DOI: 10.11817/j.issn.1672-7207.2019.04.011

海底天然气水合物水力提升系统参数和提升性能作用规律

徐海良1, 2,胡文港1,杨放琼1,2

(1. 中南大学 机电工程学院,湖南 长沙,410083;

2. 中南大学 高性能复杂制造复杂制造国家重点实验室,湖南 长沙,410083)

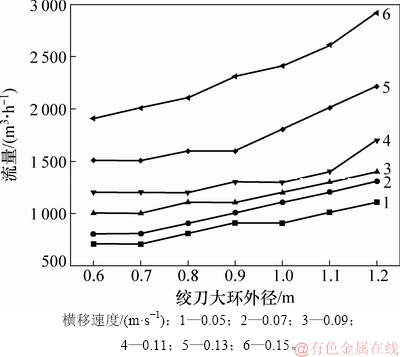

摘要:运用MATLAB软件分析天然气水合物水力提升系统水力损失、矿浆泵扬程与系统中固相体积分数、系统流量、颗粒粒径、管道直径之间的理论关系;建立绞刀头工作三维流场模型,运用计算流体力学理论和Fluent仿真软件对绞刀头工作区域内固液两相流场进行数值模拟,比较不同工作参数下流场出口和入口固相质量的比值达到95%时所需的绞吸流量。研究结果表明:当绞吸流量为1 000~1 300 m3/h时,切削头绞吸效率最高,在该区间内,绞刀大环外径的分布范围为0.9~1.0 m,绞刀横移速度分布范围为0.07~0.11 m/s。

关键词:天然气水合物;绞吸式;切削头;破碎量;模拟仿真

中图分类号:TH231 文献标志码:A 文章编号:1672-7207(2019)04-0837-08

Law of system parameters and lifting performance in marine gas hydrate hydraulic lifting system

XU Hailaing1, 2, HU Wengang1, YANG Fangqiong1, 2

(1. School of Mechanical and Electrical Engineering, Central South University, Changsha 410083, China;

2. State Key Laboratory of High Performance Complex Manufacturing,

Central South University, Changsha 410083, China)

Abstract: The MATLAB software was used to analyze the theory relationship between the hydraulic loss, the lift of the slurry pump of the hydraulic lifting system for natural gas hydrate and the transmission parameters of the system, such as solid-phase volume, concentration system flow, particle size and pipe diameter. A three-dimensional flow field model of cutting head was established, the computational fluid dynamics theory and Fluent simulation software were employed to simulate the solid-liquid two-phase flow field in the working area of the cutting head, and the cutter-suction flow which made the ratio of solid phase mass between outlet and inlet is 95% with different work parameters was compared. The results show that the cutting head has the highest efficiency when the suction flow rate is 1 000-1 300 m3/h. In this interval, the distribution range of reamer big ring outside diameter is 0.9-1.0 m, and the distribution range of traverse speed for cutter is 0.07-0.11 m/s.

Key words: gas hydrates; cutter suction; cutting head; crushing; analog simulation

天然气水合物分布广泛,在地球上储量巨大,同时,天然气的燃烧不会像化石燃料一样产生对环境有害的气体,因此,天然气水合物被认为是最具潜力的新型能源,对海底天然气水合物进行开发研究极具应用价值[1-3]。根据海底天然气水合物的特性,研究人员提出了多种开采方式,总体分为3大类[4-5]:第1类是通过在海底改变天然气水合物赋存条件加速天然气水合物分解,然后将天然气收集至海面,其方法包括降压开采法以及热激发开采法;第2类是通过化学反应在海底分解出天然气,其方法包括化学试剂注入法以及CO2置换法[6-7];第3类是将海底固态天然气水合物提升至海面,再进行分解的固态开采法。基于固态开采理论的海底天然气水合物绞吸式开采方案工作原理是:通过采矿车上的切削头将海底天然气水合物破碎成颗粒,在泥浆泵的抽吸作用下,颗粒状的天然气水合物被吸入管道,经过软管进入垂直输送硬管,在矿浆泵的作用下提升至海面进行分解,剩余的废物通过尾矿管排至海底[8-10]。天然气水合物绞吸式开采方案的核心问题之一是固相颗粒通过管道的水力输送问题。CHRISTIAN等[11]研究了长管道输送铁精矿时输送参数对能量利用率的影响;VAN WIJK等[12]使用流化理论分析了垂直水力输送系统稳定性,通过实验证明了该理论的预测结果在一定条件下符合实际情况;邱灏等[13]通过大量输送粗颗粒的实验结果,给出了粗颗粒在管道输送中临界流速的计算式;黄中华等[14]采用理论分析和数值计算相结合的方法分析了多金属硫化物颗粒垂直管道水力提升规律。这些研究都是针对管道内浆体流场,关于浆体在管道入口处的流场研究很少。为此,本文作者首先运用MATLAB软件分析输送系统设计参数与流体初始特性参数之间的理论关系。为了保证切削的天然气水合物颗粒被高效率的运输到水面,以绞刀头工作区域和管道入口处流场为研究对象,运用fluent软件仿真天然气水合物破碎量与输送系统流量之间的合理匹配关系,得出管道入口处流体初始特性参数和输送系统设计参数的预测和确定方法,为天然气水合物管道输送规律以及系统设计理论研究提供合理的流体初始特性参数和系统设计参数。

