搅拌摩擦挤压AA7022铝合金线材的耐腐蚀性能

来源期刊:中国有色金属学报(英文版)2019年第8期

论文作者:Kamin TAHMASBI Masoud MAHMOODI Hossein TAVAKOLI

文章页码:1601 - 1609

关键词:搅拌摩擦挤压;铝合金线材;晶粒尺寸;硬度;耐腐蚀性能

Key words:friction stir extrusion; aluminum alloy wire; grain size; hardness; corrosion resistance

摘 要:搅拌摩擦挤压(FSE)是一种新型制造技术,它使得通过金属片或实心坯的固结和挤压直接生产线材成为可能。本文作者采用搅拌摩擦挤压法将AA7022铝合金切屑制备成线材,研究基材和挤压后样品的显微组织和力学性能。用动电位极化曲线法测试样品的耐腐蚀性能。结果表明,在较高转速下制备的试样其表面质量较好。随着转速的增加,样品的加工温度升高,晶粒尺寸增大,而力学性能下降。使用FSE可使晶粒细化、晶界的体积分数提高以及使影响合金耐腐蚀性能的析出相进行再分布。此外,腐蚀试验结果表明,采用FSE法制备的试样具有足够的耐腐蚀性能,但在较高模具转速下制备的样品其腐蚀电流密度增加,耐腐蚀性能下降。

Abstract: Friction stir extrusion (FSE) is known as an innovative manufacturing technology that makes it possible to directly produce wire via consolidation and extrusion of metal chips or solid billets. In this study, wire samples were produced using aluminum alloy AA7022 machining chips by the use of the FSE. To this end, the microstructures and mechanical properties of the base material (BM) and the extruded samples were investigated. The corrosion resistance of the given samples was also determined using potentiodynamic polarization technique. The results showed that the samples manufactured at higher rotational speeds possessed good surface quality, the process temperature and the grain size similarly increased following the rise in rotational speed, and the mechanical properties consequently decreased. Using the FSE led to crystallite refinement, increase in volume fraction of grain boundaries, as well as re-distribution of precipitates affecting corrosion resistance. Furthermore, the findings of the corrosion tests revealed that the produced samples by the FSE had adequate corrosion resistance and the growth in die rotation rate augmented current density and subsequently reduced corrosion resistance.

Trans. Nonferrous Met. Soc. China 29(2019) 1601-1609

Kamin TAHMASBI1, Masoud MAHMOODI1, Hossein TAVAKOLI2

1. Department of Mechanical Engineering, Semnan University, Semnan 3513119111,Iran;

2. Faculty of Materials & Metallurgical Engineering, Semnan University, Semnan 3513119111,Iran

Received 12 October 2018; accepted 17 May 2019

Abstract: Friction stir extrusion (FSE) is known as an innovative manufacturing technology that makes it possible to directly produce wire via consolidation and extrusion of metal chips or solid billets. In this study, wire samples were produced using aluminum alloy AA7022 machining chips by the use of the FSE. To this end, the microstructures and mechanical properties of the base material (BM) and the extruded samples were investigated. The corrosion resistance of the given samples was also determined using potentiodynamic polarization technique. The results showed that the samples manufactured at higher rotational speeds possessed good surface quality, the process temperature and the grain size similarly increased following the rise in rotational speed, and the mechanical properties consequently decreased. Using the FSE led to crystallite refinement, increase in volume fraction of grain boundaries, as well as re-distribution of precipitates affecting corrosion resistance. Furthermore, the findings of the corrosion tests revealed that the produced samples by the FSE had adequate corrosion resistance and the growth in die rotation rate augmented current density and subsequently reduced corrosion resistance.

Key words: friction stir extrusion; aluminum alloy wire; grain size; hardness; corrosion resistance

1 Introduction

Friction stir extrusion (FSE) refers to a variant of the direct conversion method of recycling, which was firstly invented by THOMAS et al [1] at the Welding Institute of Cambridge, UK. In this process, friction at the interface between the die and the material generates a large amount of heat, resulting in a temperature increase in the material. Under high pressure, the consolidated and softened metal is also extruded out through the extrusion hole and forms a wire. The process may be recognized as an industrially useful technique to achieve several purposes, e.g. recycling of machining waste, consolidation of powder products, manufacturing of wire feedstock for additive production processes and, potentially, producing nano-grain structure in bulk materials and developing novel alloy composites [2]. The FSE process has been addressed by numerous researchers in recent years. Even though these investigations have thoroughly demonstrated the potential of the given process to emerge as an important recycling technique, not much is known about corrosion characteristics and there are no studies concerning corrosion resistance of aluminum samples manufactured via the FSE. It should be noted that aluminum offers a high potential for use as a lightweight structural material in aerospace, automobile, and construction industries. Since these materials may be subjected to hard environments, their corrosion resistance is regarded as a major concern.

