DOI:10.19476/j.ysxb.1004.0609.2019.07.13

加压烧结树脂碳包覆石墨/铜复合材料的显微组织和性能

刘 滩,方华婵,李金伟,朱佳敏,肖 鹏

(中南大学 轻质高强结构材料国防科技重点实验室,长沙 410083)

摘 要:以电解铜粉、树脂包覆石墨粉和二氧化硅粉为原料,经粉末冶金和冷压成坯块后,分别采用常压烧结和加压烧结工艺制备树脂碳包覆石墨/铜复合材料,对比两种烧结工艺制备的树脂碳包覆石墨/铜复合材料与现有法国罗兰MCXXP牌号电刷高速列车用接地电刷的显微组织和导电、力学、摩擦磨损性能。结果表明:与常压烧结材料相比,采用加压烧结制备的树脂碳包覆石墨/铜复合材料中,铜相的连通性更好,石墨分布更离散均匀,二氧化硅更好、更多地被嵌入铜基体,复合材料的密度、抗弯强度、硬度、导电和摩擦磨损性能显著提高,且与法国罗兰MCXXP牌号电刷的性能相当。

关键词:加压烧结;树脂碳包覆石墨/铜复合材料;导电性;力学性能;摩擦性能

文章编号:1004-0609(2019)-07-1446-11 中图分类号:TG146.1 文献标志码:A

近几年,我国髙速铁路迅速发展,取得了举世瞩目的成就。按照《中长期铁路网调整规划方案》,2020年,我国将机车最高时速由200 km提高至350 km[1]。在高速的运行条件下,保持稳定的受流和导流质量成为了高速列车安全运行的关键因素之一,作为重要导流部件,接地电刷的性能对列车所有设备的接地安全可靠具有重要影响[2]。目前,国内外广泛使用的接地电刷材质为石墨/铜复合材料,该材料具有良好的导电、耐磨和力学性能,制备工艺以粉末冶金为主[3-4]。目前,国内高速列车使用的接地电刷以进口为主,如法国罗兰电刷、英国摩根电刷等。由于石墨与铜的界面不润湿[5-6],导致界面结合性能差,降低了复合材料的导电、力学和摩擦磨损性能,限制了复合材料的应用。提高或改善石墨与铜界面结合性能的主要方法有石墨表面处理(如电化学法表镀铜[7]、镀镍[8]等)、基体合金化(添加Ti[9]等)和发展新型制备工艺(如热压烧 结[10]、放电等离子烧结[8]等)。其中,石墨表面镀覆金属工艺复杂,不可控因素较多,成本过高。基体合金化则是通过掺入微量元素与基体形成合金或与石墨反应生成化合物改善石墨/铜的润湿性,但工序复杂。热压烧结和放电等离子烧结等设备价格昂贵、工艺操作繁琐。因此,急需发展兼具高性能和低成本的石墨/铜复合材料制备工艺。

酚醛树脂具有大量还原性官能团(羟基和醛基),作为石墨的表面改性剂广泛应用于锂离子电池的电极材料中,研究表明石墨在树脂的酒精溶液中浸渍后,再经高温热解处理,可在其表面包覆无定形碳层,通过无定形碳与石墨碳间的C—C结合的方式增强石墨表面结构,防止石墨剥离。而热解生成的无定形碳为多孔结构,有利于锂离子的扩散,丰富的表面积则利于锂离子的存储,提高石墨电极的电化学效率,从而提高锂离子电池的电化学性能[11-12]。

肖鹏等[13]以酚醛树脂包覆石墨粉为原料,在国内首次制备了树脂碳包覆石墨/铜复合材料,相比于天然鳞片石墨粉,其导电性与摩擦磨损性能显著提高,但仍存在致密性较低和孔隙较多等问题。为进一步提高复合材料的致密度,本文通过加压烧结制备了树脂碳包覆石墨/铜复合材料,并与现有高速列车用接地电 刷—法国罗兰MCXXP牌号电刷的显微组织和导电、力学、摩擦磨损性能进行对比,为低成本制备高性能接地电刷提高基础。

1 实验

1.1 材料制备

通过对法国罗兰电刷(Roland sample)的成分进行化学分析和扫描电镜分析,发现其中有约83%(质量分数,下同)的铜和17%左右的碳元素,以及少于1%的二氧化硅。以此为依据,选择电解铜粉(北京兴荣源科技有限公司提供,纯度大于99.9%,平均粒径40 μm)、二氧化硅粉(深圳市海扬粉体科技有限公司提供,纯度大于99%,平均粒径20 μm)、天然鳞片石墨(青岛富润达石墨有限公司提供,碳含量大于99%,平均粒径35 μm)和酚醛树脂为原料。

酚醛树脂包覆石墨粉的制备工艺:以质量比为4:1称取天然鳞片石墨与酚醛树脂粉末,将树脂溶于酒精溶液,得到饱和的酚醛树脂酒精溶液,再加入天然鳞片石墨粉,搅拌混合并浸渍3.5 h后放入85 ℃烘箱干燥,将干燥的石墨与树脂的混合块体进行破碎过筛,制得树脂包覆石墨粉(平均粒径40 μm)。