1 仿真模型建立

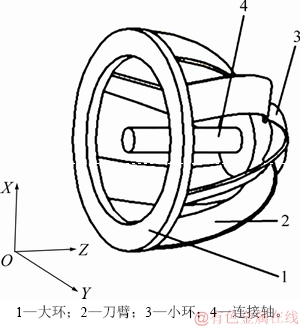

使用Pro/E三维建模软件建立挖掘天然气水合物绞刀简化三维模型,如图1所示。其中,刀臂外轮廓曲线方程为[15]

(1)

(1)

刀臂内轮廓曲线为

(2)

(2)

绞刀大环外径的研究范围为0.6~1.2 m,其他参数根据绞刀大环外径进行调整。

图1 绞刀简化模型

Fig. 1 Simplified model of cutter

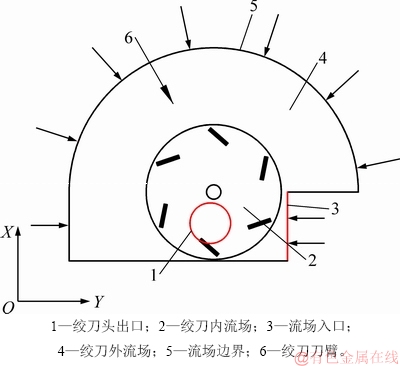

图2所示为绞刀工作数值模拟仿真分析的简化模型,其中绞刀内流场2为旋转动网格区域,绞刀外流场4为静区域。

图2 绞刀工作数值模拟模型

Fig. 2 Model of numerical simulation for cutter

调整绞刀工作参数可以在切削过程中直接改变管道吸口处初始流体特性参数,绞刀破碎后的天然气水合物颗粒要通过管道输送至海面,因此,管道入口处流体特性参数是决定产量的关键因素。

输送管道入口处流体特性参数中,天然气水合物密度、海水密度和管道管径为已知参数,流体密度、天然气水合物沉降速度和流体临界流速可通过其他参数确定,而流量、流速、固相体积分数、颗粒粒径这4个参数在输送过程中可根据要求调节。流体初始特性参数确定后,水力输送系统工作参数如扬程、功率、水力损失由入口处的流体特性参数决定。采用单因素变量法,分别研究固相体积分数、流量、颗粒粒径以及管道直径与系统工作参数之间的关系。

2 水力提升系统参数分析

2.1 矿浆泵扬程

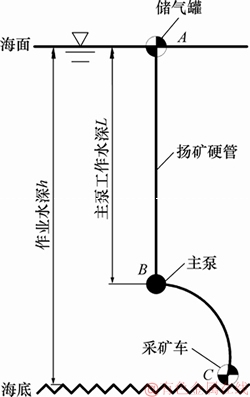

图3所示为深海采矿水力输送模型。从图3可以看出:将固体颗粒从硬管入口处(图3中B点)提升至海面采矿平台(图3中A点),此过程消耗的能量全部由矿浆泵提供。根据水力输送理论,此过程所需要的矿浆泵最小扬程可由以下公式计算[16]:

(3)

(3)

式中:Hmin为矿浆泵所需最小扬程;ρω为淡水密度;g为重力加速度;ρl为海水密度;L为主泵工作水深;ρm为混合浆体密度;△pm为压力损失;uout为管道出口混合流体流速;pout为管道出口压力。

由式(3)可得所需要的矿浆泵最小扬程Hmin计算式为

图3 提升系统简化模型

Fig. 3 Simplified model of hydraulic lifting system

(4)

(4)

式中: 为管道出口处流体的压力能;

为管道出口处流体的压力能; 为混合流体势能;

为混合流体势能; 为海水势能;

为海水势能; 为管道出口处固液两相的动能;

为管道出口处固液两相的动能; 为固液两相流在管道中的水力损失。

为固液两相流在管道中的水力损失。

式(4)中,扬矿硬管出口压力为分解仓中的压力,近似取值为0 Pa;在中继仓水深一定时,海水势能为定值。由于扬矿硬管内混合流体流速一般不会太大,扬矿硬管出口混合流体的动能所需的扬程在5 m以下,对矿浆泵扬程的影响较小。因此,决定矿浆泵扬程的变量是混合流体势能以及固液两相流在提升过程中的水力损失。

2.2 压力损失

在水力提升过程中,由于各种原因存在压力损失,总体而言分为3种:摩擦阻力损失、碰撞阻力损失以及沉降阻力损失。摩擦阻力损失是指天然气水合物颗粒在水力输送的过程中与绞刀、管壁等之间的摩擦造成的能量损失,摩擦阻力损失的影响因素主要有颗粒密度、固相体积分数以及浆体流速等;碰撞阻力损失是指天然气水合物颗粒之间以及天然气水合物颗粒和绞刀、管道的碰撞造成的能量损失,因颗粒的碰撞过程复杂、内部机理尚未明确,一般难以计算,碰撞阻力损失与固体颗粒速度及大小、形状相关;沉降阻力损失是由固体颗粒在液体中的自由沉降所致,为了维持固体颗粒在液体中悬浮所需的能量,沉降速度越大,沉降阻力损失越大。水力提升过程中的压力损失难以计算,通常根据实验以及经验总结出来的计算方法进行计算。据Englemann理论,可以得到压力损失的微分dpm计算方法[17]:

(5)

(5)

式中:φv为固相体积分数;λl为提升管道对海水的阻力系数;λs为提升管道对固体颗粒的阻力系数;ds为扬矿硬管的微分长度;ul为海水平均流速;us为矿石颗粒平均速度;Di为提升管道直径。

(6)

(6)

(7)

(7)

式中:△为管道内壁粗糙度,在垂直水力提升系统中一般取0.1 mm; 为固体颗粒的质量流速,

为固体颗粒的质量流速, =Qsρs;Qs为固体颗粒流量;

=Qsρs;Qs为固体颗粒流量; 为海水质量流速,

为海水质量流速, =Qlρl;Ql为海水流量。由式(5)可知固液两相流在管道中的压力损失△pm为

=Qlρl;Ql为海水流量。由式(5)可知固液两相流在管道中的压力损失△pm为

(8)

(8)

式中:L为中间仓水深,本文研究中中继仓水深为3 km。

式(6)中,影响海水阻力系数的因素有管道直径和管壁粗糙度。由于式(6)中存在对数,管径和粗糙度对海水阻力系数的影响有限。式(7)中,矿石颗粒的阻力系数与颗粒直径、管道直径、管道内流速、固液两相密度有关。式(8)中,由于管道中的固相体积分数一般较小,海水所产生的压力损失会比固相颗粒产生的压力损失大1~2个数量级,固液两相之间的滑移是产生压力损失的主要因素。

2.3 矿浆泵轴功率

为了将混合浆体从海底提升至海面,矿浆泵所需最小轴功率越小,说明所消耗能量越少,水力提升系统工作效率越高。矿浆泵轴功率可由以下公式计算[18]:

(9)

(9)

