文章编号:1004-0609(2008)02-0323-07

氧化工艺对ZL201铝合金阳极氧化膜受热开裂行为的影响

刘伟华,左 禹,郭 超,赵旭辉

(北京化工大学 材料科学与工程学院,北京 100029)

摘 要:用电化学方法和扫描电子显微镜研究氧化时间、硫酸浓度、氧化电流密度等氧化工艺参数对ZL201铝合金阳极氧化膜受热开裂行为的影响,并分析讨论氧化膜中内应力的产生机理。结果表明:氧化膜封闭后存在少量缺陷,加热时会沿缺陷形成开裂并产生新裂纹。随氧化时间延长,氧化膜受热后裂纹数量增多;随硫酸浓度增大,氧化膜受热后裂纹密度增大;而随着氧化电流密度的增大,氧化膜受热后裂纹密度减小。

关键词:阳极氧化膜;耐热性;裂纹;内应力

中图分类号:TG 146.21 文献标识码:A

Effects of anodizing parameters on cracking behavior of anodic film on ZL201 aluminium alloy

LIU Wei-hua, ZUO Yu, GUO Chao, ZHAO Xu-hui

(School of Materials of Science and Engineering, Beijing University of Chemical Technology, Beijing 100029, China)

Abstract: The effects of oxidation time, sulfuric acid concentration and current density on heat-resistance of anodic film formed on ZL201 aluminium alloy were studied by scanning electron microscopy (SEM) and electrochemical impedance spectroscopy (EIS). The generation of residual stress was also discussed. The results show that there exists a few cracks in sealed anodic oxidation films. When the films are heated, the initial cracks become larger and some new cracks occur. The longer the anodic oxidation is, the more the cracks in the films after heating. The higher density of cracks in anodic films, which are anodized in higher concentration of sulfuric acid solutions, can also be found after heating. On the contrary, with the increase of oxidation current density, the density of cracks in anodic films after heating decreases.

Key words: anodic oxide film; heat-resistance; crack; internal stress

阳极氧化膜本身有着良好的耐高温性能,但由于氧化膜与铝基体的热膨胀系数相差较大,受热条件下氧化膜内应力的释放等因素影响,往往抗热疲劳性能不佳,在热循环和膜内原有内应力的作用下导致膜中出现裂纹等缺陷,从而力学性能与耐蚀性显著下降。众多的科研工作者对阳极氧化膜的形成机理、氧化工艺、封闭工艺以及其性能等做了大量的研究[1-5]。但是对阳极氧化膜在受热和热循环条件下的破裂失效行为研究较少。郭超[6]对不同氧化工艺条件下形成的阳极氧化膜在受热后的耐蚀行为进行了研究,认为薄膜有利于提高氧化膜受热后的保护作用。马跃辉[7]也对阳极氧化膜在日光暴晒条件下的开裂行为进行了研究,认为封闭填充物在日光照射条件下脱水膨胀而涨破膜孔;适当提高氧化温度,控制氧化膜厚度可降低氧化膜破裂倾向。

影响氧化膜在不同温度下性质变化的主要因素有氧化膜和基体的热膨胀系数差、氧化膜内残留内应力及氧化膜自身的性质。研究这些影响因素以及不同温度下膜微观结构、力学与化学性能的变化,深入理解各种因素对氧化膜抗热疲劳性能的影响、作用机制以及各种因素的相互关系,有助于更深入理解铝合金阳极氧化膜的结构与性能的科学本质;同时在此基础上制备出具有耐热、抗热疲劳并耐腐蚀的阳极氧化膜层,具有重要、直接的工程应用前景。

本文作者从氧化膜内残余内应力角度研究氧化时间、硫酸浓度和氧化电流密度等氧化工艺对氧化膜受热开裂行为的影响。

1 实验

1.1 材料

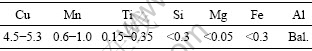

实验材料为ZL201铸造铝合金,其化学成分(质量分数,%)如表1所列。

表1 铝合金的化学成分

Table 1 Chemical compositions of tested alloys (mass fraction, %)

