文章编号:1004-0609(2010)10-1907-06

一种新型可焊耐蚀6×××系铝合金材料

季 凯,祖国胤,姚广春

(东北大学 材料与冶金学院, 沈阳 110004)

摘 要:在商用6005A铝合金的基础上,设计开发一种新型高速列车用铝合金材料,并采用正交试验考察Mg、Mn、Cu和Cr元素含量对MIG焊后焊接接头强度的影响规律,分析合金添加元素改善材料耐蚀性的作用机理,确定优化的合金成分。结果表明:自制的6005A铝合金可与焊丝ER5356实现良好焊接,焊接热影响区内晶粒无过分长大现象,焊接接头抗拉强度可达237 MPa,为商用6005A铝合金接头强度的1.25倍。拉伸断口呈典型韧性断裂特征;合金元素的适量添加可有效提高合金的自腐蚀电位,显著改善耐大气等常规介质腐蚀的能力;研究确定的最佳6005A铝合金的化学成分(质量分数)为Mg 1.0%、Si 0.8%、Mn 0.70%、Cu 0.40%、Cr 0.20%、铝余量。

关键词:6005A铝合金;焊接性;正交试验;抗拉强度;自腐蚀电位

中图分类号:TG401 文献标志码:A

A novel welded and corrosion-resistant 6××× aluminum alloy

JI Kai, ZU Guo-yin, YAO Guang-chun

(School of Materials and Metallurgy, Northeastern University, Shenyang 110004, China)

Abstract: A new kind of aluminum alloy welded was prepared based on 6005A-T6 commercial aluminum alloys. Through the orthogonal test, the influences of alloy element Mg, Mn, Cu and Cr on the strength of welded joint were investigated and the corrosion resistance of alloying element was analyzed. The results show that the wire of ER5356 can achieve good connection with self-made 6005A-T6 aluminum alloys. The grain growth in heat affected zone (HAZ) is not obvious, the tensile strength of the welded joints reaches 237 MPa, which is 1.25 times of that of commercial 6005A alloy, and the fracture shows typical characteristics of fracture toughness. The addition elements improve the corrosion potential, it can significantly improve the resistance of atmospheric corrosion. The optimum compositions(mass fraction) for 6005A alloy are identified as Mg 1.0%, Si 0.8%, Mn 0.70%, Cu 0.40%, Cr 0.20% and balance Al.

Key words: 6005A aluminium alloy; weldability; orthogonal experiment; tensile strength; corrosion potential

当前,世界高速列车的发展方向为安全性、舒适性、减量化与节能减排。6000系铝合金由于具有优异的成型性能、适宜的强度水平和良好的焊接性,已成为一类重要的高速列车车体用材料。目前,我国高速列车常用的铝合金材料主要为6005A和7020两种铝材,相对应的列车最高时速为270 km/h。而据报道,德国IEC高速列车的选材标准有10余种[1],列车最高运营时速可达380 km/h。在现在常用的高速列车用铝合金材料中,多采用热处理强化铝合金作为承载构件,但由于焊后不能对构件进行整体热处理,焊接过程形成的软化区会导致接头强度降低。因此,开展可焊铝合金结构材料的研究应主要考虑基体与焊丝在焊接过程中的物理冶金行为对接头组织与性能的影响。目前,国内外研究者多从工艺因素和冶金因素两方面来探索兼具理想强度水平与良好耐蚀性能的新型高速列车用铝合金材料。工艺因素的研究主要集中在搅拌摩擦焊和激光复合焊等先进焊接技术对材料组织与性能的影响规律[2-4],冶金因素的研究则主要关注匹配焊丝的开发以及Sc和Zr等微量合金元素对成熟牌号铝合金性能的优化[5-6]。而旨在提高基体材料的强度与耐蚀性,进而实现高速列车重要结构件的整体性能升级的报道很少,这方面的研究无疑对形成具有我国自主知识产权的高速列车车体铝合金材料体系具有十分重要 意义。

本文作者根据欧洲《轨道车辆及其部件的焊接》EN15085—2系列标准对车体材料力学性能的要求[7],综合考虑材料使用过程中强度水平及耐腐蚀能力,在商用6005A铝合金的基础上进行合金成分的优化设计。采用正交试验分析合金成分Mg、Mn、Cu和Cr等对材料力学性能及抗腐蚀性能的影响规律,探讨其相关的作用机理,确定一种适于未来高速列车用可焊铝合金材料的合金成分。研究结果对开发高性能商用高速列车用车体材料具有一定的参考价值。

