DOI:10.19476/j.ysxb.1004.0609.2019.05.11

IN718镍基高温合金的热机械疲劳性能

邓文凯1, 2,徐睛昊1, 2,江 亮1, 2

(1. 中南大学 粉末冶金国家重点实验室,长沙 410083;

2. 中南大学 粉末冶金研究院,长沙 410083)

摘 要:对IN718镍基高温合金进行温度循环为350~650 ℃及不同应变幅条件下的同相(IP)和反相(OP)热机械疲劳试验;比较同相和反相的热机械疲劳循环应力响应行为、滞后回线以及疲劳寿命;运用金相显微镜、扫描电子显微镜对材料的微观结构以及断口特征进行分析。结果表明:IN718合金的热机械疲劳应力-应变滞后回线最大拉应力与压应力不对称,表明合金在350~650 ℃范围内高温时抵抗变形阻力较小;合金的循环应力响应行为在低应变幅的同相热机械疲劳的高温半周呈现循环硬化现象,其余情况均为循环软化现象;合金的同相热机械疲劳寿命明显低于反相热机械疲劳寿命,合金热机械疲劳寿命在应变幅超过0.6%的条件下符合Coffin-Manson方程,在应变幅0.4%的情况下实际疲劳寿命值偏高;IN718合金的同相热机械疲劳的疲劳源处断口为沿晶断裂,反相热机械疲劳的为穿晶断裂,裂纹扩展区和瞬断区均为韧窝断裂。

关键词:IN718镍基高温合金;热机械疲劳;同相;反相;疲劳寿命;断口

文章编号:1004-0609(2019)-05-0983-07 中图分类号:TG146 文献标志码:A

航空发动机作为飞机的动力系统,其性能直接影响飞机的飞行能力以及安全可靠性,被称为飞机的“心脏”[1-2]。航空发动机中的高温合金部件在服役过程中,不仅要承受高温的环境,而且受到离心力、外部约束力以及自身重力等复杂机械应力的叠加作用,导致材料在局部区域发生一定程度的塑性变形,在长期循环的过程中使得部件发生疲劳、蠕变等损伤[3]。因此,对于航空发动机上的高温合金材料的性能要求非常高。

航空发动机的高温合金部件,特别是转动件,常常经受周期性载荷作用。虽然这种载荷作用的应力大小不足以一次性对部件发生破坏,但在周而复始的循环过程中,材料往往会发生疲劳断裂。通常的低周疲劳是指材料在保持恒定的温度情况下,承受周期性循环载荷作用且疲劳寿命在1×105次循环以下的疲劳断裂[4]。然而近期的研究表明,快速的温度变化会对在服役过程中的部件产生额外的损伤,从而导致部件的疲劳寿命明显降低[5-6]。因此,采用温度与应力交变循环的热机械疲劳实验比传统的低周疲劳实验能更好地模拟部件的实际工况。

IN718镍基高温合金是目前航空发动机领域应用最广泛的高温合金之一。该合金在650 ℃以下具有优异的综合性能,包括较高的强度和塑形、良好的抗氧化性以及耐腐蚀性等。IN718合金作为制造涡轮盘、压气机盘等重要零部件的主要材料,其低周疲劳性能已被大量研究。FOURNIER等[7]研究了室温下和550 ℃时的IN718合金低周疲劳性能。CLAVEL等[8]对25、550和650 ℃下IN718合金低周疲劳裂纹扩展机制进行了分析。PARK等[9]研究了649 ℃下IN718合金的低周疲劳的棘轮效应以及低周疲劳寿命的预测机制。XIAO等[10]开展了硼含量对IN718合金的变形组织和650 ℃下低周疲劳性能的影响的分析。关于IN718合金热机械疲劳性能方面的研究则相对较少。JACOBSSON等[11]研究了IN718合金的热机械疲劳裂纹扩展机制。MOVERARE等[12]分析了IN718合金热机械疲劳在最高温度下的保载行为对裂纹扩展的影响。XIAO等[13]探索了硼和碳含量对IN718合金热机械疲劳性能的影响。但是,关于IN718合金的同相和反相热机械疲劳断裂机制对比以及合金热机械疲劳寿命预测机制的研究工作开展不足。

