粉末冶金Ti-47Al-2Nb-2Cr-0.2W金属间化合物的高温动态力学行为

来源期刊:中国有色金属学报(英文版)2019年第6期

论文作者:欧阳思慧 刘彬 刘咏 昝祥 梁霄鹏 李争

文章页码:1252 - 1262

关键词:TiAl金属间化合物;变形机制;粉末冶金;动态变形;霍普金森拉杆

Key words:TiAl intermetallics; deformation mechanism; powder metallurgy; dynamic deformation; Split Hopkinson Bar

摘 要:采用分离式霍普金森拉杆动态冲击变形实验研究粉末冶金Ti-47Al-2Nb-2Cr-0.2W (at.%)双态组织和近层片组织在高应变率下(800~1600 s-1)的动态力学行为和变形机理。结果表明,粉末冶金TiAl金属间化合物的韧性-脆性转变温度(DBTT) 随应变速率增加而增大,动态加载下两种组织的高温强度均高于准静态加载下的高温强度;在高应变速率(800~1600 s-1)和高温(650~850 °C)条件下,粉末冶金TiAl金属间化合物的双态组织和近层片组织的加工硬化速率均对应变速率和温度不敏感。在动态加载条件下,堆垛层错及孪晶的形成是主要的变形机制。Zerilli-Armstrong模型能够恰当描述粉末冶金TiAl金属间化合物的高温动态变形行为。

Abstract: Split Hopkinson Tension Bar (SHTB) experiments were conducted to explore the dynamic mechanical behavior and deformation mechanism of powder metallurgical (PM) Ti-47Al-2Nb-2Cr-0.2W (at.%) intermetallics with near lamellar (NL) and duplex (DP) microstructures. Results show that, under dynamic loading, the high temperature strength of the PM TiAl intermetallics is higher than that under quasi-static loading, and the ductile to brittle transition temperature (DBTT) increases with the increase of strain rate. Formation of twinning and stacking faults is the main deformation mechanism during dynamic loading. The work hardening rates of the PM TiAl intermetallics are nearly insensitive to strain rate and temperature at high strain rates (800-l600 s-1) and high temperatures (650-850 °C). Zerilli-Armstrong model is successfully used to describe the dynamic flowing behavior of the PM TiAl intermetallics. In general, the PM TiAl intermetallics are found to have promising impact properties, suitable for high-temperature and high-impact applications.

Trans. Nonferrous Met. Soc. China 29(2019) 1252-1262

Si-hui OUYANG1, Bin LIU1, Yong LIU1, Xiang ZAN2, Xiao-peng LIANG1, Zheng LI3

1. State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China;

2. School of Materials Science and Engineering, Hefei University of Technology, Hefei 230027, China;

3. Yuanmeng Precision Technology (Shenzhen) Institute, Shenzhen 518055, China

Received 11 September 2018; accepted 22 April 2019

Abstract: Split Hopkinson Tension Bar (SHTB) experiments were conducted to explore the dynamic mechanical behavior and deformation mechanism of powder metallurgical (PM) Ti-47Al-2Nb-2Cr-0.2W (at.%) intermetallics with near lamellar (NL) and duplex (DP) microstructures. Results show that, under dynamic loading, the high temperature strength of the PM TiAl intermetallics is higher than that under quasi-static loading, and the ductile to brittle transition temperature (DBTT) increases with the increase of strain rate. Formation of twinning and stacking faults is the main deformation mechanism during dynamic loading. The work hardening rates of the PM TiAl intermetallics are nearly insensitive to strain rate and temperature at high strain rates (800-l600 s-1) and high temperatures (650-850 °C). Zerilli-Armstrong model is successfully used to describe the dynamic flowing behavior of the PM TiAl intermetallics. In general, the PM TiAl intermetallics are found to have promising impact properties, suitable for high-temperature and high-impact applications.

Key words: TiAl intermetallics; deformation mechanism; powder metallurgy; dynamic deformation; Split Hopkinson Bar

1 Introduction

Titanium aluminides are considered as promising structural materials due to their high specific strength, low density (approximately 3.9-4.2 g/cm3), excellent high-temperature creep strength, and high oxidation resistance [1-3]. So far, Gamma titanium aluminides (γ-TiAl) have been used in aerospace vehicles, airplanes and automobiles [4-7]. Because of the specificity of service environment, such as collisions, high-velocity airflow, and ballistic impact, TiAl intermetallics are often exposed to high-rate impact loads under high temperatures [8-11].

The mechanical response of TiAl intermetallics under dynamic loading is different from that of the quasi-static deformation. The high strain-rate mechanical response of the γ-TiAl intermetallics prepared by ingot metallurgy (IM) method has been reported in recent years. MALOY and GRAY [12] investigated the compressive deformation behavior of IM Ti-48A1- 2Nb-2Cr intermetallics with duplex (DP) microstructure at strain rates of 0.001 and 2000 s-1, and found that the deformation mechanism included twinning and dislocation movement, and the twinning propensity increased with the strain rate. The á101] super- dislocations were pinned in a screw orientation at high temperatures and high strain rates, resulting in anomalous flow stress. ZAN et al [13] reported the tensile impact behavior of the IM Ti-46.5Al-2Nb-2Cr alloy. In their study, the flow stress anomaly was not observed and the deformation mechanism was mainly twinning. In addition, their works also indicated that the deformation behavior of the IM TiAl intermetallics under dynamic loading is different from that under quasi-static loading. Compared with the IM method, powder metallurgy (PM) technology is a promising method to produce high-performance TiAl materials. PM technology can effectively eliminate segregation of the products and decrease the processing steps to provide a more homogeneous microstructure with a finer grain size [14]. So far, limited research has reported on the tensile behavior of PM TiAl intermetallics under dynamic loading at high strain rates.

