文章编号:1004-0609(2010)05-0923-07

AZ31镁合金型材连续流变挤压成形过程的数值模拟

管仁国1,赵占勇1,陈礼清2,王付兴1

(1. 东北大学 材料与冶金学院,沈阳 110004;

2. 东北大学 轧制技术及连轧自动化国家重点实验室,沈阳 110004)

摘 要:通过数值模拟,分析AZ31镁合金在连续流变挤压成形过程中的温度场与流场分布规律。结果表明: 辊-靴型腔内合金的温度从入口至出口逐渐降低,合金等温线向工作辊偏移;随着浇注温度的降低,辊-靴型腔内半固态区间逐渐增大;为了获得优良的半固态金属浆料,确定浇注温度为710~770 ℃;合金在辊-靴型腔内层流运动时,越靠近工作辊内表面,合金的运动速度越快;随着挤压模具扩展角的增大,挤压模具出口型材宽度上中心与两侧边部合金的温度差减小;半固态合金进入模具后呈辐射状逐层向前推进填充模具扩展腔,最后再逐渐向模具出口合拢;为了改善模腔内金属流动速度的不均匀性,扩展角以45?为宜。

关键词:镁合金;AZ31合金;半固态;连续挤压;流变挤压;数值模拟;温度;速度

中图分类号:TG111.4; TG244.1 文献标志码:A

Numerical simulation of continuous rheo-extrusion process of

AZ31 alloy

GUAN Ren-guo1, ZHAO Zhan-yong1, CHEN Li-qing2, WANG Fu-xing1

(1. School of Materials and Metallurgy, Northeastern University, Shenyang 110004, China;

2. State Key Laboratory of Rolling and Automation, Northeastern University, Shenyang 110004, China)

Abstract: Through numerical simulation, the temperature and velocity distributions during the continuous rheo-extrusion process of AZ31 alloy were analyzed. The results show that the temperature of the alloy gradually decreases from the casting mouth to the exit in the roll-shoe gap, and the isothermal line deviates from the shoe side to the roll side. The semi-solid region in the roll-shoe gap increases with decreasing casting temperature. In order to prepare a good quality semi-solid slurry, the casting temperature of 710-770 ℃ is suggested. The alloy flows in the roll-shoe gap with a laminar pattern and the velocity near the roll is larger than that near the shoe. The temperature difference between the center and the side of the product at the deformation zone decreases with the increase of extending angle; the semi-solid alloy gradually fills the extending mould with a laminar pattern, then, it gathers at the exit of deformation mould. In order to modify the inhomogeneous flow of the alloy in the mould cavity, the extending angle is suggested to be 45?.

Key words: magnesium alloy; AZ31 alloy; semi-solid; continuous extrusion; rheo-extrusion; numerical simulation; temperature; velocity

金属半固态成形是一种高效节能的近终形新技术,在国外已经较大规模商业化生产,而在我国商业化应用并不广泛[1-3]。触变成形是目前主要的半固态 生产技术,触变成形虽然比传统加工流程大大缩短,但是制坯、加热及成形3个环节仍然是独立分开的,相对流变成形的流程还是较长,如何采用流变成形,将制浆与成形结合,实现一步成形是众多学者的追求目标[4-6]。射铸技术采用颗粒料,在螺旋机构的剪切作用下发生熔化、球化和细化,并在一体机上实现压铸成形,华中科技大学与北京有色金属研究院已引进了此技术[7-10]。除了对先进的流变成形技术进行引进消化之外,同时还应该开发具有自己知识产权的、低成本的流变成形新技术。近年来,在连续铸挤技术的基础上,发展了连续流变挤压成形技术。该技术利用合金在连续铸挤过程中存在半固态区,通过控制半固态区以实现半固态金属浆料的制备和连续流变挤压成形。日本的东京大学已成功利用该技术制备优良的半固态金属浆料,国内的东北大学对连续流变挤压成形进行了理论与应用研究[11-12],实现了铝合金型材和管材的连续流变扩展挤压成形[13-14]。镁合金连续流变挤压成形技术是在此基础上发展起来的,基本原理如下:合金熔体在辊-靴型腔顶端入口进行浇注,通过旋转工作辊施加的摩擦力,合金熔体被拖入辊-靴型腔,并被逐渐冷却,通过旋转工作辊剪切搅拌使合金在凝固过程中固相组织发生细化和球化,形成优良的半固态材料,并在型腔出口安装扩展成形模,将制浆与 挤压成形有机结合,实现浆料制备与流变挤压成形的一体化和连续化。它采用液体镁合金为原料,通过连续流变挤压成形直接加工镁合金棒材和型材等产品,克服了镁合金固态成形难度大、材料制备成本高等缺点。

