DOI:10.19476/j.ysxb.1004.0609.2018.08.06

微量Mn添加对Mg-6Zn-3Al镁合金非枝晶组织演变的影响

张 玉1,黄晓锋1, 2,郭 峰1,杨健长1,马 颖1, 2,郝 远1, 2

(1. 兰州理工大学 省部共建有色金属先进加工与再利用国家重点实验室,兰州 730050;

2. 兰州理工大学 有色金属合金及加工教育部重点实验室,兰州 730050)

摘 要:利用光镜(OM)、扫描电镜(SEM)、X射线衍射仪(XRD)研究了Mg-6Zn-3Al-xMn(x%=0%, 0.1%, 0.3%, 0.5%,质量分数)合金的铸态组织和在等温热处理过程中的非枝晶组织演变规律。结果表明:铸态基体合金由α-Mg、Mg2Zn3、Mg7Zn3和Mg32(Al, Zn)49)相组成。添加Mn后,析出了AlMn和Al8Mn5相,且随Mn含量的增加,晶粒逐渐得到细化。合金经580 ℃等温保温30 min后,获得的非枝晶组织由初生α1-Mg颗粒和包裹在共晶组织中二次水淬凝固形成的α2-Mg颗粒及分布在初生颗粒间呈蜂窝状的共晶相组成。随着Mn含量增加,固相颗粒的平均尺寸和形状因子呈先减小后增加的趋势,组织中液相比例逐渐减少。当Mn含量(质量分数)为0.1%时,可获得近似球状、细小圆整、均匀分布的固相颗粒。在等温热处理过程中,溶质扩散和界面张力对组织演变起主导作用。Zn和Al溶质原子在液相中的成分起伏是初生颗粒在分离和球化过程中产生颈缩的重要原因。

关键词:Mg-6Zn-3Al合金;Mn含量;等温热处理;组织演变;颈缩

文章编号:1004-0609(2018)-08-1532-10 中图分类号:TG146.2 文献标志码:A

镁合金是工业应用中最轻的金属结构材料,其低密度、高比强度、高热导率、良好的减震性能等优点使其在汽车、航空航天、国防军工和交通运输等领域有着巨大的应用潜力,被认为是目前最具发展前景的金属材料[1-2]。目前,应用最广泛的镁合金系是以Mg-Al和Mg-Zn为基体的Mg-Al-Zn和Mg-Zn-Zr三元系,如AZ31、AZ80、AZ91、ZK31和ZK60等合金[3-4]。这些合金由于具有良好的铸造性能且成本较低而得到了大力的发展,但其较差的室温力学性能且在熔融状态下易燃、易爆和易氧化等。这些缺点为上述合金系及其他镁合金产品的生产及更广泛的商业应用带来了困难和阻碍。有研究报道[5],镁合金可以通过合金元素的添加来实现晶粒的细化和组织的改善,进而提高力学性能。所以,最近几年新型镁合金的研究成为众多学者们的关注焦点。近年来已开发的新型Mg-Zn-Al系合金有ZA65和ZA72[6-7]等。此外,相比传统铸造方法,一些新的成形方法能够改善成形过程中热冲击、氧化等缺点。众所周知,19世纪70年代美国麻省理工学院FLEMINGS教授提出的半固态成形技术是一种新型的成形加工工艺[8]。半固态成形技术综合了传统铸造和锻造两种成形方法的优点[9],成形加工温度低,有利于减少镁合金的易燃、易爆和氧化等缺点,对模具的热冲击小进而提高模具使用寿命等优点。此外,具有凝固收缩小、偏析小、节约能源、产品质量较高、近终成形等优良特性,被誉为21世纪新一代金属成形技术[10-11]。在半固态成形过程中,如何获得良好的半固态非枝晶组织是半固态成形技术的基础和关键。目前,制备半固态非枝晶组织的方法有机械搅拌法、超声振动法和等温热处理法[12-14]等。其中,等温热处理法省略了半固态坯料的制备,在半固态成形前的二次加热过程中实现半固态非枝晶组织,其工艺简单,成本低廉,生产效率高,受到了广大研究者的关注[15-16]。合金化是细化晶粒的一种有效方法。Mn作为镁合金常用添加元素之一,可以改善镁合金的耐蚀性能,细化晶粒和提高力学性能。SABRINA等[17]研究了Mn含量对AZ31和AZ10挤压镁合金力学性能与疲劳性能的影响,发现随着Mn含量增加,晶粒逐渐细化,合金抗拉强度与硬度有所提高。STANFORD等[18]研究发现,微量Mn加入到Mg-Zn-Al合金中后,形成Al-Mn相颗粒,为新晶核的孕育形核起基底的作用,从而起到细化晶粒的效果。王春建等[19]研究了Mn元素对高纯Mg-3Al合金晶粒尺寸的影响,结果表明,当合金中的Mn元素含量小于0.21%时,合金的晶粒尺寸变化不大;但当Mn元素含量大于0.21%时,Mn元素的存在则使合金的晶粒尺寸迅速增大。KHAN等[20]研究了Mn含量对挤压态镁合金的影响,结果表明,Mn的添加细化了晶粒,同时提高了AZ61合金的抗拉强度和疲劳寿命。因此,基于以上关于Mn的报道,可以猜想添加Mn能够有效地细化晶粒。为此,本文作者以Mg-Zn-Al合金的半固态组织研究为前提,在自主开发的新型Mg-6Zn-3Al(ZA63)合金中添加不同量的Mn,采用等温热处理法在相同保温条件下研究Mn含量对ZA63合金半固态非枝晶组织演变的影响。同时,为Mg-Zn-Al半固态合金的设计开发、合金元素的选择以及半固态成形提供实践指导意义。