本文作者主要研究IN718镍基高温合金的热机械疲劳性能及热机械疲劳行为和断裂机制,分析IN718合金在不同阶段的显微组织,将IN718合金同相(IP)和反相(OP)的热机械疲劳实验结果进行对比,并结合Coffin-Manson疲劳应变-寿命方程对IN718合金的热机械疲劳寿命开展分析。

1 实验

1.1 实验材料与试样

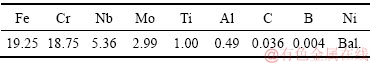

本实验中原材料采用高Nb的IN718合金锻棒,锻造工艺如下:加热温度1100~1120 ℃,开锻温度为1020 ℃,终锻温度为920 ℃,末火变形量大于30%。其化学成分如表1所列。

表1 高Nb IN718镍基高温合金的化学成分

Table 1 Element content of IN718 superalloy (mass fraction, %)

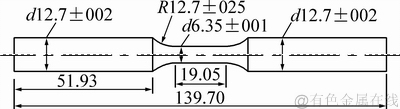

IN718镍基高温合金的热处理制度如下:固溶处理温度为955 ℃,保温1 h,随后空冷到室温;一级时效温度为720 ℃,保温8 h,随后以50 ℃/h的冷却速率降温到620 ℃进行二级时效,保温8 h,最后空冷到室温[14-16]。IN718合金热机械疲劳试样几何尺寸如图1所示。试样为实心圆棒试样,标距部分直径为6.35mm,试样总长度为139.70mm。试样表面粗糙度为0.2 μm。

图1 IN718合金热机械疲劳试样

Fig. 1 IN718 superalloy specimens for TMF test (Unit: mm)

1.2 实验装置与方法

本实验中采用DM4000M型金相显微镜对IN718镍基高温合金在热处理前、热处理后以及应变幅为0.6%的同相热机械疲劳后断口附近的材料显微组织进行分析。热机械疲劳实验在MTS810型热机械疲劳试验机上进行,采用三角波波形、同相和反相两种加载模式,利用机械应变控制,机械应变幅分别为0.4%、0.6%、0.8%和1.0%,应变比R=-1。热机械疲劳实验的循环温度为350~650 ℃,循环周期为120 s。本实验中使用FEI Quanta FEG 650扫描电子显微镜对应变幅为0.6%的同相和反相热机械疲劳后试样断口进行断口分析,工作电压为15 kV。

