文章编号:1004-0609(2016)-10-2071-07

随焊超声冲击对2A14铝合金TIG焊接接头显微组织和力学性能的影响

陈琪昊,林三宝,杨春利,范成磊,曲宏韬

(哈尔滨工业大学 先进焊接与连接国家重点实验室,哈尔滨 150001)

摘 要:为了改善2A14铝合金TIG焊接头的显微组织与力学性能,在TIG焊过程中,利用超声变幅杆对焊缝进行超声冲击,超声通过固体母材和焊缝传入熔池内,影响熔池的流动及凝固,从而达到细化焊接接头晶粒和提高接头力学性能的目的,利用激光测振仪对熔池表面的振动进行测量。结果表明:超声冲击使焊接接头的显微组织发生明显的变化,焊缝中心和熔合区的晶粒由柱状晶变为了等轴晶,晶粒尺寸减小,第二相尺寸变小且分布更加分散。超声冲击使接头抗拉强度提高,抗拉强度由246.18 MPa 提高到265.50 MPa,断后伸长率由5.33%增加到6.47%。超声冲击使熔池的流动性增强,导致熔池内温度更加均匀;温度梯度减小,有利于等轴晶的形成及晶粒的细化。

关键词:铝合金;超声冲击;TIG焊接;熔池;显微组织;力学性能

中图分类号:TG457.1 文献标志码:A

铝合金具有良好的力学性能及抗腐蚀等性能,在航空航天领域具有广泛的应用[1-2]。在铝合金焊接方法中,钨极氩弧焊(TIG)由于焊接品质高、成形美观以及容易操作等优点,是一种最常用的焊接方法[3]。然而,铝合金TIG焊接头常常因为接头晶粒粗大且缺陷较多,导致接头强度较低,影响了铝合金构件的使用。为了提高铝合金TIG焊接头的力学性能,必须对常规TIG焊接工艺进行改进。

超声波是一种高频机械振动,当超声波在液体中传播时,会产生声流动及声空化现象[4]。在铸造领域,已有研究表明,超声波熔体处理对于铸件的晶粒细化是一种简单而又有效的方法[5-10]。超声场下铸件组织细化的原理主要基于熔体中超声产生的声流动及声空化作用。

焊接和铸造有一定的相似性,都涉及到熔体的凝固过程。研究人员也将超声波振动与焊接技术进行复合,研究出许多超声波焊接复合加工技术,比如超声波辅助钎焊[11]、电弧激励超声辅助焊接[12]、超声波电弧复合焊接[13-15]。其中在超声波电弧焊接领域,利用超声波的能量影响熔池的流动及凝固,可以细化焊接接头晶粒,提高接头的力学性能。

在超声波电弧焊接领域,目前,有两种超声波辅助电弧焊方法。一种是超声波通过电弧空间从熔池正上方传入熔池内部[12, 14-15];另一种是超声波工具头固定在母材上,超声波通过固体母材传入熔池内部[13]。然而,这两种超声波电弧焊方法目前还不完善,仍存在一些问题。由于在焊接的过程中,电弧是一种高温等离子体,当超声波在电弧空间传播时,衰减较大,导致传入熔池内部的超声能量较小,超声的利用率较低。当将超声波工具头固定在母材上,在焊接的过程中,母材表面上的超声输入位置与熔池之间的距离越来越远,当距离非常大时,熔池内超声能量较小,超声细化焊接接头组织的能力也会减弱,不利于超声复合焊接技术的实际应用。因此,为了提高超声波的利用率,同时保持超声改善焊接接头组织和力学性能的均匀性,必须设计一种新的超声波辅助电弧焊方法。

为了解决这些问题,本文作者设计了一种新的超声波辅助电弧焊方法。在TIG焊接的过程中,在熔池后方一定距离处,利用超声工具头间断性地冲击焊缝表面,将超声波振动从固体母材和焊缝传入熔池内。在焊接的过程中,熔池和超声冲击位置之间的距离始终保持不变。此种方法有两个优点:第一,超声波能量从固体母材和焊缝传入焊接熔池内,超声能量的利用率较高;第二,超声输入位置和熔池之间的距离始终保持不变,这样在焊接的过程中,保证熔池内的超声能量不会逐渐下降。

本文作者使用这种随焊超声冲击焊接方法对2A14铝合金进行平板对接焊,研究了随焊超声冲击对2A14铝合金TIG焊接头显微组织和力学性能的影响,同时分析了超声冲击环境下2A14铝合金TIG焊接头显微组织改善的原因。

