文章编号: 1004-0609(2004)09-1609-06

Ti3Al基合金在700~850℃空气中的循环氧化行为

钱余海1, 2, 李美栓2, 张亚明2

(1. 宝山钢铁股份有限公司 技术中心, 上海 201900;

2. 中国科学院 金属研究所 沈阳材料科学国家(联合)实验室, 沈阳 110016)

摘 要: 研究了2种成分相近的Ti3Al基合金(Ti-24Al-14Nb-3V-0.5Mo-0.3Si(摩尔分数)及Ti-24Al-14Nb-3V-0.5Mo-0.6Si在700~850℃空气中的循环氧化行为; 重点考察了合金的循环氧化动力学行为; 结合SEM/EDX及EPMA分析了循环氧化后样品的表面、 断面微观形貌及断面成膜元素面分布。 结果表明: 2种合金在各氧化温度下表面生成了Al2O3和TiO2混合氧化物, Al2O3主要分布在最外层; 在700℃下2种合金具有较好的抗循环氧化性能, 而在800℃及以上的温度条件下, 表面氧化膜易于开裂和剥落; 合金在较高温度下表面氧化膜失效方式为膜层中微裂纹的复合及由于这一过程的反复进行而导致的氧化膜间物理分层开裂。

关键词: Ti3Al基合金; 循环氧化; 氧化动力学 中图分类号: TQ174.5; TG172.82

文献标识码: A

Cyclic oxidation behaviors of Ti3Al-based alloys at 700-850℃ in air

QIAN Yu-hai1, 2, LI Mei-shuan1, ZHANG Ya-ming1

(1. Technology Center, Bao Shan Iron & Steel Company Ltd., Shanghai 201900, China;

2. Shenyang National Laboratory for Materials Science, Institute of Metal Research, Chinese Academy of Sciences, Shenyang 110016, China)

Abstract: The cyclic oxidation behaviors of two Ti3Al-based alloys with similar content of Ti-24Al-14Nb-3V-0.5Mo-0.3Si(molar fraction, %)and Ti-24Al-14Nb-3V-0.5Mo-0.6Si at 700-850℃ in air were investigated. The emphasis was placed on the characteristics of cyclic oxidation kinetics, the microstructure of surface and cross-section of oxide scales and the depth profiles of alloying elements by means of XRD/EDX and EPMA. The results show that during the oxidation process, the mixture of Al2O3 and TiO2 is formed and the outside layer is enriched with Al. Cyclic oxidation resistance of these two Ti3Al-based alloys is good at 700℃. But at 800℃ or above that, the surface oxide is prone to cracking and spallation. The failure mode of the oxide scale at higher temperatures is contributed to the physical delamination in the scales due to the initiation and propagation of micro-cracks and during the cyclic oxidation process.

Key words: Ti3Al-based alloy; cyclic oxidation; oxidation kinetics

有序金属间化合物如Ti3Al和TiAl具有突出的性能, 如具有高的比强度、 弹性模量和高温蠕变强度等, 是一类很具应用前景的新型高温结构材料[1, 2]。 已进行的研究表明, 对比于镍基合金, 在保证使用强度的前提下, 钛铝化合物可使质量降低50%[3]。 目前在国外由Ti3Al基合金制成的发动机零件如高压涡轮支撑环和高压压空机机匣等已成功地通过试车[4]。

作为高温结构材料, 抗高温氧化性能是一个重要因素。 特别是Ti-Al基合金, 由于Ti也具有高的氧亲和力, 易于形成不具抗氧化性的TiO2, 因此合金的抗氧化性能尤其受到关注。 Ti3Al在815℃仍具有良好的高温蠕变强度, 但在650℃以上其抗氧化性不足[5]。 有关Ti3Al基合金的氧化行为, 已进行的研究表明, 其表面不生成保护性的Al2O3, 而是形成以TiO2为主的混合氧化物, 并且其氧化动力学行为较复杂[6-10]。 为了提高Ti3Al抗氧化性能, 可行的途径为合金化或涂覆表面涂层。 加入β相稳定化元素可以降低氧化速率[10, 11], Choudhury及Mendiratta等[12, 13]的研究表明, 添加元素铌和钨可以极大地提高Ti3Al的抗氧化性能。