2 结果与讨论

2.1 试样微观组织

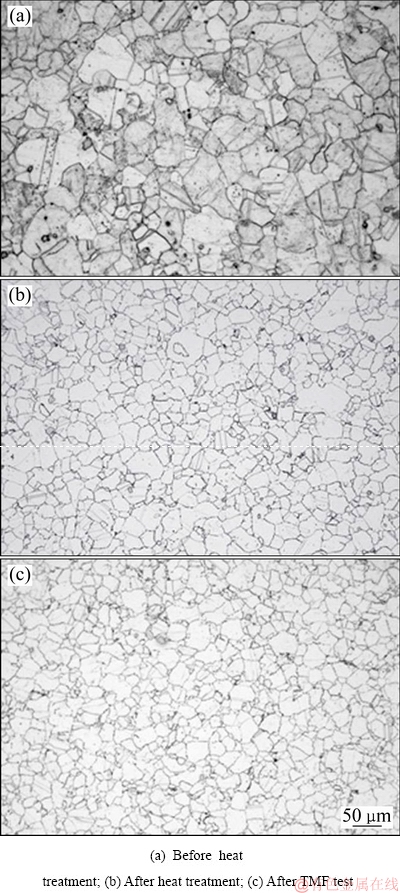

IN718高温合金在锻造之后的组织形貌如图2(a)所示。合金的基体相为γ相,晶粒尺寸不均匀,晶内存在大量孪晶,组织中还保留有一些冶炼过程中形成的块状碳(氮)化物。合金在经过热处理后的显微组织如图2(b)所示。通过固溶处理和一级、二级时效处理后,IN718合金的晶粒尺寸明显比热处理前的晶粒尺寸更为均匀,同时平均晶粒尺寸明显减小。IN718合金在0.6%应变幅的同相热机械疲劳之后的断口附近显微组织如图2(c)所示,通过对比,合金的微观形貌与疲劳之前的微观形貌无明显差异,平均晶粒尺寸稍有增大。

图2 IN718镍基高温合金锻态、热处理后以及热机械疲劳后的金相组织

Fig. 2 Metallographs of IN718 superalloy

2.2 热机械疲劳应力-应变滞后回线

IN718镍基高温合金在不同应变幅下的同相和反相热机械疲劳中半寿命循环周期的滞后回线分别如图3(a)和(b)所示。当应变幅为0.4%时,材料的同相和反相热机械疲劳均没有表现出明显的滞后回线,且反相热机械疲劳的滞后环更小。而且随着应变幅的增加,滞后回线越明显。当应变幅为1.0%时,同相和反相热机械疲劳均呈现出明显的循环塑性。

对于同相和反相热机械疲劳,其滞后回线均呈现明显的不对称性。其中,对于同相热机械疲劳,在承受拉应力时温度较高,相同应变时的应力相对较低,在承受压应力的时候温度较低,相同应变时的应力相对较高,从而导致滞后环呈现不对称,样品受到一个压缩的平均应力。对于反相热机械疲劳,其在承受拉应力时温度较低,则受到一个拉伸的平均应力。这说明IN718镍基高温合金在350~650 ℃之间温度对其力学性能产生了较为明显的影响,高温状态下材料抵抗变形的阻力相对较小[17],产生相同应变时所需的应力值较低。

图3 同相和反相热机械疲劳应力-应变滞后回线

Fig. 3 Stress-strain hysteresis loop of IP (a) and OP (b) TMF test

2.3 热机械疲劳循环应力响应

IN718镍基高温合金的同相热机械疲劳循环应力响应如图4(a)所示。当应变幅为1.0%时,试样的初始最大拉压应力值均相对较高,拉应力峰值为1031 MPa,压应力峰值达到1212 MPa,并在整个疲劳过程中发生明显的循环软化,直到试样发生脆性断裂。对于应变幅为0.8%和0.6%的同相热机械疲劳,其初始的最大拉压应力基本相同。在疲劳初期,0.8%应变幅的试样在高温半周应力较为稳定,在低温半周出现循环软化,而0.6%应变幅的试样在高温半周呈现循环硬化的效果,在低温半周则为明显的循环软化。对于应变幅为0.4%的同相热机械疲劳,试样的初始最大拉压应力均较低,拉应力峰值为540 MPa,压应力峰值为817 MPa,在疲劳前几个循环的高温半周呈现循环硬化现象,在低温半周则为循环软化。应变幅为0.8%、0.6%和0.4%的同相热机械疲劳试样均为韧性断裂。