1 实验

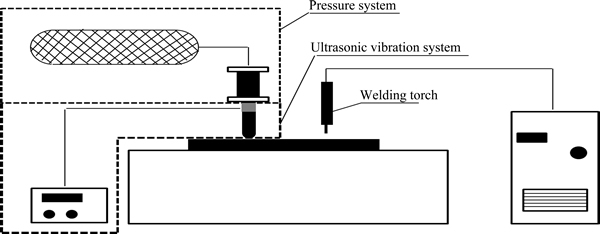

本研究所使用的随焊超声冲击设备如图1所示,设备主要包括两大系统,分别为超声冲击系统和焊接系统。超声冲击系统包括超声振动系统和压力系统。超声振动系统包括超声波电源、换能器和工具头,超声振动系统的作用是产生超声波振动,当工具头与固体母材和焊缝接触后将超声波振动传入固体母材内;压力系统包括气缸和空气压缩机,其作用是为超声振动系统的上下移动提供动力,实现超声工具头对焊件表面的机械冲击。超声工具头对焊件表面进行机械冲击,将间断性的超声波振动传入到熔池内部。

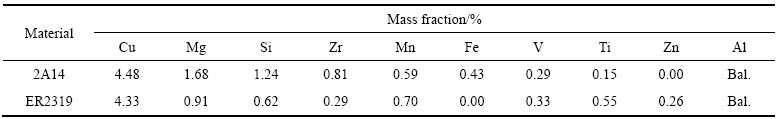

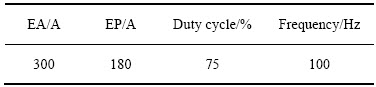

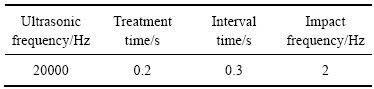

利用设备对4 mm厚的2A14铝合金板进行平板对接焊,开45° Y型坡口,钝边2 mm。使用的焊丝材料为ER2319,其直径为1.2 mm。母材及焊丝成分如表1所列。本研究所用的焊接电源为Dynasty 350交流逆变焊机,焊接电源参数如表2所列,表2中EN代表电流负半波幅值,EP代表电流正半波幅值。其他焊接参数为:焊接速度为150 mm/min,氩气流量为15 L/min,电弧长度为3 mm,送丝速度为1800 mm/min。超声冲击参数如表3所列。

利用光学显微镜(OLYMPUS-PMG3)和扫描电镜(Hitac-hi-S3400N)对焊接接头横截面和纵截面显微组织进行观察,利用电子万能试验机(CSS44300)对2A14铝合金TIG焊接头的拉伸力学性能进行测试,利用激光测振仪(OFV-505/500)对熔池上表面的振动进行测量。

图1 随焊超声冲击焊接实验设备示意图

Fig. 1 Schematic diagram of experimental apparatus of ultrasonic impact during TIG welding

表1 母材和焊丝化学成分

Table 1 Chemical compositions of base metal and filler metal

表2 TIG焊接电源参数

Table 2 Parameters of TIG welding power

表3 超声冲击参数

Table 3 Parameters of ultrasonic impact

2 结果与分析

2.1 超声冲击对显微组织的影响

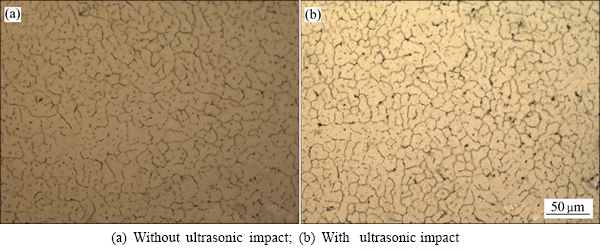

利用随焊超声冲击焊接方法,对4 mm厚的2A14铝合金板材进行平板对接焊实验,焊丝选用ER2319焊丝。焊后截取焊接接头的横截面进行显微组织分析,分析了随焊超声冲击对焊缝中心区(WZ)、熔合区(FZ)以及热影响区(HAZ)的显微组织的影响,研究结果如图2和3所示。结果表明:在焊缝中心处,施加超声冲击后,晶粒尺寸有变小的趋势;在熔合区,对于常规TIG焊接头,其晶粒为柱状晶,晶粒生长具有明显的方向性,沿着散热方向生长。在TIG焊接过程中施加超声冲击后,熔合区晶粒的生长不再具有方向性,柱状晶的生长受到了抑制,柱状晶变为等轴晶;在热影响区,施加超声冲击后,晶粒形态及尺寸无明显变化。可见,在TIG焊过程中施加超声冲击后,超声能量对2A14铝合金TIG焊缝的显微组织产生了较大的影响。

