文章编号:1004-0609(2015)-05-1308-06

Cu单元素基合金表面FeCoCrAlCu激光高熵合金化涂层的制备

张春华1,单丽娜1,吴臣亮1,张 松1,关 锰2,谭俊哲2

(1. 沈阳工业大学 材料科学与工程学院,沈阳 110870;

2. 沈阳鼓风机集团 核电泵业有限公司,沈阳 110869)

摘 要:采用Nd:YAG激光辐照法在Cu单元素基合金表面制备FeCoCrAlCu高熵合金化涂层。利用扫描电镜、能谱仪、X射线衍射仪、显微硬度计及纳米压痕仪等研究FeCoCrAlCu激光高熵合金化层形成机制及性能。结果表明:采用优化的激光辐照工艺参数对等摩尔比的Fe、Co、Cr、Al四元合金粉末进行激光辐照合金化,可制备出含有基体主元Cu的FeCoCrAlCu高熵合金化涂层。合金化涂层由FCC+BCC简单结构固溶体组成,其显微组织主要以颗粒状组织为主,且与基体呈良好的冶金结合。FeCoCrAlCu激光高熵合金化层的硬度是基体材料的7倍以上,其弹性模量、弹性比和同样深度承受的最大载荷远高于基体材料的,具有良好的强度和韧性。

关键词:FeCoCrAlCu;Cu单元素基合金;激光高熵合金化;固溶体;纳米硬度

中图分类号:TG146.4 文献标志码:A

Synthesis of FeCoCrAlCu laser high entropy alloying coating on surface of single-element Cu base alloy

ZHANG Chun-hua1, SHAN Li-na1, WU Chen-liang1, ZHANG Song1, GUAN Meng2, Tan Jun-zhe2

(1.School of Materials Science and Engineering, Shenyang University of Technology, Shenyang 110870, China;

2. Nuclear Power Pump Industry Co., Ltd., Shenyang Blower Works Group Corporation, Shenyang 110869, China)

Abstract: FeCoCrAlCu high entropy alloying coating was synthesized by Nd:YAG laser irradiation method on Cu single-element base alloy. Formation mechanism and properties of FeCoCrAlCu laser high entropy alloying layer were investigated using SEM, EDS, XRD, microhardness tester and nanoindentation tester. The results show that FeCoCrAlCu high entropy alloying coating can be synthesized on the surface of Cu single-element base alloy using equal molar ratio of Fe, Co, Cr, Al quaternary alloy powders by laser irradiation alloying with optimized processing parameters. The alloying coating is composed of FCC+BCC simple structural solid solutions, and the microstructure is mainly granuliform. A good metallurgical bonding between the layer and the substrate can be achieved. The microhardness of FeCoCrAlCu layer is 7 times higher than that of the substrate, and the elastic modulus, elasticity ratio and the maximum load subjected at the same depth of the layer are higher than those of Cu substrate, indicating that the alloying coating has good strength and toughness.

Key words: FeCoCrAlCu; Cu single-element base alloy; laser high entropy alloying; solid solution; nanoindentation

与传统合金不同,高熵合金作为一种新型合金材料,含有5~13种元素,每种元素的摩尔分数在5%~35%之间。研究发现,高熵合金由于具有高的混合熵和原子扩散迟滞等特性,容易获得稳定性较高的FCC、BCC或FCC+BCC简单结构固溶体[1]。高熵合金通常拥有优异的强度、韧性、高硬度、耐高温软化,抗氧化及耐腐蚀性能,这些性能在石油、化工、冶金、航天航空等工业领域具有广阔的应用前景。目前,用电弧熔铸等方法已制备出多种高熵合金[2-3],在材料表面制备高熵合金涂层的研究亦有报道[4-6],而有关利用单元素基合金(SEBA)基体主元参与表面合金化过程,通过激光辐照反应合成制备多主元高熵合金涂层的研究鲜有报道[7-9]。Cu由于具有良好的导电性、导热性,高的延展性和良好的加工性能,是一种重要的工程材料,然而铜的硬度低、耐磨性较差,限制了其应用范围。由于激光表面改性技术可有效改善材料表面性能[10-11],因此,本文作者通过激光辐照反应合金化技术,在Cu单元素基合金表面制备含有基体主元的FeCoCrAlCu高熵合金化涂层,并对其形成机制及力学性能进行系统研究。

