文章编号:1004-0609(2014)03-0659-09

时效处理对喷射成形7075合金晶间腐蚀的影响

苏睿明,曲迎东,李荣德,解骐鸣,尤俊华

(沈阳工业大学 材料科学与工程学院,沈阳 110870)

摘 要:采用拉伸试验、电镜观察和晶间腐蚀(IGC)试验,研究回归再时效(RRA)处理对喷射成形7075合金组织形貌、力学性能和晶间腐蚀性能的影响,并与T6峰值时效、T73过时效进行对比分析。结果表明:经T6处理后,晶内大量细小弥散的η′相使合金的抗拉强度达到760 MPa,但晶界处连续分布的η相和窄小的晶界无析出带(PFZ)使合金抗晶间腐蚀性能变差,晶间腐蚀深度达131.4 μm;经T73处理后晶界η相断开及PFZ大幅增宽可改善合金的耐蚀性,晶间腐蚀深度仅为2.0 μm,但晶内η′相粗化及体积分数的减小使合金抗拉强度大幅下降,仅为676 MPa;采用(120 ℃,24 h)+(200 ℃,10 min)+(120 ℃,24 h)的RRA处理后合金晶内η′相再次大量析出,致使抗拉强度达758 MPa,略低于T6态的抗拉强度,而晶界处断续分布的η相和宽度略增的PFZ使合金抗晶间腐蚀性能也显著改善,晶间腐蚀深度为16.8 μm,与经T73处理后的接近。

关键词:7075合金;喷射成形;回归再时效;晶间腐蚀;显微组织

中图分类号:TG146.2 文献标志码:A

Effect of aging treatment on intergranular corrosion of spray forming 7075 alloy

SU Rui-ming, QU Ying-dong, LI Rong-de, XIE Qi-ming, YOU Jun-hua

(School of Materials Science and Engineering, Shenyang University of Technology, Shenyang 110870, China)

Abstract: The microstructure, mechanical properties and intergranular corrosion (IGC) behavior of spraying forming 7075 alloy undergone retrogression and re-aging (RRA) were studied by tensile test, electron microscopy, and IGC test, and compared with those of T6 peak aging and T73 overaging treatments. The results show that after T6 treatment, abundance transgranular dispersive η′ phases make the tensile strength of the alloy reach 760 MPa, continuous η phases at grain boundaries and narrow precipitate free zones (PFZ) make the IGC resistance decrease and IGC depth reach 131.4 μm. After T73 treatment, interrupted η phases at grain boundaries and wide PFZ can improve IGC resistance, and the IGC depth is only 2.0 μm, but depressed volume fraction of coarsening transgranular η′ phases greatly reduces the tensile strength of alloy to 676 MPa. After RRA treatment of (120 ℃, 24 h)+(200 ℃, 10 min)+(120 ℃, 24 h), abundance transgranular dispersive η′ phases separate out again, η phases at grain boundaries interrupt, and PFZ widen slightly. The tensile strength of alloy is 758 MPa, which is a little less than the strength after T6 treatment. IGC depth is 16.8 μm, which is close to that of the T73 treatment.

Key words: 7075 alloy; spray forming; retrogression and re-aging; intergranular corrosion; microstructure

7075铝合金属于7xxx系高强度可热处理Al-Zn-Mg-Cu合金,因其具有比强度高、易加工等优点,被广泛应用于航空航天领域[1-2]。传统铸造方法制备的7075合金,由于制备工艺的局限,因此,合金强度很难超过700 MPa[3-4]。直至喷射成形等快速凝固技术在7075铝合金制备当中得到应用,使得7075合金的强度提高到730 MPa以上,并使7075合金的制备进入到一个全新阶段。

但是,7xxx系铝合金易发生局部腐蚀,主要的形式包括孔蚀、缝隙腐蚀、晶间腐蚀(IGC)和剥蚀等。其中,晶间腐蚀是对7xxx系合金危害较大的腐蚀形式,将导致材料强度和塑性的大幅度下降[5],从而降低材料的使用寿命。自20世纪40年代起,铝合金的晶间腐蚀就引起了科学家的很大兴趣。目前,已经提出了铝合金晶间腐蚀的3种主要理论[6-8]。

针对这3种主要理论,已有大量文献报道热处理工艺对7xxx系铝合金晶间腐蚀性能的影响[9-12],这些报道仅局限于传统铸造方法制备的7xxx系铝合金。此外,文献[13-16]也对喷射成形7xxx铝合金热处理工艺进行了研究,但这些研究并未提及合金的晶间腐蚀性能。并且文献[17-19]中表明,由于喷射态合金与传统方法制备的合金在原始及热处理后的组织特征存在较大差异,对耐腐蚀性也产生较大影响,其影响规律需深入研究。

