文章编号:1004-0609(2011)12-3064-07

AISI 304不锈钢表面Fe3Si型硅化物渗层的制备及渗硅机理

安 亮1, 2,贾建刚1,马 勤1,李 鹏1

(1. 兰州理工大学 甘肃省有色金属新材料省部共建国家重点实验室,兰州 730050;

2. 兰州工业高等专科学校 材料工程系,兰州 730050)

摘 要:以n(NaCl):n(KCl):n(NaF)=2:2:1碱金属卤化物混合体系做载体,采用不同摩尔比的Na2SiF6和Si粉作渗硅剂,在800 ℃下利用熔融盐法分别对AISI 304不锈钢进行渗硅处理。采用X射线衍射仪(XRD)分析渗硅层的物相组成,用附带能量色散谱仪(EDS)附件的扫描电子显微镜(SEM)研究渗层截面的形貌和成分,分析熔盐法渗硅层的形成机理。结果表明:融盐中SiF62-的浓度决定渗层中Si元素的含量,由于SiO2在融盐体系中的溶解,融盐中SiF62-得到补充,渗层中Si元素的含量进一步提高。

关键词:AISI 304不锈钢;Fe3Si;硅化物渗层;渗硅机理;渗硅体系

中图分类号:TG156.8 文献标志码:A

Preparation and siliconizing mechanism of Fe3Si type silicide layer deposited on AISI 304 stainless steel

AN Liang1, 2, JIA Jian-gang1, MA Qin1, LI Peng1

(1. State Key Laboratory of Gansu Advanced Non-ferrous Metal Materials, Lanzhou University of Technology,

Lanzhou 730050, China;

2. Department of Materials Engineering, Lanzhou Polytechnic College, Lanzhou 730050, China)

Abstract: The silicide layers deposited on the AISI 304 stainless steel were formed in the molten salts at 800 ℃ using the molten mixture of different mole ratios of Na2SiF6 to Si using the siliconizing agent and the molten halogenide of alkali metals of NaCl+KCl+NaF at mole ratio of 2:2:1 as the siliconizing agent carrier. In order to reveal the siliconizing mechanism in the molten salts, the phase of the silicide layer was analyzed by X-ray diffractometry. Meanwhile, the micrographs and the composition of the cross section of the silicide layer were studied by scanning electron microscopy (SEM) attached with energy dispersive X-ray spectrometer (EDS). The results show that the silicon content in the layer depends on the ion concentration of SiF62- in the molten salts. The dissolving of SiO2 in the molten salts supplies the SiF62- continuously and as a result, the silicon content in the layer is enhanced.

Key words: AISI 304 stainless steel; Fe3Si; silicide layer; siliconizing mechanism; siliconizing system

金属间化合物由于具有金属键与共价键之混合键型,而呈现出金属性与陶瓷性两者兼有的独有特性。但是,其室温脆性大和高温强度低的弊端依然是困扰这类材料实用化的关键问题。毫无疑问,硅化物的脆性问题一旦得以显著改善,这类材料将成为苛刻环境下使用的首选材料[1-6]。

AISI304奥氏体不锈钢(0Cr18Ni9)具有优异的耐腐蚀性能而被广泛应用,在室温至800 ℃之间由于具有良好的抗氧化性能,也可用作耐热钢。Fe3Si具有优异的软磁性能、良好的抗氧化和耐腐蚀性以及优越的耐磨性能[7-9],其性能随Si含量不同而不同。其中,含Si约6.5%的Fe-Si合金与普通硅钢片(Si 3%,质量分数)相比[10],具有铁损低、磁致伸缩接近于零、磁导率高、矫顽力低等特点;Si 含量为25.2%(摩尔分数)甚至能够抵抗沸腾硫酸的侵蚀[8]。然而,Si含量超过6.5%的Fe-Si系合金往往形成有序相而难以机械加工。研究表明:利用熔盐渗硅方法在AISI 304表面生成一层Fe3Si型过渡族金属硅化物渗层,可以避开Fe3Si的脆性问题,改善304不锈钢的抗氧化性能和耐磨性。通过调整渗硅体系,在304表面形成不同含Si量的金属硅化物渗层,则可在更广的范围内改善AISI 304不锈钢的性能。