1 实验

实验所用基体材料为纯Cu板材,样品尺寸为25 mm×100 mm×10 mm,基材表面经打磨、喷砂后,在丙酮溶液中超声波清洗干燥备用。涂层粉末为等摩尔比的Fe、Co、Cr、Al四元混合粉末,其中Fe、Co、Cr、Al纯金属粉末纯度高于99.9%,混合粉末采用Ar保护球磨2 h。将混合粉末在真空干燥箱中80 ℃烘干2 h,干燥后的四元合金粉末预置于Cu基材表面,预置合金粉末厚度为0.4~0.5 mm。

采用ZQM-SD型500W Nd:YAG固体脉冲激光器进行表面合金化处理,优化工艺参数如下:电压为380 V、电流为170 A、光斑直径为1.2 mm、扫描速度为4 mm/min、脉宽为12 ms、频率为4 Hz、保护气Ar流量为15 L/min。

激光合金化样品沿截面进行线切割、镶嵌、研磨、抛光后,采用10%草酸溶液电解腐蚀样品。采用S-3400N型扫描电镜(SEM)及能谱仪(EDS)对样品截面组织及微区成分进行分析。采用D/max2500Pc型X射线衍射仪(XRD)对FeCoCrAlCu激光合金化涂层进行相结构分析。

利用HVS-1000显微硬度计测量高熵合金化层截面硬度分布,法向载荷为2 N,加载时间为10 s。采用Nano Indenter G200型纳米压痕仪进行纳米硬度测试,实验条件如下:恒定应变速率为0.05 s-1,最大下限深度为320 nm。采用恒定压痕法计算样品表面的纳米硬度、弹性模量等性能参数。

2 结果与讨论

2.1 FeCoCrAlCu激光高熵合金化涂层显微组织

图1所示为FeCoCrAlCu激光合金化涂层截面显微组织。合金化层内无孔洞和裂纹等缺陷(见图1(a)),其显微组织由致密的平面晶状组织和灰色基体组成。在合金化层与基体间存在一条明显的熔合线(见图1(b)),说明合金化层与基材形成了良好的冶金结合。当激光合金化涂层凝固时,固液界面处液相内的温度梯度GL很大,因此温度梯度GL和凝固速度v的比值GL/v极大,此时固液界面为平面状,该界面向前推进而形成一层平面晶组织。在激光合金化涂层的近表层,出现了略粗大的类胞状晶显微组织(见图1(c)),不同取向的晶粒界面出现白色条状物(见图1(d))。EDS分析表明,胞状晶内及晶界合金元素成分分布未有明显变化。

图1 FeCoCrAlCu激光高熵合金化层截面不同区域的显微组织

Fig. 1 Sectional microstructures of FeCoCrAlCu high entropy alloying coating in different areas

2.2 FeCoCrAlCu激光高熵合金化涂层形成机制

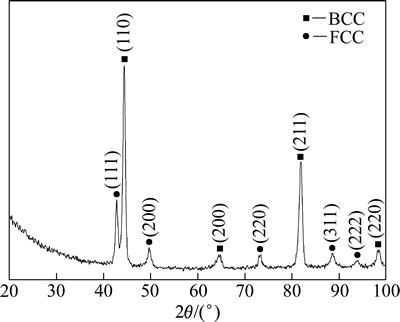

图2所示为FeCoCrAlCu激光高熵合金化涂层的XRD谱。由图2可知,合金化涂层由FCC和BCC两种简单结构固溶体组成,XRD衍射峰位置分别对应Cu(PDF 06-0696)和Fe(PDF 04-0836),对应晶格常数分别为0.365和0.288 nm。由于多主元FeCoCrAlCu高熵合金化涂层在热力学上处于亚稳状态,其XRD峰值强度相对较弱。结果表明:激光快速熔凝过程中,合金化涂层相形成涉及多主元的重新分配及置换型扩散,这将造成原子扩散迟滞,使得合金化涂层内各元素原子的有效扩散受到阻碍,从而导致合金化涂层内熔体形核及长大过程受到抑制。在本实验条件下,不同元素原子半径的差异会造成晶格畸变,多主元合金化涂层较大的晶格畸变造成了晶格结构原子面凸凹不平,使其XRD衍射峰强度比传统合金的略低。

