文章编号:1004-0609(2012)07-1939-06

吹气法制备泡沫铝单炉发泡工艺中熔体剩余比例的预测

刘兴男1,李言祥1, 2,陈 祥1, 2

(1. 清华大学 机械工程系,北京 100084;2. 教育部先进成形制造重点实验室,北京 100084)

摘 要:指出吹气法制备泡沫铝的单炉发泡工艺必定会有熔体剩余,并进行了实验验证。建立了单炉发泡工艺中颗粒含量和吹气深度的微分方程,其边界条件就是泡沫的稳定判据公式。对含公称直径9 μm Al2O3颗粒的两个 A356铝合金发泡过程进行了计算,并与实验值比较。结果表明:计算时,尽管由于将颗粒直径和吸附系数取为定值,使计算存在误差,但结论仍然合理可信;为减少单炉发泡过程的熔体剩余,应该提高颗粒含量和初始吹气深度,减小颗粒尺寸和临界覆盖率。

关键词:泡沫铝;吹气法;单炉生产;稳定性;熔体剩余

中图分类号:TG146.2+1 文献标志码:A

Prediction of residual melt ratio in batch type gas injection aluminum foaming process

LIU Xing-nan1, LI Yan-xiang1, 2, CHEN Xiang1, 2

(1. Department of Mechanical Engineering, Tsinghua University, Beijing 100084, China;

2. Key Laboratory for Advanced Materials Processing Technology, Ministry of Education, Beijing 100084, China)

Abstract: It was presented that there must be some melt residual in batch type gas injection foaming process of aluminum. And it was proved by experiments. The differential equation of particle content and gas injection depth in the batch type process was presented, by which the melt residual ratio was predicted with the stability criterion equation as boundary condition. The residual ratio of the melt containing Al2O3 particles with 9 μm in nominal particles was calculated in two foaming process. The calculation results were compared with the experimental data. The results show that, although the calculations have some errors as the particle diameter and the adsorption coefficient are all regarded as the constant, the conclusions are also reasonable. For decreasing the residual melt, the particle content and the initial injection depth should increase, and the particle diameter and the critical coverage ratio should decrease.

Key words: aluminum foam; gas injection; batch type production; stability; residual melt

泡沫铝是20世纪90年代以来兴起的一种闭孔多孔金属材料,其内部含有大量人为引入的胞状气孔。泡沫铝除了具有质量轻、比强度和比刚度高等泡沫材料的基本特点之外,还具有吸声隔音、防火阻燃、吸收冲击能量、易加工、易回收利用等优异性能,是一种结构和功能一体化材料。泡沫铝可制成轻结构件、高刚度填充件、声屏障、安全护具等,在汽车、航空航天、道路交通、建筑装饰、安全防护等行业有着广泛的应用前景[1-4]。

吹气法是制备泡沫铝的一种重要工艺[5]。该工艺中气体通过特定的吹气装置被送入含有陶瓷颗粒的铝合金熔体中,在熔体上方堆积成泡沫层,将泡沫收集成型就制成了泡沫铝。按照生产过程中原料的供应方式,吹气法可以分为连续生产和单炉生产两种形式[5-6]。对于后者,熔体深度和颗粒体积分数都在不断减少。现有的连续生产工艺对泡沫铝扰动较大,只适合于制备冷却速度较快的板材,而单炉发泡工艺可以制备出3个方向上都比较大的块体材料,拓宽了泡沫铝的应用领域,具有较高的研究价值[7]。

吹气法工艺中,要想获得稳定的泡沫,气泡上浮时必须吸附足够量的颗粒[8]。IP等[9]、徐方明等[10]以及王倩等[11]都证明在一定条件下,只有当熔体中的颗粒含量大于一定值时,泡沫才能稳定存在。LEITLMEIER等[6]系统研究了熔体中颗粒含量与最小吹气深度之间的关系。本文作者在前期工作中提出了吹气法泡沫的稳定判据公式,对颗粒含量与最小吹气深度之间的关系进行了深入研究[12-13]。根据这些研究可判断:单炉生产方式中,当液面深度和颗粒含量下降到一定值时,工艺条件不再满足泡沫稳定性的要求,发泡过程不能继续进行,炉中必然剩余一定量的熔体。

从已有研究可以推断出单炉发泡工艺中熔体会有剩余,但还没有见到对其专门的研究报道,更没有讨论过熔体剩余比例的计算。实际上,这方面工作有助于制定合理的发泡工艺,减少原料浪费。吹气法稳定判据公式为预测熔体剩余比例提供了可能性,本文作者在此探讨如何预测已知颗粒含量、颗粒直径、初始深度的铝合金熔体在单炉发泡工艺中熔体的剩余比例。

