文章编号:1004-0609(2014)04-1056-07

高铅渣液态还原过程中有价金属分布

陈 霖1, 2,杨天足1,刘伟锋1,张杜超1,宾 舒1,宾万达1

(1. 中南大学 冶金与环境学院,长沙 410083;

2. 山东黄金集团有限公司 博士后科研工作站,济南 250101)

摘 要:以铅精矿氧化熔炼产生的高铅渣为原料,通过静态实验研究其熔池熔炼还原过程。使用X射线衍射(XRD)和等离子体发射光谱(ICP)对反应原料及产物进行分析,探讨铁硅比、钙硅比、还原煤用量、还原温度、还原时间等对有价金属元素(Pb、Cu、Zn)在高铅渣还原产物中分布的影响。结果表明:静态实验中的Pb、Cu主要进入金属相,而Zn则基本进入还原渣中。最有利于有价金属综合回收的工艺条件如下:铁硅比1.25,钙硅比0.8,还原时间为60 min,还原温度为1200 ℃,还原剂的用量为理论量的1.3倍。

关键词:高铅渣;液态还原;熔池熔炼;金属分布

中图分类号:TF812 文献标志码:A

Distribution of valuable metals in liquid high lead slag during reduction process

CHEN Lin1, 2, YANG Tian-zu1, LIU Wei-feng1, ZHANG Du-chao1, BIN Shu1, BIN Wan-da1

(1. School of Metallurgy and Environment, Central South University, Changsha 410083, China;

2. Post-Doctoral Research Center, Shandong Gold Group Co., Ltd., Ji’nan 250101, China)

Abstract: The bath smelting reduction process of high lead slag, which is generated in the lead concentrate smelting process, was studied in static experiments. The raw material and the products of the process were analyzed using X-ray diffraction (XRD) and inductively coupled plasma (ICP). The influence of technical parameters, including iron to silica ratio, calcium oxide to silica ratio, dosage of reductant, reduction temperature and reduction time, on the distribution of valuable metals between the products of the reduction process was investigated. The results reveal that Pb and Cu mainly enter the metal phase, while Zn mainly enters the slag phase. The best process parameters for comprehensive metal recovery are that iron to silica ratio is 1.5, calcium oxide to silica ratio is 0.8, reduction temperature is 1200 ℃, reduction time is 60 min, dosage of reductant is 1.3 times of the stoichiometric value.

Key words: high lead slag; liquid reduction; bath smelting; metal distribution

铅金属被广泛应用于蓄电池、核能、化工等行业[1]。由于铅传统生产工艺污染严重,近年来我国在引进国外技术的基础上,自主发展了氧气底吹氧化熔炼-鼓风炉还原熔炼铅冶炼技术(水口山法)[2]。但是底吹炉所产生的高铅渣在进入鼓风炉之前需要通过铸渣机铸块,高温熔体自身的热能没有得到充分利用,降低了该工艺的能量效率[3]。为了解决这一问题,研究者们开发多种高铅渣液态直接还原技术,包括底吹炉还原熔炼、侧吹炉还原熔炼等[4-8]。研究认为,高铅渣液态还原能耗约为鼓风炉还原能耗的70%[9-10]。近年来,随着国家节能及环保政策的日益严格,推行高铅渣液态直接还原技术势在必行。

高铅渣液态还原时主要以熔融态与固体焦炭发生反应[6]。李卫锋等[11]研究发现高铅渣液态还原最佳工艺条件为1150 ℃,还原时间为1 h,还原剂率为3.5%,还原渣含铅可降低至约3%。王吉坤等[12-13]对高铅渣还原过程机理及渣型的影响进行了研究,发现还原温度达到1200 ℃时反应程度较高,渣钙硅比比的提高有利于铅的还原[12-13]。由于铅的市场价格较低,在回收铅的同时附带提取其他高附加值的金属(Cu、Zn、Ag等)是提高铅冶炼工业经济效益的关键[14]。目前,对于铅冶炼过程中有价金属分布的研究主要集中于铅精矿氧化熔炼阶段,例如赵红梅[15]对富氧顶吹炼铅过程的研究发现,Ag主要分布于氧化熔炼产生的一次粗铅中(78.08%),其余则分散于高铅渣(11.15%)、烟尘(3.93%)和铅冰铜(4.51%)中,而Zn主要进入高铅渣中(89.61%)。但对高铅渣液态直接还原过程中有价金属行为并没有进行系统的探索。而国外对于熔池熔炼过程中有价金属行为的研究则主要集中于铜镍冶炼工 艺[16-17],对铅冶炼过程研究较少。因此,尚未见工艺条件对高铅渣还原过程中有价金属分配行为影响的报道。