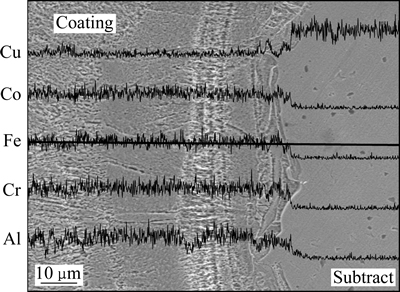

图3所示为FeCoCrAlCu激光高熵合金化涂层与基体界面附近元素线分布曲线。由图3可以看出,激光高熵合金化涂层内元素分布比较均匀,合金化涂层与基体界面附近存在元素的交互扩散现象,说明二者之间形成了良好的冶金结合。

图2 FeCoCrAlCu合金化涂层的XRD谱

Fig. 2 XRD spectrum of FeCoCrAlCu laser alloying coating

图3 FeCoCrAlCu激光合金化涂层界面附近的元素分布

Fig. 3 Element distribution of FeCoCrAlCu laser alloying coating near interface

ZHANG等[12]提出高熵合金相变主要通过3个参数来判定,分别为综合原子尺寸差δ、混合焓△Hmix及混合熵△Smix,其中δ表达式如式(1)所示:

(1)

(1)

式中: 为多主元合金组元的原子平均半径,

为多主元合金组元的原子平均半径, ;ci、ri分别为i种元素摩尔分数及原子半径。

;ci、ri分别为i种元素摩尔分数及原子半径。

混合焓可表示为

(2)

(2)

式中: 为第i和j两组元之间二元混合焓。

为第i和j两组元之间二元混合焓。

合金化体系吉布斯混合自由能△Gmix可表示为

△Gmix=△Hmix-T△Smix(3)

(4)

(4)

式中:T为温度;R为摩尔气体常数。

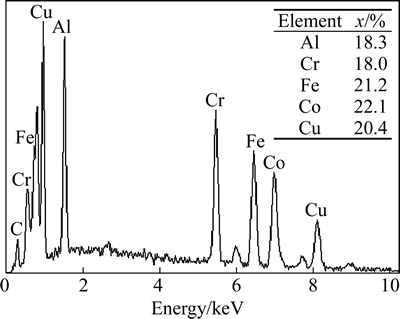

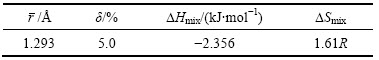

图4所示为FeCoCrAlCu激光合金化涂层近表面EDS谱,利用式(1)、(2)和(4)可计算出相应的综合原子尺寸差δ及热力学参数△Hmix和△Smix(见表1)。根据式(4)计算可得,合金化层近表面熵值达到1.61R,符合高熵合金的熵值范围。由多组元合金δ与△Hmix之间关系图[13]可知,当合金的δ与△Hmix满足:5 kJ/mol<△Hmix<15 kJ/mol,且δ<5%时,合金以固溶体组织为主。经计算,FeCoCrAlCu激光合金化涂层表面区域的δ与△Hmix在上述区间限定范围内。结合XRD分析结果可知,Cu单元素基合金表面的等摩尔比Fe、Co、Cr、Al四元合金粉末在激光辐照条件下可形成FeCoCrAlCu高熵合金化涂层。合金化涂层内除Al元素以外,各主元原子半径差较小,可随机相互置换占据晶格结点位置,从而形成无序固溶体。