式中:μ为矿浆泵的效率,μ=0.80~0.85。

2.4 天然气水合物绞吸式开采系统参数

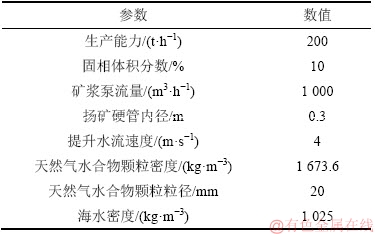

我国1个中小型天然气企业的年产气量为0.1~1.0亿m3[19]。为使本文的中试开采系统具备一定的商业价值,其产气量应达到小型天然气企业的目标,取产气量为0.5亿m3,按照1年中规定工作时间的80%计算,所需要的流量约为1 350 m3/h,固相体积分数约为10%。基于水力输送理论,根据天然气水合物开采的特殊条件,结合国内外水力提升海试经验[20-23],设计得到天然气水合物绞吸式开采水力提升系统参数。要使水力提升系统达到一定经济效益,其输送管径一般超过0.3 m,扬矿硬管内固相体积分数为8%~12%,同时,扬矿硬管内的水流流速应为4 m/s左右。而系统对颗粒粒径的要求较低,设计得到天然气水合物绞吸式开采系统设计参数见表1。

2.5 边界条件和求解方法

1) 进口条件:定义进口边界为速度入口,设定进口速度和固相体积分数。固相速度不同表示绞刀横移速度不同,速度方向垂直入口面。定义湍流强度和水力直径。

2) 出口条件:选用压力出口,定义出口压力、湍流强度和水力直径。

3) 壁面:采用无滑移固定壁面边界。

4) 动网格:定义绞刀旋转速度,旋转轴为绞刀轴线。

5) 数值解法:采用瞬态数值计算,方程离散采用一阶迎风差分格式,方程求解采用SIMPLE算法,求解精度设置为10-3。

表1 天然气水合物绞吸式开采系统参数

Table 1 Parameters of natural gas hydrate system

3 仿真结果分析

3.1 扬程和水力损失变化规律

使用Matlab软件编程,以表1中天然气水合物绞吸式开采系统参数为依据,通过改变某个参数而其他参数保持不变,仿真不同参数变化对水力提升系统工作参数的影响规律。

3.1.1 固相体积分数对水力损失和扬程的影响

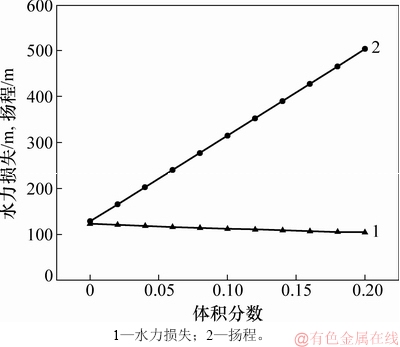

使用Matlab软件,在其他参数不变时计算固相体积分数对系统水力损失和矿浆泵所需扬程的影响,结果如图4所示。从图4可见:流体固相体积分数增加,水力损失几乎保持不变,而矿浆泵所需扬程迅速增加。

当固相体积分数低于20%时,固相体积分数从0增加到20%,系统水力损失从123 m下降至105 m;所需扬程从129 m增至502 m,增加373 m,说明当固相体积分数低于20%时,固相体积分数增加所引起的水力损失以及流体动能所消耗的扬程并不大。从海底提升至海面流体的势能是扬程增加的主要因素;矿浆泵轴功率和流量以及扬程成正比,在流量一定时,固相体积分数越大,所需扬程越大,因此,所消耗的轴功率也越大。为避免功耗过大,选择固相体积分数10%作为本文研究对象。

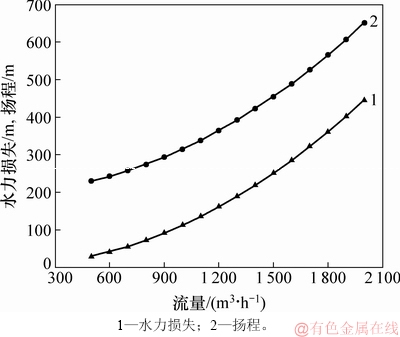

3.1.2 系统流量对水力损失和扬程的影响

使用Matlab软件计算系统流量改变对所需扬程和水力损失的影响,结果见图5。从图5可以看出:随着系统流量增加,水力损失和矿浆泵所需扬程都相应增加;当流量从500 m3/h增加到2 000 m3/h时,水力损失从29 m增加到446 m,水力损失增加417 m;矿浆泵所需扬程从230 m增加到650 m,扬程增加420 m,说明流量增加会导致水力损失较大,此时,水力损失是导致系统扬程增加的主要因素。矿浆泵轴功率和流量以及扬程成正比,随着流量增加,扬程也增加,因此,所消耗的轴功率将会更多。