采用VH-14 V型混合机对质量分数分别为16%、83%、1%的电解铜粉、树脂包覆石墨粉和二氧化硅结进行混合,时间为8 h。将混合粉在YH41-25C型单柱校正压装液压机上冷压成形,压力为400 MPa,保压30 s。将压坯置于氢气气氛下分别进行常压烧结和加压烧结。常压烧结在SK2-6-10型管式气氛炉中进行,烧结工艺:按10 ℃/min的速率由室温升到180 ℃,保温30 min;再升温至950 ℃,保温2 h,最后以25 ℃/min的速率降至室温,制得常压烧结树脂碳包覆石墨/铜复合材料(Normal sintered carbon-coated C/Cu composites, NCG/Cu composites)。加压烧结在Z1250型钟罩式加压烧结炉中进行,烧结工艺按10 ℃/min的速率由室温升到950℃,升温压力为0.12 MPa;再950 ℃保温2 h,保温阶段压力为0.82 MPa;最后以25 ℃/min冷却至室降温,冷却压力为0.22 MPa,制得加压烧结树脂碳包覆石墨/铜复合材料(Pressure sintered carbon-coated C/Cu composites, PCG/Cu composites)。

1.2 组织表征与性能测试

采用Quanta FEG250型扫描电镜(Scanning electron microscopy,SEM)观察树脂包覆前后石墨的表面形貌与包覆后树脂层厚度,表征复合材料的显微组织,结合能谱分析和D/max2550型X射线衍射分析石墨/铜复合材料的成分和物相组成。

分别采用HVS-5数显小负荷维氏硬度计(载荷 9.8 N)和D60K数字金属电导率测量仪测量石墨/铜复合材料的硬度和电导率;阿基米德排水法测试石墨/铜复合材料的密度;在Instron3369型材料试验机上采用三点弯曲法测量石墨/铜复合材料的抗弯强度,试样尺寸20 mm×12 mm×6 mm,跨距为15 mm,加载速度2 mm/min,结合SEM对抗弯断口形貌进行观察。

接地电刷的摩擦方式与MMD-1多功能销盘式摩擦实验机的工作原理一致,故采用MMD-1多功能销盘式摩擦实验机测试试样的摩擦磨损性能。试样尺寸为d 4.8 mm×12 mm,载荷为20 N,转速为500 r/min,时间为3 h,对偶材料为铜锌合金。根据式(1)、(2)、(3)计算材料的摩擦因数和体积磨损率:

(1)

(1)

(2)

(2)

(3)

(3)

式中:T为摩擦力矩,N;p为试样所承受的垂直载荷,N;R为试样摩擦半径 mm:μ为摩擦因数;W为体积磨损量,mm3;D为试样直径,mm; 为摩擦前后试样高度变化,mm;k为体积磨损率,mm3/(m·N);L为滑动距离,mm。

为摩擦前后试样高度变化,mm;k为体积磨损率,mm3/(m·N);L为滑动距离,mm。

采用SEM观察摩擦磨损实验后试样表面的磨痕以及磨屑的形貌,结合HIROX KH-7700型数字显微镜观察试样表面的3D形貌,研究复合材料的摩擦磨损机理。

取树脂包覆石墨于900 ℃真空条件下保温2 h进行碳化,得树脂碳包覆石墨粉。采用JEM-2100F场发射透射电子显微镜(Transmission electron microscopy,TEM),观察树脂包覆石墨碳化后树脂碳层的厚度,以及与石墨的界面结合情况。采用D/max2550型X射线衍射仪和LabRAM HR800型拉曼光谱对天然鳞片石墨粉和树脂碳包覆石墨粉的结构进行表征。

采用座滴实验测定树脂包覆石墨与铜的润湿性。分别取天然鳞片石墨粉与树脂包覆石墨粉压制成饼状(作为基片);取原料铜粉压制成高约6 mm的坯体,置于950 ℃氢气气氛下烧结,切取纯铜座滴(尺寸为d 3 mm×5 mm),将基片与座滴置于1200 ℃真空条件下保温30 min,用光学显微镜测定每一座滴与基片接触面的直经(d)及同一座滴的高度(h),座滴质量(w)。由式(4)计算接触角,由式(5)式计算比接触面积(S):

(4)

(4)

式中:d为基片接触面的直经,mm:D为实验后座滴的赤道直径,mm。

(5)

(5)

式中:d为基片接触面的直经,mm:w为座滴的质量,g:S为比接触面积,mm2/g。

2 实验结果

2.1 树脂包覆石墨粉的表征

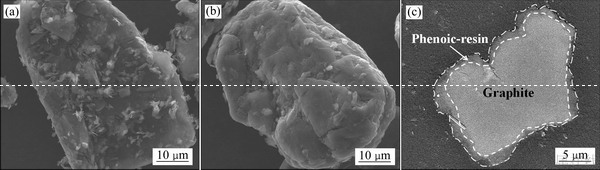

图1所示为天然鳞片石墨(Natural graphite, NG)表面的SEM形貌以及树脂包覆石墨(Resin coated graphite, RG)表面形貌和截面的SEM像。由图1可知,天然鳞片石墨表面粗糙,有大量缺陷(微裂纹、凹坑等)(见图1(a));树脂包覆后,石墨表面缺陷消除且更加光洁,包覆较完整(见图1(b));通过观察其截面发现,石墨表面酚醛树脂层厚约1~3 μm,且石墨与树脂层间结合较致密(见图1(c))。

