切割对铝合金厚板残余应力分布影响的仿真与分析

闫鹏飞,吴运新,廖凯

(中南大学 机电工程学院,湖南 长沙,410083)

摘 要:使用有限单元法对切割加工过程对于铝合金厚板残余应力分布造成的影响进行研究,利用大型商用非线性有限元软件MSC.Marc提供的单元生死技术建立7075铝合金厚板切割的有限元模型,对切割前、后铝合金厚板内应力的变化进行模拟,并进行实验验证。仿真和实验结果表明:切割产生的边缘处由于失去原有相邻的材料对其的拉伸或压缩作用,应力减小,应力变化随着与边缘距离的增加而减小;与边缘的距离超过板材厚度的部分应力变化很小,可以忽略;切割对表面应力的影响较大、对芯部应力影响较小;对与其方向垂直的应力影响较大,对与其方向平行的应力影响较小。

关键词:铝合金;厚板;应力场;切割加工;有限元仿真

中图分类号:TG146.2 文献标志码:A 文章编号:1672-7207(2010)06-2213-05

Simulation and analysis of effect of cutting machining on residual stress distribution in thick aluminum alloy plate

YAN Peng-fei, WU Yun-xin, LIAO Kai

(School of Mechanical and Electrical Engineering, Central South University, Changsha 410083, China)

Abstract: Finite element method was used to study the variation of residual stress distribution in thick aluminum plate. The finite element model was achieved by virtue of non-linear software MSC marc, in which the birth-death element is available. The variation of residual stress in thick aluminum alloy plate before and after cutting was simulated and several experiments were done to verify the results of the simulation. The results show that the residual stress on the boundary formed by the cutting decrease is caused by losing the adjacent material; the variation value decreases as the distance to the boundary increases; as the value of distance is greater than the thickness, the variation value is very small, even can be ignored; cutting has greater influence on the surface stress than core stress and has greater influence on the stress that is vertical to its direction than the one that is parallel to it.

Key words: aluminum alloy; thick plate; stress field; cutting machining; finite element simulation

随着航空工业的发展,对现代飞机的性能要求不断提高,飞机的结构设计发生了较大变化。从零件结构上来看,为了减少质量,整体结构件在新机型中得到了尽可能多的应用。航空整体结构件通常采用高强度变形铝合金厚板直接铣削加工而成[1-2]。7×××系高强铝合金是一类应用于航空航天工业的铝合金材 料[3-5],现代航空航天工业的高速发展对7×××系合金的大尺寸高性能构件尤其是高性能厚板材料的需求日趋迫切[6]。残余应力造成的铝合金轧制板材加工变形是高性能铝材加工过程中的一大问题,因而,对铝合金材料应力的研究越来越受到重视。切割是对铝合金轧制板材进行加工的第1步,通过切割可以将外型尺寸较大的轧制铝合金板分割成尺寸合适的毛坯件,以便进行后续加工或投入使用。因此,对切割加工对于板材应力分布的影响进行研究具有一定的实际意义。由于目前的测试方式多为破坏式的检测,在截取试样时改变了其应力状态;X线衍射法可对试样应力进行非接触式测量,但仅适合于测试表面或浅层的残余应力[7-8],为此,本文作者拟通过有限元仿真的方法探讨切割对铝合金厚板残余应力分布的影响规律。

1 有限元仿真

使用大型非线性有限元商业软件MSC.Marc建立淬火铝合金厚板7075T73的切割有限元模型。

1.1 初始条件

要研究切割过程对于材料应力场分布的影响,必须首先测试材料初始的应力场分布,进而作为仿真的初始条件施加到有限元模型中。目前,残余应力的测试方法虽多,但都存在一定的局限性,特别是在测试材料内部三维残余应力时,由于其分布复杂,即使能够准确测量材料初始的残余应力场,也难以将其准确地施加到有限元模型中[9]。因此,类似问题的研究中多以“铝合金厚板残余应力在某一深度上均匀分布”的假设为前提[10-12]。

本文作者采用有限元法模拟材料淬火热处理工艺,计算得到试样内部的初始残余应力场。对于有限元模拟淬火残余应力的过程可以分为热和力2个部分进行准耦合分析:先进行热传导分析,采用热传导方程求解淬火过程的温度场;再读入前面计算得到的随着时间变化的温度场,进行瞬态热应力场分析,从而实现准耦合模拟[13],模拟过程中的各种热力学参数(换热系数、比热容、弹性模量和屈服极限等)均随着温度的变化而变化[14-16],淬火残余应力场就是试样温度冷却至室温时热应力场的最终状态。在切割过程的有限元模型中可以将其映射到模型中,作为初始残余应力。