1.2 阳极氧化膜的制备

铝合金经线切割为尺寸15 mm×10 mm×1 mm的试片,然后依次用水砂纸从300#打磨至1500#,丙酮脱脂除油,碱性化学除油(50 g/L NaOH,2 min,50 ℃),出光(200 g/L HNO3,0.5 min,常温),去离子水洗,最后进行阳极氧化。典型的氧化工艺条件选择直流电流密度为2 A/dm2,硫酸浓度200 g/L,温度25 ℃,氧化时间1 h。考虑氧化工艺影响时,分别改变氧化时间、硫酸浓度和氧化电流密度等条件。样品阳极氧化后经去离子水洗,冷风吹干。

1.3 阳极氧化膜的封闭与加热

1) 沸水封闭:在沸水中封闭30 min, pH=6~7.5。

2) 加热:30 min升温至300 ℃并保温6 h,随炉冷却至室温。

1.4 氧化膜性能测试及表面分析测试

氧化膜的厚度采用TP230涡流测厚仪测试,每片试样分别在不同部位测10组数据,取平均值。

采用三电极体系,以饱和甘汞电极为参比电极,铂电极为辅助电极,工作电极用环氧树脂涂封,暴露面积约1 cm2。用美国PE公司生产的电化学测试系统测定氧化膜在3.5%(质量分数)NaCl溶液中的交流阻抗谱(EIS)(测试信号为幅值10 mV正弦波,测量的频率由100 kHz至0.1 Hz,测试软件为Powersine),数据处理用Origin7.0完成。

用LEO-1450扫描电子显微镜(SEM)观察加热后阳极氧化膜的截面和表面形貌,每种处理条件选3幅表面形貌图片,测量每幅图片裂纹长度和,取其平均值作为该条件下图片所示面积内裂纹长度,并定义该长度值与图片面积比为裂纹密度,表征一定条件下形成裂纹的数量。

2 实验结果

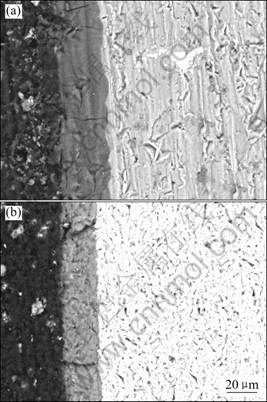

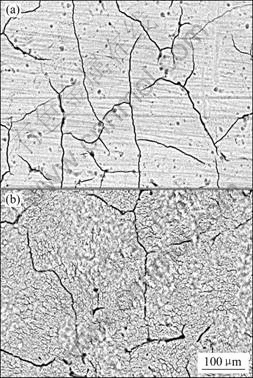

2.1 氧化膜加热前后形貌

图1和图2所示分别为在标准条件下阳极氧化膜加热前后的截面形貌和表面形貌。由图可见,氧化膜在封闭后存在少量缺陷,并在缺陷处形成微裂纹。但从氧化膜截面形貌来看,这些裂纹是非穿透性的,可能仅仅发生在多孔层,而阻挡层并未受到破坏,对基体还能起到很好的保护作用。加热后,原有的微裂纹进一步扩展,深度、长度和宽度都变大,并在不同部位会产生新的裂纹。多数裂纹延伸至铝基体[6],氧化膜对基体的保护作用显著下降。

图1 加热前后氧化膜截面SEM照片

Fig.1 Cross-section SEM images of anodic oxide films: (a) Before heating; (b) After heating

图2 氧化膜加热前后表面形貌

Fig.2 Surface morphologies of anodic oxide films: (a) Before heating; (b) After heating

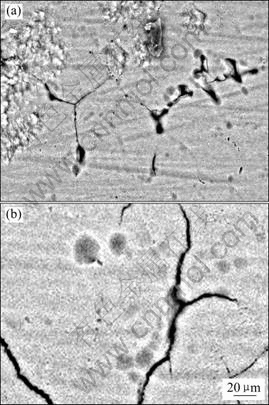

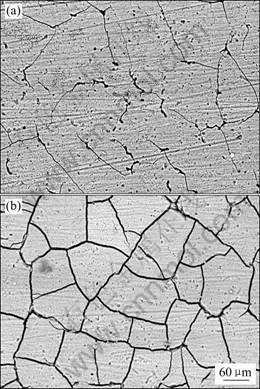

2.2 氧化时间对氧化膜受热开裂的影响

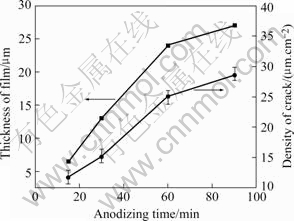

图3所示为在25 ℃、200 g/L硫酸和2 A/dm2氧化电流密度条件下分别氧化30和60 min形成的氧化膜在加热后的SEM像。图4所示为分别在氧化15 min、30 min、60 min和90 min后形成的阳极氧化膜厚度和加热后裂纹密度的变化曲线。由图可见,随着氧化时间的延长,氧化膜厚度和裂纹密度均增大。