为此,本文作者以喷射成形7075铝合金为对象,研究200 ℃回归处理及再时效处理后合金的显微组织及腐蚀敏感性。同时与经T6、T73处理后的合金进行对比分析,探讨喷射成形7075铝合金峰值时效状态、过时效状态、回归处理状态和回归再时效状态下的微观组织和耐蚀性能变化规律,旨在为喷射成形7075铝合金热处理工艺提供理论和实验依据,为进一步的研究提供参考。

1 实验

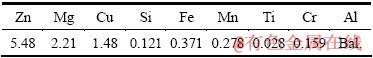

本实验所用合金为7075铝合金,其合金成分(质量分数)在喷射成形后的化学分析结果见表1。

表1 喷射成形7075合金的化学成分

Table 1 Chemical composition of spray forming 7075 alloy (mass fraction, %)

喷射成形实验具体工艺参数如下:采用二级雾化,雾化气体为高压氮气,垂直喷射距离为370~380 mm;盘面偏心为60~65 mm;导液管内径为3.6 mm;沉积盘倾角(即液流入射角)为37°~39°;浇注温度为770~780 ℃;保温坩埚温度为735~745 ℃;沉积盘水平移动速度为0.15 mm/s;垂直移动速度为0.18 mm/s;喷射时间约为12~12.5 min。

对喷射成形制得的沉积坯件经进行热挤压(挤压温度400 ℃,挤压比30:1,坯锭保温0.5 h,模具预热温度380 ℃,挤压速率1.5 mm/s),然后采用固溶处理制度为(450 ℃,1 h)+(475 ℃,2 h),进行热处理水淬。T6峰值时效处理工艺参数为120 ℃、24 h,空冷。对经T6处理后的试样进行200 ℃回归处理,最后对经回归处理后的试样进行120 ℃、24 h再时效处理。另进行(120 ℃,8 h)+(160 ℃,16 h)的T73过时效处理,以进行对比分析。

晶间腐蚀试验按照GB/T 7998—2005标准[20]和ASTM G110—1992 (2009)标准[21]进行。挤压后的试样为d13 mm棒材,故截取40 mm长试棒并车削去皮作为腐蚀试验试样,每个状态的样品取3个。将样品垂直悬挂腐蚀液(57 g/L NaCl+10 mL H2O2)中,浸泡6 h,实验温度保持在(35±2) ℃,试样腐蚀面积与腐蚀液容积比小于20 mm2/mL,避免试样与容器及试样之间相互接触。腐蚀后的试样水洗吹干。将经腐蚀试验的试样在距离试棒侧5 mm处垂直切开,按金相试样制备方法对试样进行磨制和抛光,通过显微镜放大500倍观察。晶间腐蚀等级评定标准如下:腐蚀最大深度不超过10 μm为1级;深度在10~30 μm为2级;介于30~100 μm为3级;100~300 μm之间为4级;超过300 μm为5级。

拉伸性能测试在CSS-55100型电子万能试验机上进行,每个状态合金测定3个有效样品,取平均值。电导率测试采用FH-1型涡流式电导仪,每个试样测量5次,取平均值。透射样品经机械减薄至50~60 μm后冲制成直径为3 mm的圆片,然后进行双喷减薄,双喷电解液为硝酸甲醇溶液,其中硝酸与甲醇体积比为3:7,温度控制在-25 ℃以下,工作电压为12~15 V,电流为60~80 mA。随后样品在JEM-2100透射电子显微镜(TEM)上观察。

2 结果与分析

2.1 T6与T73处理对合金组织及性能的影响

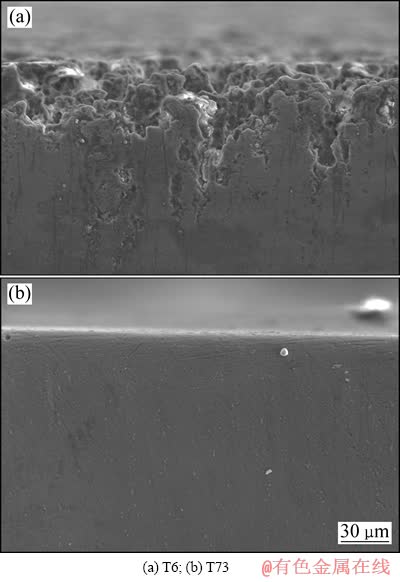

在晶间腐蚀过程中,通过各种时效处理后的试样表面出现气泡及颜色变化,并随着时间的延长,附着的气泡逐步增多,试样表面颜色逐渐变黄,后附着乳白色类盐物质。其中以T6处理后的合金变化最为明显。晶间腐蚀后垂直剖开各个试样进行显微观察,发现各试样晶间腐蚀分布较为均匀,而不同状态下样品差异较为明显。