在实际应用中, 高温构件表面氧化膜常发生开裂或剥落, 特别是在变温过程中, 氧化膜的失效过程将破坏氧化膜内已建立的各种化学态, 从而影响氧化膜内的物质传输过程、 氧化膜与基体界面间的反应气氛分压及界面处的微观结构、 成分等。 而氧化膜的剥落将产生更为严重的后果, 它将新鲜的合金表面直接暴露于氧化气氛中, 加速合金的氧化。 因此, 研究合金的抗循环氧化性能对高温合金或构件的实际应用过程具有重要的指导意义。

本文作者研究了Ti-24Al-14Nb-3V-0.5Mo-0.3Si合金及Ti-24Al-14Nb-3V-0.5Mo-0.6Si合金在不同氧化温度下(700、 800、 850℃)的循环氧化行为, 以考察合金的抗循环氧化能力, 为该类合金的实际应用提供必要的技术参考。

1 实验

实验所用Ti-24Al-14Nb-3V-0.5Mo-0.3Si(简略为03Si)及Ti-24Al-14Nb-3V-0.5Mo-0.6Si(简略为06Si)合金由中国科学院金属研究所钛合金研究室提供。 其冶炼方法及热处理制度分别为: 用真空自耗炉冶炼2次得合金铸锭, 首先在β单相区进行开坯锻造, 然后在α2+β两相区锻造, 得到截面尺寸为21mm×21mm的棒材; 锻后的合金热处理制度为1000℃, 1h, AC+850℃, 2h, AC。 氧化实验所用的样品尺寸为10mm×12mm×2mm, 采用线切割方法制得。 将样品用耐水砂纸打磨至800#, 于丙酮中超声清洗除油脂, 然后用无水乙醇洗净待用。

循环氧化在自动控制的垂直管式炉内进行, 即样品的进炉和出炉均由设备自动控制。 循环的构成为在加热炉内保温1h, 而后在空气中停留10min冷却。 选用实验条件为静态空气, 实验温度为700~850℃, 在循环过程中间隔地利用分析天平(精确度为0.1mg)称量样品质量, 以确定循环氧化动力学。 循环氧化完成后, 用X射线衍射分析样品氧化后表面产物的成分及相结构, 之后用配有能谱分析的SEM/EDX观察氧化后样品的表面形貌和截面形貌。 在进行截面形貌观察前先在样品表面化学镀镍以防表面氧化膜在制样过程中开裂或脱落。

2 结果

2.1 循环氧化动力学

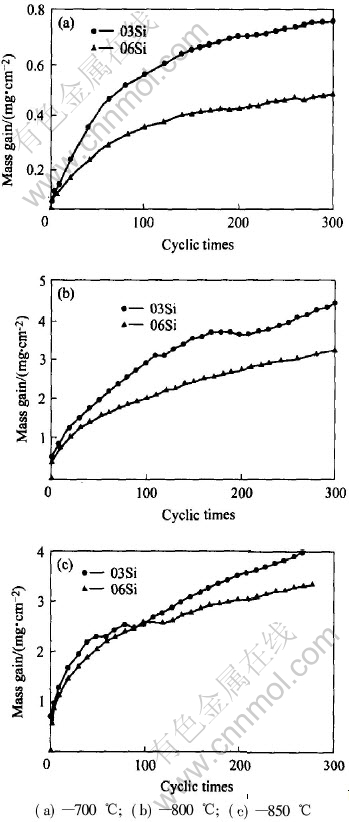

图1所示为2种合金在不同温度下循环300次后的氧化动力学曲线。 在700℃时样品氧化质量增加相对较小(图1(a)), 循环氧化动力学曲线较为平滑, 表明在循环过程中氧化膜基本完整。 而在更高的氧化温度下, 氧化质量明显增大(图1(b), (c)), 此时氧化动力学曲线出现拐点, 表明在更高的温度下氧化膜在循环过程中发生失效(开裂或剥落)。 另外, 在850℃条件下, 氧化膜出现拐点的循环次数提前, 表明氧化膜发生失效的时间提前, 温度升高使合金的抗循环氧化性能降低。