1 实验

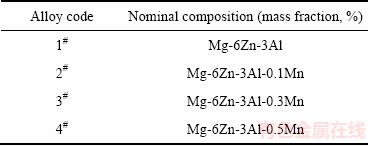

本研究中采用金属材料纯度约为99.99%Mg、Zn和Al锭及Mg-5%Mn中间合金来配置Mg-6Zn-3Al- xMn合金,设计的4种合金成分如表1所示。实验合金在熔炼之前大致预热至200 ℃。合金的熔炼在SG2-7.7kW井式电阻炉中完成。为防止合金的氧化燃烧,熔炼过程中采用RJ-2覆盖剂和Ar对熔体进行保护。熔炼工艺为:加入的Mg锭完全熔化后于680 ℃加入Zn和Al,待温度升至760 ℃时加入Mg-Mn合金并保温30 min。随后熔体温度降至740 ℃时,用钟罩将2%(占实验合金总质量的比例)的C2Cl6通过人工搅拌加入到熔体中以精炼除渣、除气。精炼完后迅速撇净熔体表面的残渣并静止保温10~15 min。最后,待温度降至720 ℃时将其浇注于已预热至210 ℃左右的金属铸型中获得所需的铸锭。

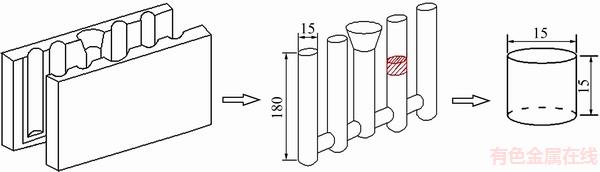

在棒状铸锭的相同位置处用线切割获取d 15 mm×15 mm的圆柱状试样,实验试样取样过程如图1所示。根据文献[21],将获取的试样放置在d 40 mm×30 mm钢制小坩埚中,随后在设定的温度580 ℃下保温30 min,达到保温时间后取出试样且迅速进行水淬以保持部分重熔组织。等温热处理时为了避免合金试样燃烧,用RJ-2熔剂覆盖保护。铸态和热处理后的试样依次经粗磨、精磨,最后抛光后分别采用4%硝酸乙醇和8%硝酸溶液侵蚀。利用MeF-3光学显微镜、场发射扫描电镜(SEM)和配套的EDS观察非枝晶组织演变和微区成分分析。采用X射线衍射仪(XRD, D/max-2400)分析合金中的物相组成,Cu靶,扫描角度10°~90°。利用Image-Pro Plus 6.0软件分析半固态组织的液相率、初生固相颗粒的形状因子F和平均尺寸D。初生固相颗粒α-Mg平均尺寸D和形状因子F[22]计算公式如下:

(1)

(1)

(2)

(2)

式中:Ai表示单个固相颗粒的面积;N表示固相颗粒总数;Pi表示单个固相颗粒的周长;形状因子F越趋近于1时,表明初生α-Mg颗粒越圆整。

表1 实验合金设计成分

Table 1 Chemical compositions of studied alloys

2 实验结果

2.1 铸态组织

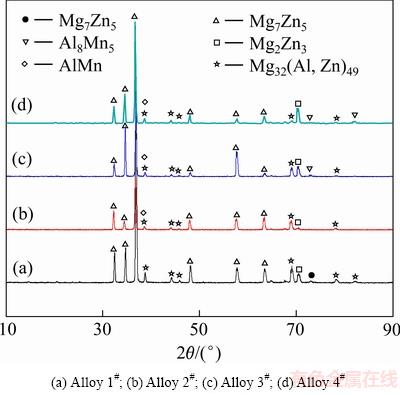

图2所示为铸态Mg-6Zn-3Al-xMn合金的XRD谱。

图1 模具、坯锭和实验试样示意图

Fig. 1 Schematic diagram for permanent mould, ingot and dimension of experimental sample (unit: mm)

图2 Mg-6Zn-3Al-xMn铸态合金的XRD谱

Fig. 2 XRD patterns of as-cast Mg-6Zn-3Al-xMn alloys

由图2可看出,合金1#中主要由α-Mg、二元合金相Mg2Zn3和Mg7Zn3及三元合金相Mg32(Al, Zn)49组成。添加不同量的Mn后,由图2(b)、(c)和(d)看出,合金中除了α-Mg、Mg2Zn3、Mg7Zn3和Mg32(Al, Zn)49相外,还有AlMn和Al8Mn5相生成,且Al8Mn5相的衍射峰随着Mn含量提高而增加。根据存在的报道[23],Al8Mn5属于密排六方晶体结构(a=1.273 nm,c=1.588 nm)。