传统盐浴渗硅温度在1 050 ℃左右[11],SUZUKI等[12]通过调整NaCl-KCl二元共晶系中NaCl和KCl的比例,在纯Fe试样表面进行了硅化物沉积,其目的是降低NaCl-KCl-NaF三元体系的熔点。上述研究中,渗硅剂中Si与Na2SiF6的摩尔比(下同)均为约9:2,而改变两者比例对渗硅层的影响未见报道。何小凤等[13]对NaCl-KCl-NaF三元体系的熔点进行了详细研究,发现n(NaCl):n(KCl):n(NaF)=2:2:1的熔融中性盐具有最低的初晶温度,其平均值为587.6 ℃[13]。本文作者采用上述比例的NaCl-KCl-NaF体系作为渗硅时活性Si离子的环境介质,通过调整渗硅剂的比例,采用3种渗硅体系在800 ℃下对AISI 304奥氏体不锈钢进行渗硅处理,在基体表面获得了Si元素含量分别为13.21%、18.92%和20.03%(摩尔分数)的Fe3Si型过渡金属硅化物渗层。对渗硅层的组织结构进行初步表征,并简要探讨渗硅层的形成机理。

1 实验

实验材料选用国内某钢铁集团生产的连铸态AISI 304奥氏体不锈钢。采用电火花切割法将不锈钢加工成10 mm×10 mm×5 mm的块状试样,表面经金相砂纸打磨后用无水乙醇清洗,烘干后备用。熔盐选用n(NaCl):n(KCl):n(NaF)=2:2:1的中性盐(熔盐A),渗硅剂成分为Na2SiF6和Si粉(渗剂B)。实验采用的3种渗硅体系中组元的摩尔分数如表1所列。

将渗硅剂和中性盐混合物装入氧化铝坩埚,加热至800 ℃熔化,然后将准备好的不锈钢试样放入熔融状态下的盐浴中分别保温预定时间后空冷至室温。为使渗硅层与基体之间具有良好的结合(渗层太厚会导致渗层/基体界面局部开裂),将渗层厚度控制在400~600 μm左右,为此,体系1的保温时间为20 h,体系2和3的保温时间分别为5 h。实验结束后,先用清水清洗试样表面,然后用超声波进一步清理试样表面残盐。

表1 渗硅体系的成分

Table 1 Components of siliconizing systems

利用DMM-200C的光学显微镜观察渗层截面组织;用D8型X射线衍射仪(XRD)分析渗层的物相结构;用附带Genesis XM2型能量色散谱仪(EDS)的JSM-6700F型扫描电子显微镜(SEM)观察渗层断面的形貌以及确定各元素在渗层中的分布。

2 结果与讨论

2.1 渗层截面的组织与成分

2.1.1 AISI 304在渗硅体系1经800 ℃保温20 h的截面组织与成分

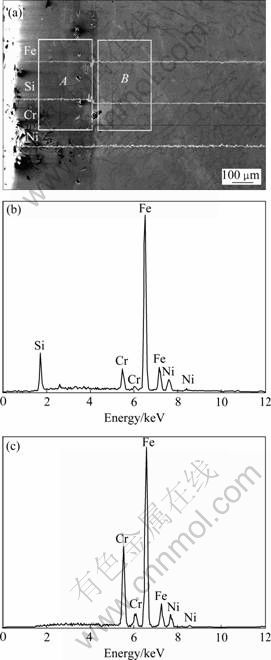

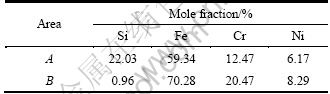

图1所示为800 ℃盐浴保温20 h渗硅体系1的硅化物渗层截面SEM像、元素线分布以及EDS谱。EDS谱分别对应图中渗层A和基体B区域。表2所列为渗硅体系1中微区EDS数据。

