文章编号:1004-0609(2015)02-0367-08

CoCrFeNiTi0.5高熵合金在熔融Na2SO4-25%NaCl中的腐蚀行为

李 萍,庞胜娇, 赵 杰,李廷举

(大连理工大学 材料科学与工程学院,大连 116024)

摘 要:研究CoCrFeNiTi0.5高熵合金在熔融Na2SO4-25%NaCl(质量分数)中的腐蚀行为,应用TGA获得其在650和750 ℃空气中的腐蚀动力学曲线;采用XRD、SEM(EDS)和EPMA对腐蚀产物的截面形貌及元素分布进行分析。结果表明:喷涂Na2SO4-25%NaCl的CoCrFeNiTi0.5高熵合金在650和750 ℃时的腐蚀动力学曲线相似,呈“指数”增长规律;腐蚀截面由含较多TiO2、部分Cr2O3以及微量尖晶石结构氧化物构成的氧化层与含孔隙且贫Cr和Ti、富Fe、Ni和Co的腐蚀影响区两部分构成;延长腐蚀时间或提高腐蚀温度后,氧化层破裂,与基体的结合程度显著下降,发生严重剥离甚至脱落。分析认为:CoCrFeNiTi0.5高熵合金在Na2SO4-25%NaCl中的高温腐蚀归因于氧化、硫化以及氯化的综合作用。

关键词:高熵合金;硫化;氯化;氧化

中图分类号:TB304 文献标志码:A

Corrosion behavior of CoCrFeNiTi0.5 high entropy alloy in molten Na2SO4-25%NaCl

LI Ping, PANG Sheng-jiao, ZHAO Jie, LI Ting-ju

(College of Materials Science and Engineering, Dalian University of Technology, Dalian 116024, China)

Abstract: The corrosion behavior of CoCrFeNiTi0.5 high entropy alloy (HEA) in molten Na2SO4-25%NaCl (mass fraction, %) was investigated. The corrosion kinetic curves at 650 and 750 ℃ were analyzed by TGA method. The scale structure and composition of the corroded products were examined by XRD, SEM equipped with EDS and EPMA. The results show that the corrosion kinetic curves of the CoCrFeNiTi0.5 alloy corroded at 650 and 750 ℃ are similar and follow exponent growth law. The cross-section consists of the oxide layers and the corrosion affected zones. The former is composed of mainly TiO2 and partly Cr2O3 as well as tiny compound oxides with spinel structure, and the latter with porous is depleted in Cr, Ti and rich in Fe, Ni and Co. Prolonging the exposure time or elevating the corrosion temperature, the oxide layer is broken and the adhesion with the matrix is worsened, and is peeled from the matrix. It is concluded that the corrosion behaviors of CoCrFeNiTi0.5 HEA in molten Na2SO4-25%NaCl is attributed to the interaction of oxidation, sulfidation and chlorination.

Key words: high entropy alloy (HEA); sulfidation; chlorination; oxidation

自20世纪90年代中期台湾学者YEH等[1-2]提出新的合金设计理念伊始,高熵合金的研发受到了众多学者的广泛关注[3-4]。高熵合金具有简单的面心和体 心立方相,表现出高强度、高硬度、抗氧化、较高的热稳定性以及耐腐蚀等优异性能[5-8],使其有望用作超超临界电站锅炉热交换器等高温耐热耐蚀设备的候选材料[13-14]。燃煤电站锅炉服役过程中,不可避免地发生以硫酸盐为主要成分的高温熔盐腐蚀。研究发现:当煤中氯含量达到一定值时(约大于0.3%),其对炉管的腐蚀作用远远超过硫的危害,与氯有关的高温腐蚀倾向更为严重,所以其危害性更不容忽视[15]。现有的关于高熵合金耐高温腐蚀的研究大多集中于高温氧化性能[16-19],至于其在较为苛刻的熔盐环境下,尤其是在含硫酸钠和氯化钠等腐蚀介质下耐腐蚀特性的研究报道却非常有限[20]。因此,在考虑将高熵合金用于制造含氯燃煤气氛下服役的热交换器等高温耐热设备时,有必要结合高熵合金的成分与组织特点,对其在氯盐中的腐蚀行为及其相关机制进行深入而细致的探讨,这不仅具有学术研究价值,对其在工业领域的应用也具有工程指导作用。