1 实验

1.1 正交试验方案

正交试验设计是研究多因素多水平的一种高效率、快速、经济的实验设计方法,并在合金成分设计中发挥着重要作用。本文作者在充分考虑主合金元素对6005A铝合金组织与性能影响作用的研究成果的基础上,借鉴相关铝合金化学成分正交试验设计的原则与研究思路,参照挤压用6005A铝合金中强化相Mg2Si的设计要求,固定硅含量为0.2% (质量分数)[8]。确定以Mg、Mn、Cu和Cr元素为主要变量进行4因素4水平的试验,采用了L16(45)型正交表,具体正交试验设计方案如表1所列。

表1 正交试验因子水平表

Table 1 Orthogonal experiment factors and levels

1.2 实验方法

实验用熔炼铸造法制备铝合金。合金冶炼工艺流程为:将AlCu、AlMn、AlCr和AlSi等中间合金及纯Mg、工业纯Al等原料置于坩埚式电阻炉中进行熔炼,熔炼温度为740 ℃。熔炼后的合金液于720 ℃浇入预热温度250 ℃的铁模中,浇铸得到尺寸为100 mm×100 mm×35 mm的合金铸锭。铸锭的均匀化热处理制度为550 ℃保温4 h。铸锭铣面后经500 ℃热轧至15 mm;热轧样品经415 ℃,2 h的中间退火,最后冷轧至10 mm。冷轧合金板材的热处理工艺为500 ℃,2 h固溶,水淬(水温15 ℃),180 ℃时效8 h[9]。焊接用铝合金板材的规格为100 mm×100 mm×10 mm。

采用半自动MIG焊接法对自制6005A铝合金试样进行连接,焊接方式为单面焊,坡口倾角60?。选用直径为4 mm的ER5356焊丝,焊丝的主要化学成分为Mg5.0,Cr 0.1,Zn 0.1,Al余量(质量分数,%)。焊接工艺参数见表2。焊接后沿垂直于焊缝方向截取拉伸试样,拉伸试样尺寸如图1所示。在WEW-1000B型万能材料试验机上测试试样的拉伸性能,拉伸速度为1 mm/min。在SSX-550扫描电镜上观察焊接接头断口形貌,分析元素分布特点。焊接接头显微组织观察在POLYVAR2MET型金相显微镜上进行。

表2 焊接工艺参数

Table 2 Process parameters in welding

图1 板材拉伸试样示意图

Fig.1 Schematic diagram of tensile specimens(mm)

电化学测试在德国IM6e电化学工作站完成。采用三电极体系,以铂电极为对电极、饱和甘汞电极(SCE)为参比电极,测试溶液为3.5%NaCl溶液,电位扫描速率为2 mV/s,试样的测试面积均为1 cm2。

2 结果与分析

2.1 正交试验结果与分析

根据测试中正交试验制得的16种铝合金焊接试样的抗拉强度,计算得到反映各种合金元素对合金抗拉强度影响大小的K值与R值,其中K1、K2、K3和K4分别代表试样1~4、5~8、9~12和13~16抗拉强的平均值;R为极差;代表K平均值中的最大值与最小值之差,以期据此设计出一种具有更理想接合性能的高速列车用铝合金材料,相关测试数据及计算结果见表3。

图2所示为不同合金元素含量对自制铝合金焊接接头抗拉强度正交实验结果的影响。从图2中可以看出:Mn和Cr含量对试样抗拉强度的影响相对较大,其抗拉强度随着Mn含量的增加先缓慢减小后迅速增加;当Mn含量为0.6%时,接头强度达到最低值(153 MPa);当Mn含量为0.8%时,接头强度达到最高值(188 MPa)。合金中Cr元素含量为0~0.2%时,焊接强度缓慢增加至186 MPa,当Cr元素含量为0.3%时,焊接接头强度则迅速下降至154 MPa。其原因在于基体在焊接过程中,适量Mn和Cr通过异质形核,产生均匀的弥散相MnAl6及(CrMn)Al12,这些颗粒可阻止位错迁移,提高再结晶温度,有效阻止再结晶过程中晶粒的形核与长大,起到细化焊接接头合金组织的作用。同时,基体中含有一定量的Mn和Cr时,可作为铁中和剂来溶解焊接有害相α(Al12Fe3Si),降低裂纹敏感性,改善合金焊接性能[10]。但由于合金中的颗粒状物质与基体的变形能力存在一定差异,变形时易成为裂

表3 铝合金焊接接头抗拉强度的正交试验

Table 3 Orthogonal experiment for tensile strength of welded joint of aluminum alloy