图4 同相(a)和反相(b)热机械疲劳应力循环曲线

Fig. 4 Variation of stress amplitude with cycle in IP (a) and OP (b) TMF test

IN718合金的反相热机械疲劳循环应力响应如图4(b)所示。对于应变幅为1.0%的反相热机械疲劳试样。与同相热机械疲劳试样类似,在疲劳初始阶段的最大拉压应力均较高,拉应力峰值为1137 MPa,压应力峰值为1116 MPa,试样在整个循环过程中呈现循环软化现象,到269个循环时发生脆性断裂。应变幅为0.8%和0.6%的反相热机械疲劳试样初始的拉压应力峰值均相当,在整个疲劳过程中两根试样在高温半周和低温半周均为循环软化现象,直到试样发生韧性断裂。应变幅为1.0%、0.8%和0.6%的反相热机械疲劳试样在高温半周的循环软化现象比低温半周更为明显,试样逐渐承受一个拉伸的平均应力。对于应变幅为0.4%的反相热机械疲劳试样,其初始最大拉压应力值均较低,拉应力峰值为793 MPa,压应力峰值为641 MPa,试样从疲劳初期即呈现出循环稳定状态,疲劳后期在高温半周出现一定的循环软化,直到发生韧性断裂。

2.4 热机械疲劳寿命

COFFIN(1954)和MANSON(1954)在独立研究热疲劳问题时分别提出了一种以塑形应变幅为参量的疲劳寿命描述方法[18],即Coffin-Manson方程:

(1)

(1)

式中:Δεp为塑性应变范围; 为疲劳延性系数;C为疲劳延性指数;Nf为发生破坏的循环周次。式(1)只适用于短寿命区的疲劳寿命预测。

为疲劳延性系数;C为疲劳延性指数;Nf为发生破坏的循环周次。式(1)只适用于短寿命区的疲劳寿命预测。

对于恒应变幅的热机械疲劳实验,总的机械应变幅Δεm/2可以写成弹性应变幅Δεe/2和塑形应变幅Δεp/2之和,即

(2)

(2)

而弹性应变幅可以由弹性应力幅σa和弹性模量E表示,即

(3)

(3)

在恒应力幅疲劳实验中,描述应力幅与发生破坏的循环次数之间关系的表达式为

(4)

(4)

式中: 为疲劳强度系数;b为疲劳强度指数。

为疲劳强度系数;b为疲劳强度指数。

由此,Coffin-Manson方程可以转化为

(5)

(5)

总的机械应变幅可在更大范围内描述材料的疲劳寿命,包括预测室温低周疲劳寿命、高温低周疲劳寿命以及热机械疲劳寿命[19-20]。

IN718镍基高温合金的热机械疲劳S-N曲线如图5所示。在循环温度350~650 ℃条件下,IN718合金各个应变幅的同相热机械疲劳寿命均明显低于反相热机械疲劳寿命。在双对数坐标下的热机械疲劳S-N曲线中,IN718合金的同相和反相的热机械疲劳的应变-寿命均分别呈线性分布,符合Coffin-Manson疲劳寿命预测方程。然而当应变幅为0.4%时,疲劳寿命稍微偏离寿命预测曲线,实际疲劳寿命值偏高,说明在应变幅较低甚至接近疲劳极限的情况下,运用Coffin-Manson方程对IN718镍基高温合金进行疲劳寿命分析存在一定的局限性。

图5 IN718镍基高温合金热机械疲劳S-N曲线

Fig. 5 S-N curve of IN718 superalloy TMF test

2.5 疲劳断口分析

IN718镍基高温合金的应变幅为0.6%的同相和反相热机械疲劳宏观断口形貌如图6(a)和(b)所示。宏观断口分为疲劳源区(1区)、疲劳裂纹扩展区(2区)和瞬断区。瞬断区由纤维区(3区)和剪切唇区(4区)组成[21]。疲劳源区和疲劳裂纹扩展区呈浅黄色,瞬断区呈深蓝色。

图6 IN718合金在应变幅为0.6%时的同相和反相热机械疲劳宏观断口形貌

Fig. 6 Macro fractures of IN718 superalloy in strain amplitude of 0.6% IP (a) and OP (b) TMF test