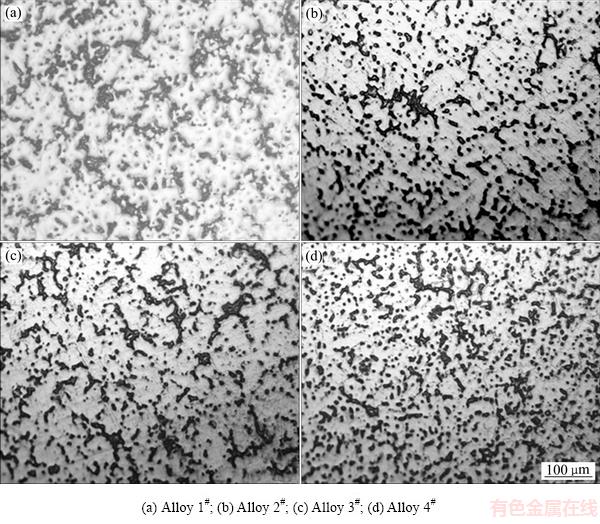

图3 Mg-6Zn-3Al-xMn合金的铸态显微组织

Fig. 3 Optical microstructures of as-cast Mg-6Zn-3Al-xMn alloys

图3所示为铸态Mg-6Zn-3Al-xMn合金的OM组织。由图3可以看出,合金的显微组织都呈典型的非平衡凝固枝晶结构,主要由呈白色基体α-Mg和沿晶界呈黑色半连续网状或孤立弥散的共晶相组成。由于凝固过程属于非平衡结晶,形成了偏聚于晶界及枝晶臂间的化合物相。这些化合物被推移到固液结晶前沿富集,增加了熔体的成分过冷,抑制了液相溶质原子向固相中扩散,起到了抑制晶粒长大的作用。同时看到,添加微量Mn后,相比基体合金,弥散的第二相粒子逐渐增多。根据文献[24]的报道,Mn元素添加到Mg-Al系或Mg-Zn-Al系合金中后,与合金中的Al优先化合产生多种Al-Mn金属间化合物。在非平衡凝固时,Al-Mn相可以包括Al6Mn、 Al4Mn、Al11Mn8以及许多的亚稳定相。这些Al-Mn相粒子一般弥散孤立地分布在镁合金的晶内和晶界处,形状有针状、十字状和角块状。由图3(a)可看出,合金1#的组织主要由枝晶状α-Mg固溶体与晶界上和枝晶间的低熔点共晶相组成,晶粒比较粗大。从图3(b)可看出,添加0.1%Mn后,合金2#中α-Mg晶粒得到了稍微的细化,且孤立弥散的第二相粒子趋于增多,晶界处共晶相的形貌趋于纤细。从图3(c)看出,添加0.3%Mn后,相比合金2#,合金3#中晶粒尺寸和弥散的第二相粒子数量变化不大,枝晶结构变得发达且共晶相的形貌趋于粗化。如图3(d)所示,当Mn含量达到0.5%后,相比合金1#、2#和3#,合金4#中大量非平衡共晶相沿晶界或枝晶边界断续分布,晶粒得到了明显细化且弥散孤立分布的第二相粒子显著增多。

2.2 非枝晶组织

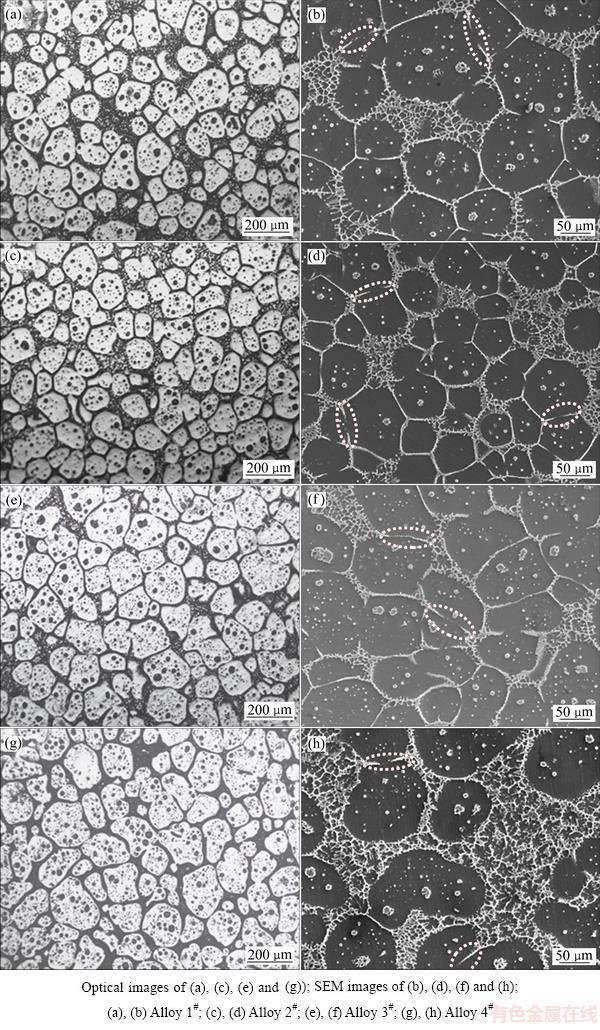

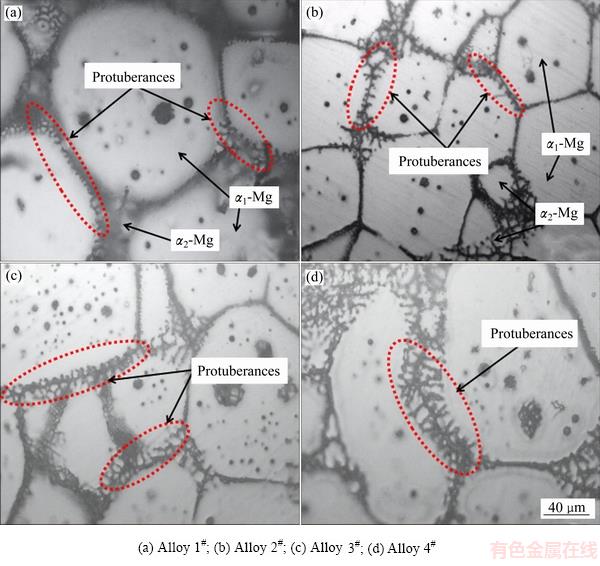

图4 Mg-6Zn-3Al-xMn合金在580 ℃保温30 min的非枝晶显微组织

Fig. 4 Non-dendritic microstructures of Mg-6Zn-3Al-xMn alloys treated at 580 ℃ for 30 min