在此,本文作者主要考察高铅渣还原过程中主要工艺参数对Pb、Zn、Cu行为的影响,拟通过分析渣型、还原剂用量、还原温度、还原时间等因素对高铅渣还原过程中Pb、Zn、Cu在金属和渣中的分配比例,获得最佳工艺条件,研究有价金属在高铅渣还原过程中的分配行为。

1 实验

1.1 实验原料

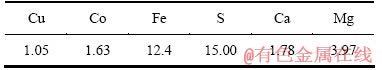

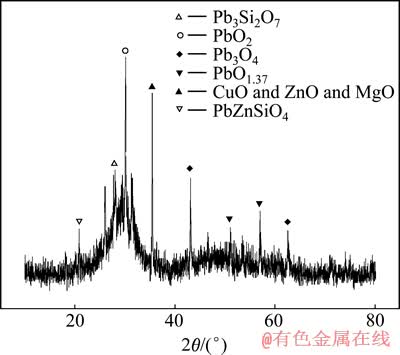

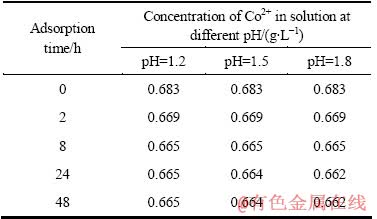

实验所采用的原料为河南某铅冶炼企业所产的高铅渣,其中主要元素质量分数如表1所列。高铅渣XRD分析结果如图1所示。

表1 高铅渣的主要成分

Table 1 Composition of high lead slag (mass fraction, %)

由图1可以看出,高铅渣中主要元素Pb、Cu、Zn、Fe、Si等均以金属氧化物或者硅酸盐的形式存在。

实验中使用氧化钙,二氧化硅及氧化铁化学纯试剂(天津科密欧)配制熔剂。以粉煤作为还原剂,其化学成分(质量分数)如表2所列。

图1 高铅渣XRD谱

Fig. 1 XRD pattern of high lead slag

表2 还原煤的化学成分

Table 2 Composition of coal (mass fraction, %)

从表2中可以看出,粉煤中碳含量为55.36%,挥发分和灰分的含量分别为27.34%和16.8%,同时还含有少量的水分。

1.2 实验设备

熔池熔炼还原实验设备为高温井式炉(合肥科晶,VTF1600X)。实验容器采用粘土坩埚(直径为90 mm,高为70 mm)。熔炼反应完成后金属相和渣相中金属含量分析使用等离子体发射光谱(Thermo Electron,IRIS Interprid 3 XRS),物相分析使用X射线衍射仪(Rigaku, TTRⅢ)。

1.3 实验方法

根据高铅渣成分和所需渣型可以计算出各熔剂的配入量。根据高铅渣中金属(Pb、Zn、Cu)还原所需理论用量计算还原煤的加入量。将配好的物料混匀,倒入坩埚后进行熔炼。实验进行时采用升温速率为10 ℃/min,到达实验温度后保温一定的时间以进行还原反应,反应结束后从熔炼炉中取出坩埚在室温下自然冷却,然后将渣相和金属相分开、称质量并分别分析渣和金属的成分。有价金属回收率通过式(1)计算:

(1)

(1)

式中:mmetal为金属相的质量;w(M)metal为金属相金属(M=Pb或Cu)的含量;mM,t为高铅渣中该金属的总质量。由于采用的是静态熔池进行实验,而且烟尘收集困难,在本研究中没有进行烟尘的分析,因此,主要通过还原渣中的锌含量来计算锌的回收率,计算式如式(2)所示:

(2)

(2)

金属在金属相和渣相中的分配比(D)通过式(3)计算:

(3)

(3)

式(2)和(3)中:w(Zn)slag为渣相中Zn的含量;mmetal、w(M)metal分别为金属相的质量和金属M在金属相中的含量;mslag、w(M)slag分别为渣的质量和该金属M在渣中的含量。

2 结果与分析

2.1 铁硅比的影响

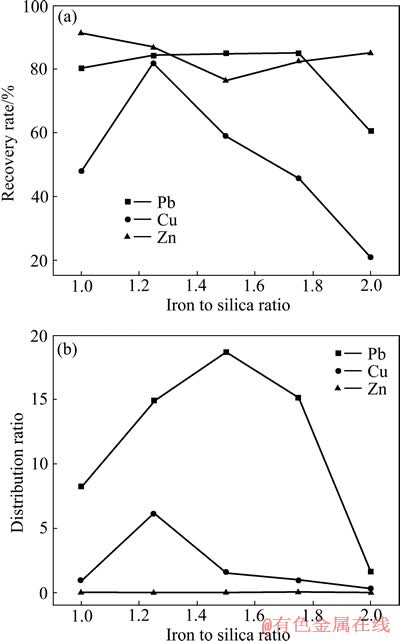

固定还原温度为1200 ℃,还原时间为60 min,还原煤用量为理论用量的1.5倍,钙硅比为0.8,研究铁硅比对有价金属回收率及其在金属、渣相中分配率的影响。

图2(a)所示为铁硅比对Pb、Zn、Cu回收率和分配比的影响。由图2(a)可知,Pb和Cu主要存在于金属相中,Zn则主要存在于渣中。Pb和Cu的回收率均呈先增大后减小的趋势,但两者趋势有明显的不同:在铁硅比为1.0~1.8的范围内,Pb回收率呈现平稳增长的趋势,在铁硅比为1.5~1.75时,达到最高(为84.8%),进一步增加铁硅比将导致Pb回收率急剧下降;Cu回收率在铁硅比为1.25时,达到最高值(为81.7%),增大或减小铁硅比均导致回收率大幅度地下降,当铁硅比增大至2时,回收率甚至降低至约20%。在研究过程中,发现在金属相中基本不存在Zn,由于铅冶炼过程中主要通过还原渣挥发回收Zn,因此,采用还原渣中Zn含量来考察Zn回收率。如图2(a)所示,其随铁硅比变化显示出与Pb、Cu相反的趋势。Zn在铁硅比为1.5时,在渣中含量最少(76%),增大和降低铁硅比将提高Zn的回收率,最高可达到约90%。

图2(b)显示了铁硅比对有价金属在金属相和渣相中分配比例的影响。由图2(b)可见,Pb、Cu的分配比随铁硅比的变化趋势与回收率相似,而Zn的分配比则平稳地保持在0附近。铁硅比对Pb分配比的影响较大。当铁硅比从1增加到1.5时,Pb分配比增大到18.6,增长幅度达到2.3倍,而Pb回收率增加并不明显,说明此过程中Pb挥发进入烟尘的量增多,使得分配比急剧增大。Cu分配比在铁硅比为1.5时达到最高值(约6.1),这也说明了Cu进入烟尘量较少。这些结果与图2(a)具有较好的对应性,说明在铁硅比为1.5的条件下,Pb、Cu可以获得在金属相中最大的分配,而Zn则主要进入渣中。

图2 铁硅比对金属回收率及分配比的影响

Fig. 2 Effects of iron to silica ratio on metal recovery rate (a) and metal distribution ratio (b)

研究发现高铅渣液态还原过程中Pb和Cu的回收率在一定范围内随着铁硅比的增加而增加,这可能是因为铁硅比的增大使得炉渣黏度降低,渣的流动性变好。贺家齐等[18]研究铁硅比对铁橄榄石炉渣黏度的影响也发现,铁硅比从1.0增大到1.9时,炉渣的黏度逐渐减小。但是铁硅比进一步增大将导致Pb和Cu的回收率及分配比均出现急剧的下降,这可能是因为过多的FeO容易导致生成高熔点的Fe3O4,引起炉渣黏度的增加,不利于金属、渣分离。过量FeO的存在也会导致Cu在炉渣中溶解度上升,使得渣相中有价金属含量增多。Zn的分配比受铁硅比的影响较小,在各条件下均主要进入渣中,这也有利于Zn的烟化回收。