The recycling and manufacturing of AA2050 and AA2195 aluminum wires through friction extrusion method have been recently examined by TANG and REYNOLDS [3]. Accordingly, they observed that the amount of generated heat, which depended on the rotational speed, was the main factor affecting the quality of produced wires. ZHANG et al [4] also examined material flow, during the friction extrusion process, and texture. In the research, they inserted AA2195 aluminum alloy into AA6061 aluminum alloy as a marker to determine the material flow. As well, ZHANG et al [5] simulated heat transfer phenomenon and temperature field during friction extrusion process using the Fluent Software and experimentally measured temperature variations. KHORRAMI and MOVAHEDI [6] also fabricated an aluminum tube through the FSE technique and perused its microstructure and mechanical properties in different areas of the tube. Additionally, TAHMASBI and MAHMOODI [7] experimentally produced AA7022 aluminum wire via the FSE and evaluated micro- structures and mechanical properties of wires through X-ray diffraction profile analysis and Rietveld refinement. The corrosion resistance of magnesium wire produced by the FSE process was also studied by SHARIFZADEH et al [8]. The corrosion resistance of the extruded specimens was then characterized by potentiodynamic polarization technique and the results suggested that the produced magnesium wires were endowed with adequate corrosion resistance.

More recently, corrosion resistance of different materials following other severe plastic deformation (SPD) processes has been also investigated [9]. In this respect, SATTARI et al [10] shed light on the corrosion behavior of Fe/Al surface composites fabricated by friction stir processing (FSP) and reported that the corrosion resistance of the FSPed steels was improved as the number of passes increased.

Moreover, RAO et al [11] assessed the effect of grain size on corrosion resistance of hypereutectic Al-30Si alloy fabricated by the FSP and observed a correlation between grain and silicon particle sizes and corrosion properties using Hall-Petch relationship. DARMIANI et al [12] also studied the corrosion behavior of Al-SiC nano-composite produced by accumulative roll bonding (ARB) and showed that the increase in ARB cycles could lead to a decline in the number of pits and a rise in pitting corrosion resistance. Furthermore, the corrosion behavior of commercial purity titanium processed by high-pressure torsion (HPT) was investigated in the study by NIE et al [13] and a complicated relationship between grain refinement and corrosion resistance, due to contradictory effects of inhomogeneous microstructure and grain size reduction was underscored. The effects of microstructural changes during ECAP on the corrosion behavior of Grade-304 stainless steel were further examined by ZHENG et al [14]. They reported that the corrosion resistance of the samples was improved following ECAP due to an increase in the stability of the passive film on Grade-304 stainless steel even though the thickness and composition of the passive films on as-received and 8-pass samples were very similar. Moreover, JIANG et al [15] reported the enhanced corrosion resistance of hypereutectic Al-Si alloy subjected to the ECAP and found that easier formation of an oxide layer with an improved adhesion force and protection efficacy in UFG structure improved corrosion behavior. IBRAHIM and SADAWY [16] similarly reported the improvement of corrosion resistance of pure aluminum samples using the ECAP.

Accordingly, the purpose of the present study was to investigate the corrosion characteristics of aluminum samples fabricated by the FSE method and to understand whether the microstructural changes were able to improve the corrosion resistance of the samples. In addition, mechanical properties of the given samples were studied.

2 Experimental

2.1 Extrusion material and device

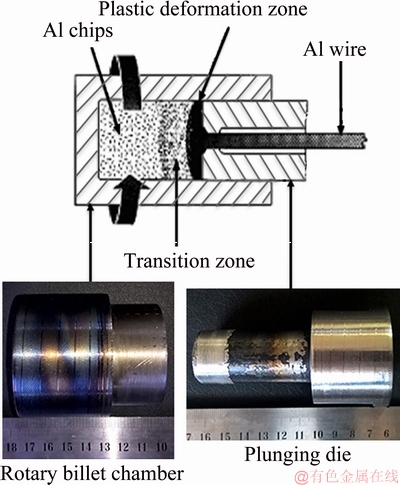

AA7022 aluminum alloy chips were used as the material for fabricating the samples. These chips were obtained from machined aluminum ingot without any lubricant fluids. The nominal composition of AA7022 was Al-4.53Zn-2.50Mg-2.07Cu-0.23Mn-0.2Si-0.2Cr. In this study, the modified lathe was also used to perform the friction extrusion process. The experimental setup of the FSE process was shown in Fig. 1. The main components utilized in the FSE experiments were a rotary billet chamber with an inner diameter of 24 mm and a plunging die with a diameter of 23.7 mm. The volume of the billet chamber wherein the chips were placed was 90.47 cm3. Both parts were made of H13 tool steel. The plunging die also had a hole in the center. The central hole possessed a diameter of 5 mm as the diameter of the produced wire in fact. The rotary billet chamber, as illustrated in Fig. 1, could rotate clockwise and it was then fixed in the spindle of the modified lathe.