图3 不同氧化时间形成的氧化膜受热后的裂纹形貌

Fig.3 Crack morphologies of anodic oxide films obtained by different anodizing times after heating: (a) 30 min; (b) 60 min

图4 氧化时间对氧化膜厚度和裂纹密度的影响

Fig.4 Effects of anodizing time on coating thickness and crack density

引起氧化膜在较高温度下开裂的根本原因是氧化膜与铝合金基体的热膨胀系数的差异。基体的热膨胀系数一般为氧化膜的5倍[8],氧化膜在热应力作用下发生开裂。当受热条件相同时,氧化膜内残余内应力会影响裂纹的数量、宽度以及形貌等。不同氧化时间下形成的氧化膜的开裂行为,可以用厚度对开裂行为的影响来解释[9-10]。在受热条件下,氧化膜因基体的膨胀作用受到拉伸荷载,产生张开型裂纹。裂纹前沿有很大的拉应力,使试样有沿厚度方向收缩的趋势;但在裂纹前沿的中间地段,因有两边材料的约束,不能自由收缩,结果使该处形成三向拉应力状态,甚至达到平面应变的程度,使材料不易发生塑性变形,促使裂纹脆性开裂,试样愈厚,这种平面应变的部位在整个试样厚度上所占的比例就会愈大,因而产生较多裂纹。

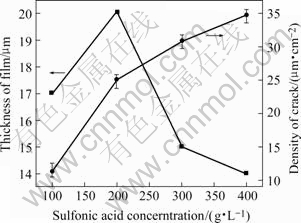

2.3 硫酸浓度对氧化膜受热开裂的影响

图5所示为在200和400 g/L硫酸溶液中形成的氧化膜经加热后的SEM像。图6所示为分别在100、200、300和400 g/L硫酸溶液中形成的阳极氧化膜厚度和加热后裂纹密度的变化曲线。由图可见,随硫酸浓度增大,氧化膜厚度先增大后减小,在硫酸浓度为200 g/L时氧化膜厚度达到最大值。加热后,各条裂纹相互交错呈网络状分布,裂纹发展无明显的方向性。硫酸浓度增大到400 g/L时,在氧化膜的外层产生了许多细小的非穿透性微裂纹。随硫酸浓度增大,裂纹密度增大。在阳极氧化过程中,氧化膜的生长和硫酸对氧化膜的溶解是同时进行的[11]。硫酸浓度较低时,氧化膜的生长速度大于其溶解速度,随硫酸浓度增大,氧化膜厚度增大;但是当硫酸浓度增大到使氧化膜的溶解速度快于其生长速度的时候,氧化膜厚度就会随硫酸浓度增大而减小。加热后出现的非穿透性微裂纹可能跟这种过溶解有关[6]。

图5 不同硫酸浓度下形成的氧化膜受热后的裂纹形貌

Fig.5 Crack morphologies of anodic oxide films obtained by different sulfuric acid concentrations after by heating: (a) 200 g/L; (b) 400 g/L

图6 硫酸浓度变化对氧化膜厚度和裂纹密度的影响

Fig.6 Effects of sulfuric acid concentration on coating thickness and crack density