2.2 复合材料的显微组织

图1 天然鳞片石墨表面、树脂包覆石墨表面和树脂包覆石墨截面的SEM像

Fig.1 SEM images of NG surface(a) and surface(b) and cross section(c) of RG

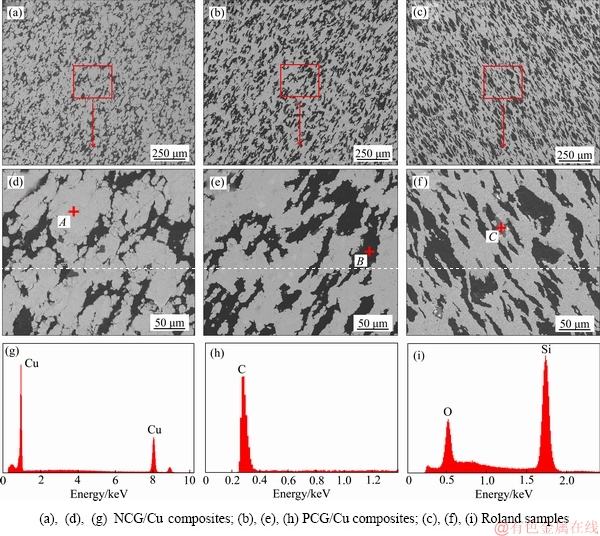

图2 石墨/铜复合材料的SEM像及能谱分析

Fig. 2 SEM images and EDXS (Energy dispersive X-ray spectroscopy) analysis of C/Cu composites

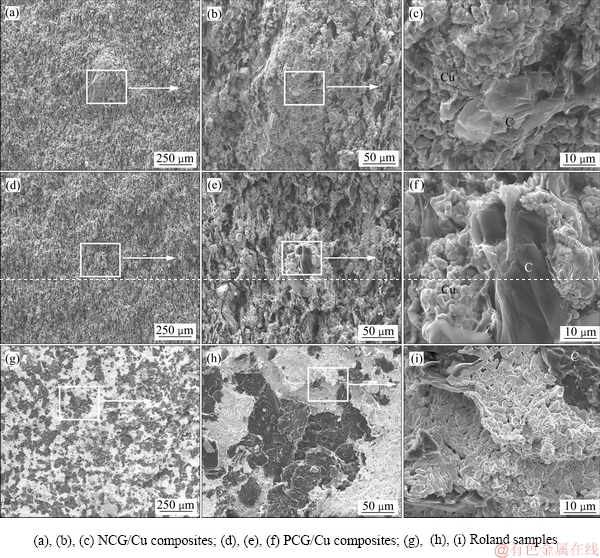

图2所示为常压、加压烧结制备树脂碳包覆石墨/铜复合材料与罗兰电刷的SEM像和能谱分析。通过能谱分析可知,图2(b)中A区对应的浅灰色区域为铜相,图2(e)中B区对应的黑色区域为石墨相,图2(f)中C区对应的深灰色颗粒相为SiO2。由图2(a)和(d)可知,常压烧结试样中仍存在未烧结致密的铜颗粒,石墨呈连续分布,残留的孔隙与未烧结致密的铜颗粒严重影响了铜基体的连通性。加压烧结试样中铜基体连通,石墨呈离散分布,SiO2较好的嵌入在铜相中(见图2(c)和(f)))。加压烧结试样与罗兰电刷的组织具有一定的相似性,石墨颗粒且呈离散、均匀分布,SiO2较好的嵌入在基体中(见图2(b)和(e))。

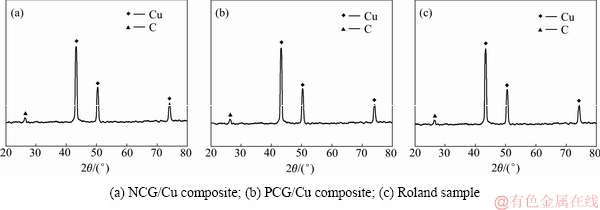

图3所示为常压、加压烧结制备树脂碳包覆石墨/铜复合材料与罗兰电刷的XRD谱。由图3可知,3种复合材料XRD图谱无明显区别,均主要由C相和Cu相组成(见图2(g),(h),(i)),且均未检测到二氧化硅的衍射峰。

2.3 复合材料的物理性能和力学性能

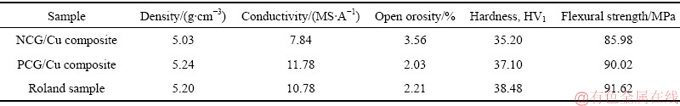

表1所列为石墨/铜复合材料的物理性能和力学性能。由表1可知,与常压烧结试样相比,加压烧结树脂碳包覆石墨/铜复合材料的致密度提高,其密度和电导率在三者中最高,分别为5.24 g/cm3、11.78 MS/A,开孔率最低为2.03%,硬度和抗弯强度提高,且力学性能与罗兰电刷的相当。说明加压烧能显著促进树脂碳包覆石墨/铜复合材料的致密化。