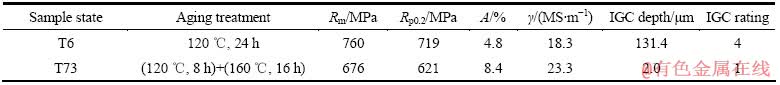

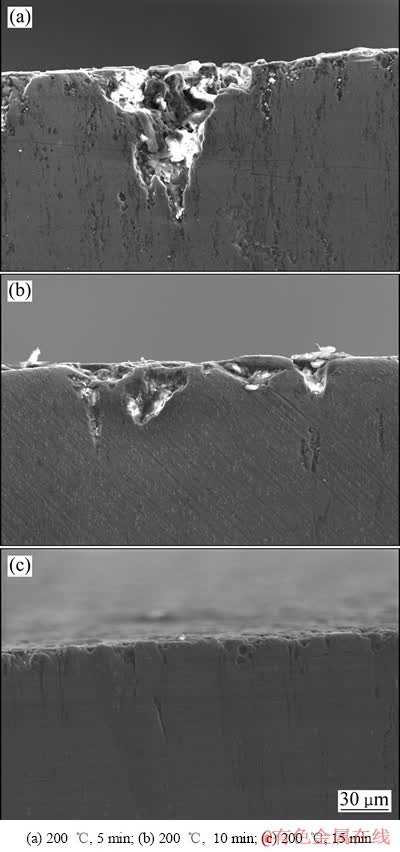

图1所示为经T6与T73时效处理后喷射成形7075铝合金晶间腐蚀SEM像。由图1可以看出,合金在经过这两种不同时效处理后,其晶间腐蚀程度有较大的差别。如图1(a)所示,经T6处理后的合金发生了极为严重的晶间腐蚀,试样点蚀程度严重,表面凸凹不平,腐蚀深入至合金内部,晶间腐蚀深度约为131.4 μm。而合金经T73处理后,其晶间腐蚀深度为2 μm左右,如图1(b)所示,合金的腐蚀表面呈零星分布的微小点蚀凹坑,合金表现出较高的耐蚀性。并依据标准[20-21]评估合金的晶间腐蚀等级,结果如表2所列。

图1 经不同时效处理后喷射成形7075合金的晶间腐蚀SEM像

Fig. 1 Intergranular corrosion SEM images of spray forming 7075 alloy after various aging treatments

从表2中还可以看出,合金在T6状态下电导率(γ)仅为18.3 MS/m,而T73处理后的电导率增至23.3 MS/m。合金的电导率可以从一个侧面反映合金的耐蚀性,其主要受基体内溶质原子的固溶度以及共格脱溶相(GP区)周围的应力场所影响[22-23]。T6峰值时效状态与T73过时效状态下合金基体固溶度基本不变,而合金内部与基体共格的GP区变化较为明显[1-2],T6状态下合金存在一定数量的GP区,GP区周围的应力场导致合金的电导率处在一个较低的状态,而经T73处理后,这些GP区及其周围应力场消失,使电导率增加。

而Al-Zn-Mg-Cu合金中强度的变化主要由GP区、η′及η相的尺寸、数量和分布所决定。7xxx系合金中沉淀相析出顺序一般为[1-2]:αSSS(过饱和固溶体)→GP区→亚稳定η′相(MgZn2)→η相(MgZn2)。其中:GP区与基体共格,η′相与基体半共格,η相与基体非共格。

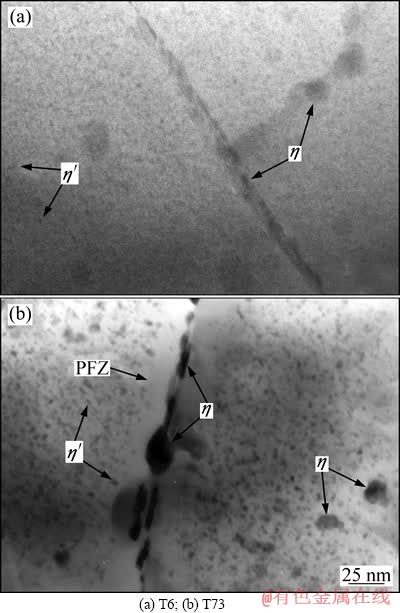

图2所示为经T6峰值时效处理与T73过时效处理后喷射成形7075合金的TEM像。从图2(a)可以看出,T6态合金晶内强化相η′呈细小弥散分布,体积分数较大,尺寸为1~2 nm;晶界上的平衡析出相η呈连续链状分布;晶界无析出带(PFZ)较窄,约5 nm。图2(b)所示为经T73处理后合金的TEM像。从图2(b)中分析可知,合金晶内析出的η′相较经T6处理后粗大且较为聚集,且体积分数减小,尺寸为3~5 nm;晶界处的η相粗化且呈断续分布,PFZ很宽,约为25 nm。