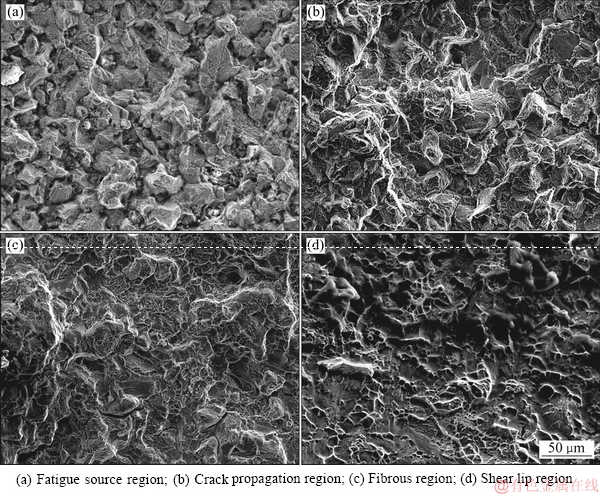

合金应变幅为0.6%的同相热机械疲劳微观断口如图7所示。疲劳源区为明显的沿晶断裂(见图7(a)),疲劳裂纹扩展区为沿晶断裂和韧窝断裂交界处,存在一定的二次裂纹(见图7(b)),纤维区为韧窝断裂(见图7(c)),剪切唇区也为韧窝断裂(见图7(d))。

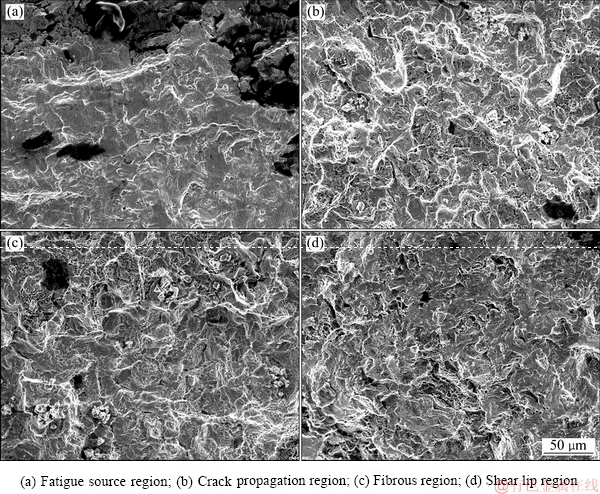

合金应变幅为0.6%的反相热机械疲劳微观断口如图8所示。疲劳源区存在疲劳辉纹,为穿晶断裂(见图8(a)),疲劳裂纹扩展区和瞬断区为韧窝断裂(见图8(b)、(c)、(d))。

图7 IN718合金应变幅为0.6%的同相热机械疲劳微观断口形貌

Fig. 7 Fracture morphologies of IN718 superalloy in strain amplitude of 0.6% IP TMF test

图8 IN718合金在应变幅为0.6%时的反相热机械疲劳微观断口形貌

Fig. 8 Fracture morphologies of IN718 superalloy in strain amplitude of 0.6% OP TMF test

3 结论

1) IN718镍基高温合金在热处理前后的微观组织差别较大,热处理后的晶粒尺寸更为均匀,平均晶粒尺寸明显减小。IN718合金在0.6%应变幅的同相热机械疲劳前后显微组织无明显差别。

2) IN718镍基高温合金在温度循环为350~650 ℃的同相和反相热机械疲劳中滞后回线均有不对称性。 合金只有在应变幅为0.6%和0.4%的同相热机械疲劳的疲劳初期最大拉应力出现循环硬化现象,在应变幅为0.4%的反相热机械疲劳的疲劳初期为循环稳定状态,其余情况全为循环软化现象。

3) IN718镍基高温合金的同相热机械疲劳寿命在各应变幅情况下均明显低于其反相热机械疲劳寿命。合金的同相和反相热机械疲劳寿命均基本符合Coffin-Manson疲劳应变-寿命方程,但在接近疲劳极限时,即应变幅为0.4%的同相和反相热机械疲劳实际寿命值偏高。

4) IN718镍基高温合金在应变幅为0.6%的同相热机械疲劳的疲劳源处为沿晶断裂,反相热机械疲劳的疲劳源处为穿晶断裂,疲劳裂纹扩展处和瞬断区均为韧窝断裂。

REFERENCES

[1] SIMS C T, STOLOFF N S, HAGEL W C. Superalloys II[M]. New York: Wiley, 1981.