在此,本文作者选择热稳定性较好的CoCrFeNiTi0.5高熵合金作为研究对象,选择Na2SO4-25%NaCl模拟炉管的沉积盐环境,应用增重法获得CoCrFeNiTi0.5高熵合金在650和750 ℃的腐蚀动力学曲线,结合XRD、SEM(EDS)和EPMA对腐蚀产物、截面形貌以及元素分布进行观察与分析,从而揭示CoCrFeNiTi0.5高熵合金在熔融Na2SO4-25%NaCl中的腐蚀特性。

1 实验

将原材料Co、Cr、Fe、Ni、Ti按摩尔比为1:1:1:1:0.5配制熔炼成铸锭,再将合金材料加工成10 mm×6 mm×2 mm的片状试样,表面用水砂纸统一打磨到800号,以保证样品表面相同的粗糙度,然后用丙酮和乙醇清洗吹干。用热喷涂法在试样表面涂覆Na2SO4-25%NaCl饱和溶液,待水分快速蒸发,使试样表面涂覆溶盐量为5 mg/cm2,涂覆层厚度变化均匀,约为100 μm,将喷涂硫酸盐的试样放在坩埚中一并置入箱式电炉中间,在650和750 ℃分别进行腐蚀,时间最长为150 h。采用精确度为0.1 mg的电子天平对腐蚀前后的样品称量,每个实验条件下,至少取3个平行样,取其质量变化的平均值绘制腐蚀动力学曲线以分析腐蚀速率变化;采用XRD对腐蚀产物相进行分析;采用SEM对腐蚀后样品表面及截面形貌进行观察,结合EDS和EPMA对腐蚀样品的截面进行元素分布分析。

2 实验结果

2.1 铸态合金的组织结构

图 1所示为铸态CoCrFeNiTi0.5高熵合金喷涂前后的显微组织。由图1可以看出:喷涂前后的CoCrFeNiTi0.5高熵合金在热腐蚀前均由典型的树枝 晶/枝晶间组织构成,树枝晶为FCC结构的固溶体相, 枝晶间隙则由富FeCr的σ相、R相和Laves相组成。这说明目前的喷涂条件不足以影响CoCrFeNiTi0.5高熵合金组织结构的稳定性。

图1 铸态CoCrFeNiTi0.5高熵合金在喷涂前后的显微组织

Fig. 1 Microstructures of as-cast CoCrFeNiTi0.5 high entropy alloy

2.2 腐蚀动力学曲线

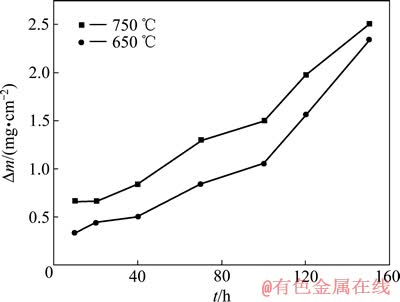

图2所示为喷涂Na2SO4-25%NaCl的CoCrFeNiTi0.5高熵合金在650和750 ℃的腐蚀动力学曲线。实验条件下,曲线呈现相似的“指数”增长趋势。腐蚀初期(40 h以内),质量增加不明显;延长腐蚀至150 h,质量增加加速。分析认为:实验条件下,CoCrFeNiTi0.5高熵合金经历了由缓慢腐蚀向加速腐蚀的转变。腐蚀初期,优先生成的氧化层对合金表面具有一定的保护作用,阻碍腐蚀的发展;随着腐蚀时间的延长,合金表面生成更多的氧化产物。升高温度,合金质量增加明显,腐蚀加速。

图2 CoCrFeNiTi0.5高熵合金在650和750 ℃的腐蚀动力学曲线

Fig. 2 Corrosion dynamic curves of CoCrFeNiTi0.5 high entropy alloy exposed at 650 and 750 ℃