图4 固相体积分数对水力损失和扬程的影响

Fig. 4 Influence of volume concentration on hydraulic loss and lift

图5 流量对水力损失和扬程的影响

Fig. 5 Influence of flow rate on hydraulic loss and lift

当工作流量为1 000 m3/h,固相体积分数为10%时,系统扬程为310 m。若要增加天然气水合物开采产量,则需要增加管道内固相体积分数或者增加系统流量,通过增加固相体积分数,产量每增加1%,扬程增加1.92 m,而通过增加流量,产量每增加1%,扬程增加3.33 m;固相体积分数增加对系统扬程的影响小于流量增加产生的影响,而流量的增加会直接增加矿浆泵轴功率,也会导致管道内流速增加。因此,若要提高系统天然气产量,增加扬矿硬管的固相体积分数比增加系统流量有效、更经济。初步选择研究工作流量为1 000 m3/h。

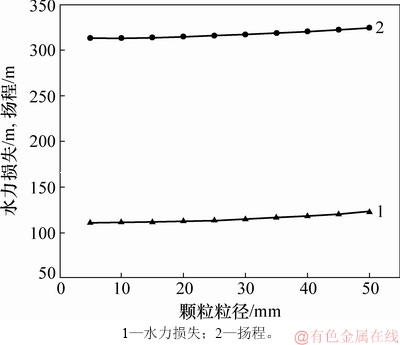

3.1.3 颗粒粒径对水力损失和扬程的影响

在Matlab软件中,改变颗粒粒径,经计算得到对应水力损失及扬程,结果如图6所示。从图6可见:颗粒粒径对水力损失以及扬程的影响均较小;当颗粒粒径从5 mm增加到50mm时,系统扬程从313 m增加到325 m,而水力损失从111 m增加到123 m;过大的颗粒粒径容易导致矿浆泵流道以及管道堵塞,但对绞刀刀具以及工作条件的要求较低;较小的颗粒粒径虽然不易引起管道和矿浆泵流道堵塞,但对绞刀刀具以及工作条件要求高,因此,初步选择颗粒粒径为20 mm。

图6 颗粒粒径对水力损失和扬程的影响

Fig. 6 Influence of particle size on hydraulic loss and lift

3.1.4 管道直径对水力损失和扬程的影响

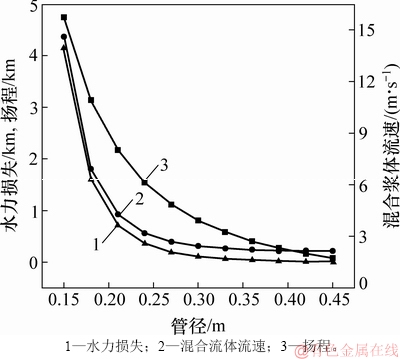

管道管径增加不仅会使矿石颗粒阻力系数λs减小,还会使管道内流体速度减小,从而减小水力损失,同时也会减少流体提升过程中的动能。选择浆体流量为1 000 m3/h,颗粒粒径为20 mm,固相体积分数为10%。在Matlab软件中计算不同管径下的水力损失、扬程以及管道内流体平均流速,结果如图7所示。从图7可见:在流量为1 000 m3/h的工况下,当管径大于0.25 m时,不同管径下的水力损失以及扬程都在500 m以下;而当管径低于0.2 m时,水力损失和扬程都急剧上升,此时,管道内流体平均流速为8 m/s。管道内流速的增加是产生水力损失的主要原因,因此,管道管径应保持在0.3~0.4 m。

