Trans. Nonferrous Met. Soc. China 23(2013) 341-346

Solid-state bonding between Al and Cu by vacuum hot pressing

Kwang Seok LEE, Yong-Nam KWON

Materials Deformation Department, Korea Institute of Materials Science, 797 Changwondaero, Changwon, Gyeongnam 641-831, Korea

Received 2 May 2012; accepted 21 September 2012

Abstract: Diffusion bonding between aluminum and copper was performed by vacuum hot pressing at temperatures between 623 and 923 K through two thermal processes: hot compression under the deformation rate of 0.2 mm/min for 10 min at pre-set temperatures, and additional pressing at 0.2 mm/min for 20 min during furnace cooling. After analyzing interface, the feasible diffusion bonding temperature was suggested as 823 K. The three major intermetallic layers generated during diffusion bonding process were identified as Al2Cu, AlCu+Al3Cu4 and Al4Cu9. Furthermore, local hardness values of Al2Cu, AlCu+Al3Cu4 and Al4Cu9 layers average at (4.97±0.05), (6.33±0.00) and (6.06±0.18) GPa, respectively.

Key words: vacuum hot pressing; diffusion bonding; Al-Cu intermetallic compound; composite interface; interface microstructures; nanoindentation

1 Introduction

The joining between dissimilar materials has attracted great attention indebted to their unique advantage for the viewpoint of multi-functionality. For example, Al-Cu bimetallic joint materials have their advantages due to their excellent properties combining low density, lightweight, corrosion resistance of aluminum, with extraordinarily high level of electrical and thermal conductivity of copper [1-8]. The major problem in the joining processes between Al and Cu is, however, the generation of complex Al-Cu intermetallic compounds (IMCs) at the interface at elevated temperatures around the liquidus of Al, which cause deleterious influence on both mechanical and electrical properties of the entire hybrid bimetallic composites. For the mechanical point of view, thermally induced brittle IMCs at interface between aluminum and copper reduce the overall ductility, though these IMCs give additional hardening to the interface [9]. Furthermore, it is well known that the interatomic bonds within IMCs between aluminum and copper reduce the number of available free electrons, resulting in higher electrical resistivities [10].

There were several studies on IMC generation during high temperature diffusion bonding between bulky copper and aluminum. It is well known that five equilibrium IMCs such as Al2Cu (q), AlCu (h2), Al3Cu4 (z2), Al2Cu3 (d) and Al4Cu9 (g2) phases could be generated by diffusion bonding between Al and Cu at temperature near 773 K [11,12]. Recently, CHEN and HWANG [13] explained the diffusion mechanism indicating the stages in formation of interface structure in terms of formation energy of each IMC and diffusivity. At temperature intervals between 573 and 773 K, the sequence of diffusion mechanism can be described as follows [13]: 1) Saturated solid solution formed in Al-side at interface between Al and Cu; 2) Since the diffusion rate of aluminum into copper side is faster than that of copper into aluminum side, together with lower formation energy of Al2Cu (0.78 eV) compared with that of Al4Cu9 (0.83 eV), Al2Cu was presumed to form first followed by the generation of Al4Cu9; 3) Additional IMCs like AlCu and Al3Cu4 were formed after generation of previous two phases such as Al2Cu and Al4Cu9.

However, there were several reports that aforementioned sequence of diffusion mechanism was varied with process temperature and time. LEE et al [10] found that there are only two IMC phases such as Al2Cu and AlCu at the interface of the friction-welded Al-Cu joints for relatively short process time presumably due to the low diffusion rate of copper into aluminum. XUE et al [14] also verified that friction stir-welded joint between aluminum and copper under the fast moving speed of 100 mm/min was composed of Al2Cu, Al4Cu9 and few AlCu particles [14]. In addition, it was found that joining between molten aluminum and solid copper wire by means of compound casting at 1003 K generated Al2Cu, AlCu and Al2Cu3 IMCs at interface [15].

The aim of this work is to focus on the possibility of joining between aluminum and cooper by vacuum hot pressing at temperatures ranging from 623 to 923 K. Detailed microstructural investigation on the soundly diffusion bonded interfaces is then carried out in order to investigate the influence of process conditions on local mechanical properties.