2.2 钙硅比的影响

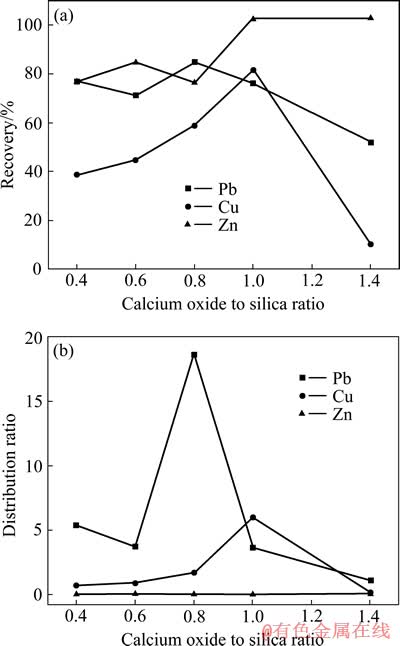

固定还原温度为1200 ℃,还原时间为60 min,还原煤用量为理论用量的1.5倍,铁硅比为1.5,研究钙硅比对有价金属回收率以及在金属、渣相中分配比的影响。

图3(a)显示了高铅渣还原过程中钙硅比对Pb、Zn、Cu回收率的影响。当钙硅比在0.4~0.8范围内增大时,Pb、Cu的回收率上升,而Zn的回收率保持在约80%;在钙硅比为0.8时,Pb达到最高的回收率(84.9%),继续提高钙硅比将降低Pb回收率,而Cu和Zn的回收率则分别提高至81.3%和100%左右;当钙硅比为1.4时,Pb和Cu回收率均大幅降低,分别为51%和10%,Zn的回收率则保持在100%左右。

图3 钙硅比对金属回收率和金属分配比的影响

Fig. 3 Effects of calcium oxide to silica ratio on metal recovery (a) and metal distribution ratio (b)

图3(b)显示了钙硅比对Pb、Zn、Cu在金属相和渣相中分配比的影响。由图3(b)可见,钙硅比为0.8、1.0时,Pb、Cu的分配比分别达到最大值,此时Pb的分配比高达约18,说明钙硅比的增大不仅使得进入金属相的Pb增多,而且增加了烟尘中的Pb。当钙硅比进一步增大至1.4时,Pb、Cu分配比均下降至最低值,Zn分配比在各钙硅比下均保持在0。这与图3(a)所示的结果基本吻合。

高铅渣还原过程中Pb及Cu的回收率随着钙硅比的变化存在极大值,其原因是FeO-SiO2渣中的SiO2常以硅氧络阴离子存在,大量SiO2会生成结构复杂的络氧阴离子,从而增大炉渣的黏度。CaO能使络氧阴离子的结构变得简单,从而降低炉渣黏度,增加熔体的流动性。但是过量的CaO会提高炉渣的熔点,不利于金属和渣的分层。这在研究中也得到了验证:当钙硅比为1.0时,Pb的分配比明显下降。事实上,研究发现在钙硅比为1.4时,渣-金属相没有明显的界线。

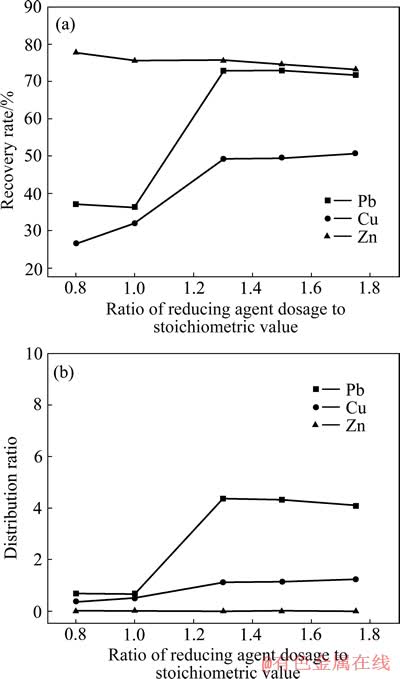

2.3 还原煤用量的影响

固定加入还原温度为1200 ℃,还原时间为60 min,铁硅比为1.25,钙硅比为0.4等条件,改变还原煤的用量依次为理论量的1.75倍、1.5倍、1.3倍、1倍、0.8倍,研究还原煤用量对有价金属回收率及其在金属和渣相中分配比的影响。