晶内析出η′相的大小和体积分数直接影响合金的强度,在T6状态下,合金晶内有大量细小的η′相,使得合金的强度保持在一个较高的状态,抗拉强度达760 MPa以上。经T73处理后,晶内η′相粗化及其体积分数的减少使合金强度大幅下降,抗拉强度仅为676 MPa(见表2)。

而7xxx系合金的抗晶间腐蚀性能与晶界区的组织状态,即晶界析出相的大小、分布及PFZ的宽度等密切相关。根据文献[24-25],合金处于腐蚀介质时,晶界析出相的电位为-1.05 V,PFZ的电位为-0.85 V,合金基体的电位为-0.75 V,由此可以看出,晶界处η相在合金腐蚀过程中为阳极相,将优先发生阳极溶解。如果晶界析出相为细小、连续的颗粒,则很容易形成连续的腐蚀通道,产生晶间腐蚀;反之,抗晶间腐蚀能力提高。此外,从三者的电位来看,晶间析出相与PFZ之间的电位差小于晶间析出相与基体之间的电位差,PFZ宽化对缓解晶间腐蚀是有利的。

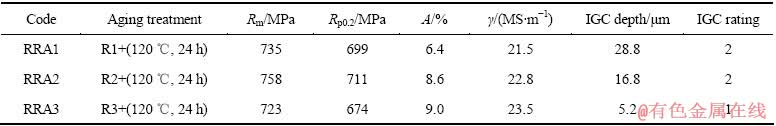

表2 不同时效状态下喷射成形7075合金的常温拉伸性能与晶间腐蚀程度

Table 2 Room temperature tensile and intergranular corrosion properties of spray forming 7075 alloy after different aging treatments

图2 经不同时效处理后喷射成形7075合金的TEM像

Fig. 2 TEM images of spray forming 7075 alloy after different aging treatments

经T6处理后合金中存在一个由晶界连续η相与其边缘铝基体组成的腐蚀电偶,进而形成一个腐蚀通道,导致经T6处理的合金具有很大的腐蚀敏感性;而经T73处理后合金晶界η相明显粗化,呈不连续分布且相间距较大,完全断开的晶界析出相η在腐蚀过程中能阻碍阳极通道的形成,有利于提高合金的腐蚀抗性。PFZ在合金中的作用一直存在争议,就本实验的结果来看,较宽的PFZ对合金的韧性和抗腐蚀性能有积极的作用,这与JIANG等[26-27]的结论基本一致。

2.2 回归处理对合金组织及性能的影响

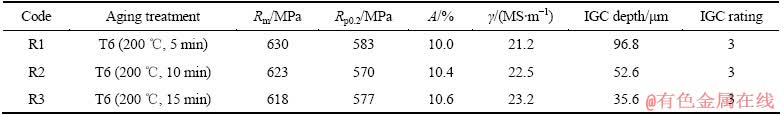

图3所示为经不同回归处理后合金的晶间腐蚀SEM像。由图3可知,当合金在经T6处理后再经过200 ℃回归处理过程中,随着回归时间的延长,合金的晶间腐蚀深度逐渐减小,如图3(a)所示,在200 ℃回归处理5 min后,由于回归时间较短,合金的晶间腐蚀程度仍然很严重,与T6后的情况基本相当,晶间腐蚀深度为96.8 μm。如图3(b)所示,当回归处理进行10 min时,合金的晶间腐蚀现象得到了一定程度的缓解,腐蚀凹坑变浅,晶间腐蚀深度为52.6 μm。当回归处理继续进行至15 min时,合金的耐蚀性大幅改善,晶间腐蚀敏感性减弱,晶间腐蚀深度为35.6 μm。通过回归处理,合金晶间腐蚀程度得到较为明显的改善,同时试样的伸长率在回归过程中也大幅度地提升,均大于10%,但强度下降过多,仅维持在620 MPa左右(见表3)。

从表3中还可看出,合金的电导率从T6状态时的18.3 MS/m(见表2)开始快速上升,在200 ℃回归5 min时就已达到21.2 MS/m,增长速度十分显著。随后增加的幅度开始减缓,10 min时为22.5 MS/m,之后电导率增长速度继续减缓,回归处理15 min时,电导率为23.2 MS/m。

图3 经不同回归处理后合金的晶间腐蚀SEM像

Fig. 3 Intergranular corrosion SEM images of alloy after various retrogression treatments

表3 经不同回归处理后合金的常温拉伸性能与晶间腐蚀程度

Table 3 Room temperature tensile and intergranular corrosion properties of alloy after various retrogression treatments

