Mg/Al异种材料瞬间液相过冷连接工艺研究

刘蒙恩,盛光敏

(重庆大学 材料科学与工程学院,重庆,400045)

摘要:采用瞬间液相过冷连接工艺对AZ31镁合金和5083铝合金进行连接实验,研究保温扩散时间t2对焊缝微观组织及力学性能的影响。利用SEM,EDS,XRD和微观硬度计对接头剖面的微观组织和力学性能进行表征;在拉伸试验机上测试接头拉伸强度,利用SEM对断口形貌进行分析。研究结果表明:采用瞬间液相过冷连接工艺可以实现Mg/Al异种材料的有效连接;随着保温扩散时间t2的增加,接头的抗拉强度随之提高,当t2=30 min时,接头抗拉强度最高达到20.5 MPa;拉伸断口形貌具有明显的脆性断裂的特征,铝合金侧主要有解理面和撕裂棱组成,而镁合金侧属于典型的沿晶断裂形貌;在接头处形成MgAl,Mg2Al3,Mg0.44Al0.56和Mg17Al12金属间化合物,结合界面的微观维氏硬度最高达320。

关键词:瞬态液相扩散;过冷连接;显微组织;抗拉强度

中图分类号:TG453.9 文献标志码:A 文章编号:1672-7207(2012)07-2542-05

Super-cooled process for transient liquid phase (TLP) bonding technology of Mg/Al dissimilar materials

LIU Meng-en, SHENG Guang-min

(School of Materials Science and Engineering, Chongqing University, Chongqing 400045, China)

Abstract: Magnesium alloy (AZ31) and aluminum alloy (5083) were bonded by super-cooled process for transient liquid phase (TLP) bonding technology. Effects of treating time parameters on microstructures and tensile properties were studied. The joints were investigated for microstructural features, phase structure, microhardness, mechanical properties by scanning electron microscopy (SEM), energy dispersive spectrometer (EDS), microhardness tester and X-ray diffractometer. The results show that Mg/Al could be bonded by super-cooled process for transient liquid phase (TLP) bonding technology without a middle layer. The tensile strength of the joints increases with increasing the treating time, and when t 2=30 min, its tensile strength can reach 20.5 MPa. The cleavage plane and tearing ridge, which was usually taken as cleavage fracture and intergranular fracture, could be seen on the tensile fracture surfaces in the side of aluminum alloy and that of the side of magnesium alloy is typical intergranular fracture. A layer of intermetallic compound is formed between magnesium alloy and aluminum alloy, leading to a low strength in joint region. There are MgAl, Mg2Al3, Mg0.44Al0.56 and Mg17Al12 intermetallic compounds, and the highest Vickers hardness is 320 in the joint zone.

Key words: transient liquid-phase bonding; super-cooled; microstructure; tensile strength

镁和铝合金密度低、比强度高、比刚性高,作为轻质工程结构材料有着越来越广阔的应用前景[1-2],鉴于镁材和铝材应用的广泛性和交叉性,将镁和铝及其合金连接形成复合结构就显得十分必要,这样既可降低结构重量,又可降低成本[3]。由于铝合金和镁合金进行连接时容易产生硬而脆的Mg-Al金属间化合 物[4-5],在采用传统的熔焊焊接方法进行焊接时,容易产生热裂纹、气孔、合金元素烧损和焊缝区软化等问题[6-7],故铝合金零件和镁合金零件及铝合金和镁合金的连接多采用机械连接,因此,大大限制了镁材和铝材的应用。国内外学者已对镁和铝异种材料连接进行大量研究,Yutaka等[8]对1050铝合金与AZ31镁合金进行了搅拌摩擦焊(FSW)研究,焊缝中形成了金属间化合物Mg17Al12,导致焊缝区硬度高达HV 200~225;刘鹏等[9-12]采用真空扩散焊对纯镁和1070A纯铝进行连接试验,接头的最大的剪切强度为18.94 MPa;李线绒等[13]采用镁铝合金粉末或镁锌合金粉末连接剂的方法实现了镁/铝异种金属的连接,试样的最高弯曲强度达到22.7 MPa;Takehiko等[14]研究了Ag箔做中间层对接头性能的影响。根据Mg-Al二元相图,Mg和Al部分互溶,在一定温度条件下,形成了MgAl和Mg2Al3等金属间化合物。过冷工艺通过在界面处产生成分过冷,破坏了传统TLP工艺的界面平衡状态,使凝固过程具有不平衡结晶特征,加快了等温凝固过程。成分过冷度的存在使传统的平直界面失稳,变成非平面状界面;并且随着凝固的完成,最终界面消失,形成无界面的组织均匀接头[15]。在此,本文作者采用过冷瞬态液相扩散连接工艺对Mg/Al异种材料进行连接试验,对接头进行性能测试,并对接头结构及拉伸断口进行微观分析。