图4 FeCoCrAlCu激光合金化涂层近表层EDS谱

Fig. 4 EDS spectrum of FeCoCrAlCu laser alloying coating near surface

表1 FeCoCrAlCu激光合金化涂层的物理参数

Table 1 Physical parameters of FeCoCrAlCu laser alloying coating

同时,合金化体系的混合熵越高,其自由能越低,涂层的偏析程度越小,从而越有利于形成固溶体,结构越趋于稳定。在FeCoCrAlCu合金化层中,除Cu主元外,其余四主元之间的混合焓均为负值,其中Al和Co混合焓为-19 kJ/mol,易于形成化合物。而Cu-Cr、Cu-Fe混合焓分别为+12 kJ/mol和+13 kJ/mol,使合金系统的混合焓接近0,且Cu-Cr和Cu-Fe之间混合熵不足以平衡它们之间较大的混合焓,因此,Cr和Fe将阻碍Cu的析出。此外,Cu具有面心立方结构,与其他四主元结构不同,难以与其他主元形成金属间化合物。吉布斯自由能较小时可以抑制金属间化合物的形成,根据式(3)可以看出,当混合焓较小,混合熵较大时,系统的△Gmix将减少。依据YANG等[14]提出参数Ω,表达式如式(5)所示:

(5)

(5)

若Ω为正值,且Ω>1,即T△Smix大于△Hmix,将促进固溶体形成;如果Ω≤1,在高熵合金中将优先形成金属间化合物,并出现偏析现象。因此,参数Ω值可以预测固溶体的形成能力,Ω值越大,合金化涂层形成固溶体的能力越强。在本实验条件下,FeCoCrAlCu激光高熵合金化涂层的Ω为9.1,因此,合金化涂层形成固溶体的能力较强。

2.3 FeCoCrAlCu激光高熵合金化涂层力学性能

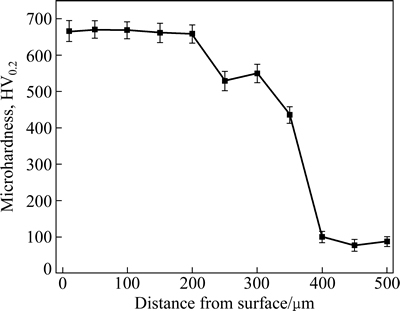

图5所示为FeCoCrAlCu激光合金化涂层截面显微硬度分布曲线。由图5可以看出,硬度的分布反映出合金化涂层显微组织的变化。FeCoCrAlCu激光合金化层的显微硬度均在400 HV以上,近表面硬度达到670 HV,约为基体硬度的7倍。这主要是由高熵合金固溶强化及激光快速熔凝晶粒细化作用所致,而合金化各主元原子半径差异引起的晶格畸变也是导致激光高熵合金化层硬度提高的重要因素。

图5 FeCoCrAlCu激光合金化涂层截面硬度分布曲线

Fig. 5 Sectional microhardness distribution curve of FeCoCrAlCu laser alloying coating

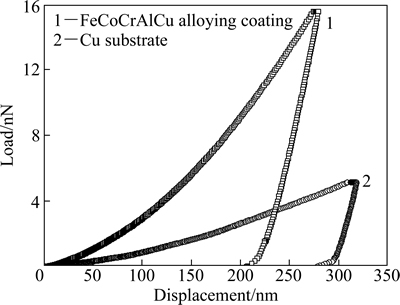

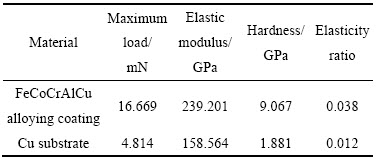

图6所示为FeCoCrAlCu激光合金化涂层与Cu基材纳米硬度的载荷-位移关系曲线。由图6可以看出,当达到限定最大深度时,合金化涂层的最大载荷远高于基材的,在加载过程中,合金化涂层的塑性变形量较小,载荷-位移曲线未出现平台,说明激光合金化使材料表面显著硬化,且合金化涂层内未产生裂纹[15]。表2所列为达到最大深度时FeCoCrAlCu合金化涂层及基材的力学性能参数。由表2可以看出,合金化涂层的弹性模量比远高于基材的,较高的弹性模量比可以减少磨损表面粗糙微凸体的数量,当法向载荷超过其弹性极限时,在滑动摩擦磨损过程中会减小摩擦因数[16]。因此,合金化涂层具有更高的弹性模量比有利于材料耐磨性的提高,同时合金化涂层弹性模量的增加也可提高材料的抗冲击性能[17]。结果表明,FeCoCrAlCu激光合金化层存在的两种不同结构固溶体对涂层力学性能将产生不同的影响:体心立方结构为硬脆相,具有较高的硬度,韧性较差,其自身的脆性对合金化涂层产生割裂作用;面心立方结构具有良好的塑性变形能力,在激光辐照快速熔凝过程中可有效地吸收合金化涂层的变形功,减小裂纹扩展倾向。由于合金化涂层内各主元原子半径不同,导致FeCoCrAlCu高熵合金化涂层具有较大的晶格畸变,应变能增加,阻碍位错的滑移,增加了固溶强化作用。因此,激光高熵合金化涂层既具有较高的强度又具有良好的韧性。