图7 管道直径对水力损失和扬程的影响

Fig. 7 Influence of pipe diameter on hydraulic loss and lift

3.2 管道入口处流体特性参数匹配关系

天然气水合物经绞刀破碎后通过绞刀出口进入输送管道,定义绞吸效率为绞刀出口进入管道的颗粒质量与绞刀破碎的天然气水合物质量之比。天然气水合物破碎量由绞刀的横移速度以及有效切削面积决定,绞刀基本尺寸可由绞刀大环外径决定。为保证天然气水合物高效率运输,绞吸流量和破碎量之间存在匹配关系,即绞吸效率与绞刀横移速率、绞刀大环外径、绞吸流量有关。

通过对不同绞刀横移速度以及绞刀大环外径进行仿真模拟,研究当绞吸效率达到95%时所需最小矿浆泵流量,通过所需最小流量的变化分析绞刀横移速度以及绞刀大环外径与流量之间的匹配关系。根据前文计算分析结果,选择固相体积分数为10%、颗粒粒径为20 mm和管道直径为0.3 m。仿真计算绞刀横移速度分别为0.05,0.07,0.09,0.11,0.13和0.15 m/s时,绞吸效率达到95%时所需绞吸流量与绞刀大环外径之间的关系。

使用Fluent软件对绞刀头绞吸过程进行仿真分析,图8所示为不同天然气水合物破碎量下,绞吸效率达到95%时所需的流量。从图8可以看出:随着绞刀横移速度以及绞刀大环外径增加,所需的流量也增加;绞刀横移速度对流量的影响较大,当绞刀横移速度超过0.11 m/s时,增加绞刀横移速度,绞吸效率达到95%时所需的流量迅速增加,其所需矿浆泵流量均超过1 500 m3/h;而绞刀大环外径对流量的影响较小,在绞刀横移速度低于0.11 m/s时,绞刀大环外径变化时绞吸效率达到95%所需的流量均低于1 500 m3/h。研究表明,绞吸流量在1 000~1 300 m3/h时切削头绞吸效率最高,在工作过程中,应保证绞吸流量为1 000~1 300 m3/h,在此区域中,绞刀大环外径的分布范围为0.6~1.2 m,而绞刀横移速度的分布范围为0.07~0.11 m/s。

图8 不同绞刀尺寸以及横移速度下绞吸效率达到95%所需流量

Fig. 8 Required flow when cutter efficiency reaches 95% with different cutter sizes and traverse speeds

3.2.1 流量和绞刀几何参数的匹配关系

在保证切削头工作效率的同时,绞刀大环外径应尽可能大。从图8可以看出:当绞刀大环外径在0.9 m以下时,绞刀大环外径的增加对矿浆泵所需的最小流量影响较小;而当大环外径为0.9~1.2 m时,大环外径增加对矿浆泵所需流量的影响逐渐增加。绞刀尺寸在工作过程中无法调整,因此,为了保证在不同绞刀横移速度下所需流量能低于1 300 m3/h,同时又有较高的产量,绞刀大环外径应取为0.9~1.0 m。

3.2.2 流量和绞刀切削速度的匹配关系

绞刀几何尺寸决定有效切削面积。天然气水合物切削速度还与绞刀相对天然气水合物矿物层的速度有关,绞刀的横移速度越快,切削破碎量越大;而绞刀的横移速度同时会受到绞吸流量、颗粒粒径、绞吸效率、绞刀转速以及刀臂数量等因素的限制,本文只考虑绞刀横移速度对矿浆泵所需流量的影响。研究表明:绞刀大环外径在0.9~1.0 m时工作性能最佳;当流量为1 000~1 300 m3/h时,绞刀的横移速度应小于0.11 m/s。

4 结论

1) 在固相体积分数较低时,固相所引起的水力损失以及流体动能所消耗的扬程并不大,从海底提升至海面流体的势能是扬程增加的主要因素;流量增加会导致水力损失增加,水力损失增加导致系统扬程增加;颗粒粒径对水力损失以及扬程的影响均较小,颗粒粒径过大会堵塞管道,太小对绞刀要求较高,所以,颗粒粒径应为20 mm左右。

2) 当管径大于0.25 m时,不同管径下的水力损失以及扬程都在500 m以下;而当管径低于0.20 m时,水力损失和扬程都急剧上升,此时,管道内流体平均流速为8 m/s。管道内流速的增加是产生水力损失的主要原因。