图2 2A14铝合金TIG焊缝中心显微组织

Fig. 2 Microstructures of cross section at TIG weld center of 2A14 aluminum alloy

图3 2A14铝合金TIG焊接头熔合区及热影响区的显微组织

Fig. 3 Microstructures of fusion zone and heat affect zone for TIG welding joint for cross section of 2A14 aluminum alloy

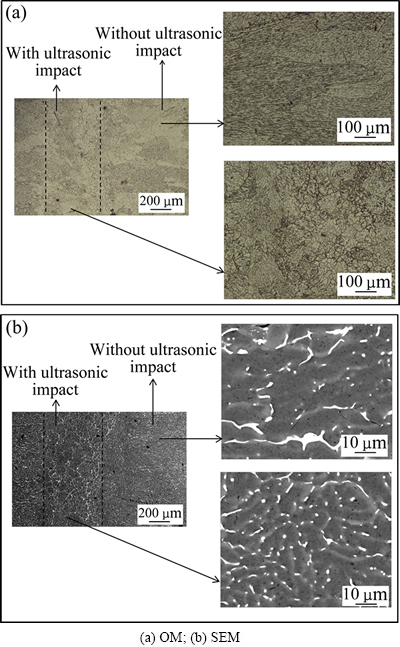

为了进一步分析超声能量对焊缝显微组织的影响,也对焊缝纵截面显微组织进行了观察,如图4所示。图4(a)为利用光学显微镜观察得到的组织,图4(b)为用扫描电镜观察得到的组织。图4中有超声冲击和无超声冲击两部分来源于同一个试件。结果表明:焊缝纵截面显微组织发生了明显的变化,无超声冲击作用时,在焊缝中心处,晶粒为柱状晶,生长具有明显的方向性;有超声冲击作用时,柱状晶消失,变成了等轴晶,如图4(a)所示。在一个试件内,无超声冲击时,焊缝中心表现为顺着焊接方向生长的柱状晶组织;施加超声冲击后,超声波传入熔池,在熔池内引起声空化和声流搅拌作用,改变了熔池结晶及晶体生长的环境,晶粒发生细化,由柱状晶变为等轴晶。在TIG焊过程中施加超声冲击,使焊缝中心处柱状晶和等轴晶交替出现,焊缝中心不再是纯粹的柱状晶,晶粒发生了细化,有利于焊接接头力学性能的提高。图4(b)为超声冲击对焊缝纵截面第二相分布的影响,结果表明:无超声冲击作用时,晶内分布有少量强化相θ′相(Al2Cu),晶界处存在大量的α(Al)+θ′相(Al2Cu)共晶;施加超声冲击后,第二相变得更加分散,θ′相(Al2Cu)及α(Al)+θ′相(Al2Cu)共晶在超声波的空化作用下被打碎,不再具有明显的长条状,弥散地分布于晶界及晶内,尺寸小并且均匀。α(Al)+θ′相(Al2Cu)共晶相硬脆,施加超声冲击后共晶相被打碎,可以减少焊缝内硬脆的共晶相产生的应力集中,从而提高力学性能。

图4 随焊超声冲击对2A14铝合金TIG焊缝纵截面微观组织的影响

Fig. 4 Effects of ultrasonic impact during TIG welding on microstructures of longitudinal section for welded joint of 2A14 aluminum alloy

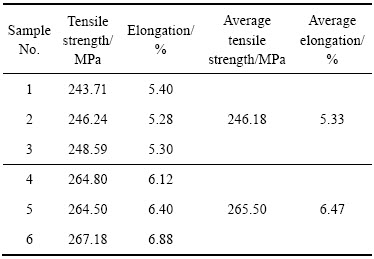

2.2 超声冲击对焊接接头拉伸性能的影响

在2A14铝合金TIG焊接的过程中,施加超声冲击前后焊接接头显微组织发生了明显的变化,显微组织的变化肯定会对接头的力学性能产生影响。表4所列为2A14铝合金TIG焊接头拉伸性能测试结果。样品1~3为常规TIG焊接头测试结果,样品4~6为施加超声冲击后的TIG焊接头测试结果。从表4中可以看到,在TIG焊接过程中,施加超声冲击后,接头抗拉强度从246.18 MPa提高到265.50 MPa;断后伸长率从5.33%提高到6.47%。施加超声能量后接头的抗拉强度提高。对接头抗拉强度提高的原因进行分析:在TIG焊过程中施加超声冲击后,焊缝熔合区和焊缝中心处晶粒由柱状晶变为等轴晶,晶粒尺寸变小,晶粒尺寸的减小有利于接头力学性能的提高。同时,超声冲击使焊缝中硬脆的第二相更加细小同时分布更加弥散,这也会提高接头的力学性能。