In this work, PM TiAl intermetallics with near lamellar (NL) and DP microstructures were prepared via hot extrusion, and the tension impact deformation behaviors were investigated at elevated temperatures. Efforts were also devoted to construct constitutive equations based on Zerilli-Armstrong model and evaluate the deformation mechanisms.

2 Experimental

Pre-alloyed powder with chemical composition of Ti-47Al-2Nb-2Cr-0.2W (at.%) was prepared via plasma rotating electrode processing (PREP). The as-prepared powders with particle size of 100-150 μm were filled into a stainless steel can with the dimension of d200 mm × 400 mm. The can was degassed at 400 °C for 12 h and sealed in vacuum. Then, the encapsulated powders were hot isostatic pressed (HIPed) at 1240 °C for 4 h under a pressure of 140 MPa. Cylindrical samples with dimension of d50 mm × 200 mm were cut from the as-HIPed billet by electric-discharge machining. The billet was further canned with stainless steel and sealed by vacuum welding. Hot extrusion was performed at 1250 °C with an extrusion ratio of 4:1. After extrusion, specimens with NL and DP microstructure were prepared by annealing at 1330 °C for 30 min and 900 °C for 2 h, followed by furnace cooling.

Tensile samples with the gauge size of 10 mm × 3.5 mm × 1.2 mm were used for dynamic tensile tests. Dynamic tensile tests were conducted on a rotating disk indirect bar-bar tensile impact apparatus (BTIA) in the strain rate range of 800-1600 s-1 and temperature range of 25-800 °C. BTIA is a kind of SHTB which was developed with a rapid contact heating system [15]. Quasi-static tension tests were performed on an INSTRON 3369 machine in the temperature range of 25-900 °C and at the strain rate of 0.001 s-1.

The deformed microstructures were analyzed by using an transmission electron microscope (TEM, FEI Tecnai 20, operating at 200 kV) and the fractograph was observed under a scanning electron microscope (SEM, FEI-Sirion 200). TEM specimens were prepared by mechanical grinding and then electropolished using a solution of 5 vol.% perchloric acid, 35 vol.% n-butyl alcohol and 60 vol.% methanol at -30 °C and 22 V.

3 Results

3.1 Initial microstructure

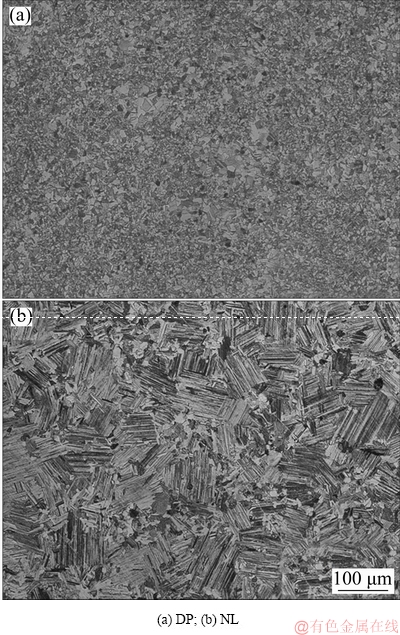

Figure 1 shows the NL and DP microstructures of the PM TiAl intermetallics, respectively. The DP microstructure contains fine γ grains and a little α2/γ colonies with an average grain size of approximately 20 μm. The NL microstructure is composed of fine γ grains and coarse α2/γ colonies. The average size of γ grains is about 10 μm, while the size of the α2/γ colonies is about 150 μm. The oxygen content of the as-extruded PM TiAl intermetallics is approximately 800×10-6 wt.%.

Fig. 1 Microstructures of TiAl intermetallics

3.2 Mechanical behavior

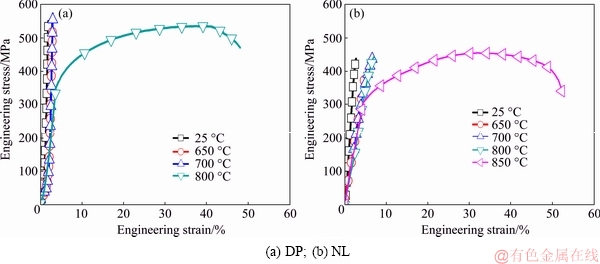

Figure 2 shows the stress-strain curves of the PM TiAl intermetallics deformed at different temperatures with strain rate of 0.001 s-1. When temperature is below 700 °C, the elongation of the DP alloy is less than 2%, and increases quickly to 54% at 800 °C. As for the NL alloy, the plasticity is quite poor below 800 °C (<2%), and the elongation increases to 52% at 850 °C. Therefore, the DBTT of the DP alloy is between 700 and 800 °C, whereas the ductile to brittle transition temperature (DBTT) of the NL alloy is between 800 and 850 °C. Apparently, the DBTT of the NL alloy is higher than that of the DP alloy. The work-hardening rate (dσ/dε) of the DP alloy is approximately 7000 MPa, and that of the NL alloy is roughly 6400 MPa. In addition, the tensile strength of the DP alloy is higher than that of the NL alloy in quasi-static deformation condition.