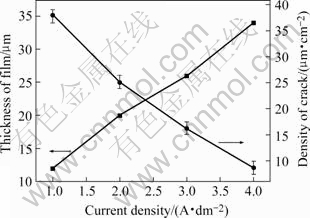

2.4 氧化电流密度对氧化膜受热开裂的影响

图7所示为在氧化电流密度分别为2和4 A/dm2条件下形成的氧化膜加热后的SEM像。图8所示为在氧化电流密度分别为1、2、3和4 A/dm2下形成的阳极氧化膜厚度和加热后裂纹密度的变化曲线。由图可见,随氧化电流密度增大,氧化膜厚度增大,而裂纹密度则减小。加热会使氧化膜产生网络状裂纹,当氧化电流密度增大到4 A/dm2时,观察发现在氧化膜表面产生大量细小的非穿透性微裂纹。一定范围内随氧化电流密度增大,氧化膜生长速度较快,致密度较高,但是当氧化电流密度超过一定值后,则膜层孔内热效应增大,会加速氧化膜的溶解。当氧化电流密度增大到4 A/dm2时,氧化膜加热后产生的微裂纹可能与这种溶解效应有关[6]。

图7 不同氧化电流密度下形成的氧化膜受热后的裂纹形貌

Fig.7 Crack morphologies of anodic oxide films obtained by different current densities after heating: (a) 2 A/dm2; (b) 4 A/dm2

图8 氧化电流密度变化对氧化膜厚度和裂纹密度的影响

Fig.8 Effects of current density on coating thickness and crack density

2.5 不同氧化工艺下形成氧化膜的EIS

由于铝阳极氧化膜在电解液中是离子导体,并且阳离子空位和氧担负电荷的输送工作[12],因此空位浓度可以由氧化膜的电阻反映出来[13]。为了比较氧化膜的电阻,采用交流阻抗法测量阳极氧化膜加热前在3.5% NaCl溶液中随硫酸浓度和氧化电流密度变化的阻抗谱图,如图9所示。高频段容抗弧代表在ZL201铝合金表面形成的氧化膜的性质。由图可见,随硫酸浓度的增大,氧化膜容抗弧逐渐变大;随氧化电流密度增大,氧化膜容抗弧逐渐变小。即随硫酸浓度的增大,氧化膜电阻增大;随氧化电流密度增大,氧化膜电阻减小。

图9 不同氧化工艺形成氧化膜的交流阻抗谱

Fig.9 EIS of films formed with different processing parameters: (a) Sulfuric acid concentration; (b) Current density

3 讨论

当氧化时间、硫酸浓度和电流密度超过一定值后,氧化液对氧化膜的溶解作用变的显著,使氧化膜外表面变的较为疏松。同时,氧化膜在较低温度下(约100℃左右)即会因为脱水而形成微裂纹。但是这些裂纹均为深度不大的非穿透性裂纹,会影响氧化膜的性能但是不会导致氧化膜的破裂失效。因此本研究重点考察较高温度下氧化膜的破裂失效行为。热应力是促使氧化膜受热开裂的根本原因,而残余生长应力则会影响裂纹的形貌[14]。相同的加热条件下,氧化膜所受热应力相近,所以主要考虑氧化膜内残余生长内应力对氧化膜开裂行为的影响。已经有许多研究者致力于氧化膜内生长应力的研究[15-18],一般认为,生长应力来源于金属和氧化物的摩尔体积的差异,即PBR(Pilling and bedworth ratio)[15],该理论可以解释随氧化电流密度增大,氧化膜的体积膨胀系数[19]和厚度增大,氧化膜内压应力增大的现象。但是也有研究者发现,当氧化电流密度进一步增大时,氧化膜内的压应力逐渐减小,甚至会出现拉应力[16]。本文作者用纯铝箔在硫酸溶液中,采用不同的氧化电流密度和不同的氧化温度进行单面氧化时也观察到了这一现象。这仅用PBR的概念无法解释。同时,HUNTZ[17]也认为PBR成为影响因素的条件是阴离子的优先扩散,对于铝合金的本质和组成来说,不存在阴离子和阳离子的优先扩散,因此,PBR不是氧化膜残余生长内应力的唯一来源。

生长应力不仅分布在整个氧化膜内,而且与氧化膜的微观结构有关,微观结构的变化来自于膜层和氧化物界面处元素的相互扩散和扩散元素向氧化膜的流动[17]。KIM等[18]认为空位是拉应力的来源。MOON等[16]综合考虑了以上工作后认为发生元素扩散的界面位于铝/氧化膜界面处不超过1 nm厚的窄带上,该处铝空位 的湮灭和氧空位