由图4(a)可见,Pb和Cu的回收率在还原剂用量为理论用量的0.8倍时分别仅为37%和27%。当还原剂用量为理论值1.3倍时,回收率大幅提高至72%和50%,继续增加还原剂用量对Pb、Cu的回收率影响较小。Zn的回收率随还原剂用量的增加呈现下降的趋势,还原剂用量从0.8倍增大至1.75倍,Zn回收率下降至约4%,可能是由于Zn挥发进入烟尘。

图4(b)显示了还原剂用量对Pb、Zn、Cu在金属和渣相中分配比的影响。与图4(a)中回收率变化相对应,Pb和Cu的分配比也呈现出先增加后稳定的趋势。在还原剂用量为1.3倍时,Pb、Cu分配比达到最高,说明此条件对于回收Pb和Cu最有利。Zn的分配比非常小,说明Zn主要进入渣中。

随着还原煤用量的增加,渣中的Pb和Cu含量逐渐降低,这是因为还原剂用量的增加创造了有利于还原的气氛。还原剂的量达到一定的值后,Pb和Cu的分配比保持稳定,但过强的还原性气氛会导致Zn挥发进入烟尘,影响后续回收。

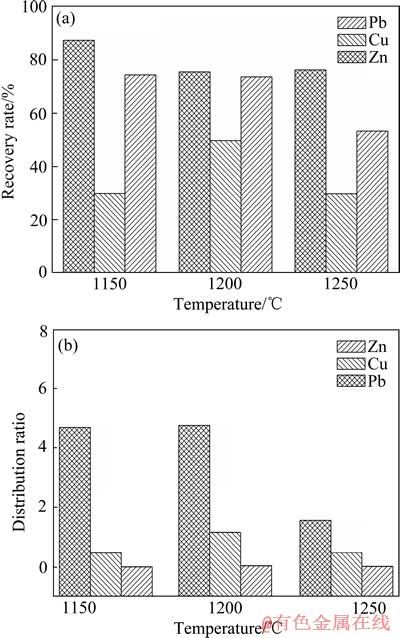

2.4 还原温度的影响

固定还原时间为60 min,铁硅比为1.25,钙硅比为0.4,还原煤的用量为理论量的1.3倍等条件,研究还原温度对有价金属回收率及其在金属、渣相中分配比的影响。

图4 还原剂量对金属回收率和金属分配比的影响

Fig. 4 Effects of reduction agent dosage on metal recovery rate (a) and metal distribution ratio (b)

由图5(a)可以看出,Pb回收率随温度的升高而逐渐地降低,在1150 ℃、1200 ℃、1250 ℃ 3个温度下分别为73.5%,72.2%和52.3%。而Cu回收率则随着还原温度的提高存在最大值:还原温度为1150 ℃和1250 ℃时,其回收率均仅为约30%,而在1200 ℃时,为50%。Zn回收率在各还原温度下均保持在75%以上,提高还原温度100 ℃(1150 ℃→1250 ℃)导致Zn的回收率降低至约12%。

图5(b)所示为不同还原温度下Pb、Zn、Cu在金属和渣相中分配比的变化。由图5(b)可知,Pb和Cu在各还原温度下分配比均大于1,在1200 ℃时,Pb、Cu的分配比取得最大值,分别为8.5、2.2。Zn的分配比在1100~1200 ℃之间基本无变化,表明Zn主要进入渣相[15]。还原温度为1250 ℃时,Pb、Zn和Cu的回收率均出现一定程度的下降,可能是随着温度升高烟尘率上升的原因。因此,使用1200 ℃的还原温度能更好地实现将Pb和Cu富集到金属中、Zn富集到渣相的目的。