Fig. 1 Experimental setup for FSE process

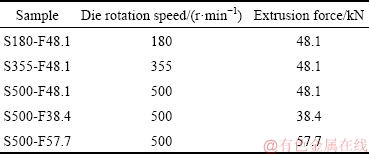

The extrusion force of plunging die is provided via a hydraulic system. The extrusion rate also varies and the pressure is kept constant during a FSE process; while in a normal extrusion, it is vice versa and the extrusion rate is kept constant and the pressure may vary to maintain a specified rate. In fact, the FSE process is a kind of indirect extrusion in which the plunging die can be led into the rotary billet chamber with a heavy force. Friction between the die and the materials along with severe plastic deformation in the materials generates a large amount of heat; as a result, the chips start to flow through the die hole and form a wire. In the friction extrusion process, the rotational speed of a billet chamber is set by the modified lathe, and both extrusion force and die movement are controlled via the hydraulic system. The experimental conditions were listed in Table 1 in which the samples were produced at various rotational speeds and different extrusion forces. In order to analyze the variations in the material after the process, a piece of the BM was investigated as an annealing sample.

Table 1 Experimental conditions

2.2 Metallography and mechanical testing

Following the fulfillment of the FSE process, the extruded wire specimens were sectioned to examine the microstructure, which was mainly studied by an OLYMPUS BH2-UMA optical microscope (OM) and a JEOL JXA-840 scanning electron microscope (SEM). The preparation of the samples for microstructural examination was respectively performed based on ASTM E407-07 and ASTM E3-11 standards. Shearing of the specimens was then carried out perpendicularly to the extruding orientation. The specimens were subsequently cut from a different position of the produced wires and selected from their best parts, which were free from surface cracks. Moreover, mechanical polishing by means of diamond paste and final polishing of the samples were performed using colloidal silica particles. After polishing, specimens were etched using the Keller’s reagent at room temperature; and finally, the microstructures were observed by OM and SEM and the average grain size of samples was calculated through the mean-linear intercept method. The EN ISO 6507-1 standard was also utilized for Vickers microhardness testing. So, the sample was put under the load of 0.5 N for 10 s. In this test, the hardness, from the center to the edge of the wire transverse cross-section, with an interval of 0.62 mm, was measured 3 to 4 times for each sample, and the mean value was obtained. As well, compression test was carried out at room temperature according to the EN ISO 7500-1 standard. The feed rate of compression test machine’s jaw was 0.1 mm/min and the dimensions of the compression specimens were considered to be d5 mm × 10 mm.

2.3 Corrosion testing

The polarization corrosion tests were conducted at room temperature in a NaCl solution (3.5 wt.%; pH=6.6). To this end, sand paper was first used to mechanically clean the surface of work electrodes (cross-sectional area 1 cm2); then they were polished, degreased with acetone, and ultimately washed with distilled water. The samples were tested after being washed. A platinum plate was also used as the auxiliary electrode. Their electric potentials were then measured in terms of the saturated reference calomel electrode (SCE). Polarization analyses were conducted on all the samples treated with an Origalys-OGF 500 potentiostat. All the tests were conducted at a potential sweep rate of 1 mV/s.

Gravimetric measurements were performed using the samples of 1 cm2. The samples were weighed before and after the corrosion tests through a scale with an accuracy of 0.0001 g. Immersion corrosion tests were also performed in aerated 3.5 wt.% NaCl solution (pH 6.6, 296 K) during 2, 4, 6, 8, 10, 12 and 14 d, respectively. At the end of each immersion time, the samples were removed from the corrosion solution, rinsed with ethanol, dried in hot air, and then weighed once again in order to calculate the mass change per unit surface area. For every immersion, the tests were repeated three times and the average weight losses were calculated.

3 Results and discussion

3.1 Microstructural analysis

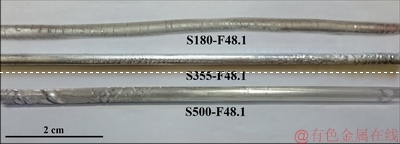

The surface appearance of the specimens produced in various conditions was depicted in Fig. 2. The length of the wires manufactured was not too long due to the limitations of the FSE process, so it was measured between 9 and 13 cm. Some of the wires produced at a low rotational speed of 180 r/min and a high extrusion forces of 57.7 kN were not of sufficient quality, as compared with other samples. Therefore, they were examined in the rest of the research. Good and poor surface qualities of the given wires were also observed.