1 理论分析

单炉发泡工艺中,假设发泡坩埚横截面积A0恒定,熔体原始高度为h0,已经发泡的熔体高度与h0之比为f,h0(1-f )即表示现有熔体的高度h。若当前熔体中颗粒体积分数为FV,则当前熔体中颗粒总体积VP1可表示如下:

(1)

(1)

当发泡进度增加df时,熔体和最新产生的泡沫中颗粒的总体积VP2可表示如下:

(2)

(2)

式中:dFV表示熔体中颗粒体积分数的变化,FVf表示最新产生泡沫中颗粒的体积分数。根据颗粒守恒原理,即VP1=VP2,有

(3)

(3)

FVf可由式(4)计算[13]

(4)

(4)

式中:R表示由于泡壁排液引入的修正系数,W表示气泡对颗粒的吸附系数,t表示泡壁厚度。将式(4)代入式(3)即得式(5)

(5)

(5)

其初始条件为式(6)

(6)

(6)

式中:FV0表示发泡之初熔体中颗粒体积分数。求解微分方程式(5)可得到f与FV的关系,也就得到h和FV的关系。

吹气法工艺中泡沫稳定的条件是颗粒对气泡界面的覆盖率大于一定值,由此可推导出式(7)所示的泡沫稳定判据公式[12]

(7)

(7)

式中:h表示吹气深度(即现有熔体的高度),FV表示熔体中颗粒体积分数,d表示颗粒直径,β表示一定发泡条件下气泡界面临界稳定覆盖率(只有当气泡界面上的颗粒覆盖率大于该值时泡沫才能稳定存在),W同前,E表示颗粒的有效覆盖率(即单个颗粒对气泡界面的覆盖面积与该颗粒大圆面积的比值,该值仅与颗粒的浸润性有关)。

显然,单炉发泡工艺中h和FV都是不断减小的。根据式(7),当式(8)成立时,发泡过程就该终止,此时的h就是剩余熔体深度,记为hc,熔体剩余比例可以表示为hc/h0,即式(8)构成式(5)的边界条件。

(8)

(8)

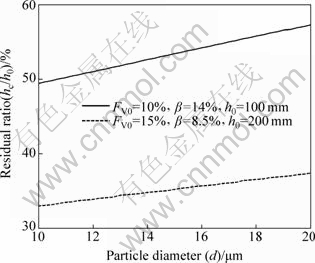

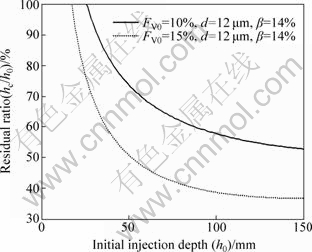

综上所述,利用式(5)、(6)和(8)就可以计算熔体剩余比例。图1~4所示为一定条件下FV0、d、β和h0对剩余熔体比例影响的计算结果。计算条件为W= 0.002,t=100 μm,E=0.88,R取值规律如式(9)所示,以上取值均参考作者前期工作[13]。

(9)

(9)

每次计算时,FV0、d、β和h0在一定范围内变化,但主要变化其中一种。从计算结果可以看出,在常见的工艺条件下,单炉发泡工艺约有25%~65%的熔体剩余,具体值取决于工艺参数。为了减少熔体剩余比例,应增大初始颗粒含量和熔体深度,减小颗粒直径和临界覆盖率。下面通过实验考察单炉发泡工艺中熔体的剩余情况,并进行理论计算,将计算值与实验值进行对比。

图1 颗粒含量FV 0对熔体剩余比例的影响

Fig. 1 Effect of particle content FV0 on residual ratio

图2 颗粒直径d对熔体剩余比例的影响

Fig. 2 Effect of diameter d on residual ratio

图3 临界覆盖率β对熔体剩余比例的影响

Fig. 3 Effect of critical coverage ratio β on residual ratio

图4 熔体深度h0对熔体剩余比例的影响

Fig. 4 Effect of melt depth h0 on residual ratio

2 实验

实验使用A356铝合金做原料。吹气法工艺中常用的稳定颗粒有SiC和Al2O3两种,由于粒度精度高的Al2O3颗粒更易取得,且价格低廉,因此本研究选用Al2O3颗粒做泡沫稳定剂。向A356熔体中加入一定数量、名义尺寸为9 μm的Al2O3颗粒,经过机械搅拌均匀后转移到发泡坩埚内进行发泡。发泡气体为压缩空气,经过减压阀、浮子流量计调节流量后,通过位于发泡坩埚底部的一个不锈钢多孔吹气头送入铝合金熔体中,如图5所示。吹气头上分布一定数量、孔径0.3~0.6 mm的微孔,通过设计不同的出气孔径、孔数和气体流量,吹气头可产生10~20 mm的气泡。控制吹气头打孔的精度,可以较好地保证泡沫孔径的均 匀性。

