DOI: 10.11817/j.ysxb.1004.0609.2021-37784

工艺参数对硅热法炼镁过程的影响机理

张 超1,宋建勋2,车玉思2,何季麟2

(1. 山东建筑大学 热能工程学院,济南 250101;

2. 郑州大学 材料科学与工程学院,郑州 450001)

摘 要:配硅比和煅白水化活性度是影响硅热法炼镁生产效率的显著因素,现有文献主要研究这些因素对总体还原过程的影响作用,不能准确反映工艺参数深层次的影响机理。本工作采用动力学实验的方法获得工艺参数对硅热法炼镁化学反应动力学的影响规律,分别建立包含配硅比(MSi)和煅白水化活性度(γ)的化学反应动力学模型,与传热模型结合后采用数值模拟的方法计算还原过程中的实时产镁速率和最终产镁量。虽然动力学数据表明还原率随配硅比和煅白水化活性度的增加而升高,但工业生产过程中并不总是表现出这种规律,因其还受到传热因素制约。当原料和粗镁价格随市场波动时,本工作可以指导生产厂家合理调整相关工艺参数。

关键词:镁;硅热法;反应动力学;动力学模型;传热;数值模拟

文章编号:1004-0609(2021)-05-1347-11 中图分类号:TQ151.8 文献标志码:A

引文格式:张 超, 宋建勋, 车玉思, 等. 工艺参数对硅热法炼镁过程的影响机理[J]. 中国有色金属学报, 2021, 31(5): 1347-1357. DOI: 10.11817/j.ysxb.1004.0609.2021-37784

ZHANG Chao, SONG Jian-xun, CHE Yu-si, et al. Influence mechanism of technology parameters on silicothermic reduction process[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(5): 1347-1357. DOI: 10.11817/j.ysxb.1004.0609.2021-37784

镁及镁合金材料凭借优良特性在航空航天[1-3]、军工、汽车[4-6]、电子[7-8]、医疗[9-10]等领域占据越来越多的市场份额,目前中国厂家主要采用硅热法炼镁技术进行原镁的工业生产[11]。影响硅热法炼镁生产效率的因素很多,如硅铁配比及品位、白云石煅烧质量、萤石配比、球团成型压力、还原温度和时间等[12-15]。这些因素相辅相成,调整任一工艺参数都可能对生产过程产生较大影响。而金属镁的价格随市场行情随时变动,适时动态调整工艺参数可降低生产成本,提高生产效率。现有文献对硅热法炼镁影响因素的研究主要关注这些因素在一个生产周期内对单个还原罐产镁总量的影响,但由于生产过程受到化学反应和传热传质共同作用[16-19],其研究成果不能直观准确反映工艺参数深层次的影响规律。因此本文从工艺参数对硅热法炼镁化学反应动力学的影响机理着手,分析获取不同工艺参数下的动力学模型,然后与传热模型结合后采用数值模拟的方法计算还原过程中的实时产镁速率和最终产镁量。

在金属镁的工业生产中,当其他工艺参数相同时,提高还原温度和增加还原时间都有助于提高生产效率。但由于受还原罐材质的限制,还原温度一般不会超过1200 ℃。在生产周期的后半部分,产镁速率急剧下降,不可能通过无限延长还原时间来获得全部的金属镁,当产镁量达到原料中含镁量80%的时候即认为完成了一个生产周期。硅铁作为最昂贵的原料,一般选取75#硅铁作为硅热法炼镁的还原剂,但配硅比可在1.0~1.2之间波动,当硅铁价格上涨或粗镁价格下降时,可适当降低配硅比以节约成本。白云石作为用量最多的原料,在煅烧过程中会消耗大量燃料。调整煅烧温度和时间对该过程的能耗影响很大,一般以煅白的水化活性度衡量煅烧质量[20]。综上所述,影响硅热法炼镁生产效率非常显著的因素是配硅比和煅白水化活性度,不同市场行情下搭配合适的配硅比(MSi)和煅白水化活性度(γ)作为工艺参数可以科学合理降低生产成本。

本文首先设计动力学实验,在不同配硅比和煅白水化活性度情况下,分别获取皮江法炼镁过程的化学反应动力学基础数据,然后根据前期研究成果采用分段动力学模型描述一定工艺参数下发生的高温化学反应过程。由于分段动力学模型中不包含配硅比和煅白水化活性度等参数,故本文在全面分析不同配硅比和煅白水化活性度的动力学数据后,分别将配硅比和煅白水化活性度作为函数参数建立相关的数学模型。该数学模型可以与传热模型结合,对还原罐内球团发生的炼镁过程进行计算模拟,获得配硅比和煅白水化活性度对还原过程中的产镁速率和产镁量的影响规律,为皮江法炼镁建立工艺参数动态优化调整机制提供科学理论指导。