Fig. 2 Surface appearances of FSE samples

The most important parameter affecting the process was the rotational speed.

The quality of the sample produced at a rotational speed of 180 r/min was degraded because of the reduced heat generated at low rotational speeds. At lower temperatures, the chips were not plasticized and did not flow as well. Therefore, the produced sample contained cracks and torsions. At very high extrusion forces, the produced specimen was not smooth and was distorted due to excessive compression of the material flow during the formation. The best and the highest-quality sample, in terms of physical appearance, was produced at a rotational speed of 500 r/min and a extrusion force of 48.1 kN.

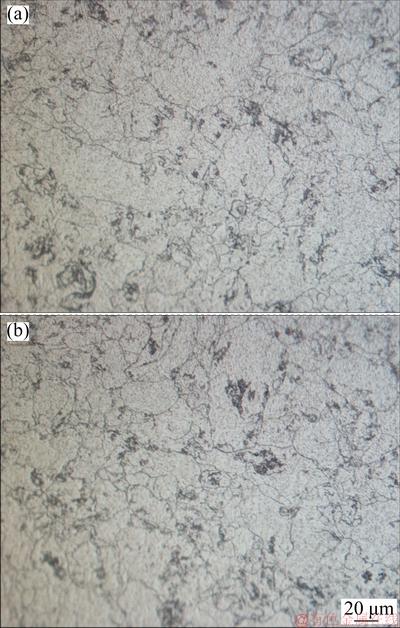

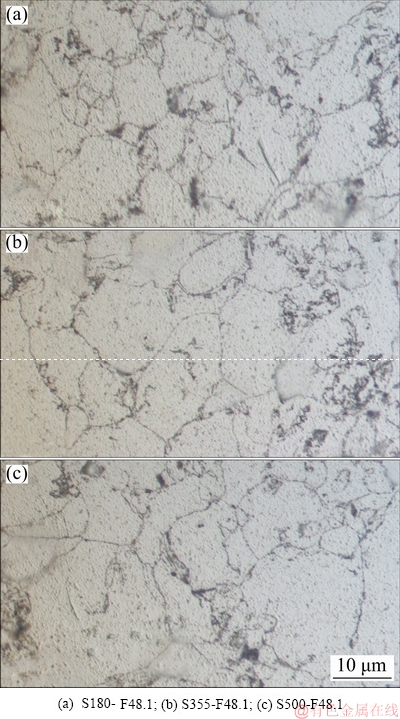

The images taken by means of optical microscopy along with the microstructure of the samples were illustrated in Fig. 3 and Fig. 4. The micrographs were captured in the central area of the wire cross-sections to examine the grain structure produced under different conditions. The recrystallization temperature of aluminum alloy was about 220 °C, and the temperature in heat affected zone (HAZ) in the FSE process could be higher than the recrystallization temperature, as confirmed by ZHANG et al [5]. The microstructure of the S355-F48.1 specimen with refined and deformed grains due to the combined heating and stirring effects during FSE, resulting in the dynamic recrystallization and deformation of original grains, was shown in Fig. 3. As can be seen, the grain size of the FSE sample decreased compared with that of the base metal. This could be accredited to the recrystallization occurred by the large heat input [17] and the severe plastic deformation [18].

Fig. 3 Microstructures of base metal (a) and FSE sample (S355-F48.1) (b)

Fig. 4 Optical micrographs of different samples

Two main factors were involved in determining grain size during the given process: (1) dynamic recrystallization phenomenon that caused the rearrangement of the grains and decreased the grain size and (2) heat imposed to material that led to annealing it and increasing the thermo-mechanically affected zone (TMAZ), known as the transition zone characterized by lack of recrystallization. The temperature also increased as the rotational speed was enhanced, and the generated high temperature caused annealing of the material and subsequently halted the dynamic recrystallization phenomenon. Therefore, as displayed in Fig. 4, the grain size increased. According to the optical micrographs and the use of the mean-linear intercept method, the grain size was calculated for each sample as presented in Table 2. The grain size also increased following the rise of rotational speed from 180 to 500 r/min, while the force was constant.