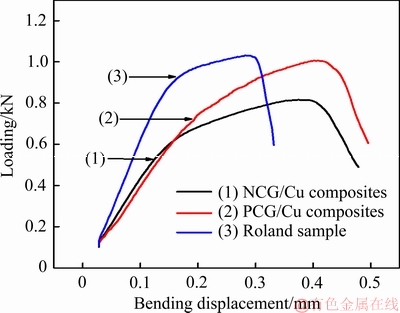

图4所示为石墨/铜复合材料的弯曲载荷随位移变化曲线图。由图4可知,常压和加压烧结的树脂碳包覆石墨/铜复合材料试样均表现出一定的延性断裂特征,而罗兰电刷试样呈明显的脆性。结合图5的弯曲试样断口SEM形貌分析可知,常压烧结试样断口表面极不平整(见图5(a)),石墨颗粒裸露,且保持一定的完整性,说明弯曲加载对石墨颗粒的破坏较小,且铜颗粒发生断裂(见图5(b)和(c)))。加压烧结试样断口表面更为平整,石墨颗粒的完整性较好(见图5(d)和(e))),且铜颗粒间的断裂较少(见图5(f))。罗兰电刷抗弯断口组织中,石墨颗粒内部断裂,铜颗粒对石墨没有明显的包裹,且铜颗粒的烧结致密较差(见图5(i)),可能与选用原料和制备工艺有关,具体有待进一步研究。

2.4 复合材料的摩擦性能

2.4.1 复合材料的摩擦因数及磨损量

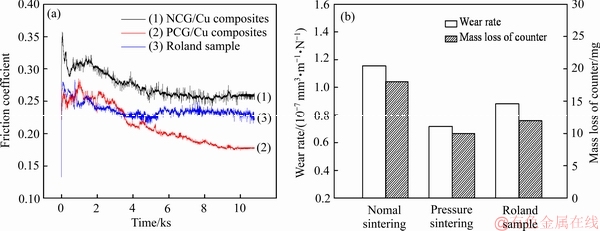

图6(a)所示为石墨/铜复合材料试样的摩擦因数随磨损时间变化曲线,摩擦时间为3 h。由图6(a)可知,3种材料的摩擦曲线按摩擦因数的变化均可分为摩擦因数的快速降低、快速升高、缓慢下降和平稳的4个阶段。摩擦0.14 h时,常压烧结试样的摩擦因数急剧下降,再快速升高,1.5 h左右,摩擦因数达到最低值(0.254),之后趋于平稳(0.260),整个实验过程中摩擦因数波动幅度较大;加压烧结试样在0.11 h时,摩擦因数急剧下降,再快速升高,2.5 h左右达到最低值(0.163),之后稳定在(0.172),摩擦因数整体波动幅度较小。罗兰电刷试样在1.4 h时,摩擦因数到最低值(为0.224),随实验时间的延长,摩擦因数仍继续波动,最后在0.232左右波动。

图3 石墨/铜复合材料的XRD谱

Fig. 3 XRD patterns of C/Cu composites

表1 石墨/铜复合材料物理性能和力学性能

Table 1 Physical and mechanical properties of C/Cu composites

图4 石墨/铜复合材料的弯曲载荷-位移变化曲线

Fig. 4 Bending load-bending displacement curves of C/Cu composites

图6(b)所示为试样磨损3 h后的体积磨损率和质量磨损量。由图6(b)可知,加压烧结试样的体积磨损率与质量磨损量最小,分别为0.717×10-7 mm3/(m·N)、10 mg,明显低于常压烧结试样的,且略低于罗兰电刷试样的(0.880×10-7 mm3/(m·N)、12 mg)。

2.4.2 复合材料的3D形貌和SEM像

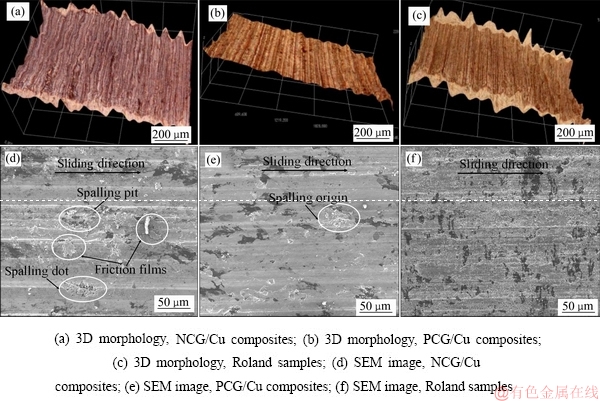

图7(a)~(c)所示为摩擦3 h后试样表面的3D形貌。由图可知,常压烧结试样的摩擦面粗糙,且起伏较大(见图7(a))。加压烧结试样和罗兰电刷试样的摩擦面较平整,起伏较小,且加压烧结试样摩擦后表面平整度更好(见图7(b)和(c))。

图7(d)~(f)所示为摩擦面的SEM像。由图可知,常压烧结试样的摩擦面粗糙不平,犁沟效应明显,划痕浅且细(见图7(d))。罗兰电刷试样摩擦膜相对平整,表面存在大量细小磨屑,部分被挤压形成较疏松摩擦膜(见图7(f))。加压烧结试样摩擦面平整,划痕较深,平整区域较多,由于部分脱落磨屑被压实,因此,形成的摩擦膜平整且连续(见图7(e))。摩擦膜是通过摩擦面与对偶之间在法向和切向的反复碾压作用下,基体少量脱落与新鲜表面在磨损表面铺展而形成的[14-17]。