2 Experimental

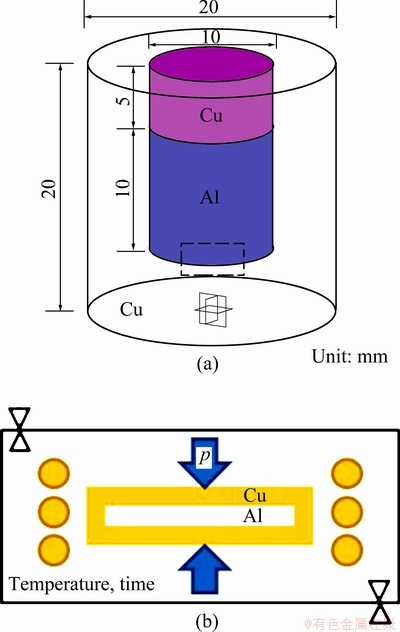

Materials used in this study were Al 1050 and oxygen-free high conductivity copper (OFHC, C101 in ASTM). Aluminum alloy was first cut as a cylindrical type. Copper alloy was then prepared as shell material for canning cylindrical aluminum. The exact dimensions are shown in Fig. 1(a). The vacuum hot pressing (VHP) was performed for diffusion bonding and the schematics is shown in Fig. 1(b). Initial stage of hot compression was done under a deformation rate of 0.2 mm/min at pre-set isothermal temperatures ranging between 623 and 923 K for 10 min within the atmosphere evacuated up to around 133.322×10-2 Pa followed by purging with purified argon gas. Then additional pressing was carried out under the same deformation rate of 0.2 mm/min after turning off the power of resistant furnace for 20 min.

Fig. 1 Schematic diagram of sample dimension of aluminum/ copper couple (a) and vacuum hot pressing used for solid-state diffusion bonding (b)

Joint samples were cut from the lower side of joint (marked as dot rectangular part in Fig. 1(a)) in order to characterize the interface microstructures. Optical micro- scope (OM), field-emission scanning electron micro- scope (FE-SEM, model TESKAN MIRA II) attached with Oxford energy dispersive X-ray spectrometer (EDS) and transmission electron microscope (TEM, model JEOL JEM-2100F) at 200 kV were applied to investigating microstructures at the Al-Cu interface. Nanoindentation measurement was also carried out on joint surfaces of the representative samples embedded in resin and polished to a mirror finish by utilizing an MTS nanoindenter XP equipped with a triangular Berkovich diamond indenter.

3 Results and discussion

Macroscopic diffusion bonding features at various vacuum hot pressing temperatures are shown in Fig. 2. It is apparent that low-temperature diffusion bonding below 773 K under the constant deformation rate results in insufficient joining between aluminum and copper. When the process temperature was increased above 873 K, no distinct lateral delamination exhibited at the interface between aluminum and copper. The thickness of diffusion-induced interfacial layers apparently increases with further increasing process temperature. It is interesting to note that the interface near the aluminum side is not smooth as the process temperature is above 898 K, presumably attributed to the drastic decrease of viscosity at semi-solid aluminum side.