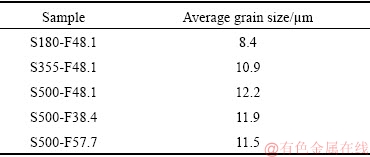

Table 2 Grain sizes of samples

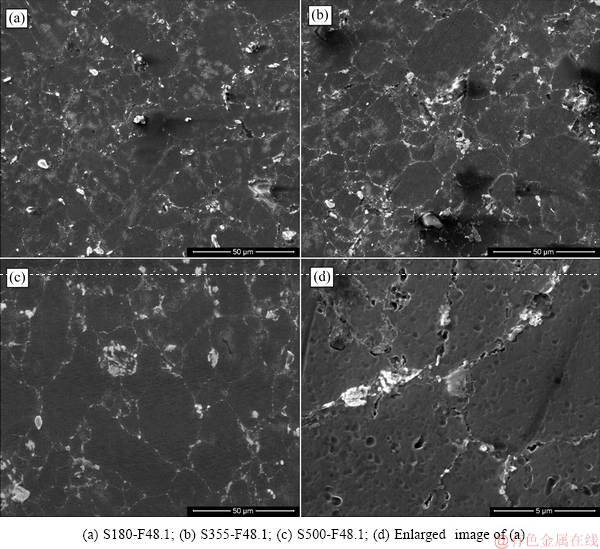

The SEM images of the specimens produced under different conditions were demonstrated in Fig. 5. Due to the low rotational speed, the process temperature was not high enough to complete the sintering, so the atoms could not move easily and migrate quickly along the particle surfaces and also atomic diffusion did not take place, which resulted in the formation of many cavities inside the sample. As clearly seen in Fig. 5(d), the impurities in the material were segregated into grain boundaries and then into cavities. The segregated impurities at the grain boundaries could reduce their energy and postpone the growth of grain size. It could be assumed as another reason for lower grain size in specimen S180-F48.1. The non-uniform distribution of inhibiting factors of grain growth such as porosity, impurities in the material structure, or even type of grain boundary structure, could make it possible that, in areas where these inhibitors did not exist, the grain size increased, due to the high motive force and excessive mobility of the grain boundary. Raising rotational speed could also increase the temperature and make sintering easier and it could consequently reduce the amount of cavity defects and impurities. Changing the rotational speed and the extrusion force, the amount of adhesion and sintering between the aluminum particles could alter and internal defects of the wire could be decreased through optimizing these parameters.

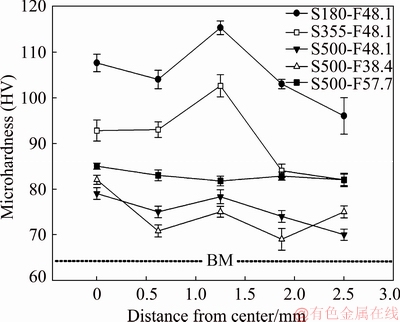

3.2 Hardness and compression test

The average hardness of the samples in terms of their distance from the center of the transverse cross-section of the wire was shown in Fig. 6. For the annealing sample, the average hardness value was approximately HV 68. The microhardness value of the BM was also reported to be lower than that of the extruded samples. The drastic increase of the micro- hardness was a result of recrystallized fine grains during the FSE process. It should be noted that a material with fine grains is usually harder and stronger than that with coarse ones, because a fine-grained structure has a larger total area of grain boundaries to curb the dislocation motion. Additionally, AA7022 alloy strongly and naturally ages and it can be the reason for part of an increase in hardness of material after the given process.

Fig. 5 SEM images of samples fabricated under different conditions

Fig. 6 Average microhardness of different samples

Age-hardening refers to a technical phenomenon which is normally a result of precipitation. Due to the formation of the precipitates over time, the mechanical properties are changed. Aging that occurs at room temperature is known as natural aging and natural age hardening is likely to occur for samples after extrusion process is fulfilled in the long term [19]. It was observed in the present study that the microhardness presented an uneven distribution. This variation of hardness could be caused by the difference in the amount of plastic deformation in the center, the middle region, and the outer surface of the extruded wires. The amount of plastic deformation also increased radially towards the center. Therefore, it was expected to detect an increasing trend of microhardness through the radius for each specimen.

As seen in the results, hardness values fell as the rotational speed increased, and the sample produced at higher rotational speed had lower hardness value in all parts of the cross-section. The reason is that temperature increases by the enhancement of the rotational speed and the grain size grows up and hardness values scale down with the increment of grain sizes. The higher extrusion force can also cause the wire cross-section to be more homogenous, and also hardness values to be steadier in different parts of the cross-section of the wire. In Fig. 6, the error bars were representative of one standard deviation. With one exception, the standard deviations were very small. According to the error bars, data scattering was high at low extrusion forces, which showed that the sample was less homogeneous than that extruded at high extrusion forces.