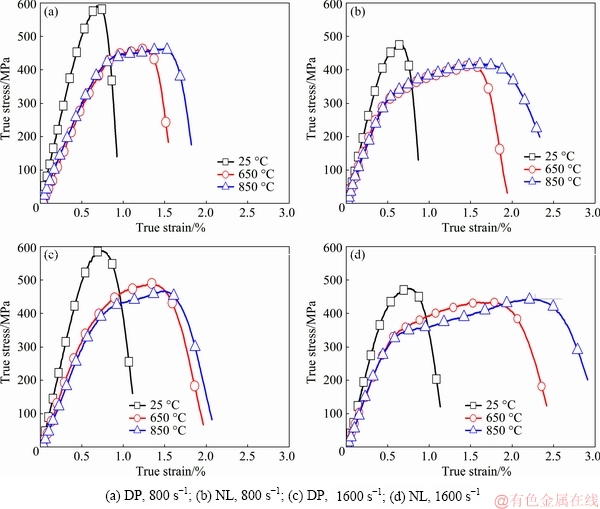

Figure 3 presents the dynamic behavior of the PM TiAl intermetallics at various temperatures and strain rates. The DP and NL alloys both demonstrate limited elongation up to 850 °C, indicating that the DBTT of DP and NL alloys under the present condition exceeds 850 °C. The tensile strengths of the DP and NL alloys decline with an increase in temperature, but the declining rate slows down at high temperatures (650-850 °C). The tensile strength of the DP alloy is still higher than that of the NL alloy. The work-hardening rate is independent of the strain rate and temperature at high strain rates (800-l600 s-1) and high temperatures (650-850 °C). The work-hardening rate of the DP alloy is approximately 7500 MPa, whereas that of the NL alloy is about 7000 MPa. In addition, the dynamic strength (yield stress σs) is higher than the quasi-static strength at the same deformation temperature.

Fig. 2 Engineering stress-strain curves of TiAl intermetallics deformed at different temperatures (strain rate of 0.001 s-1)

Fig. 3 True stress-true strain curves of TiAl intermetallics deformed at different strain rates

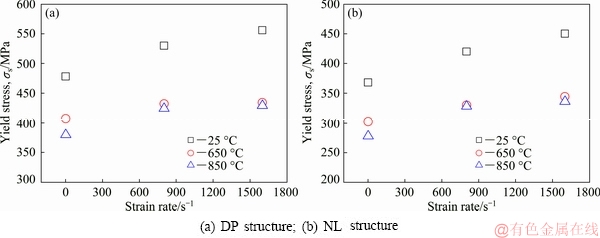

The dependence of yield stress σs on temperature and strain rate is shown in Fig. 4. The σs increases with increasing strain rate but decreases with an increase in temperature. The relationship of σs and the strain rate is not linear and σs tends to increase more at 25 °C, whereas the σs of DP and NL alloys change little at high temperatures (650-850 °C) and high strain rates (800-1600 s-1).

The temperature sensitivity (na) and strain rate sensitivity (β) are used to quantify the dependence of the strain rate hardening and the thermal softening effects [16-18]:

(1)

(1)

(2)

(2)

where σs0 and σs1 denote the flow stresses at 0.2% strain at temperatures T0 and T1, respectively.  and

and  denote the flow stresses at 0.2% strain under strain rate

denote the flow stresses at 0.2% strain under strain rate  and

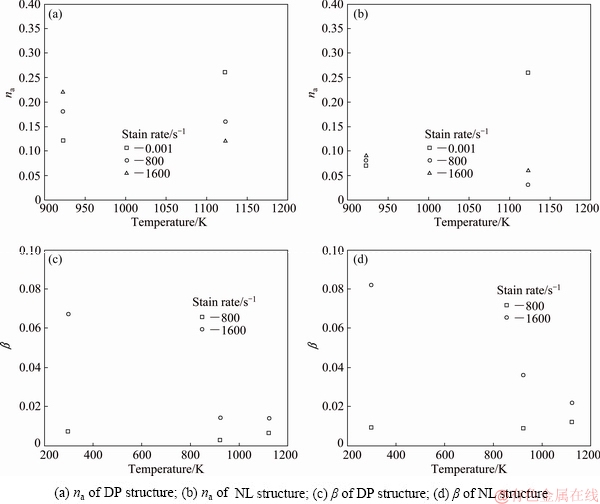

and  , respectively. Figure 5 shows temperature sensitivity na at different strain rates and strain rate sensitivity β at different temperatures. The value of na increases in line with the temperature at the strain rate of 0.001 s-1, and the value of na varies slightly with increasing the temperature at higher strain rates (Figs. 5(a, b)). The temperature sensitivity of the DP and NL alloys seems to increase with increasing temperature under quasi-static loading. However, the alloys are both insensitive to temperature during dynamic deformation. It can be inferred that the thermal softening effect of temperature on σs under dynamic loading is weaker than that under quasi-static loading. Figures 5(c, d) clearly indicate that the value of β increases at 298 K but changes little with increasing strain rates at higher temperatures. Therefore, the DP and NL alloys are insensitive to strain rate and temperature at high strain rates (800-l600 s-1) and high temperatures (650- 850 °C).