由图1(a)可以看出,AISI 304表面有完整的硅化物渗层生成,渗层厚度约400 μm。区域A所代表的渗层组织中Si元素含量的摩尔分数为13.21%,而区域B的EDS谱中则未发现Si元素的谱峰。另外,基体中Cr的含量为20.02%,而渗层中Cr的含量为5.40%。Fe在基体中的含量为74.47%,在渗层中为75.28%。Ni元素在基体中的含量为4.61%,在渗层中的含量为6.11%。可以看出,Si元素存在于渗层中,且均匀分布,越过界面后,Si元素的浓度降低至零,Cr元素在渗层中的浓度较基体中小,而Fe和Ni元素在界面两侧浓度没有明显变化。渗层中存在两种缺陷,第一种为渗层、基体界面渗层一侧分布的细小柯肯达尔空隙带;第二种为空隙带左侧的大空洞,大空洞左侧至表面较厚的范围内渗层组织致密,缺陷很少。

2.1.2 AISI 304在渗硅体系2中800 ℃保温5 h的截面组织与成分

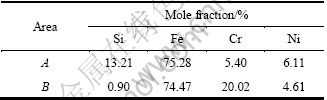

渗硅体系2的融盐与渗剂的摩尔比仍为90:10,提高Na2SiF6在渗剂中的比例,令n(Na2SiF6):n(Si)=8:2,图2(a)所示为AISI 304在800 ℃体系2的融盐中保温5 h的截面SEM像,图2(b)和(c)所示分别为图2(a)中渗层A和基体B区域的EDS谱,表3所列为微区EDS数据。

图1 AISI 304在渗硅体系1中经800 ℃保温20 h后的组织与成分

Fig.1 Microstructure and compositions of AISI 304 after siliconized at 800 ℃ for 20 h in siliconizing system 1: (a) SEM image and line distribution of elements in cross-section; (b) EDS spectrum of silicide layer; (c) EDS spectrum of substrate

表2 渗硅体系1微区的EDS数据

Table 2 EDS data of different areas of siliconizing system 1

图2 AISI 304在渗硅系2中经800 ℃保温5 h后的组织与 成分

Fig.2 Microstructure and compositions of AISI 304 after siliconized at 800 ℃ for 5 h in siliconizing system 2: (a) SEM image and line distribution of elements in cross-section; (b) EDS spectrum of silicide layer; (c) EDS spectrum of substrate

表3 渗硅体系微区2的EDS数据

Table 3 EDS data of different areas of siliconizing system 2

由图3(a)可知,渗层厚度约600 μm,渗硅体系2中Si元素在渗层中的摩尔分数为18.92%,如表4所列。与渗硅体系1相比,渗硅体系2的渗层硅含量较高,渗层的生长速度较快,但渗层中两种缺陷的直径均增大,且分布范围更宽。

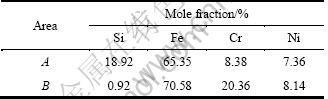

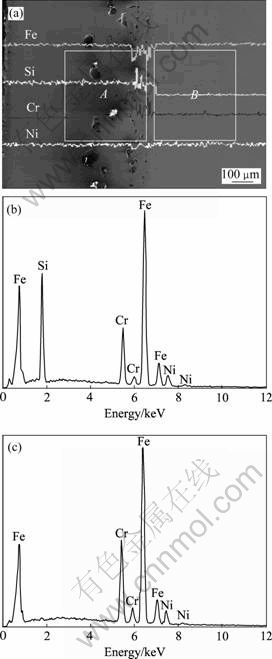

2.1.3 AISI 304在渗硅体系3中 800 ℃保温5 h的截面组织与成分

渗硅体系3是以渗硅体系2为基础,加入SiO2(透明石英管)作为渗硅促进剂。图3(a)所示为AISI 304在800 ℃体系3的融盐中保温5 h的截面SEM像, 图3(b)、(c)所示分别为图3(a)中渗层A和基体B区域的EDS谱,表4所列为微区EDS数据。