随着还原温度的增加,Pb和Zn回收率均呈现逐渐降低的趋势,而Cu的回收率则在1200 ℃出现极大值。根据热力学相图[19],铁硅比为1.25、钙硅比为0.4时,渣的熔化温度约为1110 ℃,说明在1150 ℃即可实现高铅渣的液态还原。在此基础上提高还原温度有利于提高还原反应速度,并降低渣的黏度,对金属的回收有利。但还原温度过高将加大Pb和Zn的挥发,造成有价金属的直收率下降。

图5 还原温度对金属回收率和金属分配比的影响

Fig. 5 Effects of reduction temperature on metal recovery (a) and metal distribution ratio (b)

2.5 还原时间的影响

固定铁硅比为1.75,钙硅比为0.8,还原煤的用量为理论量的1.3倍,还原温度为1200 ℃等条件,改变反应时间依次为30、60、90和120 min,研究还原时间对有价金属回收率及其在金属、渣相中分配比的影响。

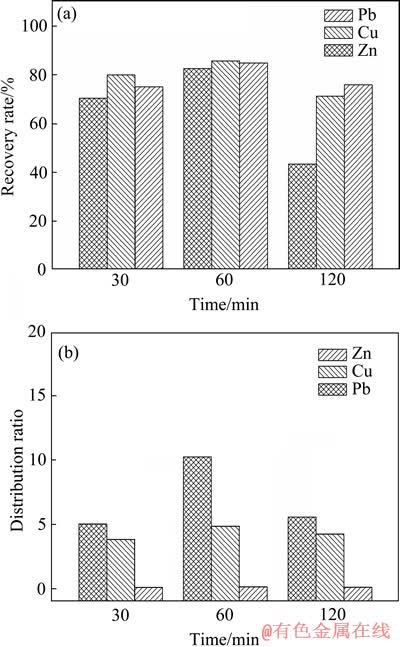

图6(a)显示了不同还原时间对Pb、Zn、Cu回收率的影响。由图6(a)可见,随还原时间增加,Pb、Cu、Zn回收率均出现先增后降的趋势。还原时间为60 min时,Pb、Cu、Zn回收率达到最高值,分别约为84%、85%和82%。Zn的回收率受还原时间的影响较明显,当还原时间增至120 min时,Zn回收率急剧下降至约43%,说明大量Zn挥发进入烟尘中。

图6 还原时间对金属回收率和金属分配比的影响

Fig. 6 Effects of reduction time on metal recovery rate (a) and metal distribution ratio (b)

图6(b)为不同还原时间时Pb、Zn、Cu在金属和渣相中分配比的变化。由图6(b)可见,Pb和Cu在还原时间为60 min时,分配比达到最大,而Zn的分配比则一直稳定在0附近。虽然还原时间为120 min时,Zn的回收率较低,但由于其主要挥发进入烟尘,因此,其分配比没有受到影响。

综合以上实验结果可以看出,还原时间为60 min最有利于Pb、Cu、Zn的回收,Pb、Cu的分配比变化也符合此趋势。还原时间的延长有利于提高还原反应程度,降低渣中金属含量,但对于Zn的回收不利。但过长的反应时间不仅需要消耗更多的能量,而且降低了生产效率,还会导致Zn挥发进入烟尘,造成其回收率降低。

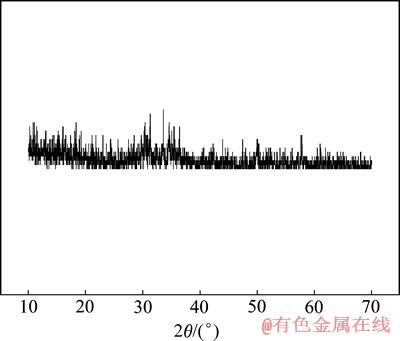

2.6 还原渣物相分析

高铅渣液态还原所产生还原渣的主要成份为Fe、Si、Ca,为重金属火法冶炼工艺中常见的硅铁钙渣,具有较低的熔点和密度,能够有效地与还原后产生的金属相分离。图7所示为还原渣XRD谱。将图7与高铅渣原料XRD谱(图1)对比可发现,还原渣中已不存在原高铅渣中的含铅物相(如PbO、Pb3O4、Pb2Si2O4等),这说明经过液态还原后高铅渣中的Pb已经被还原为金属Pb进入金属相。但还原渣结晶不好,其XRD谱中没有明显特征峰出现,说明经过高温熔融及降温过程,还原渣中成份表现主要以无定型态存在。