图5 石墨/铜复合材料抗弯断口的SEM像

Fig. 5 SEM images of bending fracture of C/Cu composites

图6 石墨/铜复合材料摩擦3 h的摩擦因数变化曲线和以及摩擦后的磨损率

Fig. 6 Friction coefficient (a) and wear rate (b) after wearing for 3 h of C/Cu composites

图7 石墨/铜复合材料摩擦3 h后表面的3 D形貌和SEM像

Fig. 7 Frictional surface 3D morphologies and SEM images of C/Cu composites after wearing for 3 h

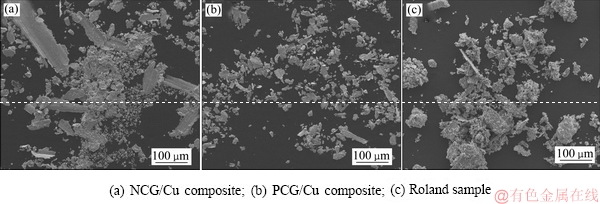

2.4.3 磨屑的SEM像

图8所示为试样摩擦3 h后磨屑的SEM像。由图8可知,常压烧结试样摩擦时产生了大量片状的磨屑,且尺寸较大,并伴有大量细碎的磨屑(见图8(a)),加压烧结试样的磨屑呈颗粒状(见图8(b)),罗兰电刷试样磨屑呈团聚状,且较疏松(见图8(c))。

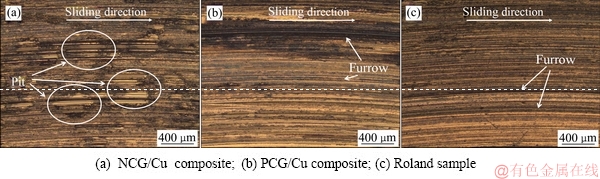

2.4.4 摩擦对偶的金相图

图9所示为摩擦3 h后摩擦对偶的金相图。由图9可知,3种材料的摩擦对偶均存在摩擦膜转移的现象,常压烧结样的对偶表面存在大量的转移摩擦膜,因此粗糙程度较高,这将加剧对偶与复合材料的磨损(见图9(a))。而加压烧结试样与罗兰电刷试样在摩擦后,对偶表面被压实成光滑且平整的石墨与铜为主的混合膜层(见图9(b)和(c))。

图8 石墨/铜复合材料摩擦3 h后磨屑的SEM像

Fig. 8 SEM images of wear swarf of C/Cu composites after wearing for 3 h

图9 摩擦3 h后摩擦对偶的金相图

Fig. 9 Friction matching plate optical microstructures of C/Cu composites after wearing for 3 h

3 分析与讨论

由上述结果可知,加压烧结制备的树脂碳包覆石墨/铜复合材料的物理、力学性能和摩擦磨损性能与法国罗兰电刷的材料相当,加压烧结后性能的提高主要来源于石墨的酚醛树脂包覆改性和加压烧结工艺的共同作用。

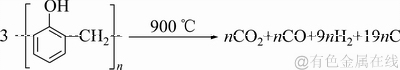

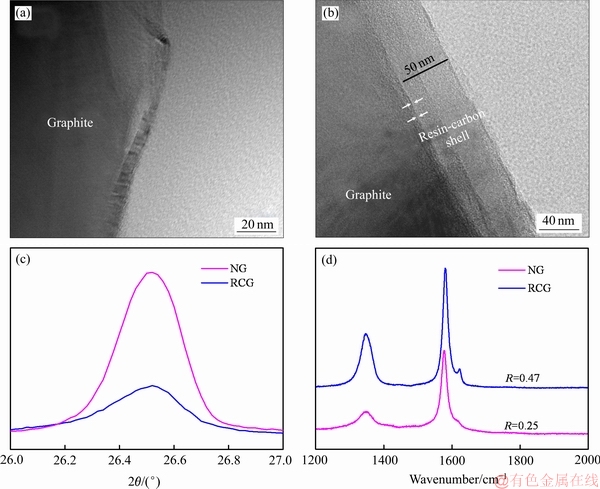

树脂包覆层的厚度损失是在(约900 ℃)时的热分解和裂解,从而导致水、挥发性物质(如苯酚衍生物和芳族化合物)和气体分子(如CO、CO2或H2)的逸出而引起的[17-18]。具体反应如方程式(5)~(7)所示。图10(a)为天然鳞片石墨的TEM像。由图10(a)可知,未进行树脂包覆的石墨颗粒边界明显。对比图3(c)可知,石墨表面树脂包覆层厚度约为1~3 mm,而碳化后得到的树脂碳包覆层厚度约50 nm(见图10(b)),且包覆层与石墨界面结合良好。

图10(c)为天然鳞片石墨和树脂碳化后的树脂碳包覆石墨的XRD谱。由图10(c)可知,图中2θ约为26.52°对应的石墨的峰的强度降低,即树脂碳包覆后石墨的(002)面的峰强减小,这是由于酚醛树脂经高温处理后,在天然鳞片石墨表面产生的无定形碳,导致石墨表面ABAB结构转变为引入树脂碳后的ABCABC结构,降低了石墨结晶度[19]。