在镁合金连续流变挤压成形过程中,温度场和流场的分布对成形过程的稳定性以及产品的组织性能有重要影响,决定了合金的半固态区分布和金属的流动规律,从而决定了合金浆料的质量、成形稳定性和成形制品的组织性能;但是由于连续流变挤压成形机的封闭式结构很难直观地研究其温度场的分布和流场分布,因此,本文作者采用ANSYS有限元软件对连续流变挤压成形过程中的温度场与流场分布进行数值模拟,研究其分布规律。

1 计算方法与步骤

1.1 计算模型的建立

在连续流变挤压成形过程中,浇注开始阶段与停止浇注阶段是非平衡过程,存在液流的冲击与扰动,求解能量方程与动量方程需要考虑这种作用。在本研究中除去开始浇注与浇注结束的两个瞬间,为进行建模求解还需作以下假设:制备过程处于连续稳定状态;金属为不可压缩的牛顿流体;合金与工模具间无相对滑动。

分别取辊-靴型腔内和模具型腔内合金为研究对象,采用三维有限元模型来模拟,按轴向( 向)将合金沿子午面一分为二,取其中之一作为研究对象加以离散。在笛卡尔直角坐标系(x, y, z)下,采用各向同性材料的六面体八节点流体单元FLUID142进行离散,离散后的三维有限元计算模型如图1所示。

向)将合金沿子午面一分为二,取其中之一作为研究对象加以离散。在笛卡尔直角坐标系(x, y, z)下,采用各向同性材料的六面体八节点流体单元FLUID142进行离散,离散后的三维有限元计算模型如图1所示。

1.2 材料的热力学参数的确定

AZ31合金的热力学参数随着温度变化会发生一系列的变化。合金密度(ρ)为温度(T)的函数,将密度随温度的变化作线性化处理,通过已有数据作近似回归得到合金密度随着温度变化的一次曲线,表达式如下:

AZ31合金的导热系数和黏度也是温度的函数,应用插值法计算得到其随温度的变化值。另外,模拟计算时涉及到凝固相变潜热,采用等效比热容法计算,

图1 离散化的几何模型

Fig.1 Meshed geometrical models: (a) Alloy in roll-shoe gap; (b) Alloy in extending extrusion mould

即将潜热折合成比热容,再与合金的比热容相加作等效比热容。

1.3 边界条件

1) 浇注入口面。在稳定成形过程中,浇注入口温度为定值,为熔体的浇注温度。

2) 挤压模具入口面。该表面温度为计算得到的 辊-靴型腔合金出口处的温度。

3) 合金与靴、工作辊以及模具的接触面。此接触面为传热边界,实际情况是传导、对流和辐射的混合作用,因此,采用一个综合传热系数来反映这些界面的传热能力,即

q=h(Tω-T∞) (1)

式中:h为综合传热系数,随温度连续变化;Tω为合金温度;T∞为合金接触的工模具表面温度。

4) 合金与冷却靴接触面。假定合金与冷却靴表面无相对滑动,因此,该表面速度为0。

5) 合金与工作辊接触面。接触面上的单元节点 速度为工作辊线速度,在平面直角坐标系下沿3个方向加载:

(2)

(2)