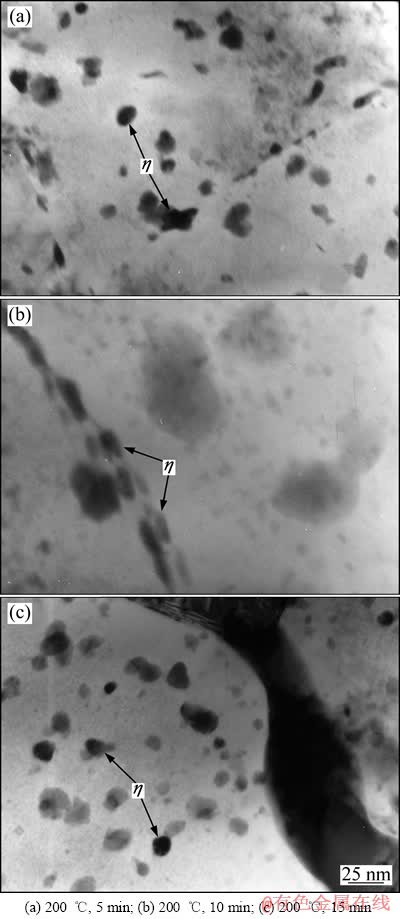

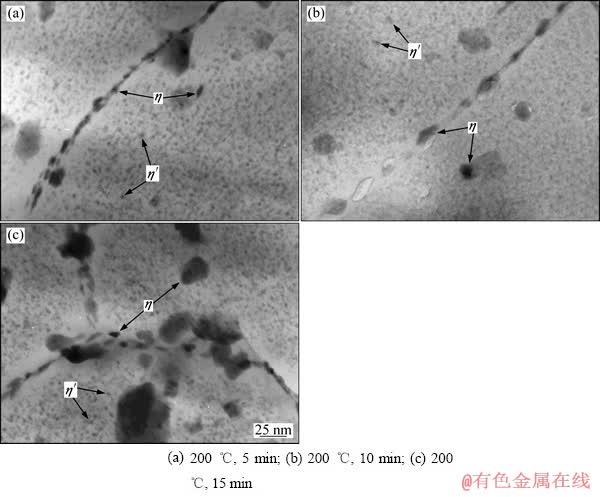

图4 经不同回归处理后合金的TEM像

Fig. 4 TEM images of alloy after different retrogression treatments

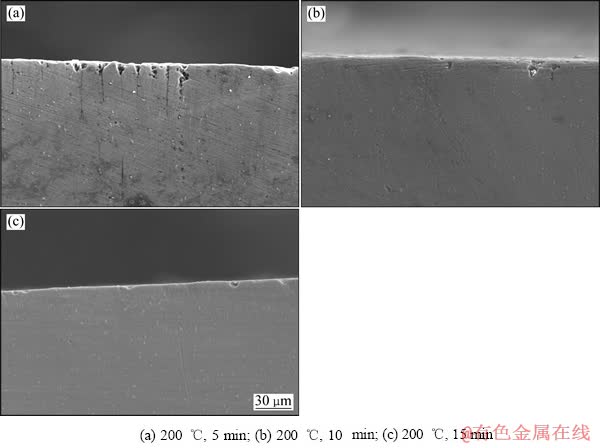

图5 不同回归制度下经RRA处理后合金的晶间腐蚀SEM像

Fig. 5 Intergranular corrosion SEM images of alloy after RRA with different retrogression treatments

图4所示为合金经不同回归处理后的TEM像。如图4(a)所示,回归初期,GP区和小于临界尺寸的析出相η′相回溶,大于临界尺寸的析出相η′长大并转化成η相,因此,回归初期合金的强度逐渐下降。如图4(b)所示,当回归时间为10 min左右,晶内的析出强化相基本都回溶到基体中。观察4(c)后发现,随着回归时间的再度延长,晶粒内的η相继续长大。当回归处理15 min后,晶内析出强化相的体积分数明显增加。此外,随着回归时间的延长,晶界处的平衡相η粗化,分布由连续变成断续,晶界析出相甚至出现孤立分布的状况,这样的晶界组织有利于降低合金的腐蚀敏感性,提高合金的抗腐蚀性能。

而合金的电导率变化是在回归初期,与基体共格的GP区和部分小于临界尺寸的半共格η′相的回溶导致GP区周围的应力场消失,使电导率增加;并且回归时间较短,基体固溶程度并未明显增大,而且与基体不共格的η相的形成和原来大于临界尺寸η′相的长大消耗了这些由GP区和细小η′相回溶产生的溶质原子。延长回归时间,合金的固溶度逐渐增大,晶格畸变加重,故电导率增加速度减缓。

2.3 再时效处理对合金组织及性能的影响

图5所示为在不同回归制度下经RRA处理后合金的晶间腐蚀SEM像。如图5(a)所示,经200 ℃、5 min回归再时效处理后,合金的表面有一些分布较为密集的点蚀坑,一部分细小的晶间腐蚀顺着这些点蚀坑向合金内部进行,晶间腐蚀深度约为28.8 μm。经回归制度为200 ℃、10 min的回归再时效处理后,试样的表面只是出现轻微的点蚀,腐蚀程度得到缓解,如图5(b)所示,晶间腐蚀深度为16.8 μm。如图5(c)所示,回归制度为200 ℃、15 min的回归再时效处理使得合金试样表面只出现零星的点蚀,合金的抗晶间腐蚀性能大幅改善,晶间腐蚀深度仅为5.2 μm。对比T6峰值时效处理,经回归再时效后合金的抗蚀性得到显著的缓解,基本接近于T73处理后的水平。