1 实验

1.1 材料

本实验使用的白云石、75#硅铁和氟化钙等与镁冶炼工业生产原料一致。

1) 白云石

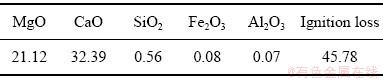

本实验使用的白云石产自山东莱州,表1所列为其组成成分。

表1 白云石组成成分

Table 1 Chemical analysis of dolomite ore (mass fraction, %)

2) 75#硅铁

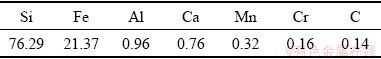

按硅和杂质含量,我国将硅铁分为众多型号,其中75#硅铁是金属镁冶炼工业生产中常用的还原剂,其成分见表2。

表2 75#硅铁组成成分

Table 2 Chemical analysis of 75% ferrosilicon alloy (mass fraction, %)

3) 氟化钙

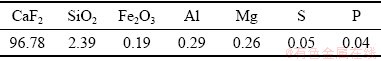

氟化钙作为催化剂用量较少,一般选用含氟化钙较高的萤石粉矿添加至生产原料。根据国家颁布的萤石粉矿品级标准,本实验使用特一级萤石粉料,其成分见表3。

表3 特一级萤石粉料组成成分

Table 3 Chemical analysis of high-quality superfine fluorite powder (mass fraction, %)

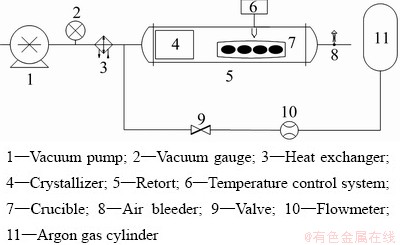

1.2 实验装置系统

在前期对硅热法炼镁动力学模型研究时[21] ,本文作者已搭建完成相关实验台并成功取得部分实验数据。该实验装置由压球系统、反应釜和真空系统组成,具体型号及参数见前期研究成果[21]。本文所需实验数据均由该系统提供,设备结构示意图如图1所示。

图1 实验装置主要设备结构示意图

Fig. 1 Schematic of self-designed experimental system

1.3 实验方法

本实验主要目的是获取不同配硅比和煅白水化活性度情况下皮江法炼镁过程的化学反应动力学基础数据,故实验方法和步骤与前期研究[21]所用相同,但球团原料配比需随工艺不同而进行调整。如研究配硅比对化学反应动力学的影响规律时,在其他原料相同的前提下,分别以1.0、1.1和1.2的配硅比压制球团作为实验对象。这是因为镁冶炼工业生产中配硅比一般最高取到1.2,而为保证镁蒸气在理论上被完全还原出来,配硅比至少取1.0,故本实验选取1.0、1.1和1.2三种配硅比以研究该因素的影响规律。同样地,在研究煅白水化活性度对化学反应动力学的影响规律时,在其他原料相同的前提下,分别以18%、25%和33%的煅白水化活性度压制球团作为实验对象。虽然煅白的理论水化活性度可超过35%,但其生产过程中受煅烧温度和时间影响一般不可能达到理论水化活性度。在实验室使用不同的煅烧温度和时间制取的最理想煅白水化活性度在32%~34%,因此本文取煅白水化活性度最高值为33%。实验采用工业生产使用的较高温度对白云石原料进行长时间的煅烧使煅白过烧,所得煅白水化活性度最低维持在18%左右,故本文取此值作为最低值。

在获取不同配硅比下的化学反应动力学数据时,在其他配料相同的前提下,用配硅比1.0、1.1和1.2分别配制若干厚度小于1 mm的球团。每次实验时取一个球团称量质量后迅速放入预热至反应温度的刚玉坩埚,然后迅速置入已用氩气置换两次的管式真空炉内,抽真空至10 Pa以下后开始计时,经过设定的反应时间后迅速将坩埚拿出放在氩气环境下冷却至室温,称重后根据质量变化计算该反应时间段内的转化率。选取的4个反应温度为1323、1373、1423和1473 K,在每个温度下进行的反应时间为5、10、15、30、45、60、75和90 min。每个实验点依次放入不同配硅比的球团进行实验,且取三次实验平均值作为最终实验数据。采用相同的方法获取不同煅白活性度下的化学反应动力学数据。

2 结果与讨论

2.1 配硅比对化学反应动力学的影响机理

根据前期研究成果,单一动力学模型无法准确描述整个化学反应过程,需采用1stAvrami化学反应模型和Jander扩散模型分段描述。本文借鉴该方法,亦采用分段模型描述不同参数下的化学反应动力学模型。根据所得实验数据,在配硅比为1.0的条件下,反应温度为1323、1373、1423和1473 K的分段化学反应动力学方程为:

(1)

(1)

式中: 为反应转化率,%;