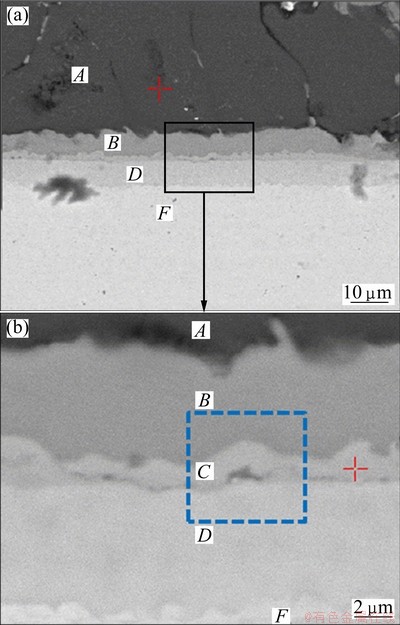

For the sample 4 diffusion bonded at 823 K in Fig. 2, EDS analysis was carried out to investigate the exact composition of each IMC layer. Figure 3 exhibits the cross-sectional backscatter electron (BSE) image for sample 4 obtained by FE-SEM, where several IMCs can be distinguished by the color. Results of EDS analysis conducted on points A, B, C, D and F in Fig. 3 are then summarized in Table 1. The newly generated layers B, C, and D could be identified as Al2Cu, AlCu, and Al4Cu9, respectively. The IMC phases were exactly consistent with other previous reports [12]. The averaged thicknesses of layers B, C and D were also evaluated as (6.32±0.31), (1.92±0.39) and (6.82±0.24) μm, respectively. On the other hand, the reason why other IMCs such as Al2Cu3 and Al3Cu4 could not be detected has to be further mentioned. Though one can assume that it is not possible for Al2Cu3 and Al3Cu4 IMCs to be generated for relatively short diffusion time at adopted temperature, it is also considered that the layer C is too thin to precisely resolve the composition at boundaries between newly generated IMC phases by means of typical EDS analysis.

Fig. 2 Macroscopic features and optical micrographs of interfacial microstructures observed from diffusion bonded samples at different temperatures ranging from 623 to 923 K

Fig. 3 FE-SEM images of interface obtained from Al-Cu joint of sample 4 in Fig. 2

Table 1 Results of EDS analysis on sample 4 diffusion bonded at 823 K

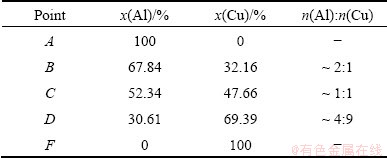

After cutting sample at the interface between aluminum and copper joined at 823 K from dot rectangular region in Fig. 3(b) by means of focused ion beam, bright-field image was obtained by TEM. As shown in Fig. 4(b), interfacial layers are composed of three different colors implying distinctive IMC phases. It is also apparent that VHP induced bonding at 823 K yields a continuous layer C with irregular thickness around 2 μm. Also elemental mapping of this Al-Cu macrocomposite shows that layers B and D are rich in aluminum and copper, respectively, as shown in Figs. 4(c) and (d).