1.2 切割过程模拟和边界条件

对于切割过程的模拟是仿真模型的关键,刀具与铝合金板接触过程中热与力的耦合作用会对残余应力场的分布造成一定的影响,但影响范围有限[17]。假设加工过程中冷却条件良好则可忽略温升对应力场的作用。由于切割加工过程中铝合金材料发生弹塑性变形的本构关系及切屑分离准则难以确定,故本文建立的有限元模型中不引入刀具,而直接使用单元生死技术对切割过程进行模拟。

单元生死技术就是将要去除单元的状态设置为“不激活”,将该单元的质量矩阵、刚度矩阵等乘以1个极小的系数(一般约为10-6),同时将其应力、应变置零,并在后处理中不显示该单元,从而达到将其切除的目的[17-18]。

MSC.Marc提供了单元生死的用户接口,可以通过编写子程序实现对特定单元的“杀死”和“激活”的操作。本文针对具体情况编制了单元生死的子程序,利用MSC.Marc对于单元的有序编号,确定需要去除的单元,建立单元去除顺序与有限元计算增量步之间的对应关系,实现按照实际切割的顺序将单元去除。

本文中选择使用MSC.Marc提供的7号八节点六面体单元。在切割过程中,对底面节点施加x,y和z 3个方向的位移约束,切割完成后对原有约束释放,换为约束试样(切割出的小块铝板)底面靠近中心位置的3个节点。

1.3 仿真参数

有限元模型中试样材料为7075铝合金,其弹性模量为68 GPa,泊松比为0.33[19]。

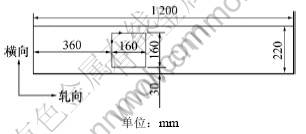

本文仿真过程模拟的是从长×宽×高为1 200 mm×220 mm×30 mm的7075铝合金厚板中切割出长×宽×高为160 mm×160 mm×30 mm的铝合金小板,小板在原大板靠近中心的位置,如图1所示。

图1 锯切试样位置示意图

Fig.1 Position of sample in plate

1.4 仿真结果

图2所示为切割前后试样沿轧向中心线上表面应力和芯部应力的变化,图中横坐标x与图1中坐标系的横坐标x相同,其变化具有以下规律:

(1) 越靠近边缘变化越大,这是因为切割加工之后,边缘部分失去了原来与其相邻的材料的拉伸或压缩作用,原有的应变能释放,应力随之释放,应力 减小。

(2) 距离边缘30 mm以上的部分应力变化则较为平缓、均匀,且变化量都在10 MPa以内。表面部分的压应力有所增大,芯部的拉应力则有所减小,但这部分的应力变化很小。

(3) 板材的表面处于开放的状态,与芯部相比其所受临近材料的约束作用较小,故切割后表面应力变化也相应较大。

图2 轧向中线上轧向应力曲线

Fig.2 Rolling stress on rolling-direction middle line

图3所示为轧向应力沿横向中线上的变化,图3中横坐标y与图1中坐标系的纵坐标y相同。由图3可见:其表现出与前面所述相似的规律;边缘部分由于失去了原有材料的约束作用,应力减小,但由于切割方向与应力方向平行,即失去的主要约束的方向与应力方向垂直,故轧向应力变化较小且影响范围也相应较小,有效的影响范围为距离边缘15 mm以内的 部分。

图3 横向中线上轧向应力曲线

Fig.3 Rolling stress on transverse middle line

切割前后,铝合金板的横向应力也具有类似的变化规律。仿真结果表现出以下规律:

(1) 切割加工产生的新的边缘处,应变能得到释放,铝合金板的残余应力减小,且变化量随着与边缘距离的增加逐渐减小,这一作用影响的距离不超过板材的厚度。

(2) 与新的边缘距离超过板材厚度的部分应力变化较为均匀,且整体上呈现出拉应力略有减小、压应力略有增大的趋势,但变化很小。

(3) 切割对于应力影响还与切割加工的方向有关,对垂直于切割方向的应力影响较大,对平行于切割方向的应力影响较小。

2 实验

2.1 实验方案

对长×宽×高为1 200 mm×220 mm×30 mm的7075铝合金厚板进行淬火处理,得到与仿真初始条件基本吻合的残余应力场,在靠近其中间的部分中划定长×宽为160 mm×160 mm的区域进行表面残余应力检测。对淬火铝合金板进行切割,取出前面检测的区域作为试样,其长×宽×高为160 mm×160 mm×30 mm,并对试样进行表面残余应力检测,比较切割前后表面残余应力的变化。