图1 2种合金在不同温度空气中的循环氧化动力学曲线

Fig.1 Cyclic oxidation kinetic curves of two alloys at different temperatures

2.2 表面形貌

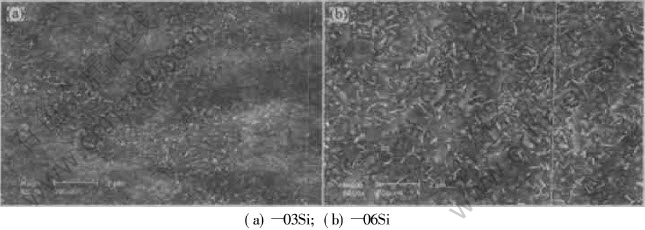

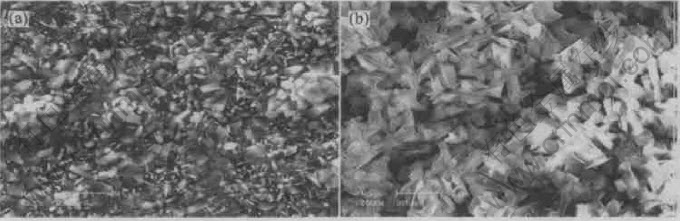

2种合金在不同氧化温度下循环300次后的表面形貌如图2, 3, 4所示。 在700℃下表面氧化膜完整, 未见开裂及剥落区。 在800℃循环过程中氧化膜均在试样的边缘处发生开裂或剥落(图3(a)), 在850℃时, 除边缘处外, 在氧化膜表面处也发生明显的剥落(图3(c)), 形貌观察结果与循环氧化动力学吻合。 XRD分析结果表明, 合金在所选的温度范围内表面氧化膜成分主要为TiO2, 同时生成少量的Al2O3。 能谱(EDX)分析表明, 少量的Al2O3主要分布于氧化膜的外表面, 其存在形式是与TiO2形成混合层。 在氧化膜的剥落区下方, EDX未能检测到铝元素的存在。

2.3 截面形貌

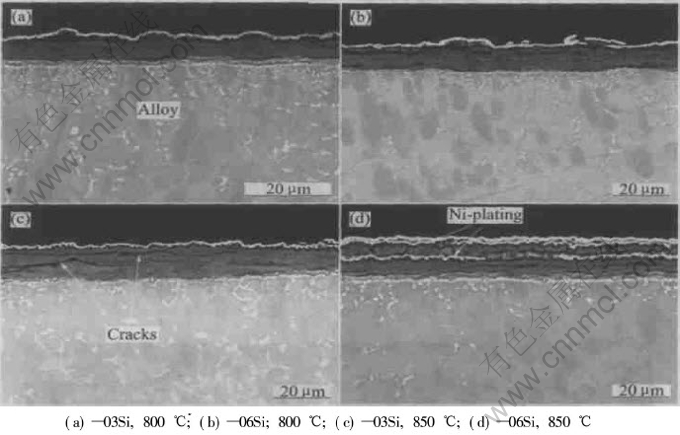

2种合金于800℃和850℃氧化后的截面形貌如图5所示。 在800℃下合金表面氧化膜最外层局[CM(22]部剥落。 在850℃下于截面图可见氧化膜呈现物理分层, 是由氧化膜失效所致。 由图5(d)可见, 氧化膜呈现横向分层开裂, 下层有微裂纹, 与上层间相互贯通, 使得在化学镀镍过程中, 在下层的部分氧化膜层间成为活性点, 而在其间产生白亮的镀镍层。

图2 2种合金在700℃循环氧化300次后的表面形貌

Fig.2 Surface morphologies of two alloys after cyclic oxidation for 300times at 700℃

图3 03Si合金在不同温度循环氧化300次后的表面形貌

Fig.3 Surface morphologies of 03Si alloy after cyclic oxidation for 300 times at different temperatures

图4 06Si合金在不同温度循环氧化300次后未剥落区的表面形貌

Fig.4 Non-spallation surface morphologies of 06Si alloy after cyclic oxidation for 300times at 800℃(a) and 850℃(b)

图5 2种合金在不同条件下循环氧化300次后的截面形貌

Fig.5 Morphologies of cross sections of two alloys after cyclic oxidation under different conditions