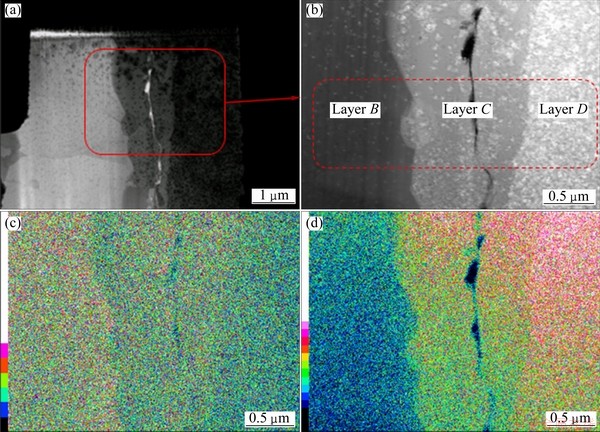

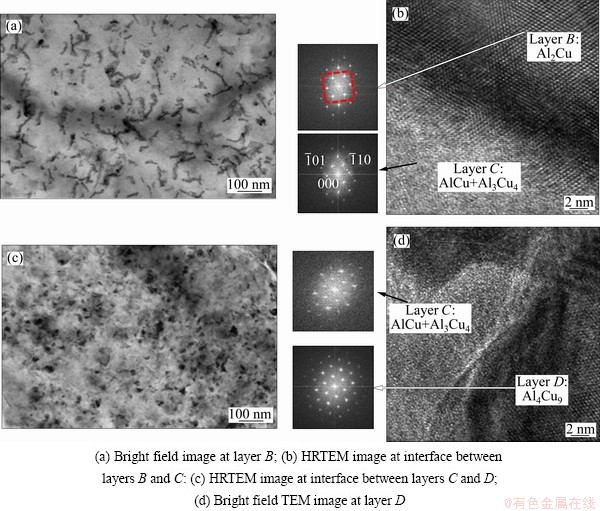

In order to further investigate the characterization of narrow diffusion band, high resolution TEM observation was also carried out and the results are shown in Fig. 5. It is clear that the Al2Cu(q) phase was precipitated within aluminum-rich matrix on layer B shown in Fig. 5(a). From HRTEM image at the interface between layers B and C in Fig. 5(b), it was seen that layer B could be indexed as Al2Cu(q) phase which exhibited a tetragonal crystal structure along [011] direction determined by the fast Fourier transformed (FTT) diffraction pattern. On the other hand, the diffraction spots obtained from narrow region of thin layer C has a difficulty for identification. From the lower inlet of Fig. 5(b), main phase in layer C could be AlCu IMC since bright spot indicates typical orthorhombic crystal structure with a=1.004 nm, b=0.695 nm and c=0.416 nm along [111] direction. But other faint isolated diffraction spots were also seen in the FFT diffraction pattern from Fig. 5(b), which implied that another phase such as Al3Cu4 having orthorhombic structure with different lattice parameters was also generated during diffusion bonding. While there is a difficulty in indexing layer C, and it is easily confirmed from Figs. 5(c) and (d) that layer D consists of the precipitation of several nm-sized Al4Cu9 IMC phase within copper-rich solid solution. From FFT diffraction pattern, the Al4Cu9 phase could be identified as simple cubic structure along the [111] direction with the lattice parameters of a=b=c=0.87 nm.

Fig. 4 SEM images of sample 4 made by focused ion beam (FIB) exhibiting three distinguished intermetallic compound layers (a), cross-sectional bright-field TEM image (b) obtained from rectangular box in (a), elemental mapping results of aluminum (c) and copper (d)

Fig. 5 TEM images of soundly diffusion bonded sample 4

Figure 6(a) illustrates a series of nanoindentation marks at the interface from sample 4 in Fig. 2, where nanoindentations with an array of 5×15 indents were performed under the displace-control mode with a depth limit of 150 nm. Furthermore the change of aluminum and copper contents along the arrow in Fig. 6(a) was overlapped onto the hardness values as a function of distance as seen in Fig. 6(b). After confirming serial number of indentation event conformed to the local mechanical property from each diffusion layer as well as parent materials, local hardness values of the layers A, B, C, D and F average at (1.58±0.32), (4.97±0.05), (6.33±0.00), (6.06±0.18) and (1.50±0.05) GPa, respectively. Noticeable higher hardness of the diffusion bonded interface than that of parent materials such as aluminum and copper confirms that layers B, C and D were high-hardness Al-Cu IMCs. Moreover, the hardness of the intermediate zone (layer C) is the highest among all of IMC layers, which means that AlCu+Al3Cu4 IMC layer could be the origin of brittle nature of the diffusion bonded Al-Cu macrocomposites.

Fig. 6 SEM image of nanoindentation arrays obtained at interface between aluminum and copper (a), hardness variation (b) of Al/Cu composites overlapped onto evolution of Al-Cu contents through given arrow in (a)

4 Conclusions

1) Vacuum hot pressing between Al and Cu was carried out in the temperature ranging from 623 to 923 K for two distinguished compression steps. Feasible diffusion bonding temperature can be proposed as 823 K because low-temperature diffusion bonding below 773 K under the constant deformation rate exhibits lateral debonding between aluminum and copper.

2) The diffusion bonded interface between aluminum and copper at 823 K exhibits planar morphology composed of three distinguished layers. The layers adjacent to the aluminum and copper base metals are indexed as Al2Cu and Al4Cu9, respectively. And the relatively thin middle layer is mainly composed of AlCu and Al3Cu4 intermetallic compounds.

3) Local hardness values of the aluminum, Al2Cu, AlCu+Al3Cu4, Al4Cu9, and copper layers averages at (1.58±0.32), (4.97±0.05), (6.33±0.00), (6.06±0.18) and (1.50±0.05) GPa, respectively. The hardness values of intermetallic layers exhibit considerably higher than those of aluminum or copper base metals. The hardness of thin middle layer is the highest among diffusion layers, implying that AlCu+Al3Cu4 IMCs might induce brittle nature of the entire joint metals.

References

[1] SARSILMAZ F. Weldability characteristics of dissimilar Al/Cu friction stir weld joints [J]. Materials Testing, 2012, 54: 85-91.

[2] SAHIN M, MISIRLI C. Properties of cold pressure welded aluminum and copper sheets [J]. Advanced Materials Research, 2012, 463-464: 244-248.

[3] XUE P, XIAO B L, WANG D, MA Z Y. Achieving high property friction stir welded aluminium/copper lap joint at low heat input [J]. Science and Technology of Welding and Joining, 2011, 16: 657-661.