在半固态等温处理过程中,合金重熔组织演变的本质是溶质原子的扩散。图4所示为合金(1#、2#、3#和4#)在580 ℃保温30 min的OM和SEM非枝晶组织。如图4所示,在相同的等温条件下,4种合金的显微组织形貌几乎相近,即所有合金的初生α-Mg晶粒已经从原始树枝晶转变成许多大小不等、形状不规则或近球状的固相颗粒且其形貌随着Mn含量的变化而变化。同时看到,合金经过重熔后,相比原始铸态组织的共晶组织,半固态组织的共晶组织形貌发生了极其显著的变化,即由原始的粗大紧密形态变成了蜂窝状的结构,部分共晶组织的边缘呈“锯齿”状形貌,这是由于液相溶质扩散引起的浸渗所致,也表明溶质扩散尚未彻底。此外,合金的初生颗粒在分离和球化过程中产生了颈缩现象。 如图4所示,在固相颗粒内存在一些大小不等呈麻点状的“小液池”。这些“小液池”形成归于以下原因:胡勇等[25]认为由于合金组织中大量缺陷(如空位、偏析等)的存在使原子不规则排列,从而使该区域出现能量起伏,然后在外界能量的作用下液相在缺陷较多的位置优先析出,形成“小液池”。另外,在等温处理时相邻枝晶臂搭接过程中由于时间短而来不及充分扩散致使将一些共晶相包裹在初生α-Mg内,随后保温温度达到共晶温度以后,这些被包裹的共晶相熔化形成具有晶内液池特征的组织。此外,在初次铸造非平衡凝固过程中,部分溶质原子扩散到α-Mg内,并在初生晶内以原子集团的形式富集,致使在重熔过程中,这些溶质原子富集区域出现液相,形成这些“小液池”。

对合金半固态组织的液相率和初生α-Mg颗粒的平均尺寸及其圆整度进行了统计分析,其结果如表2所示。从图4(a)和(b)看出,合金1#中,α-Mg固相颗粒呈不规则或近球状的形态分布在贯穿整个颗粒间的液相中,几乎所有的颗粒相互分离且晶粒边界完全被润湿。此外,部分初生颗粒在分离过程中产生了颈缩现象(红色椭圆区域)。从表2可知,初生颗粒尺寸和形状因子分别为 103 μm和1.35,液相率为38%。如图4(c)和(d)所示,添加0.1%Mn后,相比合金1#,初生α-Mg颗粒的球化速率加快,等轴化十分显著,颗粒的圆整度较好且细小;固相颗粒间形成的液膜将固相颗粒分离,均匀地分布在液相中;液相含量趋于减少,同时颗粒间也有颈缩现象。从表2可知,初生颗粒尺寸和形状因子分别为 98 μm和1.21,液相率为32%。冯凯等[21]认为:在半固态非枝晶组织演变过程中,晶界、亚晶界能为溶质原子的扩散及液相的浸渗提供便捷的通道,溶质原子沿着亚晶界的扩散速度更快,共晶组织溶解也更快,随后在亚晶界上富集的溶质原子熔化促使晶粒分离成小颗粒。加入0.1%Mn后,初次凝固结晶时可能晶粒内生成了相对多的亚结构,致使增加了一定量的小角度亚晶界,这些亚晶界促进了较细小、圆整颗粒的形成。如图4(e)和(f)所示,添加0.3%Mn后,相比合金2#,固相颗粒的圆整度趋于恶化,颗粒尺寸不均匀且趋于增大,液相比例进一步减小。从表2可知,初生颗粒尺寸和形状因子分别为 121 μm和1.53,液相率为21%。如图4(g)和(h)所示,添加0.5%Mn后,相比合金3#,颗粒的圆整度进一步恶化,颗粒尺寸进一步增大。此外,在某些区域,存在着一定数量的尺寸粗大固相颗粒,同时也有颗粒间的颈缩存在。从表2可知,初生颗粒尺寸和形状因子分别为 128 μm和1.98,液相率为20%。由上述可知,当Mn含量超过0.1%后,获得的初生颗粒形态趋于恶化,形状因子的增大反映颗粒球化效果不佳。合金3#和4#中非枝晶组织恶化的原因可归于以下方面:铸态的合金3#和4#随着Mn含量增加,晶界处形成较多的高熔点共晶产物Al8Mn5[23](见图2(c)和(d))。这种稳定的化合物熔化时需要足够的熔化潜热,其在保温过程中熔化较为缓慢,使原子的互扩散速度减缓,致使非枝晶组织演变表现迟缓,进而表现为固相颗粒的尺寸较大,圆整度较差。此外,这种高熔点稳定化合物在等温处理过程中阻碍了热量的传递,加之能量起伏引起局部温度不均使固相粒子的分离和球化过程受到阻碍,从而降低组织演变的进程。

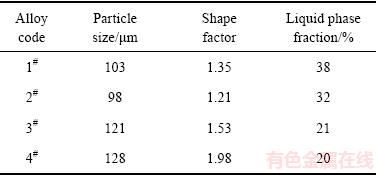

表2 实验合金的颗粒尺寸、形状因子和液相率统计结果

Table 2 Particle size, shape factor and liquid phase fraction of alloys

图5所示为实验合金在580 ℃保温30 min的OM非枝晶组织放大图。由图5看出,通过等温热处理形成的非枝晶组织由初生的α1-Mg颗粒和包裹在共晶组织中二次水淬凝固形成的α2-Mg颗粒组成[26]。同时看到,α1-Mg颗粒边缘的部分呈“锯齿”状(红色椭圆区域)。此外,看到部分α2-Mg颗粒完全依附在α1-Mg颗粒的表面并光滑牢靠地融为一体,而另外一部分α2-Mg颗粒完全游离在液相中。众所周知,重熔过程是个动态平衡过程,熔化和凝固结晶同时进行。根据异质形核理论,液态熔体中高熔点的化合物、微小的杂质质点等,它们通常是晶胚依附孕育形核的衬底,有可能成为α-Mg的形核核心,促进其形核析出。同时熔体中还会产生一些富含Mg、Zn和Al或Mg、Zn、Al和Mn元素的较大短程有序的原子集团。当合金试样水淬凝固时,在结构起伏、能量起伏和成分起伏下,液相中的杂质质点和短程有序的原子集团将发挥晶核核心作用,在较小的过冷度下孕育形核,促进晶粒产生增值。由图4可知,初生固相颗粒几乎完全被液相润湿,故固液间的润湿角较小。根据金属凝固原理[27],润湿角越小,球面的曲率半径越大,致使在较小的过冷度下便可出现达到临界形核半径条件的晶胚。润湿角和异质形核晶胚临界半径的表达式如下:

(3)

(3)

(4)

(4)

式中: 为形核衬底与液相间的润湿角;

为形核衬底与液相间的润湿角; 为凝固过程的焓变;

为凝固过程的焓变; 合金平衡凝固温度;

合金平衡凝固温度; 固液界面能;

固液界面能; 为熔体过冷度。异质形核的临界形核功为

为熔体过冷度。异质形核的临界形核功为

(5)

(5)

式中: 为固液相单位体积的吉布斯自由能之差。由公式(5)可知,润湿角越小,孕育形核的形核功越小。合金经水淬凝固时,液相中的溶质原子在能量起伏和成分起伏下通过近程迁移和长程扩散,在最小界面能驱动下和具有相同晶粒取向作用下,在较小过冷度下形核的部分α2-Mg颗粒通过近程迁移逐步移向初生的α1-Mg颗粒并牢固的“焊合”在一起,然后依附生长,而非结合的一面形成凸凹的“锯齿”状。根据存在的研究[28],晶粒间的合并是有选择性的,当晶粒间具有相近的晶体学取向时更容易合并。至于游离的α2-Mg颗粒可能由于保温时间过短没有迁移到初生α2-Mg颗上,也有可能是与初生固相颗粒的晶粒取向差异而被“孤立”,最终导致游离在液相中。此外,如图5(d)所示,在合金4#中,初生固相颗粒间游离的α2-Mg颗粒显著增多。根据界面的关系,只有当固相颗粒之间的界面能gss与固液之间的界面能gsl满足gss<gsl时,两固相颗粒才能结合在一起[29]。这种较多游离固相颗粒的形成除了上述原因外,还可能由于过多Mn的加入,使固相颗粒间的gss增大,从而阻碍了α1-Mg和α2-Mg颗粒的合并。

为固液相单位体积的吉布斯自由能之差。由公式(5)可知,润湿角越小,孕育形核的形核功越小。合金经水淬凝固时,液相中的溶质原子在能量起伏和成分起伏下通过近程迁移和长程扩散,在最小界面能驱动下和具有相同晶粒取向作用下,在较小过冷度下形核的部分α2-Mg颗粒通过近程迁移逐步移向初生的α1-Mg颗粒并牢固的“焊合”在一起,然后依附生长,而非结合的一面形成凸凹的“锯齿”状。根据存在的研究[28],晶粒间的合并是有选择性的,当晶粒间具有相近的晶体学取向时更容易合并。至于游离的α2-Mg颗粒可能由于保温时间过短没有迁移到初生α2-Mg颗上,也有可能是与初生固相颗粒的晶粒取向差异而被“孤立”,最终导致游离在液相中。此外,如图5(d)所示,在合金4#中,初生固相颗粒间游离的α2-Mg颗粒显著增多。根据界面的关系,只有当固相颗粒之间的界面能gss与固液之间的界面能gsl满足gss<gsl时,两固相颗粒才能结合在一起[29]。这种较多游离固相颗粒的形成除了上述原因外,还可能由于过多Mn的加入,使固相颗粒间的gss增大,从而阻碍了α1-Mg和α2-Mg颗粒的合并。

图5 Mg-6Zn-3Al-xMn合金在580 ℃保温30 min的非枝晶显微组织

Fig. 5 Non-dendritic microstructures of Mg-6Zn-3Al-xMn alloys treated at 580 ℃ for 30 min

2.3 初生固相颗粒的演变分析

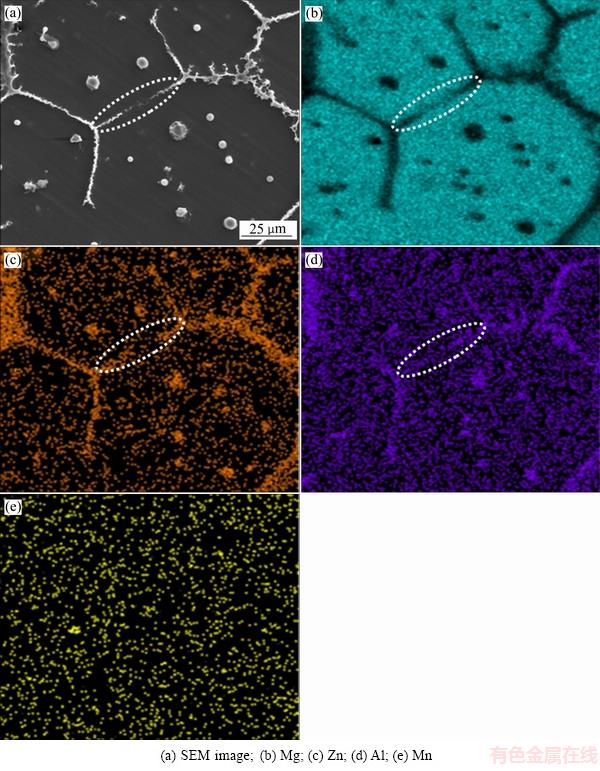

为了进一步研究实验合金在非枝晶组织演变过程中产生颈缩的原因,用SEM表征了合金#2在580 ℃保温30 min获得的非枝晶组织。图6所示为合金2#非枝晶组织的SEM像和合金中主要元素Mg、Zn、Al和Mn的面扫描分布图。在半固态等温处理时,可以认为液相中不存在对流作用,只在纯扩散条件下枝晶组织向非枝晶组织演变。如图6(a)所示,非枝晶组织在演变过程中枝晶臂处产生了颈缩现象(白色椭圆区域)。合金保温温度低于共晶温度时,溶质组元处于均质扩散状态。由于非平衡凝固使枝晶边缘处含有Zn或Zn和Al高浓度的非平衡共晶相,保温过程中这些溶质组元向枝晶臂内部扩散,促使第二相不断分解,使枝晶臂之间发生合并。当温度达到或高于共晶温度时,由于二次枝晶臂根部的浓度较高,因此,此处熔点较低,在保温过程中最先熔断脱落,脱离一次枝晶臂,形成大小不均、形状各异的颗粒。分离后的固相颗粒表面凸凹不平,因此,不同部位的曲率表现各异。固相颗粒表面不同曲率部位具有不同的平衡熔点,平衡熔点与曲率的关系式为[30]