的湮灭和氧空位 的生成对氧化膜内应力的产生有较大影响[17]。铝离子进入膜中的空位,将导致铝空位的消失,或者它们在氧化膜中吸收,这将导致氧空位的产生。铝空位的消失将增大该窄带处氧化膜的摩尔体积,在窄带内产生压应力;氧空位的产生减小该窄带处氧化膜的摩尔体积,因而产生拉应力,该理论可以通过内应力大小变化得到验证。用该理论可以解释氧化膜的受热开裂行为。

的生成对氧化膜内应力的产生有较大影响[17]。铝离子进入膜中的空位,将导致铝空位的消失,或者它们在氧化膜中吸收,这将导致氧空位的产生。铝空位的消失将增大该窄带处氧化膜的摩尔体积,在窄带内产生压应力;氧空位的产生减小该窄带处氧化膜的摩尔体积,因而产生拉应力,该理论可以通过内应力大小变化得到验证。用该理论可以解释氧化膜的受热开裂行为。

氧化膜表面到铝合金基体可被分为3层,最外层为整个氧化膜层,包括多孔层和阻挡层,中间层为对应力变化有重要影响的窄带,最内层为铝合金基体。窄带处氧化膜摩尔体积的变化会影响氧化膜层受力状况。如果窄带处膜的摩尔体积小于氧化膜层摩尔体积,窄带会对氧化膜层产生压应力,压应力随窄带处膜的摩尔体积增大而减小。如果窄带处膜的摩尔体积大于氧化膜层摩尔体积,则窄带对氧化膜层产生拉应力,拉应力随窄带处膜的摩尔体积增大而增大。氧化膜层所受压力的增大或拉力的降低,都有助于阻碍氧化膜层的受热开裂。因此,窄带处氧化膜摩尔体积减小,将会使氧化膜层的开裂倾向降低。

随氧化时间延长,阻挡层的阻抗变化并不显著,而多孔层的阻抗变化则相对比较明显[6]。多孔层阻抗变化较大是由于多孔层的厚度变化,而阻挡层的阻抗变化不显著说明窄带内应力变化不大。因此,厚度是影响氧化膜裂纹形貌的一个重要因素。随硫酸浓度增大,氧化膜厚度先增大后降低,而电阻却逐渐增大,这表明铝离子进入空位使空位浓度降低,铝离子空位的减少会增大窄带处氧化膜摩尔体积。同时考虑硫酸浓度由100 g/L增大到200 g/L时氧化膜厚度增大的影响,裂纹密度出现较大程度的增加。随氧化电流密度增大,氧化膜厚度增大,但是电阻却逐渐降低,这说明氧化膜的电阻系数降低,表明氧化膜内铝离子空位浓度增大,或者是氧空位浓度增大,这二者均有利于窄带处氧化膜摩尔体积的降低,使得氧化膜层不易开裂。因此,随氧化时间延长和硫酸浓度的增大,氧化膜受热后裂纹密度增大,而随着氧化电流密度增大,氧化膜受热后裂纹密度减小;残余生长应力对开裂行为的影响比氧化膜厚度更显著。

4 结论

1) 由于氧化膜和基体的热膨胀系数不同,氧化膜受热时产生的热应力是氧化膜开裂的根本因素。氧化膜受热时,不但会沿着原有缺陷处发生开裂,而且会在其他位置萌生新的裂纹,产生网络状穿透性裂纹。

2) 氧化膜形成过程中的生长应力影响加热后氧化膜裂纹的数量。随氧化时间延长和硫酸浓度增大,氧化膜加热后产生的裂纹密度增大;随氧化电流密度增大,氧化膜加热后产生的裂纹密度则减小。

REFERENCES

[1] GRAHAM M J, HUSSEY R J. Characterization and growth of oxide films[J]. Corrosion Science, 2002, 44(2): 319-330.

[2] ZUO Yu, ZHAO Peng-hui, ZHAO Jing-mao. The influences of sealing methods on corrosion behaviour of anodized aluminum alloys in NaCl solutions[J]. Surface and Coatings Technology, 2003, 166(2): 237-242.

[3] AERTS T, DIMOGERONTAKIS TH, DE GRAEVE I FRANSAER J, TERRYN H. Influence of the anodizing temperature on the porosity and the mechanical properties of the porous anodic oxide film[J]. Surface and Coatings Technology, 2007, 201(16/17): 7310-7317.