2.3 腐蚀产物的物相分析

将CoCrFeNiTi0.5高熵合金在650和750 ℃分别腐蚀40 h和100 h后,腐蚀产物的XRD谱如图3和4所示。由图3和4可见,温度改变对腐蚀产物相的形成未产生明显的影响。实验条件下,腐蚀产物由较多的TiO2、部分Cr2O3、Fe2O3以及微量的尖晶石结构复杂氧化物AB2O4组成。

2.4 腐蚀样品的截面形貌分析

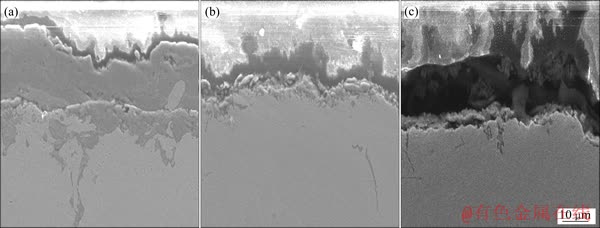

对腐蚀样品表面形貌的观察发现:样品表面生成黑褐色腐蚀产物,局部区域有腐蚀产物剥落;延长腐蚀时间,腐蚀膜的爆裂趋于严重,这意味着腐蚀产物与合金基体的结合程度在逐渐劣化。CoCrFeNiTi0.5高熵合金在650 ℃腐蚀不同时间的截面形貌如图5所示。

图3 CoCrFeNiTi0.5高熵合金在650 ℃腐蚀40和100 h后的XRD谱

Fig. 3 XRD patterns of CoCrFeNiTi0.5 high entropy alloy for 40 h and 100 h at 650 ℃

图4 CoCrFeNiTi0.5高熵合金在750 ℃腐蚀40和100 h后的XRD谱

Fig. 4 XRD patterns of CoCrFeNiTi0.5 high entropy alloy exposed at 750 ℃ for 40 h and 100 h

由图5可看出,腐蚀20 h时,基体表面形成相对较为连续且致密的厚度约为20 μm的不均匀腐蚀层,与基体接触良好,未见明显剥离。EDS分析表明该腐蚀层约含Ti(48.6%,质量分数)、Cr(19.04%)、O(30.83%),结合XRD可知该层主要由Ti和Cr氧化物组成。邻近的腐蚀影响区(氧化层与基体交界面)不均匀地分布着块状产物与微小孔隙,EDS结果分析可知,该块状产物仍为富含Ti(37.3%)、Cr(27.82%)、O(33.87%)的氧化物,孔隙周围贫Ti(0.82%)、Cr(11.46%),富Fe(29.73%)、Ni(25.13%)和Co(32.27%)以及含微量O(0.55%)、S(0.02%)。腐蚀至70 h以上,氧化层已完全破裂,样品制备过程中与基体剥离并从基体表面脱落,所以只有少量的氧化物残留,对应的腐蚀影响区发现若干孔洞萌生且有裂纹向基体中延伸。

CoCrFeNiTi0.5高熵合金在750 ℃腐蚀不同时间后的截面形貌如图6所示。腐蚀初期(20 h),氧化层破碎,变得不连续且从基体表面剥离,有孔隙存在于腐蚀影响区。结合EDS分析可知,该氧化层约含Cr(33.47%)、Ti(21.15%)、O(39.84%)、Ni(1.18%)、Co(0.92%)、Fe(1.37% );腐蚀影响区的孔隙周围含S(0.92%)、O(16.08%),相对于基体呈现明显的贫Cr(11.25%)、Ti(4.87%),富Ni(27.74%)、Fe(22.96%)、Co(32.28%);延长腐蚀时间到70 h时,氧化层完全剥落,腐蚀影响区明显增厚,约为40 μm,孔隙密度增大,孔隙深度显著增加。EDS分析结果表明:该区域贫Cr(8.25%)、Ti(0.93%),富Ni(33.93%)、Fe(20.32%)、Co(35.39%)及含少量的S元素(1.02%)和O(0.09%);继续腐蚀至150 h时,观察到厚约12 μm的含Cr(26.10%)和Ti(28.23%)、O(39.41%)、Ni(1.83%)、Co(1.19%)、Fe( 2.17%)的氧化层,厚约30 μm腐蚀影响区零星分布孔洞,孔洞处依然贫Cr(5.27%)、Ti(0.93%),富Ni(32.14%)、Fe(21.44%)、Co(35.31%)以及含微量的O(2.52%)和S(1.09%)。