(6)

(6)

式中: 为固液界面张力;

为固液界面张力; 为固液界面的熔点;Vs为固相摩尔体积;

为固液界面的熔点;Vs为固相摩尔体积; 为固液转变时摩尔焓变;k为固液界面曲率。根据公式(6),曲率半径越小,熔点越低,在重熔过程中越容易熔化[22, 31]。从图6(b)、(c)、(d)和(e)可知,Mg主要分布在固相中,Zn和Al在初生固相颗粒中分布比较均匀,而在液相中仍然存在富Zn和Al的偏析且在颈缩部位的两头方向偏析严重,Mn元素整体分布趋于均衡。由此可知,在颈缩部位的两头富集Zn和Al高浓度的非平衡共晶相,这些部位曲率半径小,在保温过程中Zn和Al在液相中的成分起伏波动较大,率先熔化成液相溶质原子在纯扩散条件下逐渐浸润渗入枝晶壁根部,且在界面张力作用下,颗粒逐渐分离和球化过程中产生了颈缩。

为固液转变时摩尔焓变;k为固液界面曲率。根据公式(6),曲率半径越小,熔点越低,在重熔过程中越容易熔化[22, 31]。从图6(b)、(c)、(d)和(e)可知,Mg主要分布在固相中,Zn和Al在初生固相颗粒中分布比较均匀,而在液相中仍然存在富Zn和Al的偏析且在颈缩部位的两头方向偏析严重,Mn元素整体分布趋于均衡。由此可知,在颈缩部位的两头富集Zn和Al高浓度的非平衡共晶相,这些部位曲率半径小,在保温过程中Zn和Al在液相中的成分起伏波动较大,率先熔化成液相溶质原子在纯扩散条件下逐渐浸润渗入枝晶壁根部,且在界面张力作用下,颗粒逐渐分离和球化过程中产生了颈缩。

图6 Mg-6Zn-3Al-0.1Mn合金在580 ℃保温30 min的非枝晶显微组织和面扫描结果

Fig. 6 Non-dendritic microstructure and map scanning results of Mg-6Zn-3Al-0.1Mn alloy treated at 580 ℃ for 30 min

3 结论

1) 基体合金铸态组织主要由α-Mg、Mg2Zn3、Mg7Zn3和Mg32(Al, Zn)49相组成。添加Mn后,有新相AlMn和Al8Mn5相生成。同时,随着Mn含量增加,晶粒逐渐得到显著细化,晶界处弥散孤立分布的第二相粒子趋于增多。

2) 实验合金经等温处理后获得的非枝晶组织由初生α1-Mg颗粒和包裹在共晶组织中二次水淬凝固形成的α2-Mg颗粒及分布在初生颗粒间呈蜂窝状的共晶相组成。

3) Mg-6Zn-3Al-xMn合金经580 ℃保温30 min后获得的非枝晶组织随Mn含量提高,固相颗粒的平均颗粒尺寸和形状因子呈先减小后增加的趋势,组织中液相比例逐渐减少。其中,Mn含量为0.1%时,获得了细小圆整、均匀分布的球状固相颗粒,颗粒平均尺寸和形状因子分别为 98 μm和1.21。

4) 等温保温过程中Zn和Al溶质原子的成分起伏是初生颗粒在分离和球化过程产生颈缩的主导机制。

REFERENCES

[1] 张胜利, 杨光昱, 刘少军, 介万奇. Mg-5.5Zn-2Gd-0.6Zr铸造镁合金的蠕变机制[J]. 中国有色金属学报, 2012, 22(2): 331-336.

ZHANG Sheng-li, YANG Guang-yu, LIU Shao-jun, JIE Wan-qi. Creep mechanism of Mg-5.5Zn-2Gd-0.6Zr cast alloy[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(2): 331-336.

[2] 严安庆, 王 霄, 刘楚明, 徐 璐. Mg-4Y-2.5Nd-0.6Zr合金显微组织及力学性能的研究[J]. 兵器材料科学与工程, 2013(5): 17-20.

YAN An-qing, WANG Xiao, LIU Chu-ming, XU Lu. Microstructure and mechanical properties of Mg-4Y-2.5Nd- 0.6Zr alloy[J]. Ordnance Material Science and Engineering, 2013(5): 17-20.

[3] 甘俊雄, 张 帆, 韩修柱, 刘楚明. 混合稀土对AZ80镁合金显微组织和力学性能的影响[J]. 兵器材料科学与工程, 2015, 38(1): 81-84.

GAN Jun-xiong, ZHANG Fan, HAN Xiu-zhu, LIU Chu-ming. Effects of mischmetal on microstructure and mechanical properties of AZ80 magnesium alloy[J]. Ordnance Material Science and Engineering, 2015, 38(1): 81-84.

[4] 朱蓓蓓, 孙扬善, 万晓峰, 薛 烽. Mg-Zn-Al系变形镁合金的显微组织和力学性能[J]. 东南大学学报(自然科学版), 2010, 40(3): 640-645.

ZHU Bei-Bei, SUN Yang-shan, WAN Xiao-feng, XUE Feng. Microstructures and mechanical properties of Mg-Zn-Al wrought magnesium alloys[J]. Journal of Southeast University (Natural Science Edition), 2010, 40(3): 640-645.

[5] WANG B G, WANG X, ZHOU J X, ZHANG G F, LIU F. Effects of solution heat treatment on microstructure and mechanical properties of Mg-3Al-1Si-0.3Mn-xSr alloy[J]. Materials Science and Engineering A, 2014, 618: 210-218.