为反应转化率,%; 为反应时间,min。

为反应时间,min。

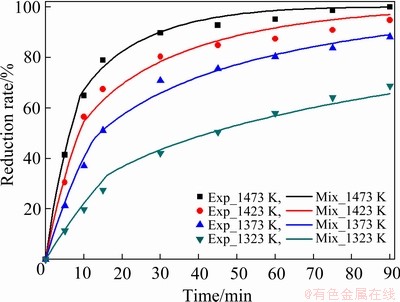

此时分段动力学模型计算结果与实验数据对比如图2所示。

在配硅比为1.1的条件下,反应温度为1323、1373、1423和1473 K的分段化学反应动力学方程为:

图2 配硅比为1.0时分段化学反应动力学模型计算结果与实验数据对比

Fig. 2 Comparison of segmental model results with experimental data when MSi=1.0

(2)

(2)

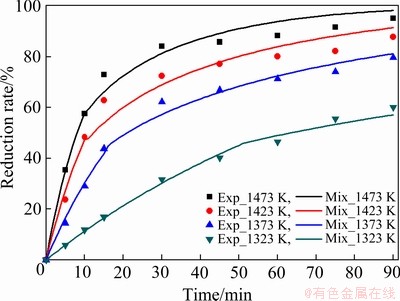

此时分段动力学模型计算结果与实验数据对比如图3所示。

图3 配硅比为1.1时分段化学反应动力学模型计算结果与实验数据对比

Fig. 3 Comparison of segmental model results with experimental data when MSi=1.1

在配硅比为1.2的条件下,反应温度为1323、1373、1423和1473 K的分段化学反应动力学方程为:

(3)

(3)

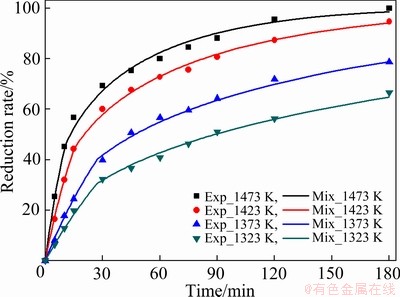

此时分段动力学模型计算结果与实验数据对比如图4所示。

对比图2、3和4数据可知,配硅比的增加并不会改变分段动力学模型的类型,但总体趋势会促进化学反应由相界面向扩散模型转变,尤其是低温情况下更明显。比如反应温度为1323 K,当配硅比由1.0上升到1.1和1.2时,分段动力学模型的转变时间点由50 min分别下降至20 min和15 min。这是因为相界面模型处于颗粒接触反应的初期阶段,当反应速率加快产生的镁蒸气向外扩散环节受到限制后则转变为扩散模型。配硅比的增加加快了模型的转变,减少了反应处于低效率的相界面模型阶段的时间,促进化学反应尽快以较高效率的扩散模型进行。

图4 配硅比为1.2时分段化学反应动力学模型计算结果与实验数据对比

Fig. 4 Comparison of segmental model results with experimental data when MSi=1.2

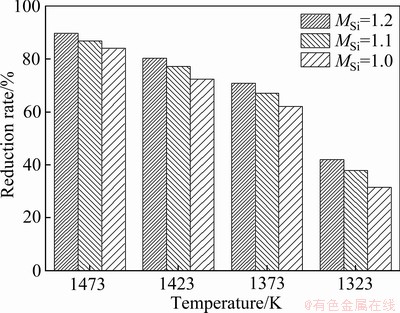

分析图2、3和4可知,同一配硅比条件下还原率随还原温度的升高和还原时间的增加而上升。为了直观形象地表达配硅比对皮江法炼镁化学反应动力学的影响规律,选取反应时间30 min时不同配硅比的还原率数据,并采用柱状图的形式来表示配硅比对皮江法炼镁化学反应动力学的影响规律,如图5所示。

由图5可知,在相同还原温度和反应时间条件下,还原率随着配硅比的降低而呈现下降趋势,且下降速率随着配硅比的降低而增加,为保证较高生产效率,金属镁冶炼厂家一般选取1.2作为最佳配硅比。但由于工业生产过程中,镁蒸气的生产速率不只受化学反应动力学控制,还与还原罐内球团传热速度密切相关。且原镁价格和硅铁成本都随国际行情变化,当原镁价格偏低而硅铁价格上涨时,过高的配硅比就会增加生产成本,此时可适当调低配硅比达到降低生产成本的目的。因此,配硅比可作为动态参数实时调整,而合适的配硅比则需要将动力学模型与传热模型结合进行数值计算确定。

图5 配硅比对皮江法炼镁化学反应动力学的影响规律

Fig. 5 Effect of silicon stoichiometry on chemical kinetic mechanism (30 min)