经RRA处理后合金在保持高强度的同时,伸长率也得到了显著的提高,其中,(120 ℃,24 h)+(200 ℃,10 min)+(120 ℃,24 h)的回归再时效处理使喷射成形7075合金的抗拉强度达到758 MPa,与T6态合金的基本相当,且合金的伸长率达8.6%,甚至超过T73态合金的水平(见表4)。并且合金的电导率整体上均高于相应回归处理后试样的。

表4 不同回归制度下经RRA处理后合金的常温拉伸性能与晶间腐蚀程度

Table 4 Room temperature tensile and intergranular corrosion properties of alloy after RRA with different retrogression treatments

图6 不同回归制度下经RRA处理后合金的TEM像

Fig. 6 TEM images of alloy after RRA with different retrogression treatments

由图6经不同RRA处理后合金的TEM像发现,经再时效处理后晶内重新析出了细小、均匀、弥散分布的析出相η′。此时合金的强化出相主要为η′和η相。此外,从图6中还可以看出,经RRA处理后晶界析出相是粗大呈完全不连续分布的η。随着回归时间的延长,合金晶界处的平衡相明显粗化,断续分布程度增加,基本呈孤立分布。

经RRA处理后,合金基体的脱溶程度增高,降低了基体与晶间析出相之间的电位差,有利于提高抗晶间腐蚀能力,并且完全断开的晶界析出相在应力腐蚀开裂过程中能阻碍阳极通道的形成,同时较宽的PFZ可以缓解晶间腐蚀[24-25],所以,合金的抗晶间腐蚀能力得到显著增强。此外,重新析出的细小晶内析出相增多,使合金获得较好的强度。这样的组织特点使合金既保持了较高的强度,又提高了抗晶间腐蚀性能,与合金性能的变化规律一致。

综合上述喷射成形7075合金的组织与性能可以看出,喷射成形工艺制备的合金,在拉伸强速度和屈服强度上都远高于传统铸造制备的合金的[28],这是喷射成形工艺具备快速凝固、粉末冶金等优点,制备的合金晶粒尺寸小、晶粒圆整、偏析少等因素决定的,此前已有报道[13]。而在合金的电导率和晶间腐蚀抗性方面,喷射成形7075合金经各种热处理后的电导率和抗晶间腐蚀性能也普遍高于同类型传统铸造合金的[28-29],其主要原因是喷射成形制备的合金固溶度较高,T6时效处理初期,在晶内与晶界便可析出一定数量的析出相,随着时效处理的进行,这些析出相较早发生相变,使到达T6峰值时效状态时合金内的GP区数量少于传统铸造合金的,因此,合金的电导率较高。而在回归与再时效处理过程中,合金晶粒较小,晶界较多,晶界处的η相更易粗化、断续,因此合金抗晶间腐蚀较高。

由此可见,经RRA处理后的喷射成形7075合金组织,对合金抗晶间腐蚀性能的提高是极其有利的,并且还能够保持极优的力学性能,基本达到了RRA处理改善喷射成形7xxx系铝合金的预期目的。

3 结论

1) 喷射成形7075合金经T6峰值时效(120 ℃,24 h)处理后,晶内出现大量细小弥散的η′相,合金强度达到760 MPa,但晶界处连续分布的η相和窄小的晶界无析出带(PFZ)使合金晶间腐蚀敏感性增加。

2) 经T73过时效((120 ℃,8 h)+(160 ℃,16 h))处理后,晶界η相断开且PFZ大幅增宽,使合金的抗晶间腐蚀性能得以改善,但晶内η′相粗化及其体积分数减小使合金强度大幅下降,仅为676 MPa。

3) 200 ℃回归处理可使晶内强化相逐渐回溶至基体中,为再时效过程的重新析出做准备,并且回归处理也可使晶界析出相断开,有助于改善合金的耐蚀性。

4) 经(120 ℃,24 h)+(200 ℃,10 min)+(120 ℃,24 h)回归再时效处理后喷射成形7075合金的力学性能和耐蚀性均较好,合金抗拉强度达758 MPa,略低于T6态合金的,而晶间腐蚀抗性与T73处理后的相当,合金综合性能优良,优于同类型传统铸造合金的综合性能。

REFERENCES

[1] MARLAUD T, DESCHAMPS A, BLEY F, LEFEBVREC W, BAROUX B. Influence of alloy composition and heat treatment on precipitate composition in Al-Zn-Mg-Cu alloys[J]. Acta Materialia, 2010, 58(1): 248-260.