表4 焊接接头抗拉强度及断后伸长率

Table 4 Tensile strength and elongation of welded joints

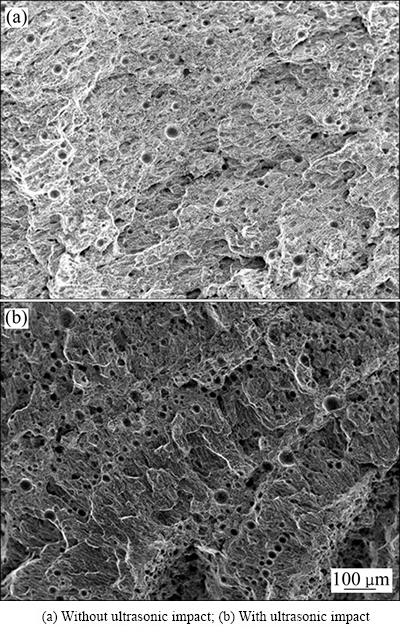

对焊缝断裂位置观察发现施加超声冲击前后断裂都发生在焊缝中心处。利用扫描电镜对焊接接头的断口进行观察,如图5所示。图5(a)为常规TIG焊接头断口形貌;图5(b)为随焊超声冲击断口形貌。常规TIG焊接头断口呈现出明显的脆性断裂特征,断口具有平面状特征;在TIG焊过程中施加超声冲击后,接头断口形貌表现出脆性断裂和韧性断裂混合断裂的特征,具有撕裂的痕迹。可见,在TIG焊接过程中施加超声冲击改变了焊接接头的断裂方式,超声冲击提高了接头的韧性,降低了接头的脆性。

2.3 超声冲击对TIG焊熔池振动的影响

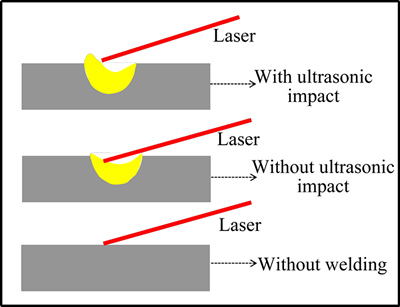

为了分析超声冲击改善焊接接头显微组织的原因,本文作者研究超声冲击对TIG焊熔池振动的影响。研究3种不同情况:1) 测试了未焊接条件下平板表面的振动,理论上其振动幅度为零;2) 在TIG焊接过程中,未施加超声冲击时熔池的振动;3) 在TIG焊接过程中,施加超声冲击时熔池的振动。测试结果如图6所示,从图6中可以看到,当未焊接时,平板表面无振动,其振幅为0,振动中心位置在0处;在TIG焊接过程中,施加超声冲击后,熔池上表面振动的中心位置发生了明显的上移,纵坐标位置在0以上;而对于常规TIG焊接,无超声冲击情况下,熔池上表面振动的中心位置位于0以下,发生了下移。这表明,在超声能量的作用下,熔池上表面的振动状态发生了明显的改变。

图5 2A14铝合金TIG焊接头断口形貌

Fig. 5 Fractographs of welded joints of 2A14 aluminum alloy

图6 随焊超声冲击对TIG熔池振动的影响

Fig. 6 Effect of ultrasonic impact during TIG welding on vibtration of weld pool

对于不施加超声冲击情况下的普通TIG焊熔池,根据已有的研究结果,液面是凹液面,熔池上表面振动的中心位置要低于平板的上表面,因此,熔池振动测试结果表现出其振动中心位置和未焊接时的平板振动中心位置不重合,低于未焊接时平板振动的中心位置。当在TIG焊接过程中,施加超声冲击后,由于声流的作用,熔池的流动性增强,熔池上表面可能处于翻滚状态,有的位置甚至高于平板的上表面,有的位置低于平板的上表面。因此,当激光照射点的位置正好处于熔池上表面翻滚的峰位时,其振动的中心位置就会和普通TIG熔池上表面振动中心位置相反,振动中心位置将高于0。熔池振动示意图如图7所示。施加超声冲击后,熔池的流动性增强。根据文献[16-17],超声作用于熔体时,由于声流作用,使熔体的流动性增强,熔体温度更加均匀,温度梯度下降,会抑制柱状晶的形成,促使等轴晶的生成,因此,在TIG焊过程中施加超声冲击,超声能量有利于焊缝中心和熔合区晶粒由柱状晶变为等轴晶。