图10(d)为天然鳞片石墨和树脂碳包覆石墨的拉曼图谱。由图10(d)可知,图谱上有2个散射强度主峰,分别位于拉曼位移约1350、1580 cm-1(即碳材料拉曼谱的G峰和D峰)处,但两者的两个峰的相对强度有差异,说明石墨表面包覆的树脂经碳化处理后,使石墨的表面结构发生了变化。石墨的无序化度是由D峰相对于G峰的强度R(ID/IG)表征的,即R值与网平面上无缺陷区域成反比关系[20]。据图计算得天然鳞片石墨的R值为0.25,而树脂碳包覆石墨的R值为0.47,而石墨无序化度的表现为R值的高低,即树脂碳化后产生的无定形热解碳提高了石墨整体的无序化度。

(6)

(6)

CO2+C→2CO (7)

2H2+C→CH4 (8)

图10 天然鳞片石墨和树脂碳包覆石墨的TEM像、XRD谱和Raman谱

Fig. 10 TEM images of NG (a) and RCG (Resin carbon-coated graphite) (b), XRD patterns (c) and Raman spectra (d) of NG and RCG

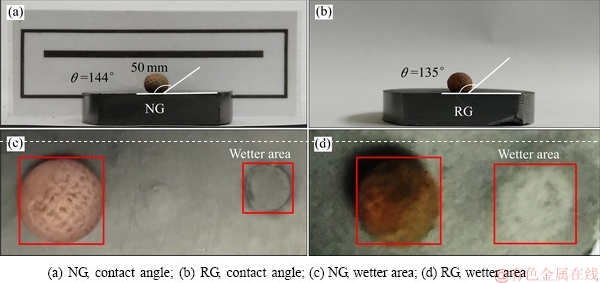

众所周知,石墨与铜不润湿,酚醛树脂作为一种高分子聚合物,不仅能够较好地修饰石墨表面缺陷,提高石墨颗粒的强度,而且其表面的活性基团还可以在一定程度上改善石墨和铜之间的润湿性。为研究树脂碳包覆的石墨与铜之间的润湿性,选取天然鳞片石墨粉与树脂包覆石墨粉作为基片,纯铜作为座滴,进行座滴实验以表征两者间的润湿性。

图11所示为天然鳞片石墨(NG)和树脂包覆石墨(RG)与铜的座滴实验结果。如图11所示,计算得树脂包覆石墨与铜之间的润湿角为135°(见图11(a)),略小于天然鳞片石墨与铜的(144°)(见图11(b)),树脂包覆石墨与铜座滴的接触直径d为3.21 mm,座滴赤道直径D为4.60 mm,其比接触面积为21.54 mm2/g,略大于天然鳞片石墨基片(15.08 mm2/g)。

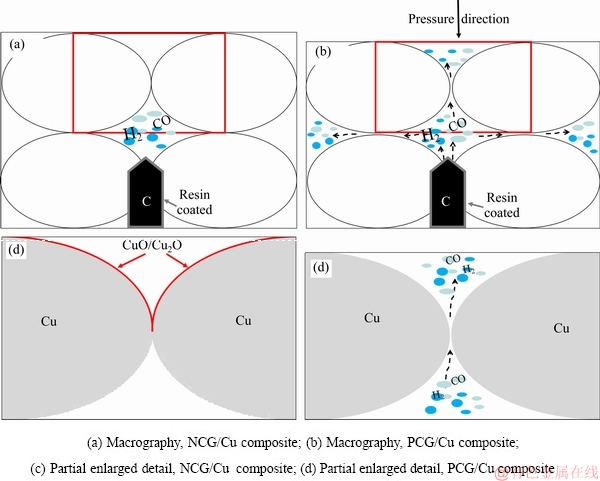

图12所示为树脂碳包覆石墨/铜复合材料在常压烧结与加压烧结时石墨表面树脂裂解产生气体的运动示意图。酚醛树脂裂解产生大量高还原性气体(如一氧

化碳、甲烷和氢气等)。常压烧结时,这些小分子气体扩散趋势较小,气体滞留在颗粒间而形成孔隙,仅能还原所接触的铜颗粒表面的氧化膜层,未接触石墨颗粒的部分铜颗粒的氧化膜无法被还原(见图12(a)和(c))。加压烧结时,施加外加压力作用使这些小分子气体被强制挤出,沿铜颗粒间和铜-石墨界面扩散开(见图12(b)),在气体流动过程中进一步对未接触石墨颗粒的铜表面的氧化膜进行还原(见图12(d)),从而促进烧结致密化的进行。

加压烧结制备的树脂碳包覆石墨/铜复合材料密度高,孔隙率低;连续网状铜基体的形成以及石墨在铜基体中的离散分布,提高了材料的导电性能。材料表面抵抗外力压入的能力变大,力学性能提高。而且其中石墨分布均匀,呈完整块状分布,在摩擦过程中易均匀的脱落形成摩擦膜,摩擦膜中稳定的石墨含量可降低材料的摩擦因数。