[2] MARLAUD T, DESCHAMPS A, BLEY F, LEFEBVREC W, BAROUX B. Evolution of precipitate microstructures during the retrogression and re-ageing heat treatment of an Al-Zn-Mg-Cu alloy[J]. Acta Materialia, 2010, 58(14): 4814-4826.

[3] GEORGE S L, KNUTSEN R D. Composition segregation in semi-solid metal cast AA7075 aluminium alloy[J]. Journal of Materials Science, 2012, 47(11): 4716-4725.

[4] RICKER R E, LEE E U, TAYLOR R, LEI C, PREGGER B, LIPNICKAS E. Chloride ion activity and susceptibility of Al alloys 7075-T6 and 5083-H131 to stress corrosion cracking[J]. Metallurgical and Materials Transactions A, 2013, 44(3): 1353-1364.

[5] KNIGHT S P, SALAGARAS M, TRUEMAN A R. The study of intergranular corrosion in aircraft aluminium alloys using X-ray tomography[J]. Corrosion Science, 2011, 53(2): 727-734.

[6] BROWN R H, FINK W L, HUNTER M S. Measurement of irreversible potentials as a metallurgical research tool[J]. Trans AIME, 1941, 143: 115-122.

[7] MAITRA S, ENGLISH G C. Mechanism of localized corrosion of 7075 alloy plate[J]. Metallurgical Transactions A, 1981, 12(3): 535-541.

[8] BUCHHEIT R G, WALL F D, STONER G E, MORAN J P. Anodic dissolution-based mechanism for the rapid cracking, preexposure phenomenon demonstrated by aluminum- lithium-copper alloys[J]. Corrosion, 1995, 51(6): 417-428.

[9] KNIGHT S P, BIRBILIS N, MUDDLE B C, TRUEMAN A R, LYNCH S P. Correlations between intergranular stress corrosion cracking, grain-boundary microchemistry, and grain-boundary electrochemistry for Al-Zn-Mg-Cu alloys[J]. Corrosion Science, 2010, 52(12): 4073-4080.

[10] ASKARI-PAYKANI M, MERATIAN M, SHAYAN M, RAEISSI K. Effects of heat treatment parameters on microstructural changes and corrosion behavior of Al 7075 Alclad alloy[J]. Anti-Corrosion Methods and Materials, 2012, 59(5): 231-238.

[11] KRISHNA K G, SIVAPRASAD K, NARAYANAN T S N S, KUMAR K C H. Localized corrosion of an ultrafine grained Al-4Zn-2Mg alloy produced by cryorolling[J]. Corrosion Science, 2012, 60: 82-89.

[12] 游江海, 李鹏辉, 李国锋, 刘胜胆, 朱航飞. 回归处理工艺对7050铝合金力学和晶间腐蚀性能的影响[J]. 中南大学学报: 自然科学版, 2008, 39(5): 968-974.

YOU Jiang-hai, LI Peng-hui, LI Guo-feng, LIU Sheng-dan, ZHU Hang-fei. Effect of retrogression processing on mechanical properties and intergranular corrosion of 7050 aluminum alloy[J]. Journal of Central South University: Science and Technology, 2008, 39(5): 968-974.

[13] SU R M, QU Y D, LI R X, LI R D. Study of ageing treatment on spray forming Al-Zn-Mg-Cu alloy[J]. Applied Mechanics and Materials, 2012, 217: 1835-1838.

[14] 王 锋, 熊柏青, 张永安, 朱宝宏, 刘红伟, 何小青. 双级时效处理对喷射沉积Al-Zn-Mg-Cu 合金微观组织和力学性能的影响[J]. 中国有色金属学报, 2007, 17(7): 1058-1060.

WANG Feng, XIONG Bai-qing, ZHANG Yong-an, ZHU Bao-hong, LIU Hong-wei, HE Xiao-qing. Effect of two-step aging treatment on microstructure and mechanical properties of spray-deposited Al-10.8Zn-2.8Mg-1.9Cu alloy[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(7): 1058-1060.

[15] BAI P, HOU X, ZHANG X, ZHAO C, XING Y. Microstructure and mechanical properties of a large billet of spray formed Al-Zn-Mg-Cu alloy with high Zn content[J]. Materials Science and Engineering A, 2009, 508(1): 23-27.

[16] 左玉婷, 王 锋, 熊柏青, 张永安, 朱宝宏, 刘红伟, 李志辉. 喷射成形 Al-9.97Zn-2.65Mg-1.94Cu-0.12%Zr合金均匀化过程中的组织演变[J]. 中国有色金属学报, 2010, 20(5): 820-826.

ZUO Yu-ting, WANG Feng, XIONG Bai-qing, ZHANG Yong-an, ZHU Bao-hong, LIU Hong-wei, LI Zhi-hui. Microstructural evolution of spray formed Al-9.97Zn-2.65Mg-1.94Cu-0.12%Zr alloy during homogenization[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(5): 820-826.