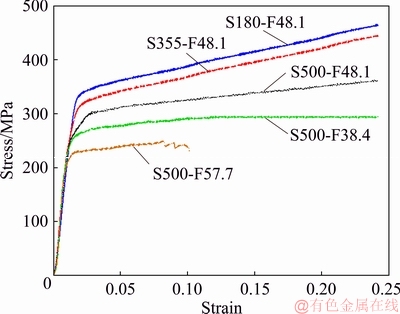

The stress-strain diagram for the samples produced under different FSE conditions was illustrated in Fig. 7. The compression test results were also considered to be positive to facilitate the investigation. For the BM (annealing sample), the yield strength value was 230 MPa. It is remarkable that the strength of all the extruded wires, excluding S500-F57.7, exceeded that of the BM. As can be seen in Fig. 7, the yield strength decreased as the rotational speed increased. The reason for the reduction in yield strength was a growth in the grain size following an increase in rotational speed and temperature which could be seen in microstructure images of the samples. Specimen S180-F48.1 showed the enhanced mechanical properties in both hardness and mechanical strength, which was primarily due to its more refined grain structure compared with other specimens.

Fig. 7 Stress-strain diagram of extruded samples

In addition, impurities at grain boundaries, as observed in Fig. 5 in the specimens, could change the mechanical properties of the metals. The mobility of dislocations also diminished with the accumulation of dislocations behind obstacles such as impurities and grain boundaries; as a result, the yield strength of the material increased. The yield strength was also dependent on extrusion force in addition to the rotational speed, and increasing the extrusion force to a certain level caused a rise in the yield stress of the material. Sample S500-F57.7, as expected because of production under high extrusion force conditions, was distorted and broke down at low strains. During the compression test, cracks also formed in the samples at an angle of 45° and finally the samples failed. Furthermore, buckling defect occurred due to lack of alignment in some samples, which reduced the axial compressive strength.

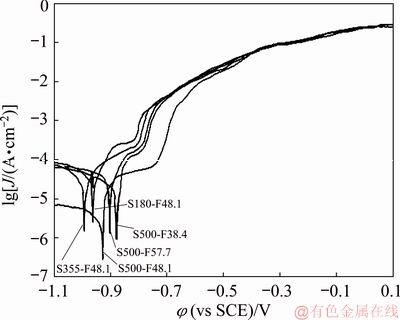

3.3 Corrosion analysis

Pitting is by far known as the most common type of corrosion for aluminum alloy. It occurs only in the presence of an electrolyte (either water or moisture) containing dissolved salts, usually chlorides. The corrosion generally shows itself as extremely small pits that reach the maximum penetration of a minor fraction of the thickness of the metal in the open air. As well, penetration may be greater in water and soil. Upon the contact of the aluminum alloy with an aquatic electrolyte, an aluminum hydroxide layer is formed. If Cl- aggressive ions are present in the aquatic electrolyte, they will attack this layer, causing the passive layer to dissolve. The potentiodynamic polarization diagrams were thus plotted to examine the effects of the FSE treatment on the corrosion properties of aluminum. The polarization diagrams plotted for the samples treated in the voltage range of 100-1100 mV were shown in Fig. 8. The general patterns of these diagrams were almost similar for all the samples.

Fig. 8 Potentiodynamic polarization curves for samples treated in voltage range of 100-1100 mV

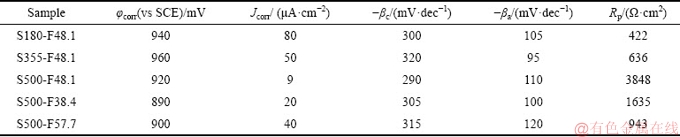

The corrosion current density was calculated for different cases via the linear Tafel extrapolation method. Accordingly, the corrosion current density, corrosion potential information, anodic and cathodic Tafel slops, as well as polarization resistance for the treated samples were given in Table 3. The former represents the required information related to the kinetics and corrosion rate, and the latter refers to the thermodynamic characteristics of the samples. The polarization resistance (Rp) of the samples could be also extracted from the Stern-Geary equation and using φ-lg J potentiodynamic curves:

(1)

(1)

where Jcorr is corrosion current density, βa and βc are anodic and cathodic Tafel slops, respectively. High Rp of a metal implies high corrosion resistance and low Rp denotes low corrosion resistance.

Increasing die rotation rate also reduced corrosion current density and augmented polarization resistance. Based on Fig. 5 and Table 2, a rising trend in die rotation rate led to a corresponding increase in temperature, which in turn caused the grains to grow. The given growth also made the grain boundaries shrink, thereby the corrosion resistance of the samples increased.