图3 AISI 304在渗硅体3中经800 ℃保温5 h后的组织与 成分

Fig.3 Microstructure and compositions of AISI 304 after siliconized at 800 ℃ for 5 h in siliconizing system 3: (a) SEM image and line distribution of elements in cross-section; (b) EDS spectrum of silicide layer; (c) EDS spectrum of substrate

表4 渗硅体系3微区EDS数据

Table 4 EDS data of different areas in siliconizing system 3

由图3(a)可知,渗硅体系3渗层厚度约600 μm,Si在渗层中的摩尔分数为22.03%,如表4所列。渗层中的缺陷与渗硅体系2的基本相当。

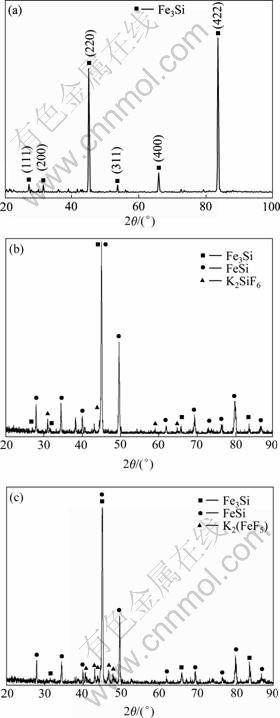

2.2 各渗硅体系的XRD谱

图4(a)所示为AISI 304在渗硅体系1中经800 ℃保温20 h后的XRD谱,图4(b)和(c)所示分别为AISI 304在渗硅体系2和3中经800 ℃保温5 h后的XRD谱。从图4(a)可以看出,渗层为单一的DO3型Fe3Si金属间化合物,其判断标志为XRD谱中出现了(111)、(200)和(311)晶面的超结构衍射峰。需要指出的是,生成的Fe3Si渗层的次强峰(422)面的衍射强度超过了其主衍射峰(220)面的衍射强度。在图4(b)与(c)中,XRD谱以Fe3Si、FeSi的衍射峰为主。图4(b)和(c)中分别出现K2SiF6和K2(FeF5) 的衍射峰,为试样表面残盐未清理干净所致。

2.3 各渗硅体系试样表面硅化物渗层的形貌与成分

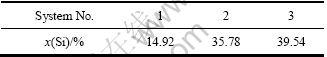

图5(a)所示为AISI 304在渗硅体系1、2和3中保温不同时间后所得试样表面的SEM像。由图5(a)可知,渗层表面为致密的等轴晶组织,晶粒的平均尺寸为20 μm。由图5(b)可知,晶粒呈珊瑚礁状,由许多Fe-Si化合物晶粒组成团状结构,其平均尺寸约为10 μm,每个晶粒团包含许多更为细小的晶粒。由图5(c)可知,晶粒团形状为球形,尺寸从亚微米至10 μm不等。表5所列为图5(a)、(b)、(c)试样表面Si元素的含量。

从表5可以看出,渗硅体系2和3的渗层表面Si元素含量为35.78%和39.54%,而对应的渗层中Si元素的含量分别为18.92%和20.03%,且元素线分布结果显示Si元素在渗层中分布均匀,所以渗层中的组织为Fe3Si。由于渗层表面为富硅状态,表面生成很薄的FeSi,这就解释了XRD谱中出现了FeSi衍射峰的原因,如图4(b)和(c)所示。另外,从图5(b)和(c)可以看出,渗硅体系2和3的渗层表面存在孔隙,这会使残盐难以彻底清理干净,对应的XRD谱中出现了盐的衍射峰。

图4 AISI 304在各渗硅体系中渗硅后的XRD谱

Fig.4 XRD patterns of AISI 304 stainless steel after siliconizing in siliconizing systems: (a) Siliconizing system 1; (b) Siliconizing system 2; (c) Siliconizing system 3