图5 CoCrFeNiTi0.5高熵合金在650 ℃腐蚀不同时间后的腐蚀样品截面形貌

Fig. 5 Cross-section micrographs of CoCrFeNiTi0.5 HEA exposed at 650 ℃ for 20 h(a), 70 h(b), 150 h(c)

图6 CoCrFeNiTi0.5高熵合金在750 ℃腐蚀不同时间后的腐蚀截面形貌

Fig. 6 Cross-section micrographs of CoCrFeNiTi0.5 high entropy alloy exposed at 750 ℃ for 20 h(a), 70 h(b) and 150 h(c)

2.5 腐蚀样品截面元素分布

CoCrFeNiTi0.5高熵合金在650和750 ℃分别腐蚀40 h的截面元素分布如图7和8所示。元素Ti和O分布于整个氧化层,Cr偏聚于氧化层内侧与基体内部,氧化层与基体交界面约20 μm的腐蚀影响区贫Cr、Ti,富Ni、Co、Fe以及含微量O与S。提高腐蚀温度至750 ℃,氧化层除富集较多的Ti、Cr外,该区域还发现存在少量的Ni、Fe和Co;腐蚀影响区元素分布未变。

3 分析与讨论

综合上述腐蚀动力学曲线、腐蚀产物相的XRD谱以及对截面形貌和元素分布的观察,分析认为:元素Cr和Ti具有较快的扩散速率,且与O有更好的亲和力,所以,CoCrFeNiTi0.5高熵合金在腐蚀初期发生选择性氧化,合金表面优先形成了连续致密且对基体具有保护性作用的富含Ti、Cr的氧化层,与基体接触良好;其他合金元素如Co和Ni等的存在不仅促进合金氧化层的形成,还能够提高它们的致密性与粘附性。不仅如此,多种组元的氧化产物又相互作用,生成具有复杂结构的尖晶石型氧化层,其产生对于合金基体也具有一定的保护作用。因此,腐蚀初期在CoCrFeNiTi0.5高熵合金表面形成的多种氧化物延长了腐蚀的孕育期,阻碍了盐膜对基体的腐蚀,增强合金的抗腐蚀能力,表现在腐蚀初期的氧化质量增加不显著。

文献[21]中指出:当Na2SO4与NaCl的质量比为3:1时,混合盐的熔点不超过630 ℃,这意味着实验条件下,合金表面将发生混合盐膜的熔融。熔融的NaCl与腐蚀初期形成的氧化物或金属发生如下反应[22-25]:

4NaCl+Cr2O3+5/2O2→2Na2CrO4+2Cl2 (1)

Cr+2NaCl+2O2→Na2CrO4+Cl2 (2)

上述反应中生成的Cl2或者挥发到空气中,也可能与基体合金元素发生如下反应生成金属氯化物:

(Fe,Cr,Ni,Co)+1/2yCl2→(Fe,Cr,Ni,Co)Cly (3)

相对于元素Ni和Co,Cr、Fe与Cl2反应的驱动力更大[26],所以元素Ni、Co因与Cl2反应的趋势较小而易于被保留在基体中,造成腐蚀影响区中Ni和Co含量偏高。

图7 CoCrFeNiTi0.5高熵合金在650 ℃腐蚀40 h后的截面形貌及元素分布

Fig. 7 SEM image and element map scanning results of CoCrFeNiTi0.5 entropy alloy corroded at 650 ℃ for 40 h

图8 CoCrFeNiTi0.5高熵合金在750 ℃腐蚀40 h后的截面形貌及元素分布

Fig. 8 SEM image and element map scanning results of CoCrFeNiTi0.5 high entropy alloy corroded at 750 ℃ for 40 h