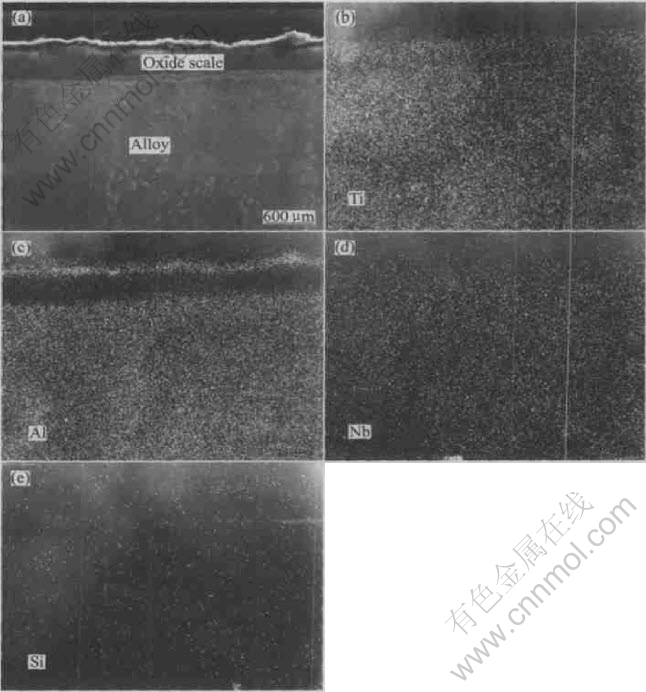

2.4 元素面分布

元素面分布(图6)分析表明, 03Si合金在850℃空气中循环氧化300次后氧化产物中最外层富Al, 次外层富Ti, 在次外层中基本没有Al的分布, 其它氧化温度下的结果与此相似。 EPMA元素面分布结果进一步证实了XRD及EDX分析结果。

3 分析与讨论

由图1(b)和(c)可知, 在循环氧化初始阶段, 由于在合金表面形成氧化物而使样品质量增加, 随后单位时间内的质量增加有所下降。 随着氧化物厚度的增加, 一定的循环次数后, 样品开始出现质量损失, 表明氧化膜局部发生剥落。

氧化膜最严重的开裂和剥落多数发生在降温过程中。 循环氧化实验是考察合金表面氧化膜粘附性的重要手段, 在循环氧化过程中合金/氧化膜体系经历冷却-加热的交替作用。 如果氧化膜与合金基体间存在热膨胀系数的差异, 则氧化膜将主要受热应力的作用。 热应力还与其它诸多因素有关, 如膜和基体的相对厚度、 冷却速率、 基体的曲率和表面粗糙度等[14]。

图6 03Si合金在850℃循环氧化300次后的截面形貌及元素面分布

Fig.6 Cross-section views and element distributions of 03Si alloy after cyclic oxidation for 300 times at 850℃

合金表面形成的氧化膜具有抗氧化性的一个必要条件是氧化膜均匀、 完整、 致密, 且与基体合金结合好, 只有满足这一条件氧化膜才可以起到隔绝氧化介质与合金基体之间发生化学反应。 实验中所选用的合金表面氧化膜主要为Al2O3和 TiO2的混合物, 其中Al2O3未能形成连续的膜层, 因此在700℃以上合金的抗氧化性能不足, 表现为循环氧化过程中氧化质量增加较大。 另外, 表面氧化膜产生开裂和剥落现象较为严重, 表面生成的氧化膜不能起到有效的防护作用。 如果将此类合金应用于700℃以上的氧化环境中, 必须采取其它的防护措施, 如在合金表面涂覆耐高温涂层。

Evans[15, 16]总结了氧化膜的破裂方式, 提出了2种典型的失效模型: 如果膜/金属界面结合强度较膜自身强度高时, 膜内首先产生纵裂纹, 进而扩展至界面, 导致这部分膜剥落; 如果氧化膜自身结合强度较高, 裂纹首先在界面处形成, 应力作用使膜发生弯曲, 当界面裂纹扩展至膜内时, 该区域的膜最后剥落掉。 对于实验所用合金, 在800℃及更高温度下氧化时, 在氧化膜的层间发生开裂, 在氧化膜/空气界面处氧化膜局部剥落, 氧化膜失效方式为物理分层效应所致。 由图5(c), (d)可见, 在氧化物膜层间存在许多微裂纹, 可能是氧化膜受生长应力和热应力联合作用的结果。 因为研究表明, 形成金红石TiO2时将产生相当高的生长应力[17]。 这些微裂纹在循环氧化时互相连接则可以产生氧化膜的层间裂纹, 由于合金氧化产物以TiO2为主, 其氧化机制为氧向内的扩散, 这样在靠近膜/合金界面的新生成的膜层内将重复进行微裂纹的产生及联接, 从而形成了截面图中所见的分层失效特点。 另外由图5中(c), (d)可知, 温度升高, 这种物理分层失效效应愈显著, 这种失效方式有别于前述Evans所提出的2种模式。

4 结论

1) 2种合金在700℃条件下具有较好的抗循环氧化性能, 而在800℃及以上的温度条件下, 表面氧化膜易于开裂和剥落。

2) 合金在较高温度下表面氧化膜失效方式为膜层中微裂纹的复合及由于这一过程的反复进行而导致了氧化膜间物理分层开裂。

REFERENCES

[1]仲增墉. 金属间化合物高温结构材料[J]. 材料科学进展, 1990, 4(2): 132-142.