3) 当工作流量为1 000 m3/h,固相体积分数为10%时,系统扬程为310 m;要增加系统产量,可通过增加固相体积分数实现;产量每增加1%,扬程增加1.92 m;通过增加流量,产量每增加1%,扬程增加3.33 m。而流量增加会直接导致矿浆泵轴功率增加,因此,要提高系统产量,增加固相体积分数比增加系统流量更有效、更经济。

4) 为保证在不同绞刀横移速度下所需流量低于 1 300 m3/h,同时又有较高产量,绞刀大环外径应取为0.9~1.0 m,绞刀的横移速度应小于0.11 m/s。

参考文献:

[1] RAJNAUTH J, BARRUFET M. Monetizing gas: focusing on developments in gas hydrate as a mode of transportation[J]. Energy Science and Technology, 2012, 4(2): 61-68.

[2] MOHEBBI V, BEHBAHANI R M. Experimental study on gashydrate formation from natural gas mixture[J]. Journal of Natural Gas Science & Engineering, 2014, 18: 47-52.

[3] MAKOGON Y F. Natural gas hydrates-a promising source ofenergy[J]. Journal of Natural Gas Science and Engineering, 2010, 2(1): 49-59.

[4] 思娜, 安雷, 邓辉, 等. 天然气水合物开采技术研究进展及思考[J]. 中国石油勘探, 2016, 21(5): 52-61.

SI Na, AN Lei, DENG Hui, et al. Discussion on natural gas hydrate production technologies[J]. China Petroleum Exploration, 2016, 21(5): 52-61.

[5] 吴传芝, 赵克斌, 孙长青, 等. 天然气水合物开采研究现状[J].地质科技情报, 2008, 27(1): 47-51.

WU Chuanzhi, ZHAO Kebin, SUN Changqing, et al. Currentresearch in natural gas hydrate production[J]. Geological Scienceand Technology Information, 2008, 27(1): 47-51.

[6] LEE S, LEE Y, LEE J, et al. Experimental verification of methane-carbon dioxide replacement in natural gas hydrates using a differential scanning calorimeter[J]. Environmental science & Technology, 2013, 47(22): 13184-13190.

[7] 徐纯刚, 李小森, 蔡晶, 等. 二氧化碳置换法模拟开采天然气水合物的研究进展[J]. 化工学报, 2013, 64(7): 2309-2315.

XU Chungang, LI Xiaosen, CAI Jin, et al. Advance onsimulation exploitation of natural gas hydrate by replacementwith CO2[J]. Journal of Chemical Industry and Engineering.2013, 64(7): 2309-2315.

[8] ZENG Yicong, XU Hailiang, WU Wanrong, et al. Research on mining method of submarine natural gas hydrates based on a double-channel lift pump[J]. Advanced Materials Research, 2012, 569: 509-516.

[9] LI Li, XU Hailiang, YANG Fangqiong. Three-phase flow of submarine gas hydrate pipe transport[J]. Journal of Central South University, 2015, 22(9): 3650-3656.

[10] 徐海良, 陈旺, 吴波, 等. 海底天然气水合物绞吸式开采切削头绞吸特性[J]. 四川大学学报(工程科学版), 2016, 48(6): 126-131.

XU Hailiang, CHEN Wang, WU Bo, et al. Characteristic of cutting head in marine gas hydrate by cutter suction exploitation[J]. Journal of Sichuan University (Engineering Science Edition), 2016, 48(6): 126-131.

[11] CHRISTIAN F I, SANTIAGO M S, ALDO T B. A cost perspective for long distance ore pipeline water and energy utilization. part II: effect of input parameter variability[J]. International Journal of Mineral Processing, 2013, 122: 54-58.

[12] VAN WIJK J M, TALMON A M, VAN RHEE C. Stability of vertical hydraulic transport processes for deep ocean mining: an experimental study[J]. Ocean Engineering, 2016, 125: 203-213.

[13] 邱灏, 曹斌, 夏建新. 粗颗粒物料管道水力输送不淤临界流速计算[J]. 水利水运工程学报, 2016(6): 103-108.