虽然公式(1)、(2)和(3)分别给出了配硅比为1.0、1.1和1.2条件下的化学反应动力学方程,但使用起来比较繁琐,且不能覆盖配硅比1.0~1.2的全部数据,给后续动力学模型与传热模型的结合带来困难。因此,本文将配硅比视为与反应温度和反应时间相同的自变量,反应温度选取1323、1373、1423和1473 K时,该模型的自变量减少为两个,分别为配硅比MSi和反应时间 。此时,包含参数配硅比MSi的化学反应动力学模型为:

。此时,包含参数配硅比MSi的化学反应动力学模型为:

(4)

(4)

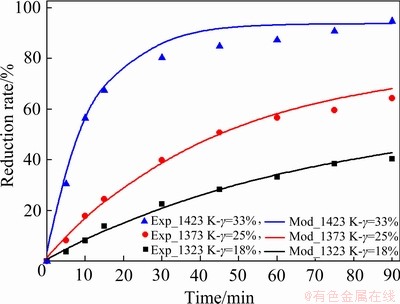

为了验证此模型的准确性,在反应温度1323 K和配硅比1.0、反应温度1373 K和配硅比1.1、反应温度1423 K和配硅比1.2三种代表性条件下,用该模型计算还原率随反应时间的变化,并与实验结果作对比,如图6所示。

图6 包含配硅比的化学反应动力学模型计算结果与实验数据对比

Fig. 6 Comparison of results of chemical kinetics model containing silicon stoichiometry with experimental data

由图6可知,该模型计算的还原率与实验值相差全部控制在5%以内,且计算值与实验值的偏差一般低于4%。所建包含参数配硅比MSi的化学反应动力学模型比较准确,采用线性插值得到其他反应温度下的动力学模型后可以用来做数值模拟计算。

2.2 煅白水化活性度对化学反应动力学的影响机理

煅白水化活性度越高说明其化学反应能力越强,还原效果越好。但高活性煅白在磨粉、配料和运输过程中因吸水较多严重影响产镁效率,因此,研究煅白水化活性度对化学反应动力学的影响机理,并在此基础上与传热模型结合计算对工业生产意义重大。

在煅白水化活性度为18%的条件下,采用分段模型得到反应温度为1323、1373、1423和1473 K下的皮江法炼镁化学反应动力学方程为:

(5)

(5)

此时分段动力学模型计算结果与实验数据对比如图7所示。

图7 煅白水化活性度为18%时分段化学反应动力学模型计算结果与实验数据对比

Fig. 7 Comparison of segmental model results with experimental data when g=18%

在煅白水化活性度为25%的条件下,反应温度为1323、1373、1423和1473 K的分段化学反应动力学方程为:

(6)

(6)

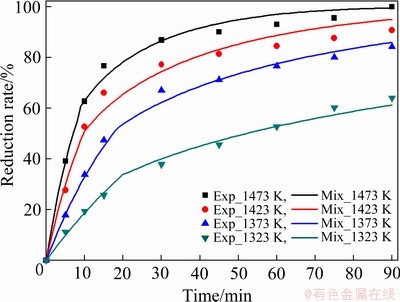

此时分段动力学模型计算结果与实验数据对比如图8所示。

在煅水化活性度为33%的条件下,其动力学方程与研究配硅比对化学反应动力学的影响机理中配硅比1.2条件相同,不再赘述。

与配硅比对反应动力学的影响机理类似,煅白水化活性度的增加也不会改变分段动力学模型的类型,但总体趋势也是促进化学反应由相界面向扩散模型转变。比如反应温度为1473 K,当煅白水化活性度由18%上升到25%和33%时,分段动力学模型的转变时间点由13 min分别下降至10 min和8 min。煅白水化活性度的增加同样加快了模型的转变,减少了反应处于低效率的相界面模型阶段的时间,促进化学反应尽快以较高效率的扩散模型进行。

图8 煅白水化活性度为25%时分段化学反应动力学模型计算结果与实验数据对比

Fig. 8 Comparison of segmental model results with experimental data when g=25%

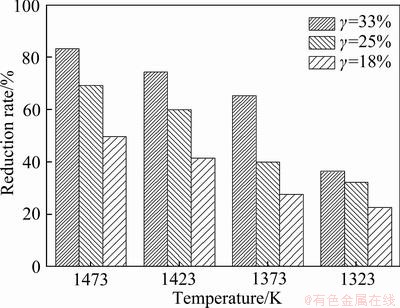

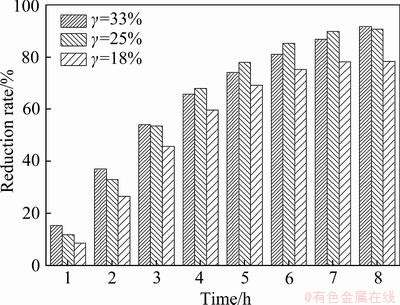

分析图7、图8和图4可知,在同一煅白水化活性度条件下,还原率随还原温度的升高和还原时间的延长而上升。为了直观形象地表达煅白水化活性度对皮江法炼镁化学反应动力学的影响规律,选取反应时间30min时不同煅白水化活性度的还原率数据,并采用柱状图的形式来表示煅白水化活性度对皮江法炼镁化学反应动力学的影响规律,如图9所示。