ZHONG Zeng-yong. Intermetallic compounds for high temperature structural materials[J]. Materials Science Progress, 1990, 4(2): 132-142.

[2]Subrahmanyam J. Cyclic oxidation aluminized[J]. Journal of Material Science, 1988, 23: 1906-1910.

[3]Holwach J, Redden T K. Ti/Al design/cost trade-off analysis[R]. AFAPL-TR-78-74, Cincinnati, Ohio: General Electric Co., 1978.

[4]唐兆麟, 王福会, 吴维[SX(B-*5]山[]文[SX)]. 高温钛合金及钛铝金属间化合物的腐蚀与防护[J]. 稀有金属, 1996, 20(4): 291-296.

TANG Zhao-lin, WANG Fu-hui, WU Wei-tao. Corrosion and protection of high temperature Ti-based alloys and Ti-Al intermetallic compounds[J]. Rare Metals, 1996, 20(4): 291-296.

[5]Lipsitt H A. Titanium aluminides—an overview[A]. Koch C C, Liu C T, Stoloff N S. High Temperature Ordered Intermetallic Alloys[C]. Pittsburgh: Materials Research Society, 1985. 351-364.

[6]Perkins R A, Chiang K T, Meier G H . Formation of alumina on Ti-Al alloys[J]. Scripta Metall, 1987, 21: 1505-1510.

[7]Sankaran S N, Clark R K, Unnam J, et al. Oxidation characteristics of Ti-14Al-21Nb(%) ingot alloy[R]. NASA-TP-3012, Washington: NASA, 1990.

[8]Meier G H, Appalonia D, Perkins R A, et al. Oxidation of titanium-base alloys[A]. Grobstein T, Doychak J. Oxidation of High Temperature Intermetallics[C]. Cleveland, Ohio: The Minerals, Metals & Materials Society/AIME, 1989. 185-193.

[9]Welsch G, Kahveci A I. Oxidation behavior of titanium aluminide alloys[A]. Grobstein T, Doychak J. Oxidation of High Temperature Intermetallics[C]. Cleveland, Ohio: The Minerals, Metals & Materials Society/AIME, 1989. 207-218.

[10]Perkins R A, Chiang K T. Formation of alumina on niobium and titanium alloys[A]. Grobstein T, Doychak J. Oxidation of High Temperature Intermetallics[C]. Cleveland, Ohio: The Minerals, Metals & Materials Society/AIME, 1989. 157-169.

[11]Khobaib M, Vahldie F W. High temperature oxidation behavior of Ti3Al alloys[A]. Froes F H, Cull R A. Space Age Metals Technology[C]. Covina, CA, USA: Society for the Advancement of Material and Process Engineering, 1988. 262-270.

[12]Choudhury N S, Graham H C, Hinze J W. Oxidation behavior of titanium aluminides[A]. Properties of High Temperature Alloys with Emphasis on Environmental Effects[C]. Princeton N J: Electrochemical Society Inc., 1976. 668-680.

[13]Mendiratta M G, Choudhury N S. Properties and microstructure of high temperature materials[R]. AFML-TR-78-112, Dayton, Ohio: Systems Research Laboratories Inc., 1978.

[14]Tien J K, Davidson J M. Oxide spallation mechanisms[A]. Cathcart J V. Stress Effects and the Oxidation of Metals[C]. Detroit, M I: Metallurgy Society AIME, 1975. 200-219.

[15]Evans H E, Stress effects in high temperature oxidation of metals[J]. International Materials Review, 1995, 40(1): 1-40.

[16]Evans H E, Lobb R C. Conditions for the initiation of oxide scale cracking and spallation[J]. Corrosion Science, 1984, 24: 209-222.

[17]Bertrand G, Jarraya K, Chaix J M. Morphology of oxide scales formed on titanium[J]. Oxid Met, 1983, 21: 1-19.

基金项目: 国家自然科学基金资助项目(50371095); 沈阳市科技基金资助项目(030190)

收稿日期: 2004-01-05; 修订日期: 2004-05-22 作者简介: 钱余海(1973-), 男, 工程师.

通讯作者: 李美栓, 研究员; 电话: 024-23915913; E-mail: mshli@imr.ac.cn

(编辑 李向群)