在金属-氧-氯系统中,氧化物为最终稳定相,所以铁、铬氯化物在向外扩散的过程中通过反应(4)又被氧化形成金属氧化物和Cl2[27-28],生成的Cl2再重复反应(3)~(4)过程。

x(Fe,Cr)–Cl2+1/2yO2→(Fe,Cr)xOy+Cl2 (4)

在氯化/氧化循环过程中,Cl元素通过氯化物的形成、汽化、再氧化导致金属损耗加剧。因此,在有NaCl参与的热腐蚀过程中,容易导致氧化层与基体的剥离,从而产生二次氧化。由于Cr的氯化物与O2反应的ΔG更小,所以Cr的氧化物易于先生成,之后生成铁的氧化物并覆盖于铬的氧化物之上[29]。

不仅如此,腐蚀过程中多种挥发性产物的形成还破坏了氧化层的致密性,使试样表面的氧化层呈现疏松多孔的形貌,这将加速熔盐通过孔隙与金属发生进一步的腐蚀,不仅有助于为硫元素与氧元素向基体中扩散提供通道,也为氧化层与基体界面以及基体内部内硫化与内氧化的发生创造更多机会。结合SEM与EDS分析可知:腐蚀影响区(氧化层-基体界面)含有微孔隙且贫Cr、Ti,富Fe、Ni、Co以及微量S、O,这是由于选择性氯化造成Fe、Cr元素向合金表面扩散,在基体中形成孔洞;熔融态的硫酸根通过疏松多孔的氧化层扩散到腐蚀影响区以及基体内部,在微孔隙周围富集,通过还原反应,形成铁镍硫化物,促使该区域发生了内硫化[30-31]。上述反应过程可描述为

SO42-+4e→S2-+2O2 (5)

x(Fe/Ni)+yS2-→(Fe/Ni)xSy (6)

综上所述,CoCrFeNiTi0.5高熵合金在熔融Na2SO4- 25%NaCl中的腐蚀可以看成是氧化、氯化与硫化共同作用的结果:氧化作用使合金表面生成具有保护性作用的保护层;融盐中的S通过扩散、还原反应使得合金发生内硫化;Cl通过氯化物的形成、汽化、再氧化破坏了氧化层对合金的保护性作用,并加速了合金多次氧化;而且,由于Cl的腐蚀是重复进行的,因此,含NaCl的混合盐对高熵合金的腐蚀作用更具破坏性。

4 结论

1) 表面喷涂Na2SO4-25%NaCl的CoCrFeNiTi0.5高熵合金在650和750 ℃腐蚀动力学曲线相似,均呈“指数”增长规律,这意味着CoCrFeNiTi0.5高熵合金经历了由稳定腐蚀向加速腐蚀的转变。

2) 腐蚀截面由含较多TiO2、部分Cr2O3以及微量尖晶石结构氧化物构成的氧化层与含孔隙的贫Cr、Ti,富Fe、Ni、Co的腐蚀影响区两部分组成。提高腐蚀温度或延长时间,氧化层与基体结合程度显著下降,氧化层破裂并与基体严重剥离,甚至脱落。

3) CoCrFeNiTi0.5高熵合金在熔融Na2SO4- 25%NaCl中的高温腐蚀归因于氧化、氯化以及硫化的综合作用。由于Cl的腐蚀作用是重复性的,这使得NaCl对合金的腐蚀作用更具破坏性。

致谢:

论文的部分工作得到了秦鹏、董永两位研究生的帮助和支持,在此表示真诚的感谢!

ReferenceS

[1] YEH J W, CHEN S K, LIN S J, GAN J Y, CHIN T S, SHUN T T, TSAU C H, CHANG S Y. Nano-structured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes[J]. Advanced Engineering Materials, 2004, 6(5): 299-303.

[2] TSAI Ming-huang, YEH Jien-wei. High-entropy alloy: A critical review[J]. Material Research Letters, 2014, 2(3): 107-123.

[3] 董 闯, 羌建兵, 袁 亮, 王 清, 王英敏. 合金相的“团簇+连接原子”模型与成分设计[J]. 中国有色金属学报, 2011, 21(10): 2502-2510.