A growth at the grain boundaries resulted in a corresponding increase in the number of corrosion initiation locations, which in turn increased corrosion rate, but reduced corrosion resistance. Moreover, increasing die rotation rate at negative potentials (the cathodic branch) caused a decrease in the cathodic current density, which was equivalent to a reduction in the corrosion rate of the samples. Increasing the potential towards positive values also led to the formation of the passive aluminum hydroxide layer which resulted in decreasing active dissolving of the samples. Further increase of the potential beyond these positive values also resulted in a rapid rise in the current density which was due to the dissolving of the passive layer on the sample surface. Increasing die rotation rate also augmented the current density in the pitting range, indicating that resistance against pitting corrosion decreased.

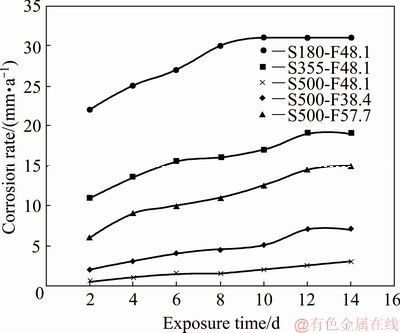

For more overview of the corrosion properties, the samples were tested for gravimetric measurement. The results of the gravimetric measurements, performed during immersion in 3.5 wt.% NaCl for 2-14 d at 296 K, were illustrated in Fig. 9. Corrosion rate values were calculated using mass loss information of the samples. The average corrosion rate (vCR) could be calculated by the following equation based on the ASTM G31 standard:

(2)

(2)

where t was time of exposure in h, m referred to mass loss in g, and A and D were areas of samples in cm2 and density of samples in g/cm3, respectively.

Table 3 Electrochemical parameters extracted from potentiodynamic curves and polarization resistance calculated using Eq. (1)

All specimens exhibited an increase in corrosion rate until 10 d of immersion. By increasing the immersion time to more than 12 d, the corrosion rate reached a constant value in each sample. With further increase in the immersion time, the corrosion rate remained stable due to the fact that the electrochemical conditions became fixed after 12 d. The lowest corrosion rate, as shown in Fig. 9, occurred in sample S500-F48.1. According to Table 3, the polarization resistance of sample S500-F48.1 was 3848 Ω·cm2, which had the highest value compared with other specimens. It should be noted that corrosion resistance increased and corrosion rate decreased, whatever polarization resistance was higher. The maximum corrosion rate, according to Fig. 9, was for sample S180-F48.1. This sample, as presented in Table 3, had the lowest polarization resistance (422 Ω·cm2). Furthermore, other samples followed this pattern. Hence, it could be concluded that the results of the gravimetric measurements confirmed those of the Tafel polarization tests.

Fig. 9 Variation of corrosion rate versus exposure time of samples at 296 K (unit of corrosion rate “mm/a” stands for mm per year)

4 Conclusions

(1) Defect-free aluminum alloy wires can be fabricated from AA7022 aluminum alloy chips via FSE method. The variations of rotational speed and extrusion force also lead to changes in surface quality of samples.

(2) Microstructure in the FSE samples mainly consists of fine recrystallized grains and the grain size grows up following excessive rise in rotational speed.

(3) Hardness and yield strength of samples are reduced as the rotational speed increases. As well, higher extrusion force causes hardness values to be steadier in different parts of the wire cross-section.

(4) The corrosion test showed that increasing die rotation rate could augment corrosion current density and reduce corrosion resistance.

(5) Increasing die rotation rate leads to a reduction in resistance against pitting corrosion.

(6) The results of Tafel polarization tests are in agreement with those of the gravimetric measurements.

References

[1] THOMAS W M, NICHOLAS E D, JONES S B. Friction extrusion metal working: US patent, 5262123 [P]. 1993-11-16.

[2] GRONOSTAJSKI J, MATUSZAK A. The recycling of metals by plastic deformation: An example of recycling of aluminum and its alloy chips [J]. Journal of Materials Processing Technology, 1999, 92: 35-41.

[3] TANG W, REYNOLDS A. Production of wire via friction extrusion of aluminum alloy machining chips [J]. Journal of Materials Processing Technology, 2010, 210: 2231-2237.

[4] ZHANG H, ZHAO X, DENG X, SUTTON M A, REYNOLDS A, MCNEILL S R. Investigation of material flow during friction extrusion process [J]. International Journal of Mechanical Sciences, 2014, 85: 130-141.

[5] ZHANG H, LI X, TANG W, DENG X, REYNOLDS A, SUTTON M A. Heat transfer modeling of the friction extrusion process [J]. Journal of Materials Processing Technology, 2015, 221: 21-30.

[6] KHORRAMI M S, MOVAHEDI M. Microstructure evolutions and mechanical properties of tubular aluminum produced by friction stir back extrusion [J]. Materials and Design, 2015, 65: 74-79.