图9 煅白水化活性度对皮江法炼镁化学反应动力学的影响规律

Fig. 9 Effect of hydration activity of calcined dolomite on chemical kinetic mechanism (30 min)

由图9可知,在相同还原温度条件下,还原率随着煅白水化活性度的降低而呈现下降趋势,煅白水化活性度对还原率的影响比配硅比大。在1200 ℃下反应30 min后,当煅白水化活性度由33%降至25%和18%时,还原率由83.3%分别降至69.3%和49.7%。与配硅比对化学反应动力学的影响规律类似,工业生产过程中镁蒸气的生产速率与化学反应速率和还原罐内球团传热速度都有关系,也可将煅白水化活性度作为动态参数实时调整,由动力学模型与传热模型结合进行数值计算确定。

为了覆盖煅白水化活性度18%~33%的全部数据,也将煅白水化活性度视为与反应温度和反应时间相同的自变量。反应温度选取1323 K、1373 K、1423 K、1473 K时,该模型的自变量减少为两个,分别为煅白水化活性度 和反应时间

和反应时间 。此时包含参数煅白水化活性度

。此时包含参数煅白水化活性度 的化学反应动力学模型为:

的化学反应动力学模型为:

(7)

(7)

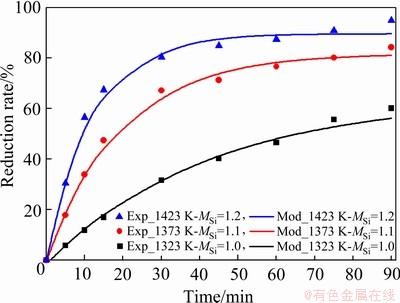

为了验证此数学模型的准确性,在反应温度1323 K和煅白水化活性度18%、反应温度1373 K和煅白水化活性度25%、反应温度1423 K和煅白水化活性度33%三种代表性条件下,用该数学模型计算还原率随反应时间的变化,并与实验结果作对比,如图10所示。

图10 包含煅白水化活性度的化学反应动力学模型计算结果与实验数据对比

Fig. 10 Comparison of results of chemical kinetics model containing hydration activity of calcined dolomite with experimental data

由图10可知,除少数几个实验点以外,数学模型计算的还原率与实验值的偏差一般低于5%。所建包含参数煅白水化活性度 的化学反应动力学模型比较准确,采用线性插值得到其他反应温度下的动力学模型后可以用来做数值模拟计算。

的化学反应动力学模型比较准确,采用线性插值得到其他反应温度下的动力学模型后可以用来做数值模拟计算。

3 数值模拟计算

本文采用动力学实验研究配硅比和煅白水化活性度对化学反应动力学的影响机理时,使用微元球团作为研究对象可以消除传热因素的影响,即认为微元球团一直处于恒温下进行化学反应,获取的是纯化学反应动力学数据。但实际工业生产过程中,大量球团装入还原罐后由外而内进行传热,且传热速率受球团导热、辐射热传递和化学反应吸热等因素影响,所以要考虑还原罐内化学反应和传热的综合作用效果。为此,将本文得到的包含参数配硅比MSi和水化活性度 的化学反应动力学模型用户自定义函数加载至数值计算软件FLUENT,建立化学反应和传热结合的数值计算模型,研究配硅比MSi和水化活性度

的化学反应动力学模型用户自定义函数加载至数值计算软件FLUENT,建立化学反应和传热结合的数值计算模型,研究配硅比MSi和水化活性度 对镁冶炼工业生产的影响规律。

对镁冶炼工业生产的影响规律。

3.1 镁冶炼工业生产物理模型、控制方程、物性参数及求解条件

镁冶炼工业生产物理模型、控制方程、物性参数及求解条件等与前期研究[21]所用一致,不同之处在于本文所用的化学反应动力学模型包含了参数配硅比MSi和水化活性度 。

。

3.2 数值模拟计算结果与讨论

3.2.1 配硅比对镁冶炼工业生产过程的影响

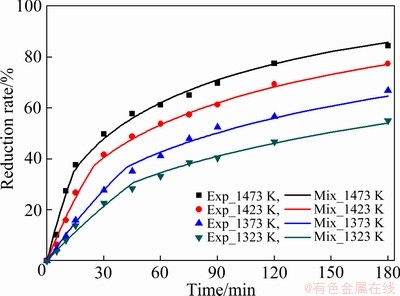

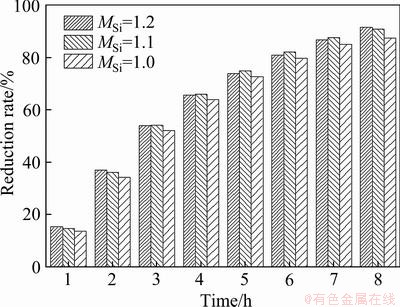

不同配硅比条件下镁冶炼工业生产过程中还原率随反应时间的变化规律如图11所示。

图11 配硅比对镁冶炼工业生产过程的影响

Fig. 11 Effect of silicon stoichiometry on reduction rate in magnesium industrial production

