表面润湿性变化,是否还由矿物晶体结构变化造成,采用XRD检测A-LiCoO2和B-LiCoO2、A-石墨和B-石墨的晶体结构,其结果如图7所示。

图6 C1s X射线光电子能谱图分峰拟合图

Fig. 6 C1s peak fitting curves of XP spectra

表6 B-LiCoO2和B-石墨表面C 1s峰的结合能、半高全宽和官能团含量

Table 6 Binding energy (BE), full-width at half-maximum (FWHM) and content of C 1s peaks for B-LiCoO2 and B-Graphite

图7 LiBs商品化电极材料和回收材料的XRD谱

Fig. 7 XRD patterns of commercialized electrode and recovered materials of LIBs

分析图7可以发现,无论是回收的钴酸锂还是石墨,均与商品化电极材料在晶体结构上并无差别;因此可以断定,回收的电极材料保持了原来的晶体结构,矿物表面润湿性的变化并非由物料本身的晶体结构造成。

3 结论

1) 商品化电极材料,钴酸锂和石墨的接触角分别为17.4°和61.8°,天然可浮性差异较大,经浮选,Co的富集比为3.24;富钴破碎产物中,钴酸锂和石墨表面有杂质附着,其接触角分别为53.9°和55.8°,表面润湿性质相近,浮选后Co的富集比为1.16,采用浮选工艺不能获得较好的分选效果。

2) 回收电极材料的表面存在大量的杂质。回收钴酸锂表面的C元素中,存在18%(摩尔分数)的炭黑以及5%(摩尔分数)左右的聚偏氟乙烯、50%(摩尔分数)左右的C—C和C—H键和各种不同氧化程度碳-氧结构。石墨表面C元素中,存在接近50%(摩尔分数)的石墨组分、6%(摩尔分数)左右的聚偏氟乙烯、33%(摩尔分数)的C—C和C—H结构和不同氧化程度的碳-氧结构。由于其表面成分较为接近,是造成表面润湿性差异不大,难于实现浮选效果的主要原因。

3) 回收电极材料为内核外衣的结构,其外层润湿性能的一致性弱化了内核表面性质的差异;根据其外层结构为有机物,且氧化程度较高的特点,推断氧化焙烧是实现去除外层杂质,实现回收LiBs电极材料表面活化的有效方法。

致谢

感谢上海电子废弃物资源化产学研合作开发中心开放基金项目(ZF1224-07)资助,感谢中国矿业大学现代分析与计算中心对本实验的技术支持。

REFERENCES

[1] NAN Jun-min, HAN Dong-mei, ZUO Xiao-xi. Recovery of metal values from spent lithium-ion batteries with chemical deposition and solvent extraction[J]. Journal of Power Sources, 2005, 152: 278-284.

[2] KANG J, SOHN J S, CHANG H, SENANAYAKE G, SHIN S M. Preparation of cobalt oxide from concentrated cathode material of spent lithium ion batteries by hydrometallurgical method[J]. Advanced Powder Technology, 2010, 21(2): 175-179.

[3] SHIN S M, KIM N H, SOHN J S, DONG H Y, YOUNG H K. Development of a metal recovery process from Li-ion battery wastes[J]. Hydrometallurgy, 2005, 79(3/4): 172-181.

[4] MANTUANO D P, DORELLA G, ELIAS R C A. MANSUR M B. Analysis of a hydrometallurgical route to recover base metals from spent rechargeable batteries by liquid-liquid extraction with cyanex 272[J]. Journal of Power Sources, 2006, 159(2): 1510-1518.

[5] CHEN Liang, TANG Xin-cun, ZHANG Yang, LI Lian-xing, ZENG Zhi-wen, ZHANG Yi. Process for the recovery of cobalt oxalate from spent lithium-ion batteries[J]. Hydrometallurgy, 2011, 108(1/2): 80-86.

[6] PRANOLO Y, ZHANG W, CHENG C Y. Recovery of metals from spent lithium-ion battery leach solutions with a mixed solvent extractant system[J]. Hydrometallurgy, 2010, 102(1/4): 37-42.

[7] JHA M K, KUMARI A, JHA A K, KUMSR V, HAIT J, PANDEY B D. Recovery of lithium and cobalt from waste lithium-ion batteries of mobile phone[J]. Waste Management, 2013, 33(9): 1890-1897.

[8] ZHU Shu-guang, HE Wen-zhi, LI Guang-ming, ZHOU Xu, ZHANG Xiao-jun, HUANG Ju-wen. Recovery of Co and Li from spent lithium-ion batteries by combination method of acid leaching and chemical precipitation[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(9): 2274-2281.

[9] 陈 亮, 唐新村, 张 阳, 瞿 毅, 王志敏. 从废旧锂离子电池中分离回收钴镍锰[J]. 中国有色金属学报, 2011, 21(5): 1192-1198.