式中:vR为工作辊轮槽表面线速度;i和j为热传导矩阵中节点编号;θ为节点到工作辊轴线的垂线与xOz平面的夹角。

2 结果与分析

2.1 辊-靴型腔内合金的温度场

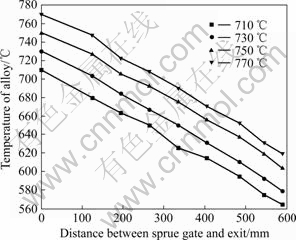

图2所示为在750 ℃浇注时,成形过程中辊-靴型腔内合金中心对称面和边侧的温度场的分布图。图3所示为在不同浇注温度条件下,由浇注口到出口沿合金中心线合金温度的变化曲线。结果表明:沿中心对称面与边侧合金温度场具有相似的变化趋势,随着合金不断向下运动,由浇口到辊-靴型腔出口的温度逐渐降低,同一位置处的合金温度随浇注温度的升高而升高。另外,贴近靴子一侧温度偏低,等温线向工作辊侧偏离。在凝固过程中速度场与温度场是相互影响的,温度场下金属发生凝固相变,使金属的黏度或流动性能发生改变,从而影响到速度场。工作辊与靴在冷却水的冷却作用下温度较低,合金温度与工作 辊-靴温度差非常大,浇注温度为710~770 ℃,而设备温度约为25 ℃,温差≥685 ℃,因此,合金液与辊-靴间存在很大的温度梯度。当合金液与辊-靴接触时,热量以较大的热流密度从合金液前沿传向工作辊-靴。由于工作辊是转动的,在工作辊的拖动下,使得靠近工作辊的合金液最先被向下拖动,尽管工作辊对合金的冷却作用较靴子的冷却作用大,但在实验给定的工作辊转速下,近工作辊合金液尚未冷却到同高度位置的近靴子合金液温度时,就已经发生了位置移动,使得等温线向工作辊侧发生偏移。

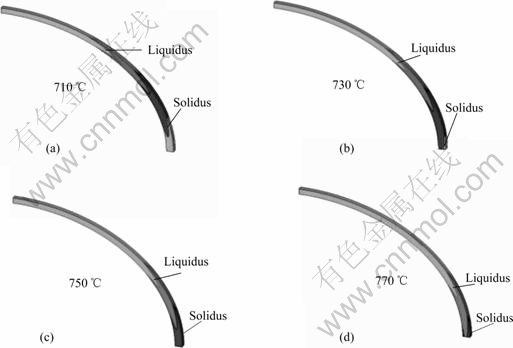

图4所示为浇注温度在710、730、750、770 ℃时,辊-靴型腔中合金在半固态区间(566~632 ℃)的分布情况。从图4可看到:随熔体浇注温度的升高半固态区间逐渐向下移动;当熔体浇注温度低于730 ℃时,出口合金温度低于合金固相线温度(566 ℃),也就是在开始填充模具时合金已经处于完全凝固状态。当浇注温度高于770 ℃时,半固态区较小,工作辊剪切作用时间短,不利于细小球状晶的形成。如果最底部的金属温度高于AZ31镁合金的液相线温度(632 ℃)

图2 750 ℃浇注时辊-靴型腔中的合金温度场分布

Fig.2 Temperature distributions of alloy in roll-shoe gap when cast at 750 ℃: (a) Central symmetrical plane; (b) Side wall

图3 在不同浇注温度条件下辊-靴型腔中沿合金中心线温度的变化

Fig.3 Temperature changes along central line in roll-shoe gap at different casting temperatures

时,说明液态金属已进入变形区,这不仅会使产品的性能下降,导致产品内部出现铸态组织,而且会使产品的表面质量变差,严重时会导致挤压产品断裂。

2.2 辊-靴型腔内合金的速度场

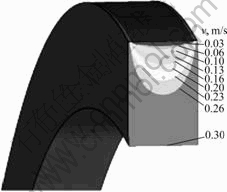

图5所示为辊-靴型腔内合金运动速度场的三维

分布图。图6所示为辊-靴型腔中心对称面上合金运动速度场的等值线。结果表明:越工作辊越近,液体层运动速度越快;离工作辊越远,液态层运动速度越慢,在近工作辊处出现速度最大值。合金速度由靴侧到工作辊侧呈线性递增,合金与靴接触边界的速度为0,这种结果与实际情况是相符合的。当合金被注入辊-靴型腔中时,黏性合金液在层流运动的情况下,各液体层间存在摩擦阻力,即所谓的内摩擦,内摩擦与重力使合金液不同部分也都具有了不同的速度[15-16]。在重力与工作辊摩擦力的作用下,合金具有了速度。近工作辊处合金受到工作辊的剪切作用越强,速度越大;离工作辊越远,合金受到的工作辊剪切力越小,合金运动速度越小。合金运动速度主要是由工作辊的剪切作用引起的,高固相率(固相率>0.6)下切应力与表观黏度(η)、固相率(fs)及微观结构的关系如下[16]:

图4 在不同浇注温度条件下的半固态区间

Fig.4 Semi-solid zones at different casting temperatures

图5 辊-靴型腔内合金的运动速度场

Fig.5 Velocity field of alloy in shoe-roll cavity

冷却作用不均匀会造成合金受到的剪切作用强度不同,从而导致合金流动速度分布不均匀。在辊-靴型腔中,近工作辊侧合金冷却速度快,合金的黏度高,合金受到工作辊的剪切作用大,流动速度快,因此,合金流动速度由靴子侧向工作辊侧 递增。

2.3 模具扩展腔内合金的温度场

图7所示为在730 ℃浇注时,挤压模具中的合金

温度场三维分布图以及扩展角(θ)为30?、45?和60?时的模腔对称面上合金温度场分布的等值线图。合金温度由模具入口到模具出口逐渐降低,合金进入模具扩展腔后开始迅速凝固,越靠近模具扩展腔壁面合金温度越低。图8所示为在730 ℃浇注和不同扩展角条件下,在定径带出口沿型材宽度上从中心到边部的温度变化。模具出口型材宽度面上合金温度上的差异必然导致模具出口型材宽度面上合金流动速度的差异。当

图6 速度场等值线

Fig.6 Isoclines of velocity

图7 在730 ℃浇注时不同扩展角度模腔对称面上合金的温度场分布图

Fig.7 Temperature fields of alloy at symmetrical plane in die cavity at different extending angles when cast at 730 ℃: (a) Three dimensional distribution of temperature at 45?; (b) Isothermal line at 30?; (c) Isothermal line at 45?; (d) Isothermal line at 60?

扩展角度为30?时,中心部位与两侧合金温度差最大,即中心部位合金流动速度大,边部合金流动速度小。为了减小模具出口型材宽度上的温差,应该适当增大模具的扩展角,以45?为宜。

图8 在730 ℃浇注时定径带出口沿型材宽度上从中心到边部的温度变化曲线

Fig.8 Temperature changes from center to side on exit of deformation zone when cast at 730 ℃

2.4 模具扩展腔内合金的速度场

图9所示为计算所得到的不同扩展角度下的合金流场矢量图。半固态合金浆料进入模具后呈辐射状逐层向前推进填充模具扩展腔,最后再逐渐向模具出口合拢。扩展挤压模形状与尺寸不同,合金的流动规律也不尽相同。合金在中心的运动速度最大,逐渐向模子侧壁递减,根据模具形状与尺寸不同,在中间出现过渡的涡流区或不出现涡流区。这是由于在合金流动过程中,中心部位上、下两处是合金的出入口,合金流动阻力很小,流动阻力来自出、入口处模子侧壁的摩擦力及在扩展区其周围黏性合金的牵拽力,这种作用力较小,因此,合金中心处速度最大。合金在扩展区发生扩展流动,但当扩展腔的壁面作用较大时,合金在封闭的两个壁面处进行涡流运动,当扩展腔壁面作用减小时,涡流区也变小,直至消失;同时在扩展腔底部两端合金速度几乎为0,该处称为合金流动的死区。涡流使合金流动不均匀,容易造成合金偏析等缺陷;同时,死区也不利于半固态挤压成形。因此,应该尽量避免涡流与死区的产生。随着模具扩展角的增大,模具出口型材宽度上合金流动速度逐渐均匀,

图9 在730 ℃浇注时不同扩展角度下模腔内合金的速度矢量图

Fig.9 Velocity vectors of alloy in die cavity at different extending angles when cast at 730 ℃: (a) Three dimensional distribution of velocity; (b) Distribution of velocity at 30?; (c) Distribution of velocity at 45?; (d) Distribution of velocity at 60?

即从中心部位合金流动速度逐渐减小,不易出现涡流现象;但θ不能过大,否则,扩展流程太长,就越会影响到挤压成形过程,以45?为宜。

3 结论

1) 辊-靴型腔内合金温度从入口至出口逐渐降低,合金等温线向工作辊发生偏移,随着浇注温度 的降低,辊-靴型腔内半固态区间逐渐增大,为获得优良的半固态金属浆料,确定浇注温度范围为710~770 ℃。

2) 合金在辊-靴型腔内层流运动,越靠近工作辊内表面,合金运动速度越大。

3) 随着挤压模具扩展角的增大,挤压模具出口型材宽度上中心与两侧边部合金的温度差减小。

4) 半固态合金进入模具后呈辐射状逐层向前推进填充模具扩展腔,最后再逐渐向模具出口合拢,为改善模腔内金属流动速度的不均匀性,以45?扩展角为宜。

REFERENCES

[1] Kirkwood D H. Semisolid metal processing[J]. International Materials Reviews, 1994, 39: 173-176.