QIU Hao, CAO Bin, XIA Jianxin. Non-silting critical velocity calculation of coarse-grained materials in hydraulic pipeline[J]. Hydro-Science and Engineering, 2016(6): 103-108.

[14] 黄中华, 曹跃, 谢雅. 多金属硫化物颗粒水力提升性能仿真[J]. 机械设计与研究, 2015, 31(2): 85-88.

HUANG Zhonghua, CAO Yue, XIE Ya. Simulation of hydraulic lifting performance of polymetallic sulfide particles[J]. Machine Design and Research, 2015, 31(2): 85-88.

[15] 杨桢毅. 绞吸式挖泥船绞刀结构与性能优化研究[D]. 武汉: 武汉理工大学能源与动力工程学院, 2010: 18-23.

YANG Zhenyi. The research of structure and performance optimization of cutter on cutter-suction dredge[D]. Wuhan: Wuhan University of Technology. School of Energy and Power Engineering, 2010: 18-23.

[16] 杨放琼, 陈奇, 曾义聪, 等. 深海采矿矿浆泵的设计方法研究[J]. 合肥工业大学学报(自然科学版), 2014, 37(12): 1413-1418.

YANG Fangqiong, CHEN Qi, ZENG Yichong, et al. Rearch on design method of slurry pump for deep-sea mining[J]. Journal of Hefei University of Technology(Science and Technology), 2014, 37(12): 1413-1418.

[17] 杨康. 深海采矿提升管系统优化研究[D]. 上海: 上海交通大学船舶海洋与建筑工程学院, 2012: 12-18.

YANG Kang. Optimization study on pipeline of deep-sea mining system[D]. Shanghai: Shanghai Jiaotong University. School of Naval Architecture, Ocean and Civil Engineering, 2012: 12-18.

[18] 武伟, 刘少军, 李流军. 深海采矿升沉补偿系统海浪运动模拟平台及其运动控制[J]. 现代制造工程, 2009, 17(7): 10-14.

WU Wei, LIU Shaojun, LI Liujun. The single-freedom ship motion simulation platform and its control in heave compensation system for deep-sea mining[J]. Modern Manufacturing Engineering, 2009, 17(7): 10-14.

[19] 邹才能, 赵群, 陈建军, 等. 中国天然气发展态势及战略预判[J]. 天然气工业, 2018, 38(4): 1-11.

ZOU Caineng, ZHAO Qun, CHEN Jianjun, et al. Natural gas in China:development trend and strategic forecast[J]. Natural Gas Industry, 2018, 38(4): 1-11.

[20] 李艳, 贾广成, 刘少军. 考虑流固耦合的深海采矿长输流硬管力学行为[J]. 中南大学学报(自然科学版), 2016, 47(11): 3670-3676.

LI Yan, JIA Guangcheng, LIU Shaojun. Mechanical characteristics on long lifting pipeline in deep-ocean mining considering fluid-structure interaction[J]. Journal of Central South University (Science and Technology), 2016, 47(11): 3670-3676.

[21] XU Hailiang, ZHOU Gang, WU Bo, et al. Influence of wave and current on deep-sea mining transporting system[J]. Journal of Central South University, 2012, 19(1): 144-149.

[22] YOON C H, PARK J M, KANG J S, et al. Shallow lifting test for the development of deep ocean mineral resources in Korea[J]. Indian Journal of Medical Research, 2011, 72(3): 619-624.

[23] 徐海良, 胡文港, 杨放琼. 天然气水合物输送管道的压力损失规律[J]. 中南大学学报(自然科学版), 2019, 50(2): 304-310.

XU Hailiang, HU Wengang, YANG Fangqiong. Pressure loss of conveying pipeline of natural gas hydrate[J]. Journal of Central South University(Science and Technology), 2019, 50(2): 304-310.

(编辑 陈灿华)

收稿日期:2018-07-10;修回日期:2018-09-21

基金项目(Foundation item):国家自然科学基金资助项目(51775561);湖南省自然科学基金资助项目(2018JJ2522)(Project(51775561) supported by the National Natural Science Foundation of China; Project(2018JJ2522) supported by the National Science Foundation of Hunan Province)

通信作者:杨放琼,博士,教授,从事深海采矿研究;E-mail:376212096@qq.com