[2] REED R C. The superalloys: Fundamentals and applications[M]. London: Cambridge University Press, 2008.

[3] 郭建亭. 高温合金材料学[M]. 北京: 科学出版社, 2008.

GUO Jian-ting. Materials science and engineering for superalloys[M]. Beijing: Science Press, 2008.

[4] SURESH S. Fatigue of materials[J]. Fatigue & Fracture of Engineering Materials & Structures, 1991, 28: 1153-1160.

[5] SEGERSALL M, LEIDERMARK D, MOVERARE J J. Influence of crystal orientation on thethermomechanical fatigue behaviourin a single-crystal superalloy[J]. Materials Science and Engineering A, 2015, 623: 68-77.

[6] LANCASTER R J, WHITTAKER M T, WILLIAMS S J. A review of thermo-mechanical fatigue behaviour in polycrystalline nickel superalloys for turbine disc applications[J]. Materials at High Temperatures, 2013, 30(1): 2-12.

[7] FOURNIER D, PINEAU A. Low cycle fatigue behavior of Inconel 718 at 298 K and 823 K[J]. Metallurgical Transactions A, 1977, 8: 1095-1105.

[8] CLAVEL M, PINEAU A. Fatigue behaviour of two nickel-base alloys I: Experimental results on low cycle fatigue, fatigue crack propagation and substructures[J]. Materials Science and Engineering A, 1982, 55: 157-171.

[9] PARK S, KIM K, KIM H. Ratcheting behaviour and mean stress considerations in uniaxial low-cycle fatigue of Inconel 718 at 649 ℃[J]. Fatigue & Fracture of Engineering Materials & Structures, 2007, 30: 1076-1083.

[10] XIAO L, CHATURVEDI M, CHEN D. Effect of boron on the low-cycle fatigue behavior and deformation structure of Inconel 718 at 650 ℃[J]. Metallurgical and Materials Transactions A, 2004, 35: 3477-3487.

[11] JACOBSSON L, PERSSON C, MELIN S. Thermo-mechanical fatigue crack propagation experiments in Inconel 718[J]. International Journal of Fatigue, 2009, 31: 1318-1326.

[12] MOVERARE J J, GUSTAFSSON D. Hold-time effect on the thermo-mechanical fatigue crack growth behaviour of Inconel 718[J]. Materials Science and Engineering A, 2011, 528: 8660-8670.

[13] XIAO L, CHEN D, CHATURVEDI M. Effect of boron and carbon on thermomechanical fatigue of IN 718 superalloy: Part I. Deformation behavior[J]. Materials Science and Engineering A, 2006, 437: 157-171.

[14] LUNDSTROM E, SIMONSSON K, GUSTAFSSON D, MANSSON T. A load history dependent model for fatigue crack propagation in Inconel 718 under hold time conditions[J]. Engineering Fracture Mechanics, 2014, 118(2): 17-30.

[15] OKAZAKI M, SAKAGUCHI M, TRAN T H, SEKIHARA M. Creep-fatigue and thermo-mechanical fatigue of friction-welded IN 718/MarM247 dissimilar joint[C]//Superalloys 2008. TMS. 2008: 221-228.

[16] 中国金属学会. 高温合金手册[M]. 北京: 中国标准出版社, 2011.

The Chinese Society for Metals. China superalloys handbook[M]. Beijing: StandardsPressofChina,2011.