使用DK7732型电火花数控切割机床对铝合金板进行切割,电火花线切割不存在切削力的作用,虽然在局部产生高温,但因其接触范围小,且冷却条件良好,故切割过程的热效应可以忽略,符合有限元模型中的诸多假设条件。

使用PROTO iXRD应力测试设备进行表面残余应力的无损检测。分别沿轧向和横向的2条中线对试样表面进行应力检测,对比其切割前后表面残余应力的变化,测试点的位置如图4所示。

2.2 实验结果及讨论

图5和图6所示分别为沿轧向中线和横向中线2条线上表面残余应力切割加工前、后的变化量?σ,其横坐标分别对应图1中坐标系的x和y。图5与图6两图中边缘部分的应力变化试验值与仿真值存在较大的误差,这与有限元网格划分密度有限有关,同时,建立有限元模型过程中假设的理想边界条件及环境等与实际情况的差异也具有一定的影响;与边缘距离超过板厚度后,试验测得结果与仿真结果有相同的变化趋势,即变化较为均匀且变化很小,而且两者在数值上也较好地吻合。

图4 测试点位置示意图

Fig.4 Position of tested points

图5 轧向中线上轧向表面应力变化曲线

Fig.5 Variation curves of surface stress on rolling-direction middle line

图6 横向中线上轧向表面应力变化曲线

Fig.6 Variation curve of surface stress on transverse middle line

3 结论

(1) 建立切割加工的有限元模型,得到切割加工前、后铝合金板材内部残余应力的变化规律:边缘部分应变能释放,应力减小,这一作用影响的距离不超过板材厚度;切割对于某一方向应力的影响程度还与切割加工的方向有关。

(2) 实验数据曲线与有限元仿真数据曲线较吻合,验证了有限元模型的正确性。可以利用其进一步推测铝合金厚板切割加工前后整体应力变化趋势。

(3) 建立的有限元切割模型忽略了切削力和切削热的影响,其具体的影响范围和作用规律有待进一步研究。

参考文献:

[1] Budak E, Altintas Y. Modeling and avoidance of static form errors in peripheral milling of plates[J]. International Journal of Machine Tools & Manufacture, 1995, 35(3): 459-476.

[2] Tsai J S, Liao C L. Finite-element modeling of static surface errors in the peripheral milling of thin-walled workpieces[J]. Journal of Material Processing Technology, 1999, 94(3): 235-246.

[3] 张新明, 张翀, 刘胜胆, 等. 轧制变形量对7A55铝合金淬火敏感性的影响[J]. 中南大学学报: 自然科学版, 2007, 38(4): 589-594.

ZHANG Xin-ming, ZHANG Chong, LIU Sheng-dan, et al. Effect of rolling reduction on quench sensitivity of aluminium alloy 7A55[J]. Journal of Central South University: Science and Technology, 2007, 38(4): 589-594.

[4] 游江海, 李鹏辉, 李国锋, 等. 回归处理工艺对7050铝合金力学和晶间腐蚀性能的影响[J]. 中南大学学报: 自然科学版, 2008, 39(5): 968-974.

YOU Jiang-hai, LI Peng-hui, LI Guo-feng, et al. Effect of retrogression processing on mechanical properties and intergranular corrosion of 7050 aluminum alloy[J]. Journal of Central South University: Science and Technology, 2008, 39(5): 968-974.

[5] Gang S, Gerezo A. Early-stage precipitation in Al-Zn-Mg-Cu alloy(7050)[J]. Acta Materialia, 2004, 52: 4503-4516.

[6] 杨守杰, 戴圣龙. 航空铝合金的发展回顾与展望[J]. 材料导报, 2005, 19(2): 75-80.

YANG Shou-jie, DAI Sheng-long. A glimpse at the development and application of aluminum alloys in aviation industry[J]. Material Review, 2005, 19(2): 75-80.

[7] Donna W. Residual stress measurement techniques[J]. Advanced Materials & Process, 2001, 159(88): 30-33.

[8] Wyatta J E, Berry J T. A new technique for the determination of superficial residual stresses associated with machining and other manufacturing processes[J]. Journal of Materials Processing Technology, 2006, 171: 132-140.