1 试验材料及方法

1.1 试验材料

试验所用材料为AZ31镁合金和5083铝合金的棒材,规格为d 16 mm×35 mm。材料的化学成见表1。

表1 试验材料的化学成分(质量分数)

Table 1 Chemical composition of tested materials %

1.2 试验方法

将AZ31镁合金和5083铝合金的连接端面用水砂纸打磨并抛光。焊接前,对抛光后的试样放在丙酮中进行超声波清洗,以去除试样端面的油污和杂质,经酒精冲洗后,为防止镁合金与铝合金在空气中再次氧化,直接将带有乙醇液膜的试样装入Gleeble-1500D型热模拟试验机中。

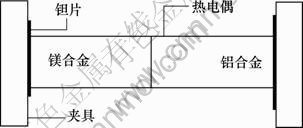

镁合金与铝合金试样装配如图1所示,将2种材料经过抛光清洗的端面对接,采用Ni-Cr/Ni-Al 热电偶进行测温,热电偶焊于铝合金侧距界面1 mm 处,为了避免试样与夹具在高温下发生黏结,在二者之间加入钽片。连接时的真空度为1×10-2 Pa。

图1 试样装配图

Fig.1 Assembly of samples

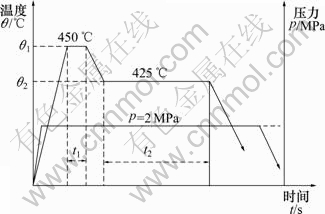

Mg/Al异种材料瞬间液相过冷连接工艺如图2所示,为探讨保温扩散时间t2对接头性能的影响,选择4个不同的保温扩散时间(分别是0,5,10和20 min),升温和降温速度均为10 ℃/s,焊接过程中施加2 MPa的轴向压力。

图2 Mg/Al过冷TLP连接工艺参数曲线

Fig.2 Super-cooled process for transient liquid phase (TLP) bonding of Mg/Al

将拉伸试样在新三思CMT5105 型材料拉伸试验机上进行拉伸,加载速率为0.1 mm/min;用微观硬度计对结合界面及附近母材的硬度变化进行测试;用Vega Tescan 型电子扫描显微镜(SEM)对拉伸断口和接头剖面的组织进行观察和分析;并用D/MAX-1400 型X线衍射仪对拉伸断口试样进行X线衍射试验,以便对试样的组织和物相进行分析研究。

2 结果及分析

2.1 接头微观组织观察

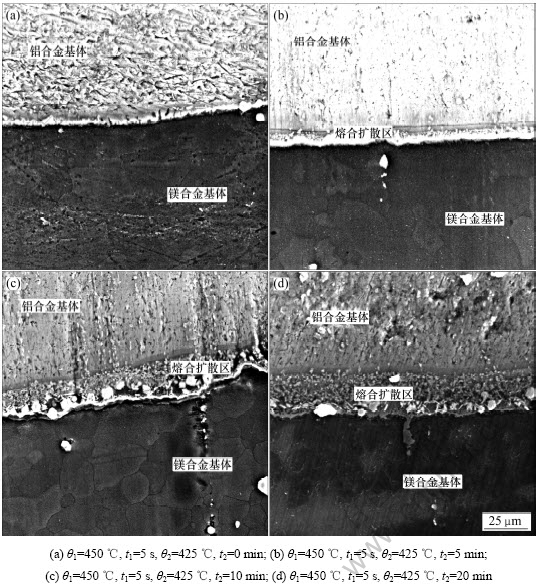

采用扫描电镜(SEM)对Mg/Al瞬间液相过冷连接接头显微组织进行观察。图3所示为t2=0~30 min不同工艺的显微组织图片。试验结果表明4种工艺均形成了有效连接,从图3(a)可以看出:由于在试样两端施加了2 MPa的压力,在压力作用下,多余的液相被挤压出去,同时促进了液相的均匀铺展,但是由于时间较短,2个试样只是靠液相的润湿性连接在一起,扩散层厚度非常薄。对比图3(a)和3(b)可以看出:相对图3(a),图3(b)已经存在一定厚度的扩散层。随着t2的延长,熔合扩散层逐渐增厚,对比图3(c)和3(d)可以看到:随着扩散时间的延长,扩散层的组织和成分更加均匀。由于过冷连接工艺在液相区形成了一个过冷温度,打破了连接面的平衡状态,导致液相结晶过程中形成了成分过冷,改善晶体生长方式从而加速了元素的扩散和界面移动。