3.2.2 煅白水化活性度对镁冶炼工业生产过程的影响

不同煅白水化活性度下镁冶炼工业生产过程中还原率随反应时间的变化规律如图12所示。

图12 煅白水化活性度对镁冶炼工业生产过程的影响

Fig. 12 Effect of hydration activity of calcined dolomite on reduction rate in magnesium industrial production

3.2.3 分析与讨论

对比图11和12可知,在不同煅白水化活性度下,相同反应时间的还原率差异较大,所以以此为例进行分析。虽然实验测定的纯化学反应动力学数据表明,在任一反应时间下还原率随煅白水化活性度的下降而降低,但镁冶炼工业生产过程中并不总是表现出这种规律。在还原过程的1~3 h,煅白水化活性度33%下的还原率均高于煅白水化活性度25%下的还原率;在还原过程的3~7 h,煅白水化活性度33%下的还原率反而均低于煅白水化活性度25%下的还原率;在还原过程发生7 h后,煅白水化活性度33%下的还原率又重新高于煅白水化活性度25%下的还原率。但在整个反应过程中,煅白水化活性度18%下的还原率始终是最低值。

出现这种情况的原因是:在还原过程的前期,高煅白水化活性度的化学反应速率因受化学反应动力学的控制,明显高于低煅白水化活性度的化学反应速率;较大的化学反应吸热量减缓了还原反应由罐壁向中心递进的速度,造成了在还原过程的中后期会出现低煅白水化活性度情况下的球团平均还原率高于高煅白水化活性度情况下的球团平均还原率;在还原过程的后期,两种煅白水化活性度情形下罐内大部分球团都处于发生还原反应状态,传热因素的影响逐渐降低,化学反应动力学影响取得主要控制权,此时高煅白水化活性度情况下的还原率又逐渐高于低煅白水化活性度的情况;但在煅白水化活性度18%情况下,还原反应始终受化学反应动力学影响较大,整个还原过程中其球团平均还原率一直处于最低值,所以工业生产过程中应该避免使用此种活性程度的煅白作为原料。

由于目前绝大部分皮江法金属镁冶炼厂家的生产周期都超过8 h,所以选用水化活性度在33%左右的煅白作为生产原料具有一定的经济优势。但因生产厂家烧制煅白技术不同,可能导致所用煅白的水化活性度并非都在最高水平,此时则需要根据本文的数值计算模型预测还原过程中罐内瞬时产镁速率,根据预测数据生产合理水化活性度的煅白。

配硅比对镁冶炼工业生产过程的影响规律与煅白水化活性度的影响规律基本一致,原因分析也相同,不再一一赘述。

4 结论

1) 在相同还原温度和反应时间条件下,还原率随着配硅比的降低而呈现下降趋势,且下降速率随着配硅比的降低而增加。

2) 在相同反应时间条件下,还原率随着煅白水化活性度的降低而呈现下降趋势,且下降速率随着煅白水化活性度的降低而降低。煅白水化活性度对还原率的影响比配硅比大。

3) 配硅比和煅白水化活性度可视为与反应温度和反应时间相同的自变量,建立分别包含参数配硅比MSi和煅白水化活性度 的化学反应动力学模型,可以用来做数值模拟计算。

的化学反应动力学模型,可以用来做数值模拟计算。

4) 受传热速率和化学反应吸热双重因素影响,在同样的还原时间内,镁冶炼工业生产过程中还原罐内球团平均还原率并不总是呈现随配硅比和煅白活性度的升高而增加的规律,这一点与这两个参数对纯化学反应动力学的影响规律明显有差异。

5) 建立了分别包含参数配硅比MSi和煅白水化活性度 的硅热法炼镁化学反应动力学模型,并与传热模型结合预测不同配硅比和煅白水化活性度下的产镁速率,为皮江法炼镁建立工艺参数动态优化调整机制提供科学理论指导,可根据市场行情调整合适工艺参数使企业利润最大化。

的硅热法炼镁化学反应动力学模型,并与传热模型结合预测不同配硅比和煅白水化活性度下的产镁速率,为皮江法炼镁建立工艺参数动态优化调整机制提供科学理论指导,可根据市场行情调整合适工艺参数使企业利润最大化。

REFERENCES

[1] 卢翰林, 陈乐平, 周 全. 泡沫镁制备技术研究现状及其在航空航天领域的应用前景[J]. 精密成形工程, 2020, 12(2): 104-108.