[9] 毕运波, 柯映林, 董辉跃. 航空铝合金薄壁件建工变形有限元仿真与分析[J]. 浙江大学学报: 工学版, 2008, 42(3): 397-402.

BI Yun-bo, KE Ying-lin, DONG Yue-hui. Finite element simulation and analysis of deformation in machining of aeronautical aluminum alloy thin-walled workpiece[J]. Journal of Zhejiang University: Engineering Science, 2008, 42(3): 397-402.

[10] Bouzid S W, Ben S N, Lebrun J L. Influence of machining by finishing milling on surface characteristics[J]. International Journal of Machine Tool & Manufacture, 2001, 41(3): 443-450.

[11] Prime M B, Hill M R. Residual stress and stress relief in homogeneity in aluminum plate[J]. Scripta Materialia, 2002, 46(1): 77-82.

[12] 黄志刚, 柯映林, 董辉跃. 框类整体结构件铣削加工顺序的有限元模型[J]. 浙江大学学报: 工学版, 2005, 39(3): 368-372.

HUANG Zhi-gang, KE Ying-lin, DONG Hui-yue. Finite element model of milling process sequence for frame monolithic components[J]. Journal of Zhejiang University: Engineering Science, 2005, 39(3): 638-372.

[13] 柯映林, 董跃辉. 7075铝合金厚板预拉伸模拟分析及其在淬火残余应力消除中的作用[J]. 中国有色金属学报, 2004, 14(4): 639-645.

KE Ying-lin, DONG Hui-yue. Pre-stretching process and its application in reducing residual stress of quenched 7075 aluminum alloy thick-plates[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(4): 639-645.

[14] 姚灿阳. 7050铝合金厚板淬火温度场及内应力场的数值模拟研究[D]. 长沙: 中南大学机电工程学院, 2007: 18-22.

YAO Can-yang. A study on the numerical simulation of distribution of temperature and stress in quenching process of aluminum alloy 7050[D]. Changsha: Central South University. School of Mechanical and Electrical Engineering, 2007: 18-22.

[15] 张园园, 吴运新, 廖凯. 铝合金厚板淬火过程换热系数的求解与验证[J]. 热加工工艺, 2008, 37(12): 87-97.

ZHANG Yuan-yuan, WU Yun-xin, LIAO Kai. Solution and validation of heat conduct equation for aluminum alloy ultra-thickness plate during quenching[J]. Hot Working Technology, 2008, 37(12): 87-97.

[16] 廖凯, 吴运新, 张园园. 铝合金厚板淬火表面换热系数的离散解析求法[J]. 材料热处理学报, 2009, 30(1): 192-196.

LIAO Kai, WU Yun-xin, ZHANG Yuan-yuan, A discretized and analytical method of heat transfer coefficient during quenching of aluminum alloy plate[J]. Transactions of Materials and Heat Transfer, 2009, 30(1): 192-196.

[17] 王树宏. 航空铝合金厚板初始残余应力及其对铣削变形影响的基础研究[D]. 南京: 南京航空航天大学机电学院, 2005: 54-57.

WANG Shu-hong. Study on initial residual stress and their effects on milling distortion for thick aero-aluminum-alloy plate[D]. Nanjing: Nanjing University of Aeronautics and Astronautics. College of Mechanical and Electrical Engineering, 2005: 54-57.

[18] 王秋成. 航空铝合金残余应力消除及评估技术研究[D]. 杭州: 浙江大学机械与能源工程学院, 2003: 95-97.

WANG Qiu-cheng. Evaluation and relief of residual stresses in aluminum alloys for aircraft structure[D]. Hangzhou: Zhejiang University. College of Mechanical and Energy Engineering, 2003: 95-97.

[19] 肖亚庆, 谢水生, 刘静安, 等. 铝加工技术实用手册[M]. 北京: 冶金工业出版社, 2005: 176-196.

XIAO Ya-qing, XIE Shui-sheng, LIU Jing-an, et al. Practicality manual of aluminum machining technology[M]. Beijing: Metallurgy Industry Press, 2005: 176-196.

(编辑 陈爱华)

收稿日期:2009-10-31;修回日期:2009-12-28

基金项目:国家重点基础研究发展规划(“973”计划)项目(2005CB623708,2010CB731703)

通信作者:吴运新(1963-),男,广东兴宁人,博士,教授,从事机械结构动力学、机电控制和冶金机械等研究;电话:0731-88830813;E-mail: wuyunxin@mail.csu.edu.cn