图 7 熔池振动示意图

Fig. 7 Schematic diagram of vibtration of TIG weld pool

3 结论

1) 提出一种随焊超声冲击焊接方法,在TIG焊接的过程中,超声变幅杆间断性的冲击熔池后方焊缝,将超声能量通过固体母材和焊缝传入TIG熔池中从而影响熔池的流动及结晶。在焊接过程中,超声冲击位置和熔池之间的距离保持不变。

2) 在TIG焊接过程中施加超声冲击后,焊缝中心和熔合区晶粒由柱状晶变为等轴晶,晶粒尺寸减小,接头抗拉强度提高,断后伸长率增大。

3) 在TIG焊过程中施加超声冲击后,熔池流动性增强,熔池内温度梯度下降,抑制了柱状晶的生长,促进了等轴晶的形成。

REFERENCES

[1] ALBERTINI G, BRUNO G, DUNN B D, FIORI F, REIMERS W, WRIGHT J S. Comparative neutron and X-ray residual stress measurements on Al-2219 welded plate[J]. Materials Science and Engineering A, 1997, 224(1/2): 157-165.

[2] 李智伟, 刘新超, 边 毅, 周 楠. 低压铸造凝固条件对A357合金组织及力学性能影响[J]. 铸造, 2014, 63(6): 551-555.

LI Zhi-wei, LIU Xin-chao, BIAN Yi, ZHOU Nan. Effects of Solidification conditions on microstructure and mechanical properties of A357 alloy by low pressure casting process[J]. Foundry, 2014, 63(6): 551-555.

[3] 冯吉才, 王亚荣, 张忠典. 镁合金焊接技术的研究现状及应用[J]. 中国有色金属学报, 2005, 15(2): 165-178.

FENG Ji-cai, WANG Ya-rong, ZHANG Zhong-dian. Status and expectation of research on welding of magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(2): 165-178.

[4] DEHNAVI M R, NIROUMAND B, ASHRAFIZADEH F, ROHATGI P K. Effects of continuous and discontinuous ultrasonic treatments on mechanical properties and microstructural characteristics of cast Al413-SiCnp nanocomposite[J]. Materials Science and Engineering A, 2014, 617: 73-83.

[5] ZHANG L, ESKIN D G, MIROUX A, KATGERMAN L. Formation of microstructure in Al-Si alloys under ultrasonic melt treatment[C]// Light Metals. Warrendale, PA: TMS, 2012: 999-1004.

[6] 马继宇, 唐康武, 黄天佑. 功率超声在液态金属处理中作用的研究[J]. 铸造技术, 2012, 33(3): 314-317.

MA Ji-yu, KANG Jin-wu, HUANG Tian-you. Review of application of ultrasonic treatment in liquid metal processing[J]. Foundry Technology, 2012, 33(3): 314-317.

[7] 李军文, 郭文涛, 韩志凡, 颜 宏. 超声波功率对ZA27合金凝固组织及力学性能的影响[J]. 热加工工艺, 2011, 40(13): 18-21.

LI Jun-wen, GUO Wen-tao, HAN Zhi-fan, YAN Hong. Effect of ultrasonic power on solidification structure and mechanical properties of ZA27 alloy[J]. Hot Working Technology, 2011, 40(13): 18-21.

[8] 王红玲, 乐启炽, 张志强, 崔建忠, 张向文. 超声驻波作用下Al-20%Si合金的微观组织演变[J]. 中国有色金属学报, 2014, 24(11): 2749-2754.

WANG Hong-ling, LE Qi-chi, ZHANG Zhi-qiang, CUI Jian-zhong, ZHANG Xiang-wen. Microstructure evolution of Al-20%Si alloy with ultrasonic standing wave treatment[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(11): 2749-2754.

[9] PUGA H, BARBOSA J, COSTA S, RIBEIRO S, PINTO A M P, PROKIC M. Influence of indirect ultrasonic vibration on the microstructure and mechanical behavior of Al-Si-Cu alloy[J]. Materials Science and Engineering A, 2013, 560: 589-595.