CHEN Liang, TANG Xin-cun, ZHANG Yang, QU Yi, WANG Zhi-min. Separation and recovery of Ni, Co and Mn from spent lithium-ion batteries[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(5): 1192-1198.

[10] ZENG Gui-sheng, LUO Sheng-lian, DENG Xiao-rong, LI Lei, AU Chak-tong. Influence of silver ions on bioleaching of cobalt from spent lithium batteries[J]. Minerals Engineering, 2013, 49: 40-44.

[11] XIN Bao-ping, ZHANG Di, ZHANG Xian, XIA Yun-ting, WU Feng, CHEN Shi, LI Li. Bioleaching mechanism of Co and Li from spent lithium-ion battery by the mixed culture of acidophilic sulfur-oxidizing and iron-oxidizing bacteria[J]. Bioresource Technology, 2009, 100(24): 6161-6169.

[12] 邓孝荣, 曾桂生, 罗胜联, 罗旭彪, 邹建平. 氧化亚铁硫杆菌浸出废旧锂离子电池中钴酸锂的电化学行为[J]. 中南大学学报: 自然科学版, 2012, 43(7): 2500-2505.

DENG Xiao-rong, ZENG Gui-sheng, LUO Sheng-lian, LUO Xu-biao, ZOU Jian-ping. Electrochemical behavior of bioleaching LiCoO2 from spent lithium-ion batteries by Thiobacillus ferrooxidans[J]. Journal of Central South University: Science and Technology, 2012, 43(7): 2500-2505.

[13] 辛宝平, 朱庆荣, 李是珅, 李 丽, 吴 峰. 生物淋滤溶出废旧锂离子电池中钴的研究[J]. 北京理工大学学报, 2007, 27(6): 551-555.

XIN Bao-ping, ZHU Qing-rong, LI Shi-kun, LI Li, WU Feng. Study on the release of Co from retrieved Li-ion batteries by bioleaching[J].Transactions of Beijing Institute of Technology, 2007, 27(6): 551-555.

[14] 张 涛, 吴彩斌 王成彦, 何亚群. 废弃手机锂离子电池机械破碎的基础研究[J]. 中南大学学报: 自然科学版, 2012, 43(9): 3355-3362.

ZHANG Tao, WU Cai-bin, WANG Cheng-yan, HE Ya-qun. Mechanical crushing properties of spent cell phone lithium-ion batteries [J]. Journal of Central South University: Science and Technology, 2012, 43(9): 3355-3362.

[15] ZHANG Tao, HE Ya-qun, GE Lin-han, FU Ru-san, ZHANG Xia, HUANG Ya-jun. Characteristics of wet and dry crushing methods in the recycling process of spent lithium-ion batteries[J]. Journal of Power Sources, 2013, 240(6): 766-771.

[16] ZHANG Tao, HE Ya-qun, WANG Fang-fang, GE Lin-han, ZHU Xiang-nan, LI Hong. Chemical and process mineralogical characterizations of spent lithium-ion batteries: An approach by multi-analytical techniques[J]. Waste Management, 2014, 34: 1051-1058.

[17] 郭炳坤, 徐 徽, 王先友, 肖立新. 锂离子电池[M]. 长沙: 中南大学出版社, 2002: 55-64.

GUO Bing-kun, XU-Hui, WANG Xian-you, XIAO Li-xin. Lithium-ion batteries[M]. Changsha: Central South University Press, 2002: 55-64.

[18] ANTOLINI E. LiCoO2: Formation, structure, lithium and oxygen nonstoichiometry, electrochemical behavior and transport properties[J]. Solid State Ionics, 2004, 170(3/4): 159-171.

[19] B A威尔斯, T J纳皮尔·马恩. 矿物加工技术[M]. 印万忠, 译. 北京: 冶金工业出版社, 2011: 328-329.

WILLS B A, NAPIER·MAHN T J. Wills’ mineral processing technology[M]. 7th ed. YIN Wan-zhong, transl. Beijing: Metallurgical Industry Press, 2011: 328-329.

[20] 金永勋, 松田光明, 董晓辉, 雨 田. 用浮选法从废锂离子电池中回收锂钴氧化物[J]. 国外金属矿选矿, 2003, 40(7): 32-37.

JIN Yong-xun, SONGTIAN Guang-ming, DONG Xiao-hui, YU Tian. Recovering LiCoO2 from spent lithium-ion batteries with floatation process[J]. Metallic Ore Dressing Abroad, 2003, 40(7): 32-37.

(编辑 李艳红)

基金项目:上海电子废弃物资源化产学研合作开发中心开放基金项目(ZF1224-07)

收稿日期:2014-03-11;修订日期:2014-07-24

通信作者:何亚群,教授,博士;电话:0516-83592928;E-mail: yqhe@cumt.edu.cn