首先考察单炉发泡工艺的熔体剩余情况。对加入一定体积分数、名义尺寸为9 μm的Al2O3颗粒的两种熔体在不同条件下进行发泡,相关参数见表1,其中θ表示发泡温度,D表示泡沫孔径。记录初始发泡深度h0和发泡过程不再稳定时的发泡深度hc。不稳定的判断标准是泡沫上升过程中大量破裂,发起的泡沫在保温90 s之后由于塌缩严重无法取出。

图5 吹气头发泡过程示意图

Fig. 5 Schematic diagram of foaming process using gas injection device: 1—Aluminum foam; 2—Bubble; 3—Aluminum melt; 4—Crucible; 5—Furnace; 6—Gas injection device

表1 熔体的发泡工艺参数

Table 1 Foaming process parameters of melts

接下来对剩余比例进行理论计算,与实验值进行对比。在发泡之初取熔体样品,在Neophot 32光学显微镜下观察,用配套的图像分析软件对一定数量的金相照片进行统计,测量发泡熔体的初始颗粒含量FV0和实际颗粒直径d。其余参数的取值均借鉴前期实验结果[13],其中R由式(9)确定;W和t随发泡过程进行而变化,为简化,计算时代入前期工作数据的统计平均值,即W=0.002,t=100 μm;E和β在发泡过程中可认为是定值,尤其颗粒有效覆盖率E仅与颗粒浸润性有关,参考前期工作可以确定E=0.88,β受到发泡温度、气体成分、孔径大小等发泡条件影响,熔体1的发泡条件与前期论文中的相同[13],故临界覆盖率β可取为相同的14%,但熔体2在更低温度下发泡,且泡径较小,经重新测量β=8.5%,具体方法可参考前期工作[13]。

3 结果与讨论

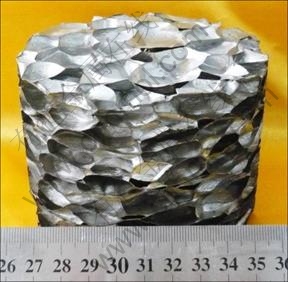

泡沫铝样品照片如图6所示。实验发现熔体1和2的单炉发泡工艺都有熔体剩余,剩余深度和比例列于表2中。由表2可知,熔体剩余比例分别为75%和31%,与前文的计算值相当,说明单炉发泡工艺若设计不当,的确会剩余较多的原料。尽管初始吹气深度h0相同,但熔体2的熔体剩余hc远少于熔体1。这主要是由于熔体2的颗粒含量更高,颗粒实际尺寸更小,发泡条件更利于稳定(即β值更小),这一趋势与前文的理论计算也是相符的。

图6 泡沫铝样品照片

Fig. 6 Photograph of aluminum foam sample

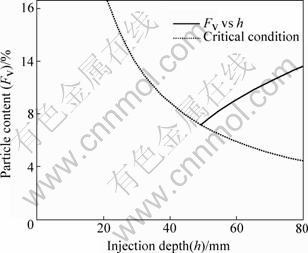

熔体样品金相照片如图7所示,图中黑色物质即为Al2O3颗粒。显然由于团聚、夹气等现象,颗粒的实际含量和尺寸与加入的名义值不同。FV0和d即在图7上测得。熔体1和2的测量结果和剩余比例的计算值列于表2中,计算得到的发泡过程中颗粒含量和吹气深度之间的关系分别如图8和9所示。

由图8和9可以看到,两次发泡过程理论计算值的相对大小关系与实验值相符,但绝对值存在较大误差,这主要是由于颗粒团聚以及吸附系数假设为定值导致的。颗粒搅拌工艺往往不能使所有的颗粒都均匀分散,熔体中存在不同尺寸的颗粒团聚,如图7所示。大颗粒不易被吸附,因此随着发泡过程进行,熔体中颗粒的平均直径逐渐增大[13]。理论计算时颗粒直径d取为初始发泡的平均值,导致了一部分误差。此外,颗粒的吸附系数W受到颗粒直径和吹气深度等因素的影响[13],在发泡过程中是一个变量。而在本研究计算中,W取为定值,也导致了误差。可见,为了精确预测单炉发泡工艺的熔体剩余比例,应该专门研究d和W在发泡过程中的变化规律。

表2 熔体剩余计算值和实验值的对比

Table 2 Comparison between calculation and experimental data of residual ratio of melts