[10] KOTADIA H R, DAS A, DOERNBERG E, SCHMID-FETZER R. A comparative study of ternary Al-Sn-Cu immiscible alloys prepared by conventional casting and casting under high- intensity ultrasonic irradiation[J]. Materials Chemistry and Physics, 2011, 131(1/2): 241-249.

[11] XU Zhi-wu, YAN Jiu-chun, ZHANG Bao-you, KONG Xiang-li, YANG Shi-qin. Behaviors of oxide film at the ultrasonic aided interaction interface of Zn-Al alloy and Al2O3p/6061Al composites in air[J]. Materials Science and Engineering A, 2006, 415(1/2): 80-86.

[12] 何龙标, 李路明, 吴敏生. 高频调制电弧的声学特性及其细化焊缝组织的应用[J]. 应用声学, 2010, 29(3): 222-226.

HE Long-biao, LI Lu-ming, WU Min-Sheng. The acoustic characteristics of high frequency modulated arc and its application in welding structure refinement[J]. Applied Acoustics, 2010, 29(3): 222-226.

[13] CUI Y, XU C L, HAN Q. Effect of ultrasonic vibration on unmixed zone formation[J]. Scripta Mater, 2006, 55(11): 975-978.

[14] 孙清洁, 林三宝, 杨春利, 闫久春. 超声-TIG复合焊接装置的研制与应用[J]. 焊接学报, 2010, 31(2): 79-82.

SUN Qing-jie, LIN San-bao, YANG Chun-li, YAN Jiu-chun. Investigation and application of ultrasonic-TIG hybrid welding equipment[J]. Transactions of the China Welding Institution, 2010, 31(2): 79-82.

[15] FAN Yang-yang, FAN Cheng-lei, YANG Chun-li, LIU Wen-ge, LIN San-bao. Development and preliminary study on the ultrasonic assisted GMAW method[J]. China Welding, 2010, 19(4): 1-5.

[16] NASTAC L. Numerical modeling of fluid flow and solidification characteristics of ultrasonically processed A356 alloys[J]. ISIJ International, 2014, 54(8): 1830-1835.

[17] LI Jun-wen, MOMONO T, FU Ying, ZHENG Jia, TAYU Y. Effect of ultrasonic stirring on temperature distribution and grain refinement in Al-1.65%Si alloy melt[J]. Transactions of Nonferrous Metals Society of China, 2007, 17(4): 691-697.

Effect of ultrasonic impact during welding on microstructures and mechanical properties of TIG welded joint of 2A14 aluminum alloy

CHEN Qi-hao, LIN San-bao, YANG Chun-li, FAN Cheng-lei, QU Hong-tao

(State Key Laboratory of Advanced Welding and Joining, Harbin Institute of Technology, Harbin 150001, China)

Abstract: In order to improve the microstructures and mechanical properties of tungsten inert gas(TIG) welded joint of 2A14 aluminum alloy, ultrasonic horn periodically impacts the seam during TIG welding. The ultrasound propagates into the weld pool through the weld and base material, so that the ultrasonic energy can effectively influence the fluidity and crystallization of weld pool. Finally, the grain was refined and the mechanical properties were improved for welded joints. The results show that the microstructures are significantly improved after applying the ultrasonic impact. The grain is changed from the column grain to the equiaxed grain in the weld center and the fusion zone, and the grain size decreases in the weld center. Moreover, the distribution of the second phase becomes more uniform and the size becomes smaller after applying the ultrasonic impact. The ultrasonic impact during TIG welding can improve the tensile strength of welded joint and it is improved from 246.18 MPa to 265.50 MPa. The elongation is improved from 5.33% to 6.47%. The ultrasonic impact can improve the fluidity of weld pool, which results in an uniform temperature, so that the form of equiaxed grain and the grain refinement can be promoted.

Key words: aluminum alloy; ultrasonic impact; TIG welding; weld pool; microstructure; mechanical property

Foundation item: Project(51435004) supported by the Key Program of the National Natural Science Foundation of China

Received date: 2015-12-15; Accepted date: 2016-04-16

Corresponding author: YANG Chun-li; Tel: +86-451-86418775; E-mail: yangcl9@hit.edu.cn

(编辑 李艳红)

基金项目:国家自然科学基金重点资助项目(51435004)

收稿日期:2015-12-15;修订日期:2016-04-16

通信作者:杨春利,教授,博士;电话:0451-86418775;E-mail: yangcl9@hit.edu.cn