LU Han-lin, CHEN Le-ping, ZHOU Quan. Research status and aerospace application prospects of foamed magnesium preparation technology[J]. Journal of Netshape Forming Engineering, 2020, 12(2): 104-108.

[2] 赵 怿, 董 刚, 赵 博. 镁合金在航空领域的应用和研究进展[J]. 有色金属工程, 2015, 5(2): 23-27.

ZHAO Yi, DONG Gang, ZHAO Bo. Research progress of magnesium alloy application in aviation manufacturing[J]. Nonferrous Metals Engineering, 2015, 5(2): 23-27.

[3] 冯 艳, 陈 超, 彭超群, 等. 镁基复合材料的研究进 展[J]. 中国有色金属学报, 2017, 27(12): 2385-2407.

FENG Yan, CHEN Chao, PENG Chao-qun, et al. Research progress on magnesium matrix composites[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(12): 2385-2407.

[4] 李宜达, 梁敏洁, 廖海洪, 等. 高性能镁合金及其在汽车行业应用的研究进展[J]. 热加工工艺, 2013, 42(10): 12-16.

LI Yi-da, LIANG Min-jie, LIAO Hai-hong, et al. Research progress of advanced magnesium alloys and its application in auto industry[J]. Hot Working Technology, 2013, 42(10): 12-16.

[5] 刘婷婷, 潘复生. 镁合金“固溶强化增塑”理论的发展和应用[J]. 中国有色金属学报, 2019, 29(9): 2050-2063.

LIU Ting-ting, PAN Fu-sheng. Development and application of “solid solution strengthening and ductilizing” for magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2019, 29(9): 2050-2063.

[6] 陈 锴, 颜银标, 徐 跃. 镁合金汽车轮毂挤压成形工艺分析及其数值模拟[J]. 机械制造与自动化, 2018, 47(3): 103-105.

CHEN Kai, YAN Yin-biao, XU Yue. Process analysis and numerical simulation of hot extrusion of magnesium alloy wheels[J]. Machine Building & Automation, 2018, 47(3): 103-105.

[7] 吕文泉, 王锦程, 杨跃双, 等. 高强镁合金的研究现状及发展趋势[J]. 材料导报, 2012, 26(3): 105-108.

Lü Wen-quan, WANG Jin-cheng, YANG Yue-shuang, et al. Situation and development trend of high-strength magnesium alloy research[J]. Materials Review, 2012, 26(3): 105-108.

[8] 陈先华, 刘 娟, 张志华, 等. 镁合金热处理的研究现状及发展趋势[J]. 材料导报, 2011, 25(23): 142-145.

CHEN Xian-hua, LIU Juan, ZHANG Zhi-hua, et al. Research status and development trend of heating treatment for magnesium alloy[J]. Materials Review, 2011, 25(23): 142-145.

[9] 张 均, 张春艳, 张世雨, 等. 医用镁基HA复合涂层的研究及发展现状[J]. 中国有色金属学报, 2020, 30(7): 1559-1573.

ZHANG Jun, ZHANG Chun-yan, ZHANG Shi-yu, et al. Research and development status of medical magnesium- based HA composite coating[J]. The Chinese Journal of Nonferrous Metals, 2020, 30(7): 1559-1573.

[10] 康志新, 张俊逸, 刘 秦. 镁合金仿生超疏水表面的制备及展望[J]. 中国有色金属学报, 2018, 28(1): 1-11.

KANG Zhi-xin,ZHANG Jun-yi, LIU Qin. Fabrication of bio-inspired superhydrophobic magnesium alloy and its prospect[J]. The Chinese Journal of Nonferrous Metals, 2018, 28(1): 1-11.

[11] 刘 芳. 镁产业发展现状及发展趋势分析[J]. 热加工工艺, 2014, 43(12): 21-23.

LIU Fang. Analysis on development status and development trend of magnesium industries[J]. Hot Working Technology, 2014, 43(12): 21-23.

[12] 何 阳, 袁秋红, 罗 岚, 等. 镁基复合材料研究进展及新思路[J]. 航空材料学报, 2018, 38(4): 26-36.

HE Yang, YUAN Qiu-hong, LUO Lan, et al. Current study and novel ideas on magnesium matrix composites[J]. Journal of Aeronautical Materials, 2018, 38(4): 26-36.

[13] BARUA S K, WYNNYCKYJ J R. Kinetics of the silicothermic reduction of calcined dolomite in flowing hydrogen[J]. Canadian Metallurgical Quarterly, 1981, 20(3): 295-306.

[14] MORSI I M, BARAWY K A, MORSI M B, et al. Silicothermic reduction of dolomite ore under inert atmosphere[J]. Canadian Metallurgical Quarterly, 2002, 41(1): 15-28.