2.2 接头强度分析

为了更加全面地对焊接接头的性能进行表征,进行了拉伸试验。试验结果如图4所示。从图4可以看出:扩散时间t2=0~30 min时,随着保温扩散时间t2的延长,抗拉强度逐渐增大,这是由于随着保温扩散时间的延长,接头与母材之间的元素相互扩散更加充分,随着保温扩散时间的延长,抗拉强度的增长趋势逐渐减弱。当t2=30 min时,抗拉强度最高达到20.4 MPa。

图3 接头SEM显微组织

Fig.3 SEM microstructures of joint

图4 连接接头的抗拉强度

Fig.4 Tensile strength of bonded joints

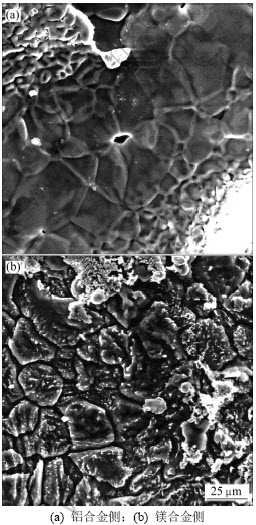

2.3 接头断口分析

利用SEM对t2=30 min试样的拉伸断口进行分析,结果如图5所示。从图5可见:铝侧断口形貌属于准解理,有台阶和撕裂棱;镁侧断口形貌扫描图片呈现典型的沿晶断裂形貌,在镁和铝两侧均存在一些白色点状新相,属于Mg-Al系金属间化合物,正是由于这些金属间化合物的存在,使接头强度较低。

图5 30 min下过冷TLP接头拉伸断口的SEM

Fig.5 Tensile fracture SEM of joint at 30 min

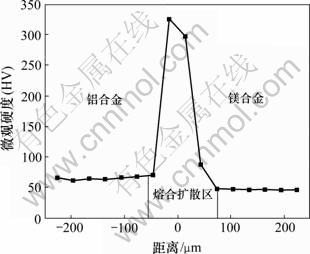

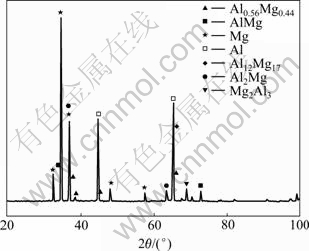

2.4 接头剖面硬度及XRD分析

用显微硬度计对接头剖面进行硬度测定,显微硬度分布如图6所示。硬度分布分为3个区间:铝合金母材、熔合扩散区和镁合金母材,熔合扩散区的硬度明显高于母材,最高维氏硬度达到320,这与微观组织观察结果一致,由于金属间化合物的生成,导致熔合扩散区硬度明显升高。

为了进一步确定熔合扩散区形成的金属间化合物种类,对接头剖面进行X线衍射分析,结果如图7所示。接头中形成了MgAl,MgAl2,Mg2Al3,Mg0.44Al0.56和Mg17Al12 5种金属间化合物,这是导致熔合扩散区硬度升高的主要原因,同时,由于这些金属间化合物的存在,导致接头强度不高。

图6 Mg/Al过冷TLP接头结合界面显微硬度分布

Fig.6 Distribution of microhardness in interface of Super-cooled transient liquid phase of Mg/Al

图7 t2=30 min时过冷TLP接头剖面X线衍射分析

Fig.7 X-ray diffraction pattern of longitudinal section of super-cooled TLP joint at t2=30 min

3 结论

(1) 采用过冷TLP连接工艺可以实现Mg/Al异种材料的有效连接,在采用2 MPa恒压的情况下,随着保温扩散时间t2的延长,接头的抗拉强度随之增高,当t2=30 min时,接头的抗拉强度可以达到20.5 MPa。

(2) 接头的微观硬度分布分为3个区:铝合金母材、熔合扩散区和镁合金母材,熔合扩散区的硬度明显高于母材,最高维氏硬度达320。

(3) 铝侧断口形貌属于准解理,有台阶和撕裂棱,镁侧断口形貌呈现典型的沿晶断裂形貌,在镁和铝两侧均存在一些白色点状新相,属于Mg-Al系金属间化合物,经X线衍射分析表明:接头过渡区存在MgAl,MgAl2,Mg2Al3,Mg0.44Al0.56和Mg17Al12 5种金属间化合物。

参考文献:

[1] Schubert E, Klassen M, Zemer I, et al. Light-weight structures produced by laser beam joining for future applications in automobile and aerospace industry[J]. Journal of Materials Processing Technology, 2001, 115(2): 2-8.