, respectively. Figure 5 shows temperature sensitivity na at different strain rates and strain rate sensitivity β at different temperatures. The value of na increases in line with the temperature at the strain rate of 0.001 s-1, and the value of na varies slightly with increasing the temperature at higher strain rates (Figs. 5(a, b)). The temperature sensitivity of the DP and NL alloys seems to increase with increasing temperature under quasi-static loading. However, the alloys are both insensitive to temperature during dynamic deformation. It can be inferred that the thermal softening effect of temperature on σs under dynamic loading is weaker than that under quasi-static loading. Figures 5(c, d) clearly indicate that the value of β increases at 298 K but changes little with increasing strain rates at higher temperatures. Therefore, the DP and NL alloys are insensitive to strain rate and temperature at high strain rates (800-l600 s-1) and high temperatures (650- 850 °C).

Fig. 4 Effects of strain rates on yield stress of TiAl intermetallics deformed at different temperatures

Fig. 5 Temperature sensitivity na and strain rate sensitivity β under different deformation conditions

3.3 As-deformed microstructures

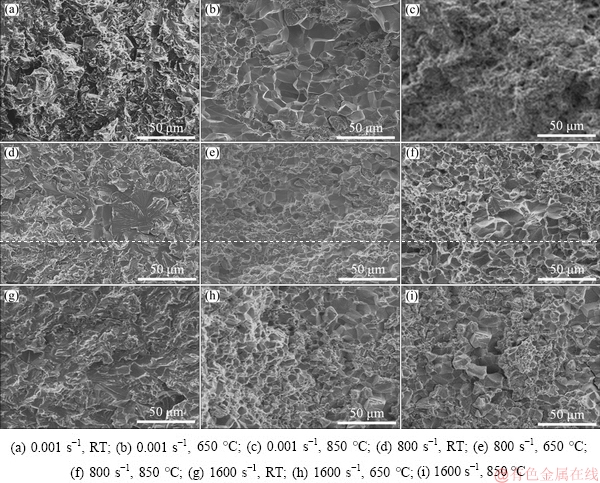

Figure 6 shows the fracture surface of the DP alloys deformed at different strain rates and temperatures. The fracture mode under quasi-static and dynamic conditions exhibits a typical cleavage fracture characterized by a river pattern (Figs. 6(a, d, g)) at 25 °C. When the temperature increases to 850 °C, some dimples appear on the fracture surface of the DP alloy under quasi-static conditions, exhibiting a ductile fracture manner. As the temperature increases, the fracture modes under dynamic condition change from a transgranular fracture (25 °C) to a mixture of transgranular and intergranular fractures (650 °C) and finally to a totally intergranular fracture (850 °C).

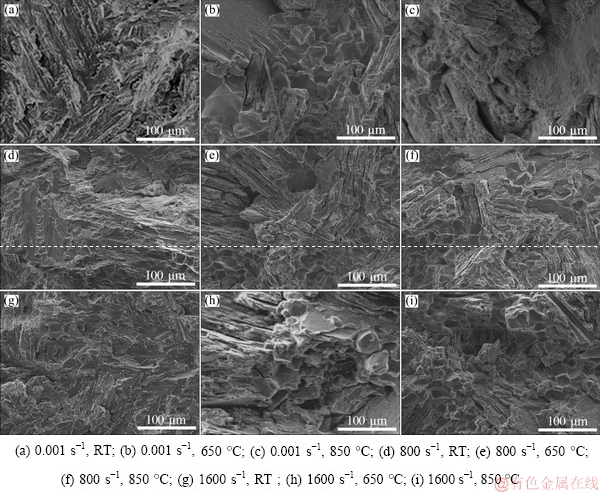

Figure 7 shows the fracture surface of the NL alloys deformed at strain rate of 0.001-1600 s-1 and temperatures of 25-850 °C. The sample deformed at 25 °C demonstrates damage with a cleavage fracture, and shows ductile fracture at 850 °C under quasi-static loading. The fracture mode under dynamic deformation at 25 °C is a transgranular fracture. However, damage mode changes to transgranular and intergranular fractures at high temperatures (650-850 °C). The fracture surface of NL structure (Fig. 7(g)) is relatively flat at 25 °C. When the temperature increases, delamination is observed (Figs. 7(h, i)), owing to the effects of grain boundary movement.

Fig. 6 Fractographs of TiAl intermetallics with DP structure deformed under different conditions

Fig. 7 Fractographs of TiAl intermetallics with NL structure deformed under different conditions

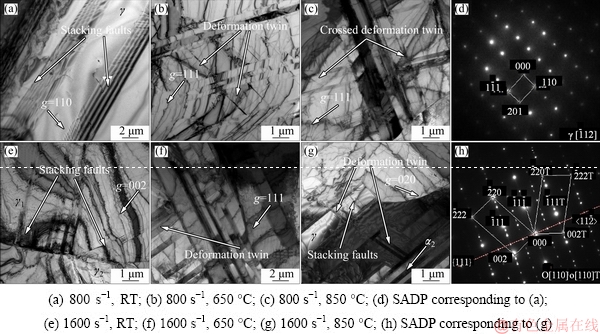

Fig. 8 TEM bright field images of TiAl intermetallics with DP structure deformed under different conditions