2.4 融盐中的化学反应机理

基体表面硅化物渗层的形成在于融盐中产生活性Si离子,TATEMOTO等[14]研究认为,Si与Na2SiF6可发生如下反应:

Si (particle in molten salt)+6F-+SiF62-→2SiF64- (1)

2SiF64-+Fe (substrate)→Fe-Si (siliconized layer)+

6F-+SiF62- (2)

图5 AISI 304在各渗硅体系中800 ℃保温后试样表面的SEM像

Fig.5 SEM images of surfaces after siliconized at 800 ℃ in different siliconizing systems: (a) Siliconizing system 1 for 20 h; (b) Siliconizing system 2 for 5 h; (c) Siliconizing system 3 for 5 h

表5 各渗硅体系渗层表面Si元素的EDS数据

Table 5 EDS data of silicon content on surfaces of different siliconizing systems

融盐中的Si粉与Si4+反应生成Si2+,如式(1)所示。Si2+在基体表面变为Si和Si4+,生成的Si渗入基体表面形成金属硅化物渗层,如式(2)所示。总的反应式如下:

Si (particle in molten salt)+Fe (substrate)→

Fe-Si (siliconized layer) (3)

式(3)表明,融盐为反应提供了平台,融盐中的纯Si与渗层中的Si由于热力学活度的不同,促使渗硅反应的进行。

根据式(1),SiF62-在融盐中的浓度决定了融盐中Si2+的浓度,从而决定了渗层中Si元素的含量。渗硅体系2的渗硅剂中Na2SiF6的比例较渗硅体系1的提高了30%,使得融盐中的SiF62-浓度得到提高,融盐中有更多的活性Si2+生成,单位时间内,更多的Si与基体金属发生反应。相比渗硅体系1,渗硅体系2获得同厚度渗层的时间减少了75%以上,渗层中Si元素的含量提高了40%左右。

SiO2参与反应的渗硅体系3,渗层中的Si含量相对于不加SiO2的渗硅体系2,提高了16%左右。根据何小凤等[15]的研究结果,SiO2在KCl-NaCl-NaF 体系中发生如下反应:

6NaF(L)+3SiO2(S)=Na2SiF6(L)+2Na2SiO3(L) (4)

由式(4)可以看出,由于SiO2与NaF反应生成Na2SiF6,融盐中SiF62-得到了持续的补充,从而维持融盐中相对较高的活性Si离子浓度[15],因此,渗硅体系3渗层中的Si元素含量高于渗硅体系2的。实验结束后,由于反应过程中SiO2的溶解,石英管的壁厚减薄了一半左右。需要指出的是,在本研究中不能用SiO2粉末取代石英管作为助渗剂,原因是SiO2颗粒悬浮在融盐中,实验过程中为渗层俘获,因而无法获得均匀的渗层。

3 结论

1) 以AISI 304为基体,在800 ℃的各卤化物混合融盐体系中保温不同时间渗硅,均得到富含Cr和Ni元素的Fe3Si型金属间化合物渗层,渗层/基体界面附近的孔洞状缺陷呈带状分布,缺陷带宽度约占渗层厚度的1/3,缺陷带之外的渗层十分致密。

2) 通过改变渗Si剂的成分,可以得到Si含量分别为13.21%、18.92%和20.03%这3种不同成分的渗层,Si元素在渗层中均匀分布。

3) 通过改变渗硅剂的比例和加入SiO2,可以逐步提高了渗层中Si元素的含量。

REFERENCES

[1] 张永刚, 韩雅芳, 陈国良, 郭建亭, 万晓景, 冯 涤. 金属间化合物结构材料[M]. 北京: 国防工业出版社, 2000: 2-4.

ZHANG Yong-gang, HAN Ya-fang, CHENG Guo-liang, GUO Jian-ting, WAN Xiao-jing, FENG Di. Structural intermetallics [M]. Beijing: National Defense Industry Press, 2000: 2-4.