图7 还原渣的XRD谱

Fig. 7 XRD pattern of reduction slag

3 结论

1) 高铅渣液态还原过程有价金属综合回收最优工艺条件为:铁硅比为1.25,钙硅比为0.8,还原时间为60 min,还原温度为1200 ℃,还原剂的用量为理论量的1.3倍。

2) 铅、铜在高铅渣液态还原过程中主要进入金属相。钙硅比和还原煤用量对Pb和Cu分配比影响较大,最高Pb、Cu分配比可分别达到18.6和6.1。Zn主要进入渣中,其分配比均稳定在0.01以下。

3) 高铅渣液态还原后含铅物相消失,还原渣以无定型形式存在。

REFERENCES

[1] DUBE R K. The extraction of lead form its ores by the iron-reduction process: A historical perspective[J]. Journal of the Minerals, Metals and Materials Society, 2006, 58(10): 18-23.

[2] 李东波, 张兆祥. 氧气底吹熔炼—鼓风炉还原炼铅新技术及应用[J]. 有色金属: 冶炼部分, 2003(5): 12-13.

LI Dong-bo, ZHANG Zhao-xiang. The application of new lead smelting technology of oxidizing in bottom blowing furnace and reduction smelting in blast furnace[J]. Nonferrous Metals: Extractive Metallurgy, 2003(5): 12-13.

[3] 王晓曦, 邹汉伟. 液态渣显热回收技术现状及前景分析[J]. 铁合金, 2007, 38(5): 34-36.

WANG Xiao-xi, ZOU Han-wei. Current situation and prospect of liquid slag sensible heat recovery technology[J]. Ferro-Alloys, 2007, 38(5): 34-36.

[4] 张 立, 蔺公敏, 宾万达, 李元香, 李小兵. 氧气侧吹还原炉及高铅渣熔融还原过程研究[C]// 全国第二届熔池熔炼技术及装备专题研讨会论文集. 西安: 中国有色金属学会重有色金属冶金学术委员会, 2011: 275-280.

ZHANG Li, LIN Gong-min, BIN Wan-da, LI Yuan-xiang, LI Xiao-bin. Research on oxygen side blow reduction furnace and high lead slag liquid reduction process[C]// The 2nd Bath Smelting Technology and Equipment Symposium. Xi’an: China Nonferrous Metal Society Heavy Metal Metallurgy Academy Committee, 2011: 275-280.

[5] 杨华锋, 翁永生, 张义民. 氧气底吹-侧吹直接还原炼铅工艺[J]. 中国有色冶金, 2010(4): 13-16.

YANG Hua-feng, WENG Yong-sheng, ZHANG Yi-min. Lead direct smelting with oxygen bottom and side blowing[J]. China Nonferrous Metallurgy, 2010(4): 13-16.

[6] 李卫锋, 陈会成, 李 贵, 张传福. 低碳环保的豫光炼铅新技术-液态高铅渣直接还原技术研究[J]. 有色冶金节能, 2011(2): 14-18.

LI Wei-feng, CHENG Hui-cheng, LI Gui, ZHANG Chuan-fu. New Yuguang lead smelting technology with low carbon and environmental protection-study on direct reduction technology of liquid rich-lead slag[J]. Energy Saving of Nonferrous Metallurgy, 2011(2): 14-18.

[7] 蔺公敏, 宾万达. 氧气侧吹直接炼铅炉[J]. 中国有色冶金, 2005, 34(6): 48-50.

LIN Gong-ming, BIN Wan-da. Oxygen side-blown direct lead smelting furnace[J]. China nonferrous metallurgy, 2005, 34(6): 48-50.

[8] CHEN Lin, BIN Wan-da, YANG Tian-zu, LIU Wei-feng, BIN Shu. Research and industrial application of oxygen-rich side-blow bath smelting technology[C]// 4th International Symposium on High-Temperature Metallurgical Processing. San Antonio: John Wiley & Sons, Inc., 2013: 49-55.