[17] 张 剑, 赵云松, 贾玉亮, 杨 帅, 骆宇时, 唐定中. 一种镍基单晶高温合金的热机械疲劳行为[J]. 机械工程材料, 2013, 37(8): 41-44.

ZHANG Jian, ZHAO Yun-song, JIA Yu-liang, YANG Shuai, LUO Yu-shi, TANG Ding-zhong. Thermo-mechanical fatigue behaviors of a nickel-base single crystal superalloy[J]. Materials for Mechanical Engineering, 2013, 37(8): 41-44.

[18] 袁 熙, 李舜酩. 疲劳寿命预测方法的研究现状与发展[J]. 航空制造技术, 2005, (12): 80-84.

YUAN Xi, LI Shun-ming. Research status and development of forecast method of fatigue life[J]. Aeronautical Manufacturing Technology, 2005, (12): 80-84.

[19] VOSE F, BECKER M, FISCHERSWORRING A, HACKENBERG H P. An approach to life prediction for a nickel-base superalloy under isothermal and thermo-mechanical loading conditions[J]. International Journal of Fatigue, 2013, 53(53): 49-57.

[20] 章晓玲, 刘 峰, 李俊俊. 镍基高温合金热机械疲劳寿命预测方法研究[J]. 辽宁石油化工大学学报, 2013, 33(4): 65-69.

ZHANG Xiao-ling, LIU Feng, LI Jun-jun. Method of the lifetime prediction for thermo-mechanical fatigue in nickel-base superalloy[J]. Journal of Liaoning Shihua University, 2013, 33(4): 65-69.

[21] 赵明汉, 张 继, 冯 滌. 高温合金断口分析图谱[M]. 北京: 冶金工业出版社, 2006.

ZHAO Ming-han, ZHANG Ji, FENG Di. Superalloy fracture analysis[M]. Beijing: MetallurgicalIndustryPress, 2006.

Thermo-mechanical fatigue behavior of Inconel 718 superalloy

DENG Wen-kai1, 2, XU Jing-hao1, 2, JIANG Liang1, 2

(1. State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China;

2. Powder Metallurgy Research Institute, Central South University, Changsha 410083, China)

Abstract: This research focuses on the thermomechanical fatigue (TMF) performance of IN718 superalloy upon in-phase (IP) and out-of-phase (OP) loading modes, respectively. The differences of strain response, hysteresis loop and fatigue life between IP and OP were compared. The hysteresis loop curves show that the stresses are not symmetric during tension and compression loading, and exhibiting relatively low deformation resistance at high temperature. In most cases, the stress exhibits cyclic softening behavior, only while at the IP TMF fatigue and upon low strain amplitude, the stress displays cyclic hardening behavior in the high temperature half cycles. The S-N curves show that the fatigue life upon out-of-phase mode exceeds that of in-phase process. The S-N plots are in accordance with the Coffin-Manson formula for the strain range over 0.6%, while it is not true below strain range of 0.4%. The microscopic examination shows that intergranular fracture dominates the deformation process for the in-phase TMF, which is contrast with the intragranular fracture for the out-of-phase counterparts. The dimples can be ubiquitously observed for these two fatigue modes.

Key words: IN718 superalloy; thermomechanical fatigue; in-phase; out-of-phase; fatigue life; fracture

Foundation item: Project(2012AA03A514) supported by the National High-Technology Program of China; Projects(51401242, 612713546, 5120531) supported by the National Natural Science Foundation of China

Received date: 2018-02-20; Accepted date: 2018-12-25

Corresponding author: JIANG Liang; Tel: +86-18673171253; E-mail: liang.jiang@csu.edu.cn

(编辑 龙怀中)

基金项目:国家高技术研究发展计划资助项目(2012AA03A514);国家自然科学基金资助项目(51401242,612713546,5120531)

收稿日期:2018-02-20;修订日期:2018-12-25

通信作者:江 亮,教授,博士;电话:18673171253;E-mail:liang.jiang@csu.edu.cn