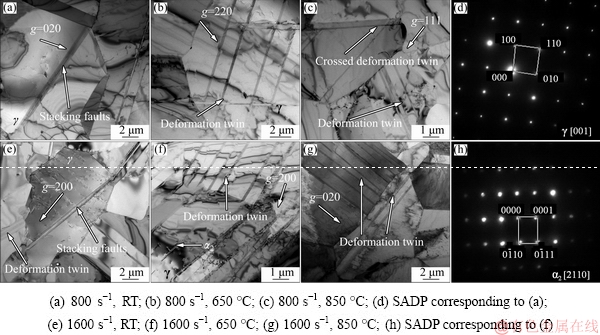

Figure 8 presents the TEM micrographs of the DP alloys. Figure 8(a) shows stacking faults in the γ grains, originating from the grain boundary and then terminating in the other side of boundary. For the diffraction vector g=020, 111 or 220, dislocation is not observed (Fig. 8(a)). Few dislocations appear for the diffraction vector g=200. Most of the twins terminate at the grain boundary rather than being impeded by localized pinning within the grain. Many crossed deformation twins are found in the γ grains, and these deformation twins exhibit an increase in density as the strain rate increases.

Figure 9 shows TEM micrographs of the NL alloys. The NL microstructure is characterized by some small γ grains situated at the periphery of the α2/γ colonies. Deformation twins form in the γ lamellae. Twins intersect on different {111} planes, as shown in Fig. 9(c).

Fig. 9 TEM bright-field images of TiAl intermetallics with NL structure deformed under different conditions

The fine dark lamella denotes the α2 phase, and the coarse bright lamella is γ phase (Figs. 9(b, c, f, g)). Figure 9(g) indicates that deformation twins are parallel to each other and impeded by a lamellar interface. The twinning system and stacking fault are identified as 1/2 {111} according to the indexed diagram shown in Fig. 9(h). Dislocation movement is difficult to identify under different reflection conditions in Fig. 8 and Fig. 9. The materials deform primarily by twinning, and dislocations are quite rare.

{111} according to the indexed diagram shown in Fig. 9(h). Dislocation movement is difficult to identify under different reflection conditions in Fig. 8 and Fig. 9. The materials deform primarily by twinning, and dislocations are quite rare.

3.4 Zerilli-Armstrong model

Zerilli-Armstrong (ZA) model considers the effects of both strain rates and temperatures on the flow stress [19]. There are two ZA models based on the crystal structure: body-center cubic (BCC) and face- center cubic (FCC) [20]. The FCC model and BCC model both can describe the dynamic flow behavior of the TiAl intermetallics under high strain rates at elevated temperatures. However, the BCC model is better since it is able to predict work-hardening behavior. The ZA model corresponding to the BCC structure is given as follows:

(3)

(3)

σ=σth+σath (4)

(5)

(5)

(6)

(6)

(7)

(7)

where σth is thermal stress, σath is athermal stress, d is the average grain diameter, and  is attributed to the initial dislocation density and effect of solutes. T is the sample temperature, εp is the equivalent strain,

is attributed to the initial dislocation density and effect of solutes. T is the sample temperature, εp is the equivalent strain,  is the equivalent strain rate and

is the equivalent strain rate and  is the reference strain rate (defined as 0.001 s-1).

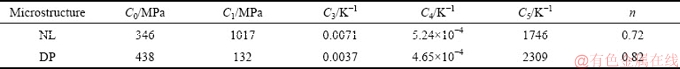

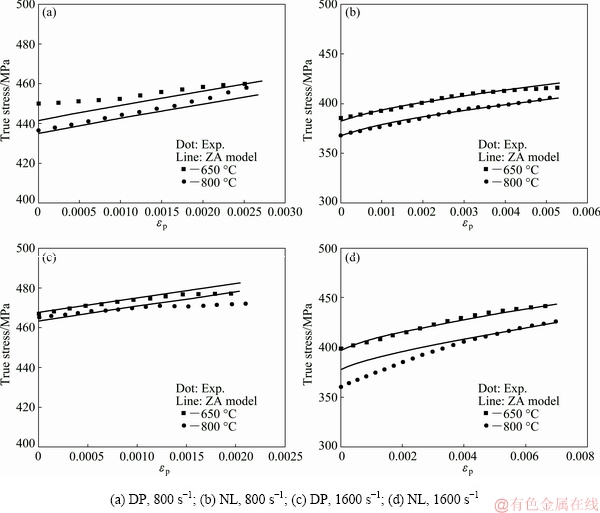

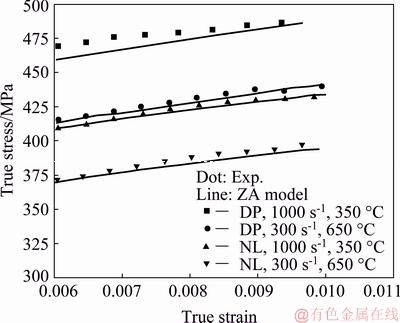

is the reference strain rate (defined as 0.001 s-1).  quantifies the work-hardening rate, and C5 and n are the work-hardening coefficient and exponent, respectively. The parameters for the ZA model for the TiAl intermetallics in this work are calculated in Table 1. The comparison between the experimental data and predicted data is shown in Fig. 10, implying that the BCC model can predict the flow stress behavior of PM TiAl intermetallics at high strain rates and elevated temperatures. To validate the effectiveness of the ZA model corresponding to BCC structure for the PM TiAl intermetallics, a comparison among four curves deformed under different conditions is made and the results are shown in Fig. 11. The average relative error (δ) is defined as

quantifies the work-hardening rate, and C5 and n are the work-hardening coefficient and exponent, respectively. The parameters for the ZA model for the TiAl intermetallics in this work are calculated in Table 1. The comparison between the experimental data and predicted data is shown in Fig. 10, implying that the BCC model can predict the flow stress behavior of PM TiAl intermetallics at high strain rates and elevated temperatures. To validate the effectiveness of the ZA model corresponding to BCC structure for the PM TiAl intermetallics, a comparison among four curves deformed under different conditions is made and the results are shown in Fig. 11. The average relative error (δ) is defined as

(8)

(8)

The average relative error of the fitting results for DP structure is 5.7%, whereas that for the NL structure is 4.8%.