图2 元素含量对铝合金焊接接头抗拉强度的影响

Fig.2 Effect of elements contents on tensile strength of welded joint of aluminum alloy

纹的萌生区域,因此,需要严格控制各种合金元素的添加量[11]。实验结果显示,元素Cu可显著提高自制铝合金的基体强度,但与ER5356焊丝焊接时,其抗拉强度呈先增加后急剧减小的趋势。这是因为基材6005A铝合金中Cu主要以Cu2Mg8SiAl5相存在。焊接过程中,在温度梯度以及应力梯度作用下,合金中Cu元素将会定向地向焊接界面扩散。随着界面区域Cu元素的不断富集,形成弥散针状相Al2Cu。弥散针状相Al2Cu在晶界液化后凝固,发生粗化,形成有害的θ相(Al2Cu),导致接头强度急剧降低[12]。研究还发现,在自制铝合金中,随Mg含量升高,合金焊接接头的抗拉强度总体呈上升趋势,但当Mg的质量分数达到1.0%后,上升幅度趋缓。同时,合金中大部分Mg元素以脆性相Mg2Si存在,其对合金的变形能力影响很大,因此,Mg元素的含量以1.0%为宜。

2.2 可焊6005A铝合金优化成分验证实验

通过正交试验成分设计初步获得了优化的自制合金成分为Mg1.0,Si0.8,Mn0.7,Cu0.4,Cr0.2(质量分数,%)。但在所进行的16组正交试验中不包括这一优化成分。为了验证优化结果的正确性,进行相应的验证实验,其具体成分见表4。然后在相同的均匀化处理工艺(565 ℃,4 h)进行轧制,轧制合金经形变热处理工艺(547 ℃,2 h固溶,水温15 ℃水淬),于180℃时效8 h后与ER5356焊丝进行焊接[9]。其优化6005A基材及焊接接头拉伸力学性能见表5。

从表5拉伸测试结果可以看出,按6005A合金元素成分优化结果所轧制铝合金焊接接头的抗拉强度σb比前面的16组正交实验高,同时也优于国外报道商用6005A焊接接头力学性能[13],而伸长率与成分优化试验相当。可见对6005A主成分优化是成功的。

6005A铝合金焊接接头的力学性能低于其基材的性能。其焊接系数(即焊接接头强度237 MPa与母材强度285 MPa比值)为83.2%。焊接接头的力学性能最薄弱处在距焊缝中心10~20 mm处,即位于焊接接头热影响区(HAZ)的软化区。但根据DIN EN288—4标准,实验用的6005A焊接接头的强度仍高于标准所要求的195 MPa。所以,6005A铝合金配用ER5356焊丝的焊接接头符合高速列车用铝合金使用条件[13]。

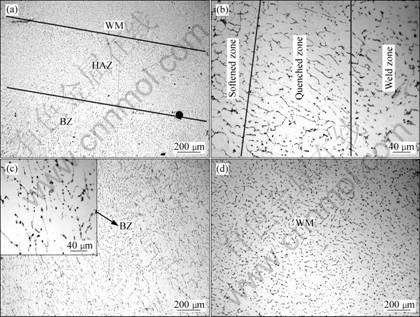

图3(a)所示为实验优化合金焊接接头显微组织。

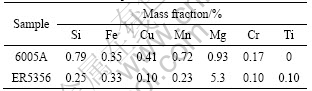

表4 6005A铝合金及焊丝ER5356的化学成分

Table 4 Chemical composition of 6005A and ER5356

表5 6005A铝合金及焊接接头拉伸力学性能

Table 5 Mechanical properties of 6005A alloy and welded joint

图3 6005A焊接接头不同区域金相组织

Fig.3 Optical micrographs of different zones of welded joint of 6005A alloy: (a) Welding joint; (b) HAZ; (c) Base alloy; (d) Welding line

图3(b)、(c)和(d)所示分别为接头区域热影响区、基材、焊缝区的显微组织。基材区为轧制态再结晶组织,由于再结晶晶粒沿轧制方向伸长,仍可见热加工后的组织变化。合金内化合物被破碎并沿轧制方向(纵向)成行排列,横向组织方向性不明显,也未见再结晶晶粒。热影响区中靠近焊缝的淬火区晶粒沿散热方向呈等轴晶分布,晶粒较细;热影响区中靠近基材区的软化区沿散热方向呈柱状晶分布,晶粒粗大。即6005A铝合金焊接软化区抗拉强度最低,较基材易发生拉伸断裂。焊缝区呈典型细小树枝状的铸造组织,树枝状组织往往容易在晶界处产生杂质的富集以及偏析[14]。