[7] TAHMASBI K, MAHMOODI M. Evaluation of microstructure and mechanical properties of aluminum AA7022 produced by friction stir extrusion [J]. Journal of Manufacturing Processes, 2018, 32: 151-159.

[8] SHARIFZADEH M, ANSARI M A, NARVAN M, BEHNAGH R A, ARAEE A, BESHARATI M K. Evaluation of wear and corrosion resistance of pure Mg wire produced by friction stir extrusion [J]. Transactions of Nonferrous Metals Society of China, 2015, 25: 1847-1855.

[9] NEJADSEY O, SHOKUFAR A, DABIRI A, AZIMI A. Combining equal-channel angular pressing and heat treatment to obtain enhanced corrosion resistance in 6061 aluminum alloy [J]. Journal of Alloys and Compounds, 2015, 648: 912-918.

[10] SATTARI B, SHAMANIAN M, ASHRA A, SALEHI M, SALIMIJAZI F. Effect of number of passes on the corrosion behavior of Fe/Al surface composites produced by plasma spraying and friction stir processing [J]. Journal of Materials Processing Technology, 2017, 250: 35-44.

[11] RAO A G, KATKAR V A, GUNASEKARAN G, DESHMUKH V P, PRABHU N, KASHYAP B P. Effect of multipass friction stir processing on corrosion resistance of hypereutectic Al-30Si alloy [J]. Corrosion Science, 2014, 83: 198-208.

[12] DARMIANI E, DANAEE I, GOLZAR M A, TOROGHINEJAD M R. Corrosion investigation of Al-SiC nano-composite fabricated by accumulative roll bonding (ARB) process [J]. Journal of Alloys and Compounds, 2013, 552: 31-39.

[13] NIE M, TING C, LANGDON T G. The corrosion behaviour of commercial purity titanium processed by high-pressure torsion [J]. Journal of Materials Science, 2014, 49: 2824-2831.

[14] ZHENG Z J, GAO Y, GUI Y, ZHU M. Corrosion behaviour of nanocrystalline 304 stainless steel prepared by equal channel angular pressing [J]. Corrosion Science, 2012, 54: 60-67.

[15] JIANG J, MA A, SONG D. Anticorrosion behavior of ultrafine- grained Al-26wt.%Si alloy fabricated by ECAP [J]. Journal of Materials Science, 2012, 47: 7744-7750.

[16] IBRAHIM M, SADAWY M M. Influence of ECAP as grain refinement technique on microstructure evolution, mechanical properties and corrosion behavior of pure aluminum [J]. Transactions of Nonferrous Metals Society of China, 2015, 25: 3865-3876.

[17] LI W, NIU P L, YAN S R, PATEL V, WEN Q. Improving microstructural and tensile properties of AZ31B magnesium alloy joints by stationary shoulder friction stir welding [J]. Journal of Manufacturing Processes, 2019, 37: 159-167.

[18] CABALLERO A O, RUANO O A, RAUCH E F, CARRENO F. Severe friction stir processing of an Al-Zn-Mg-Cu alloy: Misorientation and its influence on superplasticity [J]. Materials and Design, 2017, 137: 128-139.

[19] CALLISTER W D, RETHWISCH D G. Fundamentals of materials science and engineering: An integrated approach [M]. New Jersey: John Wiley & Sons Inc., 2012.

Kamin TAHMASBI1, Masoud MAHMOODI1, Hossein TAVAKOLI2

1. Department of Mechanical Engineering, Semnan University, Semnan 3513119111,Iran;

2. Faculty of Materials & Metallurgical Engineering, Semnan University, Semnan 3513119111,Iran

摘 要:搅拌摩擦挤压(FSE)是一种新型制造技术,它使得通过金属片或实心坯的固结和挤压直接生产线材成为可能。本文作者采用搅拌摩擦挤压法将AA7022铝合金切屑制备成线材,研究基材和挤压后样品的显微组织和力学性能。用动电位极化曲线法测试样品的耐腐蚀性能。结果表明,在较高转速下制备的试样其表面质量较好。随着转速的增加,样品的加工温度升高,晶粒尺寸增大,而力学性能下降。使用FSE可使晶粒细化、晶界的体积分数提高以及使影响合金耐腐蚀性能的析出相进行再分布。此外,腐蚀试验结果表明,采用FSE法制备的试样具有足够的耐腐蚀性能,但在较高模具转速下制备的样品其腐蚀电流密度增加,耐腐蚀性能下降。

关键词:搅拌摩擦挤压;铝合金线材;晶粒尺寸;硬度;耐腐蚀性能

(Edited by Wei-ping CHEN)

Corresponding author: Masoud MAHMOODI; E-mail: mahmoodi@semnan.ac.ir

DOI: 10.1016/S1003-6326(19)65067-3