[2] Flemings M C. Behavior of metal alloys in the semisolid state[J]. Metall Trans A, 1991, 22: 957-781.

[3] 罗守靖, 田文彤, 谢水生. 半固态加工技术及应用[J]. 中国有色金属学报, 2000, 10 (6): 765-773.

LUO Shou-jing, TIAN Wen-tong, XIE Shui-sheng. Semisolid process and application[J]. The Chinese Journal of Nonferrous Metals, 2000, 10(6): 765-773.

[4] Liu T Y, Atkinson H V, Kapranos P, Kirkwood D H. Rapid compression of aluminum alloys and its relationship to thixoformability[J]. Metallurgical and Materials Transactions A, 2003, 34(7): 1545-1554.

[5] Midson S P. Rheocasting processes for semi-solid casting of aluminum alloys[J]. Die Casting Engineer, 2006, 50(1): 48-51.

[6] Mao W M, Zhao A M, Zhong X Y. Spherical microstructure formation of the semisolid high chromium cast iron Cr20Mo2[J]. Acta Metallurgica Sinica, 2004, 17(1): 77-82.

[7] Yang B c, Zhang S m, Xu J, Shi L k, Fan Z. Hot compressive deformation of rheocast AZ31 magnesium alloy[J]. Solid State Phenomena, 2006, 116/117: 742-745.

[8] 李东南, 吴和保, 吴树森, 罗吉荣. 半固态AZ91D镁合金组织与性能研究[J]. 中国机械工程, 2006, 17(13): 1421-1424.

LI Dong-nan, WU He-bao, WU Shu-sen, LUO Ji-rong. Study on microstructure and property of semi-solid magnesium alloy AZ91D[J]. China Mechanical Engineering, 2006, 17(13): 1421-1424.

[9] Li T, Lin X, Huang W d. Microstructure evolution during semi-solid processing of SCN-water and Sn-Pb alloys[J]. Solid State Phenomena, 2006, 116/117: 437-440.

[10] GUAN R G, W J L, LIU X H. FEM analysis of aluminum AA2017 alloy thermal/fluid multiple fields during a single-roll stirring process[J]. Materials Science and Technology, 2003, 19(4): 503-506.

[11] WANG S C, CAO F R, GUAN R G, WEN J L. Formation and evolution of non-dendritic microstructures of semi-solid A2017 alloy prepared by SCR process[J]. Journal of Materials Science and Technology, 2006, 22(2): 5-9.

[12] GUAN R G, WEN J L, LIU X H. A continuous semisolid extending-extrusion process for producing AA2017 aluminum alloy flat bar[J]. Materials Science and Technology, 2006, 22(6): 706-712.

[13] 管仁国, 李 雪, 李江平, 肖召辉, 朱立杰, 温景林. 6201铝合金管材的连续流变扩展成形过程[J]. 中国有色金属学报, 2009, 19(8): 1398-1402.

GUAN Ren-guo, LI Xue, LI Jiang-ping, XIAO Zhao-hui, ZHU Li-jie, WEN Jing-lin. Continuous extending rheo-extrusion process for producing 6201 alloy tube[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(8): 1398-1402.

[14] Chino Y, Kobata M, Iwasaki H, Mabuchi M. An investigation of compressive deformation behavior for AZ91 Mg alloy containing a small volume of liquid[J]. Acta Materialia, 2003, 51: 3309-3318.

[15] Martin L, Brown S B. Shear deformation of high solid fraction (>0.6) semisolid Sn-Pb under various structures[J]. Mater Sci Eng A, 1995, 202: 111-117.

(编辑 杨 华)

基金项目:国家高技术研究发展计划资助项目(2007AA03Z111);国家自然科学基金资助项目(50974038);教育部新世纪优秀人才支持计划资助项目(NCET-08-0097);中央高校基本科研业务费资助项目(N090502003)

收稿日期:2009-03-09;修订日期:2009-08-25

通信作者:管仁国,教授,博士;电话:024-83681463;E-mail: guanrg@smm.neu.edu.cn