[17] CAI Yuan-hua, LIANG Rui-guang, SU Zhan-pei, ZHANG Ji-shan. Microstructure of spray formed Al-Zn-Mg-Cu alloy with Mn addition[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(1): 9-14.

[18] WEI Qiang, XIONG Bai-qing, ZHANG Yong-an, ZHU Bao-hong, SHI Li-kai. Production of high strength Al-Zn-Mg-Cu alloys by spray forming process[J]. Transactions of Nonferrous Metals Society of China, 2001, 11(2): 258-261.

[19] 张永安, 朱宝宏, 刘红伟, 张智慧, 熊柏青, 石力开. Zn含量对喷射成形7xxx系高强铝合金组织与性能的影响[J]. 中国有色金属学报, 2005, 15(7): 1013-1018.

ZHANG Yong-an, ZHU Bao-hong, LIU Hong-wei, ZHANG Zhi-hui, XIONG Bai-qing, SHI Li-kai. Influence of Zn content on microstructure and properties of spray-formed 7xxx series aluminum alloys[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(7): 1013-1018.

[20] GB 7998—2005. 铝合金晶间腐蚀测定方法[S].

GB 7998—2005. Test method for intergranular corrosion of aluminium alloy[S].

[21] ASTM G110—92 (2009). Standard practice for evaluating intergranular corrosion resistance of heat treatable aluminum alloys by immersion in sodium chloride + hydrogen peroxide solution[S].

[22] 曾 渝, 尹志民, 朱远志. RRA 处理对超高强铝合金微观组织与性能的影响[J]. 中国有色金属学报, 2004, 14(7): 1188-1194.

ZENG Yu, YIN Zhi-min, ZHU Yuan-zhi. Effect of RRA on microstructure and properties of new type ultra high strength aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(7): 1188-1194.

[23] 郑子樵, 李红英, 莫志民. 一种 7055 型铝合金的 RRA 处理[J]. 中国有色金属学报, 2001: 11(5): 771-776.

ZHENG Zi-qiao, LI Hong-ying, MO Zhi-min. Retrogression and reaging treatment of a 7055 type aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(5): 771-776.

[24] 李国锋, 张新明. 回归冷却速率对7050铝合金力学性能及晶间腐蚀抗力的影响[J]. 中国有色金属学报, 2013, 23(5): 1234-1240.

LI Guo-feng, ZHANG Xin-ming. Effect of retrogression cooling rate on mechanical properties and resistance to intergranular corrosion of 7050 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(5): 1234-1240.

[25] 张新明, 李鹏辉, 刘胜胆, 李国锋, 朱航飞, 周新伟. 回归时间对7050铝合金晶间腐蚀性能的影响[J]. 中国有色金属学报, 2008, 18(10): 1795-1801.

ZHANG Xin-ming, LI Peng-hui, LIU Sheng-dan, LI Guo-feng, ZHU Hang-fei, ZHOU Xin-wei. Effect of retrogression time on intergranular corrosion of 7050 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(10): 1795-1801.

[26] JIANG H, FAULKNER R G. Modelling of grain boundary segregation, precipitation and precipitate-free zones of high strength aluminium alloys—I. The model[J]. Acta Materialia, 1996, 44(5): 1857-1864.

[27] JIANG H, FAULKNER R G. Modelling of grain boundary segregation, precipitation and precipitate-free zones of high strength aluminium alloys—II: Application of the models[J]. Acta Materialia, 1996, 44(5): 1865-1871.

[28] 李朝兴, 徐 静, 李劲风, 贾志强, 郑子樵. 不同时效制度7075铝合金力学性能及腐蚀性能综合比较研究[J]. 铝加工, 2009(5): 10-16.

LI Chao-xing, XU Jing, LI Jin-feng, JIA Zhi-qiang, ZHANG Zi-qiao. Comparison of mechanical properties and corrosion behaviors of 7075 aluminum alloy at various aging systems[J]. Aluminium Fabrication, 2009(5): 10-16.

[29] 罗 勇, 许晓静, 张允康, 张振强. 强化固溶处理对7075铝合金晶间腐蚀和剥落腐蚀性能的影响[J]. 热加工工艺, 2012, 41(14): 203-208.

LUO Yong, XU Xiao-jing, ZHANG Yun-kang, ZHANG Zhen-qiang. Effect of enhanced-solid-solution on intergranular corrosion and exfoliation corrosion of 7075 Al alloy[J]. Hot Working Technology, 2012, 41(14): 203-208.

(编辑 陈卫萍)

基金项目:辽宁省高等学校优秀人才计划项目(LR2011003);辽宁省创新团队项目(LT2002004)

收稿日期:2013-06-11;修订日期:2013-11-18

通信作者:曲迎东,教授,博士;电话:024-25497132;E-mail:quyingdong@163.com