DONG Chuang, QIANG Jian-bing, YUAN Liang, WANG Qing, WANG Ying-min. A cluster-plus-glue-atomodel for composition design of complex alloys[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(10): 2502-2510.

[4] WANG Zhi-wei, YUAN Yan-bo, ZHENG Rui-xiao, AMEYAMA Kei, MA Chao-li. Microstructures and mechanical properties of extruded 2024 aluminum alloy reinforced by FeNiCrCoAl3 particles[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(7): 2366-2373.

[5] REN Ming-xing, LIZ Bang-sheng, FU Heng-zhi. Formation condition of solid solution type high entropy alloy[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(4): 991-995.

[6] NONG Zhi-sheng, ZHU Jing-chuan, YU Hai-ling, LAI Zhong-hong. First principles calculation of intermetallic compounds in FeTiCoNiVCrMnCuAl system high entropy alloy[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(6): 1437-1444.

[7] HUANG Yuan-sheng, CHEN Ling, LIU Hong-wei. Microstructure, hardness, resistivity and thermal stability of sputtered oxide films of AlCoCrCu0.5NiFe high entropy alloy[J]. Materials Science and Engineering A, 2007, 457(5): 77-83.

[8] HSIEH Ker-chang, YU Cheng-fu, HSIEH Wen-tai. The microstructure and phase equilibrium of new high per-formance high-entropy alloys[J]. Journal of Alloys and Compounds, 2008, 483(1/2): 209-212.

[9] WANG Yan-ping, LI Bang-sheng, FU Heng-zhi. Solid solution or intermetallics in a high-entropy alloy[J]. Advanced Engineering Materials, 2009, 11(8): 641-644.

[10] WEN L H, KOU H C, LI J S, CHANG H, XUE Y X, ZHOU L. Effect of aging temperature on microstructure and properties of AlCoCrCuFeNi high-entropy alloy[J]. Intermetallics, 2009, 17(4): 266-271.

[11] YANG Z, LI J, GUO Y. Precipitation process and effect on mechanical properties of Mg-9Gd-3Y-0.6Zn-0.5Zr alloy[J]. Materials Science and Engineering A, 2007, 454: 274-280.

[12] CHEN Y Y, HONG U T, SHIH H C, YEH J W, DUVAL T. Electrochemical kinetics of the high entropy alloys in aqueous environments a comparison with type304 stainless steel[J]. Corrosion Science, 2005, 47(11): 2679-2699.

[13] 高家诚, 李 锐. 高熵合金研究的新进展[J]. 功能材料, 2008, 39(7): 1059-1061.

GAO Jia-cheng, LI Rui. New progresses in the research of high entropy alloys[J]. Journal of Function Material, 2008, 39(7): 1059-1061.

[14] 刘 源, 李言祥, 陈 祥, 陈 敏. 多主元高熵合金研究进展[J]. 材料导报, 2006, 20(4): 4-14.

LIU Yuan, LI Yan-xiang, CHEN Xiang, CHEN Min. New progresses in the research of multi principal element high entropy alloys[J]. Mater Review, 2006, 20(4): 4-14.

[15] 李守信, 阎维平, 方立军. 电站锅炉受热面高温氯腐蚀的机理探讨[J]. 锅炉制造, 1999, 11(4): 19-23.

LI Shou-xin, YAN Wei-ping, FANG Li-jun. Study on the mechanism of high temperature chlorine corrosion of heating surface of boiler in power plant[J]. Boiler Manufacturing, 1999, 11(4): 19-23.

[16] 高家诚, 李 锐. AlZnSnSbPbMnMg高熵合金显微组织和耐热性的研究[J]. 功能材料, 2009, 40(4): 602-604.

GAO Jia-cheng, LI Rui. Study on the microstructure and heat resistance of AlZnSnSbPbMnMg high entropy alloy[J]. Journal of Function Material, 2009, 40(4): 602-604.

[17] 刘国军, 贾素秋, 殷世强. CuAl合金在700 ℃抗氧化性的研究[J]. 热加工工艺, 2011, 40(14): 48-51.