[2] 黄伯云. 我国有色金属材料现状及发展战略[J]. 中国有色金属学报, 2004, 14(5): 122-127.

HUANG Bai-yun. Status and developing strategy for China nonferrous metal materials industry[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(5): 122-127.

[3] Mordike B L, Ebert T. Magnesium: Properties-applications- potential[J]. Materials Science and Engineering A, 2001, 302(1): 37-45.

[4] 王东, 刘杰, 肖伯律, 等. 铝合金/镁合金搅拌摩擦焊接界面处Mg/Al反应及接头力学性能[J]. 金属学报, 2010, 46(5): 589-594.

WANG Dong, LIU Jie, XIAO Bo-lü, et al. Mg/Al reaction and mechanical properties of Al alloy/Mg alloy friction stir welding joints[J]. Acta Metal Sin, 2010, 46(5): 589-594.

[5] 谭成文, 郭冠伟, 王潇屹. AZ31镁合金表面液相渗铝的工艺与性能[J]. 中国有色金属学报, 2007, 17(7): 1053-1057.

TAN Cheng-wen, GUO Guan-wei, WANG Xiao-yi. Processes and properties of liquid aluminized coating on AZ31 magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(7): 1053-1057.

[6] Weisheit A, Galun R, Mordike B L. CO2 laser beam welding of magnesium based alloys[J]. Welding Journal, 1998, 77(4): 149-154.

[7] Munitz A, Cotler C, Shaham H, et al. Electron beam welding of magnesium AZ91D plates[J]. Welding Journal, 2000, 79(7): 202-208.

[8] Yutaka S S, Seung H C P, Michiuchi M, et al. Constitutional liquation during dissimilar friction stir welding of Al and Mg alloys[J]. Scripta Materialia, 2004, 50(9): 1233-1236.

[9] 刘鹏, 李亚江, 王娟, 等. Mg/Al异种材料真空扩散焊界面区域的显微组织[J]. 焊接学报, 2004, 25(5): 5-8.

LIU Peng, LI Ya-jiang, WANG Juan, et al. Microstructure in interface zone of diffusion-bonded joint of Mg/Al dissimilar materials[J]. Transactions of the China Welding Institution, 2004, 25(5): 5-8.

[10] LIU Peng, LI Ya-jiang. A study of phase constitution near the interface of Mg/Al vacuum diffusion bonding[J]. Materials Letters, 2005, 59(16): 2001-2005.

[11] LIU Peng, LI Ya-jiang. Investigation of interfacial structure of Mg/Al vacuum diffusion-bonded joint[J]. Vacuum, 2006, 80(5): 395-399.

[12] 刘鹏, 李亚江, 王娟. Mg/Al异种材料扩散焊界面组织结构及力学性能[J]. 焊接学报, 2007, 28(6): 45-48.

LIU Peng, LI Ya-jiang, WANG Juan. Microstructure and properties near interface zone of diffusion bonded joint for Mg/ Al dissimilar materials[J]. Transactions of the China Welding Institution, 2007, 28(6): 45-48.

[13] 李线绒, 梁伟, 赵兴国, 等. 共晶合金中间层连接镁/铝异种金属的界面组织及结合强度研究[J]. 稀有金属材料与工程, 2008, 37(11): 2016-2019.

LI Xian-rong, LIANG Wei, ZHAO Xing-guo, et al. Study on the microstructures and bond strength of Mg/Al heterogenous metal bonded with eutectic alloy interlayer[J]. Rare Metal Materials and Engineering, 2008, 37(11): 2016-2019.

[14] Takehiko W, Yoshitaka S. Resistance spot welding of a magnesium alloy AZ31B plate to a 1050 aluminum plate using Ag insert metal[J]. Journal of Japan Institute of Light Metals, 2004, 54(7): 293-297.

[15] 王学刚, 李辛庚, 严黔. 瞬间液相连接的过冷连接新工艺[J]. 金属学报, 2007, 43(10): 1096-1100.

WANG Xue-gang, LI Xin-geng, YAN Qian. A novel bonding process: Super-cooled transient liquid phase bonding[J]. Acta Metal Sin, 2007, 43(10): 1096-1100.

(编辑 何运斌)

收稿日期:2011-08-23;修回日期:2011-11-28

基金项目:国家自然科学基金资助项目(50675234)

通信作者:盛光敏(1958-),男,湖北仙桃人,博士,教授,从事金属连接研究;电话:15923066226;E-mail: gmsheng@cqu.edu.cn