[4] WU Ming-fang, SI Nai-chao, CHEN Jian. Contact reactive brazing of Al alloy/Cu/stainless steel joints and dissolution behaviors of interlayer [J]. Transactions of Nonferrous Metals Society of China, 2011, 21: 1035-1039.

[5] CHENG Xiao-le, GAO Yi-min, FU Han-guang, XING Jian-dong, BAI Bing-zhe. Microstructural characterization and properties of Al/Cu/steel diffusion bonded joints [J]. Metals and Materials International, 2010, 16: 649-655.

[6] SAEID T, ABDOLLAH-ZADEH A, SAZGIRI B. Weldability and mechanical properties of dissimilar aluminum-copper lap joints made by friction stir welding [J]. Journal of Alloys and Compounds, 2010, 490: 652-655.

[7] XIA Chun-zhi, LI Ya-jiang, PUCHKOV U A, GERASIMOV S A, WANG Juan. Microstructure and phase constitution near the interface of Cu/Al vacuum brazing using Al-Si filler metal [J]. Vacuum, 2008, 82: 799-804.

[8] XIA C Z, LI Y J, WANG J, MA H J. Microstructure and phase constitution near interface of Cu/Al vacuum brazing [J]. Materials Science and Technology, 2007, 23: 815-818.

[9] HUG E, BELLIDO N. Brittleness study of intermetallic (Cu,Al) layers in copper-clad aluminum thin wires [J]. Materials Science and Engineering A, 2011, 528: 7103-7106.

[10] LEE Won-Bae, BANG Kuek-Saeng, JUNG Seong-Boo. Effects of intermetallic compound on the electrical and mechanical properties of friction welded Cu/Al bimetallic joints during annealing [J]. Journal of Alloys and Compounds, 2005, 390: 212-219.

[11] KIM Hyoung-Joon, LEE Joo Yeon, PAIK Kyung-Wook, KOH Kwang-Won, WON Jinhee, CHOE Sihyun, LEE Jin, MOON Jung-Tak, PARK Yong-Jin. Effect of Cu/Al intermetallic compound (IMC) on copper wire and aluminum pad bondability [J]. IEEE Transactions on Component and Packaging Technologies, 2003, 26(2): 367-374.

[12] GUO Ya-jie, LIU Gui-wu, JIN Hai-yun, SHI Zhong-qi, QIAO Guan-jun. Intermetallic phase formation in diffusion-bonded Cu/Al laminates [J]. Journal of Materials Science, 2011, 46: 2467-2473.

[13] CHEN Chih-Yuan, HWANG Weng-Sing. Effect of annealing on the interfacial structure of aluminum-copper joints [J]. Materials Transactions, 2007, 48(7): 1938-1947.

[14] XUE P, XIAO B L, NI D R, MA Z Y. Enhanced mechanical properties of friction stir welded dissimilar Al-Cu joint by intermetallic compounds [J]. Materials Science and Engineering A, 2010, 527(21-22): 5723-5727.

[15] DIVANDARI M, GOLPAYEGANI A R V. Study of Al/Cu rich phases formed in A356 alloy by inserting Cu wire in pattern in LFC process [J]. Materials and Design, 2009, 30: 3279-3285.

真空热压铝和铜的固态连接

Kwang Seok LEE, Yong-Nam KWON

Materials Deformation Department, Korea Institute of Materials Science, 797 Changwondaero, Changwon, Gyeongnam 641-831, Korea

摘 要:在温度623~923 K下采用真空热压扩散连接铝和铜,具体工艺为在预置温度下,变形率为0.2 mm/min时热压缩10 min,再在炉冷过程中,以0.2 mm/min成型10 min。通过界面分析可以看出,合适的扩散连接温度为823 K,在扩散过程中产生了3种主要的金属间化合物层,分别为Al2Cu、AlCu+Al3Cu4和Al4Cu9。3种化合物层的局部硬度分别为(4.97±0.05)、(6.33±0.00)、(6.06±0.18) GPa。

关键词:真空热压;扩散结合;Al-Cu金属间化合物;复合材料界面;界面微观结构;纳米压痕

(Edited by Xiang-qun LI)

Foundation item: Project (10037273) supported by the Ministry of Knowledge Economy, Korea

Corresponding author: Kwang Seok LEE; Tel: +82-55-2803380; E-mail: ksl1784@kims.re.kr

DOI: 10.1016/S1003-6326(13)62467-X