2.4 6005A铝合金焊接接头拉伸断口的扫描电镜

图4所示为6005A焊接接头拉伸断口形貌。从低倍放大断口形貌(见图4(a))中可以看出,拉伸断口上平坦区域均匀分布着延性韧窝,焊接接头断口主要为穿晶断口,韧窝为等轴韧窝,尺寸较小。从断口的高倍放大形貌(见图4(b))中可见,在试样中心部位,微孔在垂直于正应力方向的3个方向上长大的倾向相同,故形成等轴韧窝。韧窝大小不等,呈圆形或椭圆形。在韧窝底部可以看到一些第二相粒子。韧窝断裂是微孔形成长大汇合并最终断裂的过程,显微孔洞的形成几乎全部与夹杂物或第二相粒子有关,孔洞是通过第二相粒子本身开裂或通过粒子与基体表面脱开而形成。

图4 6005A焊接接头拉伸断口扫描电镜

Fig.4 Scanning electron fractographs of welded joint of 6005A alloy

总的来说,实验合金焊接接头拉伸断口上分布有大量等轴韧窝,韧窝底部可见第二相粒子Mg2Si颗粒存在[15],试样拉断方式为韧性断裂。

2.5 6005A铝合金在NaCl溶液中的电化学行为

图5(a)所示为自制6005A铝合金的极化曲线。从图5(a)中曲线中看出,合金在腐蚀电位附近±20 mV间为活化区;在-0.720 V~-0.190 V区间出现电流平台,为铝的钝态电位区间;电位φ>-0.190 V后,阳极电流陡增,钝化膜破裂,发生点蚀。图5(a)曲线的形状与商用6005A铝合金在NaCl溶液中的极化曲线(见图5(b))的形状相似。根据图5(a)极化曲线可以看出,腐蚀电流702 nA,腐蚀电位-764.7 mV。与图5(b)中商用的6005A合金相比,自腐蚀电位φc正移了160 mV,腐蚀倾向大大降低,自腐蚀电流Ic较商用6005A合金略有提高。其原因在于本研究自制的6005A铝合金在商用6005A铝合金的基础上优化调整了Cu、Mn、Cr元素的含量,这些元素的联合添加有效提高了合金表面氧化膜的稳定性和致密性。但合金元素的添加也

图5 6005A铝合金在3.5%NaCl溶液中的极化曲线

Fig.5 Polarization curves of 6005A alloy in 3.5% NaCl solution: (a) Self-made; (b) Commercial

会使氧化薄膜在腐蚀击穿后,腐蚀能力迅速下降,但此时仍可达到高速列车用可焊耐蚀铝合金的性能 要求[16]。

3 结论

1) 提出了以Mg、Mn、Cu和Cr为变量进行正交实验,以优化6005A铝合金的化学成分,确定一种高速列车用铝合金材料的化学成分:Mg1.0、Si 0.8、Mn 0.7、Cu 0.4、Cr 0.2、Al余量(质量分数,%)。

2) 将铸造6005A铝合金经过轧制变形与退火热处理后,焊接后试样的拉伸强度显著提高。焊接接头区域的组织演化规律具有母材组织→等轴晶→柱状晶→焊缝树枝状铸造组织的典型焊接特征,气孔和夹杂等焊接缺陷较少。

3) 测试了焊接试样的拉伸性能,观察拉伸断口的微观形貌。测试数据显示试样的拉伸强度最高可达237 MPa,伸长率最佳值为9.3%。拉伸断口表面分布有大量等轴韧窝,韧窝底部可见第二相粒子Mg2Si颗粒,试样的断裂方式为韧性断裂。对比发现自制的6005A铝合金的综合力学性能优于目前商用6005A铝合金的相关数据。

4) 通过极化曲线对比,自制的6005A铝合金腐蚀性能优于商用6005A铝合金的,其中自腐蚀电位大大提高,自腐蚀电流略有下降。

REFERENCES

[1] ELSNER O. Welded structures of the railway vehicle, railway technology international[M]. New York: Pergamon Press, 1992: 111-120.

[2] CABIBBO M, MCQUEEN H J, EVANGELISTA E, SPIGARELLI S, PAOLA M D, FALCHERO A. Microstructure and mechanical property studies of AA6056 friction stir welded plate[J]. Materials Science and Engineering A, 2007, 460/461: 86-94.