[6] ZHANG Y, HUANG X F, MA Z D, LI Y, GUO F, YANG J C, MA Y, HAO Y. The influences of Al content on the microstructure and mechanical properties of as-cast Mg-6Zn magnesium alloys[J]. Materials Science and Engineering A, 2017, 686: 93-101.

[7] 冯 凯, 黄晓锋, 马 颖, 陈娟娟, 郝 远. 固溶时间对ZA72镁合金显微组织及力学性能的影响[J]. 中国有色金属学报, 2011, 21(9): 2035-2042.

FENG Kai, HUANG Xiao-feng, MA Ying, CHEN Juan-juan, HAO Yuan. Effects of different solution time on microstructure and mechanical properties of ZA72 magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(9): 2035-2042.

[8] Fan Z. Semisolid metal processing[J]. International Materials Reviews, 2002, 47(2): 49-85.

[9] 曹 婧, 乐启炽, 张志强, 宝 磊, 崔建忠. ZK60-2Ca镁合金半固态坯料的部分重熔[J]. 中国有色金属学报, 2014, 24(1): 1-7.

CAO Jing, LE Qi-chi, ZHANG Zhi-qiang, BAO Lei, CUI Jian-zhong. Partial remelting of semi-solid metal ingots of ZK60-2Ca magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(1): 1-7.

[10] 刘 伟, 张英波, 李 彬, 权高峰. 半固态等温处理Mg-Zn-Y合金微观组织演变[J]. 稀有金属材料与工程, 2015, 44(12): 3243-3247.

LIU Wei, ZHANG Ying-bo, LI Bin, QUAN G F. Microstructure evolution of Mg-Zn-Y alloys during semi-solid isothermal heat treatment[J]. Rare Metal Materials and Engineering, 2015, 44(12): 3243-3247.

[11] 胡 勇, 闫 洪, 陈国香. 原位Mg2Si/AM60镁基复合材料半固态组织演变[J]. 材料工程, 2009(6): 56-59.

HU Yong, YAN Hong, CHEN Guo-xiang. Semi-solid microstructure evolution of in situ synthesized Mg2 Si/AM60 magnesium matrix composites[J]. Journal of Materials Engineering, 2009(6): 56-59.

[12] 孙 兵, 张英波, 权高峰, 李 彬. AZ80镁合金半固态等温处理过程中的组织演变[J]. 稀有金属材料与工程, 2016, 45(2): 404-408.

SUN Bing, ZHANG Ying-bo, QUAN Gao-feng, LI Bin. Microstructures evolution of AZ80 magnesium alloy in semi-solid isothermal treatment process[J]. Rare Metal Materials and Engineering, 2016, 45(2): 404-408.

[13] ZHANG L, WU G H, WANG S H, DING W J. Effect of cooling condition on microstructure of semi-solid AZ91 slurry produced via ultrasonic vibration process[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(10): 2357-2363.

[14] 胡 勇, 倪旭武, 胡 强. 二次加热对Al-0.3Ce合金半固态组织的影响[J]. 兵器材料科学与工程, 2015, 38(3): 23-25.

HU Yong, NI Xu-wu, HU Qiang. Effects of remelting process on semi-solid microstructure of Al-0.3Ce alloy[J]. Ordnance Material Science and Engineering, 2015, 38(3): 23-25.

[15] DU L, YAN H. Effect of isothermal heat-treated on the microstructure of ZA61 rare earth magnesium alloy[J]. Chinese Journal of Materials Research, 2012, 26(2): 169-174.

[16] ZHANG Y, HUANG X F, MA Y, CHEN T J, HAO Y. Effects of Sm addition on microstructural evolution of Mg-6Zn-0.4Zr alloy during semi-solid isothermal heat treatment[J]. China Foundry, 2017, 14(2): 433-440.

[17] SABRINA A K,YUKIO M,YOSHIHARU M,ZAINUDDIN B S. Influence of Mn content on mechanical properties and fatigue behavior of extruded Mg alloys[J]. Materials Science and Engineering A, 2006, 420(1/2): 315-321.

[18] STANFORD N, ATWELL D. The effect of Mn-rich precipitates on the strength of AZ31 extrudates[J]. Metallurgical and Materials Transactions A,2013,44(10): 4830-4843..

[19] 王春建, 金青林, 周 荣, 蒋业华. Mn元素对高纯Mg-3Al合金晶粒尺寸的影响[J]. 中国有色金属学报, 2010, 20(8): 1496-1500.

WANG Chun-jian, JIN Qing-lin, ZHOU Rong, JIANG Ye-hua. Effect of Mn on grain size of high-purity Mg-3Al alloys[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(8): 1496-1500.

[20] KHAN S A, MIYASHITA Y, MUTOH Y, SAJURI Z B. Influence of Mn content on mechanical properties and fatigue behavior of extruded Mg alloys[J]. Materials Science and Engineering A, 2006, 420(1/2): 315-321.

[21] 冯 凯, 黄晓锋, 马 颖, 阎峰云, 郝 远. ZA74镁合金非枝晶组织的演变过程及机理[J]. 中国有色金属学报, 2013, 23(3): 635-644.

FENG Kai, HUANG Xiao-feng, MA Ying, YAN Feng-yun, HAO Yuan. Non-dendritic microstructure evolution process and mechanism of ZA74 magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(3): 635-644.

[22] CHEN T J, JIANG X D, MA Y, LI Y D, HAO Y. Microstructural evolution and phase transformations during partial remelting of AZ91D magnesium alloy refined by SiC[J]. Journal of Alloys and Compounds, 2010, 497(2): 147-154.

[23] HAN L H, HU H, NORTHWOOD D O, LI N Y. Microstructure and nano-scale mechanical behavior of Mg-Al and Mg-Al-Ca alloys[J]. Materials Science and Engineering A, 2008, 473: 16-27.