图11 石墨与铜座滴实验接触角与润湿面积

Fig. 11 Droplet experiment contact angle and wetter area of graphite and copper

图12 石墨/铜复合材料烧结时石墨表面酚醛树脂层高温裂解产生的气体运动示意图

Fig. 12 Schematic diagram of gas moving generated by pyrolysis of phenolic resin layer on graphite surface during sintering in C/Cu composites

4 结论

1) 以电解铜粉、树脂包覆石墨粉与二氧化硅为原料,采用粉末冶金加压烧结工艺制备了树脂碳包覆石墨/铜复合材料。与常压烧结相比,加压烧结促进了铜颗粒间的烧结致密性,铜的连通性和石墨的分散性均显著提高,二氧化硅被有效夹持与铜之间。

2) 与常压烧结相比,加压烧结制备的树脂碳包覆石墨/铜复合材料的抗弯强度和硬度均提高,分别为91.62 MPa和37.10 HV,且表现出一定的延性断裂特征,且密度、导电率显著提高,开孔率明显降低,其值分别为5.24 g/cm3、11.78 MS/A和2.03%。加压烧结的树脂碳包覆石墨/铜复合材料的物理、力学性能与罗兰电刷试样相当。

3) 与常压烧结相比,加压烧结的树脂碳包覆石 墨/铜复合材料的摩擦因数更低且更稳定,摩擦3 h时,摩擦因数约为0.172,且体积磨损率仅为0.717×10-7 mm3/(m·N)。

4) 加压烧结的树脂碳包覆石墨/铜复合材料的力学性能和摩擦性能的改善主要来源于石墨表面的树脂改性和加压烧结工艺。酚醛树脂在热处理过程产生的还原性小分子气体,加压烧结加速还原性气体的扩散,更多的铜表面的氧化膜被还原,从而促进了铜颗粒间的原子扩散烧结,有利于铜颗粒的致密结合,有效提高了材料的致密度。此外,高温下外加压力使得铜基体变形程度增加,铜颗粒间接触面积增大,材料烧结效率提高,铜颗粒间微孔体积和界面面积减少,促进了连续的网络状铜基体的形成,以及完整的石墨的离散分布。

REFERENCES

[1] 国家发展和改革委员会交通运输司. 国家《中长期铁路网规划》内容简介[J]. 交通运输系统工程与信息, 2005, 5(4): 18-21.

Department of Transportation, National Development and Reform Commission. A brief introduction to the National Middle and Long Period Plan of the Railway Network[J]. Journal of Transportation Systems Engineering and Information Technology, 2005, 5(4): 18-21.

[2] ZHANG C, CAI J, Lü P, ZHANG Y, XIA H, GUAN Q. Surface microstructure and properties of Cu-C powder metallurgical alloy induced by high-current pulsed electron beam[J]. Journal of Alloys & Compounds, 2016, 697: 96-103.

[3] 吕乐华. 高速列车摩擦接地装置材料的制备及其载流摩擦磨损性能的研究[D]. 洛阳: 河南科技大学, 2013.

Lü Le-hua. Preparation of high-speed train friction grounding material and study of its current-carrying friction and wear performance[D]. Luoyang: Henan University of Science and Technology, 2013.

[4] LI Jing-fu, ZHANG L, XIAO J K, ZHOU K C. Sliding wear behavior of copper-based composites reinforced with graphene nanosheets and graphite[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(10): 3354-3362.

[5] QIAN G, FENG Y, CHEN Y M, MO F, WANG Y Q, LIU W H. Effect of WS2, addition on electrical sliding wear behaviors of Cu-graphite-WS2, composites[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(6): 1986-1994.

[6] KUMAR J, MONDAL S. Microstructure and properties of graphite-reinforced copper matrix composites[J]. Journal of the Brazilian Society of Mechanical Sciences & Engineering, 2018, 40(4): 196-205.

[7] MOUSTAFA S F, EL-BADRY S A, SANAD A M, KIEBACK B. Friction and wear of copper-graphite composites made with Cu-coated and uncoated graphite powders[J]. Wear, 2002, 253(7): 699-710.

[8] LI B, JIA J, HAN M, WANG W Z, LI C. Microstructure, mechanical and tribological properties of plasma-sprayed NiCrAlY-Mo-Ag coatings from conventional and nanostructured powders[J]. Surface & Coatings Technology, 2017, 324: 552-559.

[9] ZHANG R, HE X, CHEN Z, QU X. Influence of Ti content on the microstructure and properties of graphite flake/Cu-Ti composites fabricated by vacuum hot pressing[J]. Vacuum, 2017, 141: 265-271.

[10] LIU B,ZHANG D Q, LI X F, HE Z, GUO X H, LIU, Z J, GUO Q G. Effect ofgraphiteflakes particle sizes on the microstructure and properties ofgraphiteflakes/copper composites[J]. Journal of alloys and compounds, 2018, 733: 382-390

[11] WU X, YANG X, ZHANG F, CAI L. ZHANG L, WEN Z. Carbon-coated isotropic natural graphite spheres as anode material for lithium-ion batteries[J]. Ceramics International, 2017, 43(12): 9458-9646.