[4] GARCIA-VERGARA S J, SKELDON P, THOMPSON G E, HABAZAKI H. A flow model of porous anodic film growth on aluminium[J]. Electrochimca Acta, 2007, 52(2): 681-687.

[5] ONO S, WADA C, ASOH H. Structure and property of anodic barrier films formed on aluminum in low voltage range[J]. Electrochimica Acta,2005, 50(25/26): 5103-5110.

[6] 郭 超. 铸造铝合金的阳极氧化工艺与耐蚀性研究[D]. 北京: 北京化工大学, 2004.

GUO Chao. Study on the technics of anodic oxidation of cast aluminum alloy and the film’s corrosion resistance[D]. Beijing: Beijing University of Chemical Technology, 2004.

[7] 马月辉. 铝型材阳极氧化膜破裂原因及预防措施[J].轻合金加工技术, 2002, 30(6): 47-48.

MA Yue-hui. Causes of aluminium profile anodic coating cracking and preventive measures[J]. Light Alloy Fabrication Technology, 2002, 30(6): 47-48.

[8] ZHOU J, WU J, YANG Y. Research on the thermal expansion behavior of anodic films on aluminium[J]. Thin Solid Films, 1999, 346(1/2): 280-283.

[9] 邓增杰, 周敬恩. 工程材料的断裂与疲劳[M]. 北京:机械工业出版社, 1995.

DENG Zeng-jie, ZHOU Jing-en. Fracture and fatigue of engineering materials[M]. Beijing: Machinery Industry Press, 1995.

[10] PATIL P S, MUJAWAR S H, SADALE S B, DESHMUKH H P, INAMDAR A I. Effect of film thickness on electrochromic activity of spray deposited iridium oxide thin films[J]. Materials Chemistry and Physics, 2006, 99(2/3): 309-313.

[11] 许 旋, 林国辉, 陈子超, 罗一帆. 影响铝合金阳极氧化膜质量因素的研究[J]. 电镀与涂饰, 2005, 24(2): 7-10.

XU Xuan, LIN Guo-hui, CHEN Zi-chao, LUO Yi-fan. Study on factors affecting quality of Al alloy anodized films[J]. Electroplating and Finishing, 2005, 24(2): 7-10.

[12] RANDALL J J, BERNARD W J. A radiotracer study of the anodization of aluminum in aqueous phosphate solutions[J]. Electrochimca Acta, 1975, 20(9): 653-661.

[13] SHACKELFORD J F. Introduction to materials science for engineers[M]. New York: Macmillan Publishing Company, 1985.

[14] 李美栓, 辛 丽, 钱余海, 李铁藩. 氧化膜应力研究进展[J]. 腐蚀科学与防护技术, 1999, 11(5): 300-305.

LI Mei-shuan, XIN Li, QIAN Yu-hai, LI Tie-fan. A review on studies of internal stress in oxide scales[J]. Corrosion Science and Technology Protection, 1999, 11(5): 300-305.

[15] NELSON J C, ORIANI R A. Stress generation during anodic oxidation of titanium and aluminum[J]. Corrosion Science, 1993, 34(2): 307-326.

[16] MOON S M, PYUN S I. The mechanism of stress generation during the growth of anodic oxide films on pure aluminium in acidic solutions[J]. Electrochimica Acta, 1998, 43(21/22): 3117-3126.

[17] HUNTZ A M. Stress in NiO, Cr2O3 and Al2O3 oxide scales[J]. Mater Sci Eng A, 1995, 201(1/2): 211-228.

[18] KIM J D, PYUN S I, ORIANI R A. Effects of applied current density and potential step on the stress generation during anodic oxidation of tungsten in 0.1M H2SO4 solution[J]. Electrochimca Acta, 1995, 40(9): 1171-1176.

[19] VRUBLEVSKY I, PARKOUN V, SCHRECKENBACH J, MARX G. Effect of the current density on the volume expansion of the deposited thin films of aluminum during porous oxide formation[J]. Applied Surface Science, 2003, 220(1/4): 51-59.

基金项目:国家自然科学基金资助项目(50571006)

收稿日期:2007-04-24;修订日期:2007-10-23

通讯作者:左 禹,教授,博士;电话:010-64423795;传真:010-64434908;E-mail: zuoy@mail.buct.edu.cn

(编辑 何学锋)