图6 FeCoCrAlCu激光高熵合金化涂层及Cu基材的载荷-位移曲线

Fig. 6 Load-displacement curves of FeCoCrAlCu alloying coating and Cu substrate

表2 FeCoCrAlCu激光合金化涂层与Cu基材的力学性能参数

Table 2 Mechanical property parameters of FeCoCrAlCu alloying coating and Cu substrate

3 结论

1) 采用Nd:YAG激光辐照法,可使等摩尔比Fe、Co、Cr、Al四元合金粉末在Cu基材表面形成FeCoCrAlCu高熵合金化涂层,合金化涂层与基材呈良好的冶金结合,其显微组织以粒状晶和灰色基体组织为主。

2) 在Cu单元素基合金表面合成的FeCoCrAlCu高熵合金化层的相结构为FCC+BCC简单结构固溶体。

3) FeCoCrAlCu高熵合金化层最高显微硬度达到670 HV,约为Cu基材的7倍,合金化层的弹性模量、弹性比和达到最大深度的法向载荷显著提高,表明FeCoCrAlCu高熵合金化层具有良好的力学性能。

REFERENCES

[1] LI Bao-yu, PENG Kun, HU Ai-ping, ZHOU Ling-ping, ZHU Jia-un, LI De-yi. Structure and properties of FeCoNiCrCu0.5Alx high-entropy alloy[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(3): 735-741.

[2] Qiu Xing-wu, Zhang Yun-peng, He Li, Liu Chun-ge. Microstructure and corrosion resistance of AlCrFeCuCo high entropy alloy[J]. Journal of Alloys and Compounds, 2013, 549: 195-199.

[3] SHENG H F, GONG M, PENG L M. Micro-structural characterization and mechanical properties of an Al0.5CoCrFeCuNi high-entropy alloying as-cast and heat-treated/quenched conditions[J]. Materials Science and Engineering A, 2013, 567: 14-20.

[4] 翁子清, 董 刚, 张群莉, 郭士锐,姚建华. 退火对激光熔覆FeCrNiCoMn高熵合金涂层组织与性能的影响[J]. 中国激光, 2014, 41(3): 59-64.

WEN Zi-qing, DONG Gang, ZHANG Qun-li, Guo Shi-rui, Yao Jian-hua. Effects of annealing on microstructure and properties of FeCrNiCoMn high-entropy alloy coating prepared by laser cladding[J]. Chinese Journal of Lasers, 2014, 41(3): 59-64.

[5] ZHANG H, PAN Y, HE Y Z. Synthesis and characterization of FeCoNiCrCu high-entropy alloy coating by laser cladding[J]. Materials and Design, 2011, 32: 1910-1915.

[6] 黄 标, 张 冲, 程 虎, 唐群华,饶湖常,戴品强. 激光熔覆 FeCoCrxNiB 高熵合金涂层的组织结构与耐磨性[J]. 中国表面工程, 2010, 23(4): 77-79.

HUANG Biao, ZHANG Chong, CHENG Hu, TANU Qun-hua, RAO Hu-chang, DAI Pin-qiang. Microstructure and wear resistance of FeCoCrxNiB high-entropy alloy coatings prepared by laser cladding[J]. China Surface Engineering, 2010, 23(4): 77-79.

[7] Zhang S, Wu C L, Zhang C H. Phase evolution characteristics of FeCoCrAlCuVxNi high entropy alloy coatings by laser high-entropy alloying[J]. Materials Letters, 2015, 141: 7-9.