[12] 李 荐, 翟炳昆, 周宏明, 王利华, 胡乐善. 酚醛树脂包覆改性对废旧石墨负极材料结构与18650电池性能的影响[J]. 电池工业, 2018(2): 94-99.

LI Jian, ZHAI Bing-kun, ZHOU Hong-ming, WANG Li-hua, HU Le-shan. Effect of phenolic resin coating modification on the structure of waste graphite anode material and performance of 18650 battery[J]. Battery Industry, 2018(2): 94-99.

[13] JIANG X, FANG H C, XIAO P, LIU T, ZHU J M, WANG Y C, LIU P F, LI Y. Influence of carbon coating with phenolic resin in natural graphite on the microstructures and properties of graphite/copper composites[J]. Journal of Alloys and Compounds, 2018, 744(5): 165-173.

[14] 周文艳, 冉丽萍, 彭 可, 葛毅成, 易茂中. Mo2C改性C/C-Cu复合材料的组织及载流摩擦磨损性能[J]. 复合材料学报, 2016, 33(9): 2074-2081.

ZHOU Wen-yan, RAN Li-ping, PENG Ke, GE Yi-cheng, YI Mao-zhong. Structure and tribological property with electric current of Mo2C modified C/C-Cu composites[J]. Acta Materiae Compositae Sinica, 2016, 33(9): 2074-2081.

[15] MA X C, HE G Q, HE D H, CHEN C S,HU Z F. Sliding wear behavior of copper-graphite composite material for use in maglev transportation system[J]. Wear, 2008, 265(7): 1087-1092.

[16] GRANDIN M, WIKLUND U. Influence of mechanical and electrical load on a copper/copper-graphite sliding electrical contact[J]. Tribology International, 2018, 121: 1-9.

[17] YEO J S, LEE J H, WANG S H. Effects of lignin on the volume shrinkage and mechanical properties of a styrene/unsaturated polyester/lignin ternary composite system[J]. Composites Part B Engineering, 2017, 130: 167-173.

[18] WANG S, JING X, WANG Y, SI J J. High char yield of arylboron-containing phenolic resins: The effect of phenylboronic acid on the thermal stability and carbonization of phenolic resins[J]. Polymer Degradation & Stability, 2014, 99(1): 1-11.

[19] MA Z, ZHUANG Y, DENG Y, SONG X, ZUO X, XIAO X, NAN J. From spent graphite to amorphous sp2+sp3, carbon-coated sp2, graphite for high-performance lithium ion batteries[J]. Journal of Power Sources, 2018, 376: 91-99.

[20] CAO Y, XIAO L, AI X, YANG H. Surface-modified graphite as an improved intercalating anode for lithium-ion batteries[J]. Electrochemical and Solid-State Letters, 2003, 6(2): 30-33.

Microstructure and properties of pressure-sintered resin carbon-coated graphite/copper composites

LIU Tan, FANG Hua-chan, LI Jin-wei, ZHU Jia-min, XIAO Peng

(National Key Laboratory of Science and Technology for National Defence on High-strength Structural Materials, Central South University, Changsha 410083, China)

Abstract: Using electrolytic copper powder, resin-coated graphite powder and silicon dioxide powder as raw materials, resin-carbon coated graphite/copper composites were prepared by using traditional powder metallurgical mixing, cold pressure and normal sintered or pressure sintered techniques, respectively. And then, the microstructure, electrical conductivity, mechanical property, friction and wear performance of these composites were compared with the grounded brushes prepared by two sintering processes for high-speed trains, France Roland MCXXP brand brushes. The results show that, compared with normal sintered resin carbon-coated graphite/copper composites, the pressure sintered resin-carbon coated graphite/copper composites have better connectivity copper matrix, more uniform dispersion of graphite, and more silica phases are better embedded in the copper matrix. The density, flexural strength, hardness, electrical conductivity and friction and wear properties are significantly improved, which are similar to those of the French Roland MCXXP brand brushes.

Key words: pressure sintered; resin coated graphite/copper composite; electrical conductivity; mechanical property; friction property

Foundation item: Project(2016J011-G) supported by the Research on Foresight Technology of EMUs, China; Project (2017J008-M) supported by Research on the Key Technology Improvement of EMUs, China; Project (2016YFB0301403) supported by the National Key Research and Development Program of China; Projects(2018zzts418, 2018zzts419) supported by the Fundamental Research Funds for the Central Universities of Central South University, China

Received date: 2018-06-28; Accepted date: 2019-04-30

Corresponding author: FANG Hua-chan; Tel: +86-731-88830614; E-mail: fanghc@csu.edu.cn;

XIAO Peng; Tel: +86-731-88830131; E-mail: xiaopeng@csu.edu.cn

(编辑 李艳红)

基金项目:动车组前瞻技术研究资助项目(2016J011-G);动车组关键技术提升研究资助项目(2017J008-M);国家重点研发计划资助项目(2016YFB 0301403);中南大学中央高校基本科研业务费专项资金资助项目(2018zzts418,2018zzts419)

收稿日期:2018-06-28;修订日期:2019-04-30

通信作者:方华婵,副教授,博士;电话:0731-88830614;E-mail:fanghc@csu.edu.cn;

肖 鹏,教授,博士;电话:0731-88830131;E-mail:xiaopeng@csu.edu.cn