The work-hardening rate of the IM TiAl intermetallics with a NL structure is approximately 6300 MPa under dynamic loading, and that of the IM TiAl intermetallics with DP structure is 6500 MPa [21]. The work-hardening rate of the PM TiAl intermetallics with DP structure is 7500 MPa, and that of the PM TiAl intermetallics with NL structure is 7000 MPa. Compared with IM TiAl intermetallics, PM TiAl intermetallics demonstrate higher C5 and n, indicating that the work-hardening rate of the PM TiAl intermetallics is higher than that of the IM TiAl intermetallics. The C5 and n values for the DP alloys are higher than those for the NL alloys. Therefore, the work-hardening rate of the DP alloys is apparently higher than that of the NL alloys, and the calculated result of work-hardening rates is consistent with the experimental one. Compared with the experimental data, the calculated curves of the DP and NL alloys exhibit a certain deviation at 800 °C and a strain rate of 1600 s-1. This is caused by the high density of twins and interaction between the twins.

Table 1 Coefficients of Zerilli–Armstrong model of TiAl intermetallics

Fig. 10 Fitting results using ZA model

Fig. 11 Validation of predictability of ZA model corresponding to BCC structure

4 Discussion

PM TiAl intermetallics with DP and NL microstructures consist of γ and α2 phases. The γ phase exhibits a face-centered tetragonal L10 structure and the α2 phase demonstrates an ordered hexagonal D019 structure [22]. Because the quasi-static deformation of γ-TiAl at different temperatures can be motivated by á110] ordinary slip, á101] superdislocation and  twinning [23,24] and á101] super- dislocations are always pinned in the screw orientation at high temperatures [25,26], anomalous yield behavior is frequently observed at high temperatures. However, in this work, no anomalous increase in yield strength is detected, which is due to the fact that, under dynamic loading, the dominant deformation mechanism is

twinning [23,24] and á101] super- dislocations are always pinned in the screw orientation at high temperatures [25,26], anomalous yield behavior is frequently observed at high temperatures. However, in this work, no anomalous increase in yield strength is detected, which is due to the fact that, under dynamic loading, the dominant deformation mechanism is  twinning, and superdislocation movements do not appear.

twinning, and superdislocation movements do not appear.

The tensile strength of PM TiAl intermetallics under dynamic loading is higher than that under quasi-static loading, because the stacking fault energy (SFE) of the γ phase is approximately 60-90 mJ/m2 [27]. Under quasi-static loadings, the critical stress for dislocations is much lower than that for twins. Therefore, dislocations are more frequently observed than twins in γ-TiAl alloy. BOLLING and RCIHMAN [28] reported that the critical stress of twinning was reduced with increasing strain rates for FCC metals. KANANI et al [29] studied the effects of strain rates and temperatures on deformation mechanisms of lamellar TiAl alloys and the results indicated that high strain rates changed the deformation mechanism, especially retarded the dislocation sliding events. This means twins are easier to form than dislocations under dynamic loadings. Plastic deformation is accommodated by dislocation glide and grain boundary sliding which is mainly controlled by growth rates. Under dynamic loadings, dislocation glide and grain boundary sliding cannot occur readily. Therefore, stress accumulates at the grain boundary, causing critical stress for twins to decrease and then twins nucleate at the grain boundary. Moreover, the growth of twinning is faster than the dislocation movement. Hence, under dynamic loadings, dislocations sweep more easily to form twins. High amount of twins causes apparent grain refinement, and thus, dynamic strength is higher than the quasi-static strength.

Twinning is more likely to operate in γ grains and γ lamellae at high temperatures [30]. The deformation twinning in the DP alloys is concentrated in the γ phase and cuts across the entire γ grains, whereas the twinning in the NL alloys is concentrated in the γ lamellae and impeded by lamellar interfaces. Because the size of twins in γ lamellae is much smaller than that in the γ grains, and the density of twins in the γ lamellae is much lower than that in the γ grains, the yield strength of the NL alloys is lower than that of the DP alloys under dynamic loading based on the consideration of the intersection stress of twin boundaries.

The work-hardening rates of PM TiAl intermetallics under dynamic loading are higher than those under quasi-static loading. This is because the twins self-intersect and cut across the grains, which can increase the work-hardening rate. CERRETA et al [31] reported that the work-hardening rates of cast γ-TiAl increased with increasing strain rates. Deformation twinning has also been shown to increase work-hardening rate in TWIP steel [32]. It is noticeable that the work-hardening rates of the DP and NL alloys are nearly insensitive to strain rate and temperature at high strain rates (800-l600 s-1) and high temperatures (650-850 °C). This is because the morphology and twinning rate of {111}<112> twins are not sensitive to strain rates (800-1600 s-1) at high temperatures (650-850 °C).