[15] 刘睿哲. 工艺条件对金属镁冶炼还原过程的影响及应用研究[D]. 西安: 西安建筑科技大学, 2015.

LIU Rui-zhe. Research of technology condition influence to magnesium metallurgy reaction process and application[D]. Xi’an: Xi’an University of Architecture and Technology, 2015.

[16] 王秀芬. 浅谈硅热法炼镁工艺中粗镁回收率的影响因 素[J]. 世界有色金属, 2018(9): 9-10.

WANG Xiu-fen. Factors affecting recovery rate of coarse magnesium in magnesium smelting process[J]. World Nonferrous Metals, 2018(9): 9-10.

[17] 刘宏专, 徐日瑶. 硅热法炼镁时球团在加热过程中的传热及温度分布[J]. 轻金属, 1995(10): 40-43.

LIU Hong-zhuan, XU Ri-yao. Heat transfer and temperature distribution of briquettes in silicothermic process[J]. Light Metals, 1995(10): 40-43.

[18] 夏德宏, 张 刚, 郭 梁, 等. 金属镁皮江法还原工艺中的热过程模拟[J]. 热科学与技术, 2005, 4(3): 257-261.

XIA De-hong, ZHANG Gang, GUO Liang, et al. Thermal simulation of magnesium reduction in pidgeon process[J]. Journal of Thermal Science and Technology, 2005, 4(3): 257-261.

[19] 杨康定, 陈 群, 任建勋. 炼镁还原罐内传热与化学反应的耦合特性[J]. 清华大学学报(自然科学版), 2009, 49 (5): 755-758.

YANG Kang-ding, CHEN Qun, REN Jian-xun. Coupled heat transfer and chemical reactions in magnesium production retorts[J]. Journal of Tsinghua University(Science and Technology), 2009, 49 (5): 755-758.

[20] LI R B, ZHANG C, ZHANG S J, et al. Experimental and numerical modeling studies on production of Mg by vacuum silicothermic reduction of CaO·MgO[J]. Metallurgical and Materials Transactions B, 2014, 45(1): 236-250.

[21] ZHANG C, WANG C, ZHANG S J, et al. The effects of hydration activity of calcined dolomite (HCD) on the silicothermic reduction process[J]. International Journal of Mineral Processing, 2015, 142: 154-160.

[22] 张 超, 付 瑾. 硅热法炼镁动力学的数学模型分析及数值模拟[J]. 化工进展, 2019, 38(9): 4155-4163.

ZHANG Chao, FU Jin. Analysis of the kinetic models of the silicothermic reduction process and their numerical simulation[J]. Chemical Industry & Engineering Progress, 2019, 38(9): 4155-4163.

Influence mechanism of technology parameters on silicothermic reduction process

ZHANG Chao1, SONG Jian-xun2, CHE Yu-si2, HE Ji-lin2

(1. School of Thermal Engineering, Shandong Jianzhu University, Jinan 250101, China;

2. School of Material Science and Engineering, Zhengzhou University, Zhengzhou 450001, China)

Abstract: Silicon stoichiometry and hydration activity of calcined dolomite are significant determinants of silicothermic magnesium production efficiency. However, current literatures focus on discussing effects of these factors on the whole reduction process, and they can not accurately reflect the deeper influence mechanism. The influences of technical parameters on the detailed kinetic were studied experimentally, and the kinetic models include process parameters were proposed, then these models were combined with heat transfer model to calculate magnesium reduction and generation rate during the production process by using numerical calculation. Although kinetic experiments show that the magnesium reduction increases with silicon stoichiometry and hydration activity of calcined dolomite, the patterns may differ in the industrial production, because the process is also affected by heat transfer. This study can guide manufacturers to adjust technical parameters and reduce the production costs when the prices of raw materials and magnesium fluctuate with the market supply and demand.

Keywords: magnesium; silicon thermistor; reaction kinetics; kinetic modeling; heat transfer; numerical simulation

Foundation item: Project(1808085QE152) supported by Anhui Provincial Natural Science Foundation of China; Project(KJ20190048) supported by Anhui University Natural Science Research Foundation; Projects(51804277, 92062223) supported by the National Natural Science Foundation of China

Received date: 2020-07-10; Accepted date: 2021-03-11

Corresponding author: CHE Yu-si; Tel: +86-18695127127; E-mail: cheys@zzu.edu.cn

(编辑 王 超)

基金项目:安徽省自然科学基金资助项目(1808085QE152);安徽高校自然科学研究项目(KJ20190048);国家自然科学基金资助项目(51804277,92062223)

收稿日期:2020-07-10;修订日期:2021-03-11

通信作者:车玉思,实验师;电话:18695127127;E-mail:cheys@zzu.edu.cn