[8] 张 松, 吴臣亮, 王 超, 伊俊振, 张春华. 铁单元素基合金表面激光高熵合金化涂层的制备[J]. 金属学报, 2014, 50(5): 555-560.

ZHANG Song, WU Chen-liang, WANG Chao, YI Jun-zhen, ZHANG Chun-hua. Synthesis of laser high entropy alloying coating on the surface of single-element Fe base alloy[J]. Act Metallurgical Sinica, 2014, 50(5): 555-560.

[9] 张 松, 吴臣亮, 伊俊振, 王 超, 张春华, 关 锰, 谭俊哲. FexCoCrAlCu/Q235激光合金化层组织及性能研究[J]. 中国激光, 2014, 41(8): 97-101.

ZHANG Song, WU Chen-liang, YI Jun-zhen, WANG Chao, ZHANG Chun-hua, GUAN Meng, TAN Jun-zhe. Microstructure and performance of a laser alloying coating of FexCoCrAlCu/Q235[J]. Chinese Journal of Lasers, 2014, 41(8): 97-101.

[10] 张培磊, 闫 华, 徐培全, 于治水, 李铸国, 姚成武. 激光熔覆和重熔制备Fe-Ni-B-Si-Nb系非晶纳米晶复合涂层[J]. 中国有色金属学报, 2011, 21(11): 2846-2851.

ZHANG Pei-lei, YAN Hua, XU Pei-quan, YU Zhi-shui, LI Zhu-guo, YAO Cheng-wu. Fe-Ni-B-Si-Nb amorphous and nanocrystalline composite coating prepared by laser cladding and remelting[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(11): 2846-2851.

[11] ZHANG S, WU C L, YI J Z, ZHANG C H. Synthesis and characterization of FeCoCrAlCu high-entropy alloy coating by laser surface alloying[J]. Surface Coatings and Technology, 2015, 262: 64-69.

[12] Zhang Y, Zuo T T, Tang Z, Gao M C, Dahmen K A, Liaw P K, Lu Z P. Microstructures and properties of high-entropy alloy[J]. Progress in Materials Science, 2014, 61: 1-93.

[13] Zhang Y, Zhou Y J, Lin J P, Chen G L, Liaw P K. Solid-Solution phase formation rules for multi-component alloys[J]. Advanced Engineering Materials, 2008, 10(6): 534-538.

[14] YANG X, ZHANG Y. Prediction of high-entropy stabilized solid-solution in multi-component alloys[J]. Materials Chemistry and Physics, 2012, 132: 233-238.

[15] TUCK J R, KORSUNSKY A M, BHAT D G, Bulla S J. Indentation hardness evaluation of cathodic arc deposited thin hard coatings[J]. Surface and Coatings Technology, 2001, 139: 63-74.

[16] CHENG J B, LIANG X B, XU B S. Effect of Nb addition on the structure and mechanical behaviors of CoCrCuFeNi high-entropy alloy coatings[J]. Surface and Coatings Technology, 2014, 240: 184-190.

[17] 樊玉杰, 周建忠, 黄 舒, 范金荣, 王呈栋, 王 维, 卫登辉, 朱 伟, 高 彬. 激光微喷丸强化纯铜表面的纳米压痕分析[J]. 中国激光, 2011, 38(6): 230-234.

FAN Yu-jie, ZHOU Jian-zhong, HUANG Shu, Fan Jin-rong, Wang Cheng-dong, Wang Wei, Wei Deng-hui, Zhu Wei, Gao Bin. Research on mechanical response of copper treated by micro laser shock peening using nanoindentation technique[J]. Chinese Journal of Lasers, 2011, 38(6): 230-234.

(编辑 王 超)

基金项目:国家自然科学基金资助项目(51271126);辽宁省自然科学基金资助项目(2013020101);沈阳市科技局计划项目(F13-318-1-52,F13-070-2-00)

收稿日期:2014-08-05;修订日期:2015-01-09

通信作者:张 松,教授,博士;电话:024-25494578;E-mail:songzhang_sy@163.com