The work-hardening rates of the PM TiAl intermetallics are higher than those of the IM TiAl intermetallics. This is because the work-hardening rate of TiAl intermetallics is closely related to the microstructures. Compared with the IM TiAl intermetallics, the PM TiAl intermetallics with DP and NL microstructures exhibit finer lamellar colonies and γ grains. Hence, the density of twins is higher and the interactions between deformation twinning and the grain boundaries are stronger. In addition, the PM TiAl intermetallics have higher oxygen content (approximately 800×10-6 wt.%), which can also lead to higher resistance to dislocation motion, and thus causes a higher work-hardening rate [33].

In general, PM TiAl intermetallics show promising impact properties, which is suitable for the high temperature and high impact applications.

5 Conclusions

(1) For the PM TiAl intermetallics, dynamic strength is higher than the quasi-static strength. Under quasi-static deformation and dynamic deformation, the DBTT increases with increasing the strain rate. The Zerilli-Armstrong model is successfully used to describe the dynamic flowing behavior of the PM TiAl intermetallics.

(2) Formation of the twin and stacking faults is the main deformation mechanism under dynamic loading at high temperatures. The propensity of twinning and stacking faults increases with increasing strain rates and temperatures.

(3) Work-hardening rates of the PM TiAl intermetallics are nearly insensitive to strain rate and temperature at high strain rates (800-l600 s-1) and high temperatures (650-850 °C). Compared with the IM TiAl intermetallics, the PM TiAl intermetallics show higher work-hardening rate, which is due to the fine-grained microstructure and high oxygen content.

References

[1] KIM Y W. Microstructural evolution and mechanical properties of a forged gamma titanium aluminide alloy [J]. Acta Metallurgica et Materialia, 1992, 40: 1121-1134.

[2] DIMIDUK D M. Systems engineering of gamma titanium aluminides: Impact of fundamentals on development strategy [J]. Intermetallics, 1998, 6(7-8): 613-621.

[3] KUMPFERT J, KIM Y W, DIMIDUK D M. Effect of microstructure on fatigue and tensile properties of the gamma TiAl alloy Ti-46.5Al- 3.0Nb-2.1Cr-0.2W [J]. Materials Science and Engineering A, 1995, 192-193: 465-473.

[4] LIU B, LIU Y, LI Y P, ZHANG W, CHIBA A. Thermomechanical characterization of beta-stabilized Ti-45Al-7Nd-0.4W-0.15B alloy [J]. Intermetallics, 2011, 19(8): 1184-1190.

[5] KEAR B H, THOMPSON E R. Aircraft gas turbine materials and processes [J]. Science, 1980, 208(4446): 847-856.

[6] LASALMONIE A. Intermetallics: Why is it so difficult to introduce them in gas turbine engines? [J]. Intermetallics, 2006, 14(10-11): 1123-1129.

[7] KOTHARI K, RADHAKRISHNAN R, WERELEY N M. Advances in gamma titanium aluminides and their manufacturing techniques [J]. Progress in Aerospace Sciences, 2012, 55(5): 1-16.

[8] LUO X, LI C, YANG Y Q, XU H M, LI X Y, LI S, LI P T. Microstructure and interface thermal stability of C/Mo double-coated SiC fiber reinforced γ-TiAl matrix composites [J]. Transactions of Nonferrous Metals Society of China, 2016, 26(5): 1317-1325.

[9] LAVERY N P, JARVIS D J, VOSS D. Emission mitigation potential of lightweight intermetallic TiAl components [J]. Intermetallics, 2011, 19(6): 787-792.

[10] CLEMENS H, SMARSLY W. Light-weight intermetallic titanium aluminides—Status of research and development [J]. Advanced Materials Research, 2011, 278: 551-556.

[11] JANSCHEK P. Wrought TiAl blades [J]. Materials Today Proceedings, 2015, 2: s92-s97.

[12] MALOY S A, GRAY G T. High strain rate deformation of Ti48Al2Nb2Cr [J]. Acta Materialia, 1996, 44(5): 1741-1756.

[13] ZAN X, HE Y H, WANG Y, LU Z X, XIA Y M. Tensile impact behavior and deformation mechanism of duplex TiAl intermetallics at elevated temperatures [J]. Journal of Materials Science, 2010, 45(23): 6446-6454.

[14] LI J B, LIU Y, LIU B, WANG Y, CAO P, ZHOU C X, XIANG C J, HE Y H. High temperature deformation behavior of near γ-phase high Nb-containing TiAl alloy[J]. Intermetallics, 2014, 52: 49-56.

[15] ZHANG W, LIU Y, WANG L, LIU B. Numerical simulation and physical analysis for dynamic behaviors of P/M TiAl alloy in hot-packed forging process [J]. Transactions of the Nonferrous Metals Society of China, 2012, 22(4): 901-906.

[16] LIU B, LIU Y, ZHANG W, HUANG J S. Hot deformation behavior of TiAl alloys prepared by blended elemental powders [J]. Intermetallics, 2011, 19(2): 154-159.

[17] HUANG W, ZAN X, NIE X, GONG M, WANG Y, XIA Y M. Experimental study on the dynamic tensile behavior of a poly-crystal pure titanium at elevated temperatures [J]. Materials Science & Engineering A, 2007, 443(1-2): 33-41.