LIU Guo-jun, JIA Su-qiu, YIN Shi-qiang. Study on the anti oxidational effects of CuAl alloy under 700 ℃[J]. Hot Working Technology, 2011, 40(14): 48-51.

[18] 蒋积超, 罗秀艳. 高熵合金AlCuTiFeNiCr和AlCuTiFeNiCrSi的高温氧化行为研究[J]. 硅谷, 2011, 24(2): 46.

JIANG Ji-chao, LUO Xiu-yan. Study on high temperature oxidation behavior of the high entropy alloy AlCuTi-FeNiCr and AlCuTiFeNiCrSi[J]. Silicon Valley, 2011, 24(2): 46.

[19] LI Bao-yu, PENG Kun, HU Ai-ping, ZHOU Ling-ping, ZHU Jia-jun, LI De-yi. Structure and properties of FeCoNiCrCu0.5Alx high-entropy alloy[J]. Transaction of Nonferrous Metals Society of China, 2013, 23(3): 735-741.

[20] 洪丽华, 张 华, 王乾廷, 唐群华, 戴品强, 吴 波. Al0.5CoCrFeNi高熵合金高温腐蚀行为研究[J]. 热加工工艺, 2013, 42(8): 56-62.

HONG Li-hua, ZHANG Hua, WANG Qian-ting, TANG Qun-hua, DAI Ping-qiang, WU Bo. High temperature corrosion behavior of Al0.5FeCoCrNi high entropy alloy[J]. Hot Working Technology, 2013, 42(8): 56-62.

[21] DEB D, RAMAKRISHNA IYER S, RADHAKRISHNAN V M. A comparative study of oxidation and hot corrosion of a cast nickel base superalloy in different corrosive environments[J]. Materials Letters, 1996, 29(1/3): 19-23.

[22] WANG Chaur-jeng, HE Tien-tsuo. Morphological dev-elopment of subscale formation in Fe-Cr-(Ni) Alloys with chloride and sulfates coating[J]. Oxidation of Metals, 2002, 58(3/4): 415-437.

[23] Hossain M K, Saunders S R J. A microstructural study of the influence of NaCl vapor on the oxidation of a Ni-Cr-Al alloy at 850 ℃[J]. Oxidation of Metals, 1978, 12(1): 1-22.

[24] Shinata Y, Hara M, Nakagawa T. Accelerated oxidation of chromium by trace of sodium chloride vapor[J]. Material Transactions-JIM, 1991, 32(10): 969-972.

[25] Hiramatsu N, Uematsu Y, Tanaka T, Kinu-gasa M. Effect of alloying elements on NaCl-induced hot corrosion of stainless steels[J]. Material Science and Engineering A, 1989, 120/121(1): 319-328.

[26] Knacke O, Kubaschewski O, Hesselmann K. Thermochemical properties of inorganic substance[M]. 2nd ed. Berlin: Springer, 1991: 12.

[27] Shinata Y. Accelerated oxidation rate of chromium induced by sodium chloride[J]. Oxidation of Metals. 1987, 27(5/6): 315-332.

[28] LAI G Y. High-temperature corrosion and materials applications[M]. Materials Park, Ohio: ASM International, 2013: 2.

[29] TSAUR Charng-cheng, Rock James C, WANG Cha-urjeng. SUB Yung-hua. The hot corrosion of 310 stainless steel with pre-coated NaCl/Na2SO4 mixtures at 750 ℃[J]. Materials Chemistry and Physics, 2005, 89(2/3): 445-453.

[30] Gupta D K, Rapp R A. The solubilities of NiO, CO3O4 and ternary oxides in fused Na2SO4 at 1200 K[J]. Journal of the Electrochemical Society, 1980, 127(10): 2194-2202.

[31] ZHAO Shuang-qun, XIE Xi-shan, SMITH G D, PATEL S J. The corrosion of inconel alloy 740 in simulated environments for pulverized coal-fired boiler[J]. Materials Chemistry and Physics, 2005, 90(2/3): 275-281.

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51134013,51171037)

收稿日期:2014-04-24;修订日期:2014-10-20

通信作者:李 萍,副教授,博士;电话:0411-84706787;E-mail: liping69@dlut.edu.cn