[24] LASTER T, NUMBERG M R, JANZ A, HARTIG C, LETZIG D, SCHMID F R, BORMANN R. The influence of manganese on the microstructure and mechanical properties of AZ31 gravity cast alloys[J]. Acta Mateialia, 2006, 54(11): 3033-3041.

[25] 胡 勇, 饶 丽, 胡 强. 等温热处理过程中半固态AZ91D镁合金组织演变[J]. 材料研究学报, 2014, 28(12): 909-913.

HU Yong, RAO Li, HU Qiang. Microstructure evolution of semi-solid AZ91D alloy during isothermal heat treatment process[J]. Chinese Journal of Materials Research, 2014, 28(12): 909-913.

[26] 黄晓锋, 张 玉, 秦牧岚, 郝 远. 等温热处理对Mg-6Zn-3Cu合金半固态组织演变的影响[J]. 材料热处理学报, 2016, 37(8): 53-59.

HUANG Xiao-feng, ZHANG Yu, QIN Mu-lan, HAO Yuan. Effects of isothermal heat treatment on microstructural evolution of Mg-6Zn-3Cu alloy[J]. Transactions of Materials and Heat Treatment, 2016, 37(8): 53-59.

[27] 高义民. 金属凝固原理[M]. 西安: 西安交通大学出版社, 2010.

GAO Yi-min. Metal Solidification Principle[M]. Xi’an: Xi’an Jiaotong University Press, 2010.

[28] 张小立, 李廷举, 藤海涛, 谢水生, 金俊泽. 等温热处理过程中铸态AZ91镁合金的微观组织演化[J]. 铸造, 2007, 56(10): 1048-1052.

ZHANG Xiao-li, LI Ting-ju, TENG Hai-tao, XIE Shui-sheng, JIN Jun-ze. Microstructure evolution of as-cast AZ91 magnesium alloy during isothermal heat treatment[J]. Foundry, 2007, 56(10): 1048-1052.

[29] 杜 磊, 闫 洪. 等温热处理对AZ61稀土镁合金半固态组织的影响[J]. 材料研究学报, 2012, 26(2): 169-174.

DU Lei, YAN Hong. Effect of isothermal heat-treated on the microstructure of ZA61 rare earth magnesium alloy[J]. Chinese Journal of Materials Research, 2012, 26(2): 169-174.

[30] 乐启炽, 张新建, 崔建忠, 路贵民, 欧 鹏. 镁合金近液相线铸造半固态坯料的部分重熔[J]. 金属学报, 2002, 38(12): 1266-1272.

LE Qi-chi, ZHANG Xin-jian, CUI Jian-zhong, Lu Gui-min, OU Peng. Remelting of SSM ingot prepared by the near liquidus casting of AZ91D magnesium alloy[J]. Acta Metallurgica Sinica, 2002, 38(12): 1266-1272.

[31] 李元东, 郝 远, 陈体军, 马 颖. 原始组织对半固态AZ91D镁合金重熔行为的影响[J]. 中国有色金属学报, 2004, 14(3): 366-371.

LI Yuan-dong, HAO Yuan, CHEN Ti-jun, MA Ying. Effects of different primary microstructure on semi-solid melting behavior of AZ91D magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(3): 366-371.

Effect of minor Mn addition on non-dendritic microstructure evolution of Mg-6Zn-3Al magnesium alloy

ZHANG Yu1, HUANG Xiao-feng1, 2, GUO Feng1, YANG Jian-chang1, MA Ying1, 2, HAO Yuan1, 2

(1. State Key Laboratory of Advanced Processing and Recycling of Nonferrous Metals, Lanzhou University of Technology, Lanzhou 730050, China;

2. Key Laboratory of Non-ferrous Metal Alloys and Processing, Ministry of Education, Lanzhou University of Technology, Lanzhou 730050, China)

Abstract: The as-cast microstructure and non-dendritic microstructure evolution of Mg-6Zn-3Al alloys with varied Mn content (0%, 0.1%, 0.3% and 0.5%, in mass fraction) under isothermal heat treatment process were investigated with an OM, SEM and XRD, respectively. The results indicate that the as-cast Mn-free alloy is composed of α-Mg, Mg2Zn3, Mg7Zn3 and Mg32(Al, Zn)49 phases. When the minor Mn is added to the based alloy after, resulting in the creation of AlMn and Al8Mn5 phases, meanwhile, the grains are gradually refined with the Mn content increasing. The alloys are isothermally treated at 580 ℃ for 30 min, the obtained non-dendritic microstructures are comprised of primary α1-Mg particles and α2-Mg particles existed in eutectic microstructures which form in secondary quenching solidification process as well as eutectic phases with alveolate morphologies distributed between the primary solid particles. With the increase of Mn content, the average size and shape factor of solid phase particles decrease first and then increase, the volume fraction of liquid phase decreases continuously. When the content of Mn is 0.1%, the similarly spherical, finer and roundness as well as uniform distribution solid phase particles are obtained. The solute diffusion and interfacial tension play a leading role in the microstructural evolution during isothermal heat treatment. The component fluctuation of Zn and Al solute atoms in liquid phase is an important reason for the generation of necking in the process of separation and spheroidization of primary particles.

Key words: Mg-6Zn-3Al alloy; Mn addition; isothermal heat treatment; microstructural evolution; necking

Foundation item: Project(51464032) supported by the National Natural Science Foundation of China; (Project (2010CB635106) supported by the National Basic Research Development Program of China

Received date: 2017-07-03; Accepted date: 2017-11-15

Corresponding author: HUANG Xiao-feng; Tel: +86-13609312769 ; E-mail: huangxf_lut@163.com

(编辑 何学锋)

基金项目:国家自然科学基金资助项目(51464032);国家重点基础研究发展计划资助项目(2010CB635106)

收稿日期:2017-07-03;修订日期:2017-11-15

通信作者:黄晓锋,副教授,博士;电话:13609312769;E-mail: huangxf_lut@163.com