[18] ZHAN H Y, KENT D, WANG G, DARGUSCH M S. The dynamic response of a β titanium alloy to high strain rates and elevated temperatures [J]. Materials Science & Engineering A, 2014, 607: 417-426.

[19] LIN Y C, CHEN X M. A combined Johnson–Cook and Zerilli-Armstrong model for hot compressed typical high-strength alloy steel [J]. Computational Materials Science, 2010, 49(3): 628-633.

[20] ARMSTRONG R W, ZERILLI F J. Dislocation mechanics aspects of plastic instability and shear banding [J]. Mechanics of Materials, 1994, 17(2-3): 319-327.

[21] ZAN X, HE Y H, WANG Y, XIA Y M. Dynamic behavior and fracture mode of TiAl intermetallics with different microstructures at elevated temperatures [J]. Transactions of Nonferrous Metals Society of China, 2011, 21(1): 45-51.

[22] APPEL F, CLEMENS H, FISCHER F D. Modeling concepts for intermetallic titanium aluminides [J]. Progress in Materials Science, 2016, 81: 55-124.

[23] APPEL F, WAGNER R. Microstructure and deformation of two- phase γ-titanium aluminides [J]. Materials Science & Engineering R: Reports, 1998, 22(5): 187-268.

[24] YOO M H. Twinning and mechanical behavior of titanium aluminides and other intermetallics [J]. Intermetallics, 1998, 6(7-8): 597-602.

[25] LIPSITT A, SHECHTMANN D , SCHAFRIK E. The deformation and fracture of TiAl at elevated temperatures [J]. Metallurgical Transactions A, 1975, 6(11): 1991-1996.

[26] MALOY S A, GRAY G T. High strain rate deformation of Ti-48Al-2Cr-2Nb in the duplex morphology [R]. Office of Scientific & Technical Information Technical Reports, 1995.

[27] HAO Y J, LIU J X, LI S K, LI J C, LIU X Z, FENG X Y. Effects of nano-twinning on the deformation and mechanical behaviours of TiAl alloys with distinct microstructure at elevated loading temperatures [J]. Materials Science and Engineering A, 2017, 705: 210-218.

[28] BOLLING G F, RICHMAN R H. Continual mechanical twinning: Part I: Formal description [J]. Acta Metallurgica, 1965, 13(7): 709-722.

[29] KANANI M, HARTMAIER A, JANISCH R. Stacking fault based analysis of shear mechanisms at interfaces in lamellar TiAl alloys [J]. Acta Materialia, 2016, 106: 208-218.

[30] EDWARDS T E G, DI GIOACCHINO F, MUNOZ-MORENO R, CLEGG W J. The interaction of borides and longitudinal twinning in polycrystalline TiAl alloys [J]. Acta Materialia, 2017, 140: 305-316.

[31] CERRETA E, CHEN S R, GRAY G T, POLLOCK T M. Dynamic deformation and damage in cast γ-TiAl during Taylor cylinder impact: Experiments and model validation [J]. Metallurgical and Materials Transactions A, 2004, 35(9): 2557-2566.

[32] BOUAZIZ O, GUELTON N. Modelling of TWIP effect on work-hardening [J]. Materials Science and Engineering A, 2001, 319-321: 246-249.

[33] MORRIS M A. Dislocation mobility, ductility and anomalous strengthening of two-phase TiAl alloys: Effects of oxygen and composition [J]. Intermetallics, 1996, 4(5): 417-426.

欧阳思慧1,刘 彬1,刘 咏1,昝 祥2,梁霄鹏1,李 争3

1. 中南大学 粉末冶金国家重点实验室,长沙 410083;

2. 合肥工业大学 材料科学与工程学院,合肥 230027;

3. 圆梦精密技术研究院,深圳 518055

摘 要:采用分离式霍普金森拉杆动态冲击变形实验研究粉末冶金Ti-47Al-2Nb-2Cr-0.2W (at.%)双态组织和近层片组织在高应变率下(800~1600 s-1)的动态力学行为和变形机理。结果表明,粉末冶金TiAl金属间化合物的韧性-脆性转变温度(DBTT) 随应变速率增加而增大,动态加载下两种组织的高温强度均高于准静态加载下的高温强度;在高应变速率(800~1600 s-1)和高温(650~850 °C)条件下,粉末冶金TiAl金属间化合物的双态组织和近层片组织的加工硬化速率均对应变速率和温度不敏感。在动态加载条件下,堆垛层错及孪晶的形成是主要的变形机制。Zerilli-Armstrong模型能够恰当描述粉末冶金TiAl金属间化合物的高温动态变形行为。

关键词:TiAl金属间化合物;变形机制;粉末冶金;动态变形;霍普金森拉杆

(Edited by Bing YANG)

Foundation item: Project (51774335) supported by the National Natural Science Foundation of China; Project (2017JJ2311) supported by the Natural Science Foundation of Hunan Province, China; Project (KFJJ11-7M) supported by the Opening Project of State Key Laboratory of Explosion Science and Technology, China; Project (HKHTZD20140702020004) supported by the Special Funds for Future Industrial Development of Shenzhen City, China

Corresponding author: Bin LIU; Tel: +86-731-88877669; Fax: +86-731-88710855; E-mail: binliu@csu.edu.cn

DOI: 10.1016/S1003-6326(19)65032-6