[3] BABU S, KUMAR T S, BALASUBRAMANIAN V. Optimizing pulsed current gas tungsten arc welding parameters of AA6061 aluminium alloy using Hooke and Jeeves algorithm[J]. Transactions of Nonferrous Metals Society of China, 2008, 18(5): 1028-1036.

[4] ZHANG Z L, ?DEG?RD J, MYHR O R, FJ?R H. From microstructure to deformation and fracture behaviour of aluminium welded joints—A holistic modelling approach[J]. Computational Materials Science, 2001, 21(3): 429-435.

[5] YAN Jun, ZENG Xiao-yan, GAO Ming, LAI Jian, LIN Tian-xiao. Effect of welding wires on microstructure and mechanical properties of 2A12 aluminum alloy in CO2 laser-MIG hybrid welding[J]. Applied Surface Science, 2009, 255(16): 7307-7313.

[6] 陈苏里, 姜 锋, 尹志民, 雷学锋, 聂 波. 含钪与不含钪铝镁钪合金焊接接头的组织与性能[J]. 中国有色金属学报, 2006, 16(5): 835-840.

CHEN Su-li, JIANG Feng, YIN Zhi-min, LEI Xue-feng, NIE Bo. Microstructure and properties of Al-Mg-Sc alloy weld joints filled with Al-Mg-Zr and Al-Mg-Zr-Sc weld wires[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(5): 835-840.

[7] EN15085-2. Railway applications - Welding of railway vehicles and components—Part 2: Quality requirements and certification of welding manufacturer[S].

[8] KUMAR T S, BALASUBRAMANIAN V, SANAVULLAH M Y. Influences of pulsed current tungsten inert gas welding parameters on the tensile properties of AA 6061 aluminium alloy[J]. Materials & Design, 2007, 28(7): 2080-2092.

[9] 田荣璋, 王祝堂. 铝合金及其加工手册[M]. 长沙: 中南大学出版社, 2000: 311-321.

TIAN Rong-zhang, WANG Zhu-tang. Aluminum and its working hand book[M]. Changsha:Central South University Press, 2000: 311-321.

[10] WU Yue-mei, XIONG Ji, LAI Ren-ming, ZHANG Xiang-yu, GUO Zhi-xing. The microstructure evolution of an Al-Mg-Si-Mn-Cu-Ce alloy during homogenization[J]. Journal of Alloys and Compounds, 2009, 475(1/2): 332-338.

[11] LODGAARD L, RYUM N. Precipitation of dispersoids containing Mn and/or Cr in Al-Mg-Si alloys[J]. Materials Science and Engineering A, 2000, 283(1/2): 144-152.

[12] 田志凌, 许良红, 彭 云, 张晓牧, 李 冉. 高强铝合金焊接接头无析出物区的形成机理[J]. 金属学报, 2008, 44(1): 91-97.

TIAN Zhi-ling, XU Liang-hong, PENG Yun, ZHANG Xiao-mu, LI Ran. Formation mechanism of the precipitate-free zone in high strength aluminum alloy welds[J]. Acta Metallurgica Sinica, 2008, 44(1): 91-97.

[13] SIMAR A, BR?CHET Y, MEESTER B D, DENQUIN A, PARDOEN T. Microstructure, local and global mechanical properties of friction stir welds in aluminium alloy 6005A-T6[J]. Materials Science and Engineering A, 2008, 486(1/2): 85-95.

[14] 姜 澜, 魏绪钧, 姚广春, 王德全. 火焰加热温度对6005A铝合金焊接接头性能的影响[J]. 东北大学学报: 自然科学版, 2003, 24(4): 365-368.

JIANG Lan, WEI Xu-jun, YAO Guang-chun, WANG De-quan. Effect of flame heating temperature on properties of welded joint of 6005A aluminium alloy[J]. Journal of Northeastern University: Natural Science, 2003, 24(4): 365-368.

[15] BARBOSA C, DILLE J, DELPLANCKE J L, REBELLO J M A, ACSELRAD O. A microstructural study of flash welded and aged 6061 and 6013 aluminum alloys[J]. Materials Characterization, 2006, 57(3): 187-192.

[16] BAYOUMI M R. Fatigue behaviour of a commercial aluminium alloy in sea water at different temperatures[J]. Engineering Fracture Mechanics, 1993, 45(3): 297-307.

(编辑 李艳红)

基金项目:国家高技术研究发展计划资助项目(2004AA33G060);国家自然科学基金资助项目(50971038)

收稿日期:2009-11-11;修订日期:2010-05-10

通信作者:姚广春,教授,博士;电话:024-83686462;E-mail:jikai1457@163.com,gcyao@mail.neu.edu.cn