[9] 皮国民, 贾著红. 粗铅冶炼富铅渣热态还原研究[J]. 有色金属: 冶炼部分, 2009(6): 17-19.

PI Guo-min, JIA Zhu-hong. Study on lead bullion smelting & reduction of hot lead-rich slag[J]. Nonferrous Metallurgy: Extractive Metallurgy, 2009(6): 17-19.

[10] 郭 明. 氧气底吹炼铅先进工艺的节能减排效果与分析[J]. 有色冶金节能, 2008(5): 15-19.

GUO Ming. Technical analysis and energy-saving & emission reduction effects of lead metallurgy by advanced oxygen bottom-blowing process[J]. Energy Saving of Nonferrous Metallurgy, 2008(5): 15-19.

[11] 李卫锋, 杨安国, 陈会成, 张传福. 液态高铅渣直接还原试验研究[J]. 有色金属: 冶炼部分, 2011(4): 10-13.

LI Wei-feng, YANG An-guo, ZHANG Chuan-fu. Technology study on direct reduction of lead-rich slag[J]. Nonferrous Metallurgy: Extractive Metallurgy, 2011(4): 10-13.

[12] 王吉坤, 赵宝军, 杨 钢, PETER H. 富铅渣的性质及其还原机理[J]. 有色金属: 冶炼部分, 2004(6): 5-8.

WANG Ji-kun, ZHAO Bao-jun, YANG Gang, PETER H. Properties and reduction mechanism of lead-rich slags[J]. Nonferrous Metallurgy: Extractive Metallurgy, 2004(6): 5-8.

[13] 杨 钢, 赵宝军, 王吉坤, PETER H. CaO/SiO2比率对富铅渣还原反应的影响研究[J]. 有色金属: 冶炼部分, 2008(4): 5-7.

YANG Gang, ZHAO Bao-jun, WANG Ji-kun, PETER H. Effect of CaO/SiO2 on the reduction of lead-rich slags[J]. Nonferrous Metallurgy: Extractive Metallurgy, 2008(4): 5-7.

[14] KONIG R, WEYER A, DEGEL D R, SCHMIDL J, KADEREIT D H, SPECHT D A. Highly Efficient Slag Cleaning–Latest Results from Pilot-Scale Tests[C]// REWAS 2013. San Antonio: John Wiley & Sons, Inc., 2013: 1-12.

[15] 赵红梅. 富氧顶吹炼铅过程中金属元素行为初探[J]. 云南冶金, 2009, 38(S1): s34-s37.

ZHAO Hong-mei. Preliminary exploration on metal element behaviors in lead smelting process of oxygen-rich top blowing[J]. Yunnan Metallurgy, 2009, 38(S1): s34-s37.

[16] JOHNSTON M D, JAHANSHAHI S, ZHANG L, LINCOLN F J. Effect of slag basicity on phase equilibria and selenium and tellurium distribution in magnesia-saturated calcium iron silicate slags[J]. Metallurgical and Materials Transactions B, 2011, 41(3): 625-635.

[17] BAKKER M L, NIKOLIC S, ALVEAR G R F. ISACONVERT (TM)-continuous converting of nickel/PGM matte with calcium ferrite slag[J]. Journal of the Minerals, Metals and Materials Society, 2011, 63(5): 60-65.

[18] 朱祖泽, 贺家齐. 现代铜冶金学[M]. 北京: 科学出版社, 2003: 79-82.

ZHU Zu-ze, HE Jia-qi. Modern copper metallurgy[M]. Beijing: Science press, 2003: 79-82.

[19] 铅锌冶金学编委会. 铅锌冶金学[M]. 北京: 科学出版社, 2003: 220-221.

Lead and Zinc Metallurgy Editorial Board. Lead and zinc metallurgy[M]. Beijing: Science press, 2003: 220-221.

(编辑 李艳红)

基金项目:国家高技术研究发展计划资助项目(2011AA061002)

收稿日期:2013-07-29;修订日期:2014-02-25

通信作者:杨天足,教授,博士;电话:0731-88830923;传真:0731-88710171;E-mail: tianzuyang@163.com