图7 熔体样品金相照片

Fig. 7 Metallograph of melt sample

图8 熔体1发泡过程中FV与h的关系

Fig. 8 Relationship between FV and h of melt 1 in foaming process

图9 熔体 2发泡过程中FV与h的关系

Fig. 9 Relationship between FV and h of melt 2 in foaming process

4 结论

1) 单炉发泡过程中颗粒含量和吹气深度不断减小,由于发泡条件逐渐不满足泡沫稳定判据公式,最终必然会有一定量的熔体剩余,剩余比例可达25%~65%。

2) 吹气法泡沫的稳定判据公式可作为单炉发泡过程中颗粒含量与吹气深度微分方程的边界条件,在求出相关参数后可对单炉工艺剩余熔体比例进行预测。将颗粒直径和吸附系数看作定值会引起较大误差,为精确计算还需要研究其变化规律。

3) 根据分析计算,为了提高单炉发泡过程的熔体利用率,应该提高颗粒含量和熔体深度,减小颗粒尺寸和临界覆盖率。

REFERENCES

[1] 陈 祥, 李言祥. 金属泡沫材料研究进展[J]. 材料导报, 2003, 17(5): 5-11.

CHEN Xiang, LI Yan-xiang. Porous metals: Research advances and applications [J]. Materials Review, 2003, 17(5): 5-11.

[2] BANHART J. Manufacture, characterization and application of cellular metals and metal foams [J]. Progress in Materials Science, 2001, 46: 559-632.

[3] LEFEBVRE L P, BANHART J, DUNAND D C. Porous metals and metallic foams: current status and recent developments [J]. Advanced Engineering Materials, 2008, 10(9): 775-787.

[4] BANHART J. Aluminium foams for lighter vehicles [J]. International Journal of Vehicle Design, 2005, 37: 114-125.

[5] JIN I, KENNY L D, SANG H. Method of producing lightweight foamed metal. US 4973358 [P], 1990-11-27.

[6] LEITLMEIER D, DEGISCHER H P, FLANKL H J. Development of a foaming process for particulate reinforced aluminum melts [J]. Advanced Engineering Materials, 2002, 4(10): 735-740.

[7] 刘兴男. 吹气法制备泡沫铝原理与工艺的研究[D]. 北京: 清华大学, 2010: 97-106.

LIU Xing-nan. Study on the gas injection processing of aluminum foams [D]. Beijing: Tsinghua University, 2010: 97-106.

[8] BABCS?N N, GARCIA-MORENO F, BANHART J. Role of oxidation during blowing of aluminium foams by external gas injection [C]//NAKAJIMA H, KANETAKE N. Porous Metals and Metal Foaming Technology: Met Foam 2005. Kyoto, Japan: The Japan Institute of Metals, 2005: 261-266.

[9] IP S W, WANG Y, TOGURI J M. Aluminum foam stabilization by solid particles [J]. Canadian Metallurgical Quarterly, 1999, 38: 81-92.

[10] 徐方明, 王 倩, 许庆彦, 熊守美. 熔体吹气发泡法制备泡沫铝的试验研究[J]. 特种铸造及有色合金, 2007, 27(7): 563-565.

XU Fang-ming, WANG Qian, XU Qing-yan, XIONG Shou-mei. Preparation of aluminum foam by gas injection foaming [J]. Special Casting and Nonferrous Alloys, 2007, 27(7): 563-565.

[11] 王 倩, 徐方明, 许庆彦, 熊守美. 熔体吹气发泡法制备泡沫铝研究[J]. 铸造, 2007, 56(8): 814-818.

WANG Qian, XU Fang-ming, XU Qing-yan, XIONG Shou-mei. Study on an aluminum foam by gas injection foaming [J]. Foundry, 2007, 56(8): 814-818.

[12] 刘兴男, 李言祥, 陈 祥, 刘 源. 吹气法制备泡沫铝工艺中泡沫的稳定性判据[J]. 机械工程学报, 2010, 46(22): 47-52.

LIU Xing-nan, LI Yan-xiang, CHEN Xiang, LIU Yuan. Foam stability criterion in gas Injection foaming process of aluminum [J]. Journal of Mechanical Engineering, 2010, 46(22): 47-52.

[13] LIU X N, LI Y X, CHEN X, LIU Y, FAN X L. Foam stability in gas injection foaming process [J]. Journal of Materials Science, 2010, 45(23): 6481-6493.

(编辑 何学锋)

基金项目:浙江省科技研究计划资助项目(2009C31049)

收稿日期:2011-06-16;修订日期:2011-11-01

通信作者:李言祥,教授,博士;电话:010-62773640;E-mail: yanxiang@tsinghua.edu.cn