[2] 林栋梁. 高温有序金属间化合物研究的新进展[J]. 上海交通大学学报, 1998, 32: 96-108.

LIN Dong-liang. Recent advances in high temperature ordered intermetallics[J]. Journal of Shanghai Jiaotong University, 1998, 32: 96-108.

[3] LIU C T, STRINGER J, MUNDY J N. Order intermetallic alloys: an assessment[J]. Intermetallics, 1997, 5: 579-596.

[4] 徐 强, 张幸红, 韩杰才, 赫晓东. 先进高温结构材料的研究现状和展望[J]. 固体火箭技术, 2002, 25: 51-55.

XU Qiang, ZHANG Xing-hong, HAN Jie-cai, HE Xiao-dong. Current status of R & D and prospects of advanced high- temperature materials[J]. Journal of Solid Rocket Technology, 2002, 25: 51-55.

[5] STOLOFF N S, LIU C T, DEEVI S C. Emerging applications of intermetallics[J]. Intermetallics, 2000, 8: 1313-1320.

[6] PETROVIC J J, VASUDEVAN A K. Key developments in high temperature structural silicides[J]. Mater Sci Eng A, 1999, 261: 1-5.

[7] 张 伟, 文九巴, 龙永强. 渗铝钢扩散层空洞对循环氧化和剥落性能的影响[J]. 材料热处理学报, 2004, 25(6): 96-100.

ZHANG Wei, WEN Jiu-ba, LONG Yong-qiang. Effect of voids in diffusion layers on cyclic oxidation and spalling resistance of aluminized steel[J]. Transactions of Materials and Heat Treatment, 2004, 25(6): 96-100.

[8] WESTBROOK J H, FLEISCHER R L. Structural applications of intermetallic compounds[M]. New York: John Wiley & Sons, 2000: 221.

[9] JIA Jian-gang, MA Qin, LU Jin-jun. Reciprocating sliding friction and wear property of Fe3Si based alloys containing Cu in water lubrication[J]. Tribol Lett, 2008, 30(2): 113-121.

[10] 李 晓, 赫晓东, 孙 跃. 高硅硅钢片的特性、制备及研究进展[J]. 磁性材料及器件, 2008, 12: 1-4.

LI Xiao, HE Xiao-dong, SUN Yue. Characteristics, preparation and research progress of high silicon electrical steel[J]. Journal of Magnetic Materials and Devices, 2008, 12: 1-4.

[11] 庄光山, 陈增清, 徐 英, 孙 毅, 孙希泰. 机械能助渗硅的研究[J]. 金属热处理, 2000, 9: 12-14.

ZHUANG Guang-shan, CHEN Zeng-qing, XU Ying, SUN Yi, SUN Xi-tai. Study on mechanical energy aided siliconizing[J]. Heat Treatment of Metals, 2000, 9: 12-14.

[12] SUZUKI R O, NISHIBATA T, NAKANISHI K. Electroless coating of Fe3Si on steel in the molten salt[J]. Steel Research, 2000, 71(4): 130-137.

[13] 何小凤, 李运刚, 李智慧. KCl-NaCl-NaF(SiO2)熔盐体系初晶温度的研究[J]. 有色金属, 2008(4): 21-31.

HE Xiao-feng, LI Yun-gang, LI Zhi-hui. Solubility and dissolving mechanism of SiO2 in KCl-NaCl-NaF molten salt[J]. Nonferrous Metals: Extractive Metallurgy, 2008(4): 21-31.

[14] TATEMOTO K, ONO Y, SUZUKI RYOSUKE O. Silicide coating on refractory metals in molten salt[J]. Journal of Physics and Chemistry of Solids, 2005, 66: 526-529.

[15] 何小凤, 李运刚, 田 薇. SiO2在KCl-NaCl-NaF体系中的溶解度及溶解机理[J]. 中国有色金属学报, 2008, 18(5): 929-933.

HE Xiao-feng, LI Yun-gang, TIAN Wei. Study on primary crystallization temperature of KCl-NaCl-NaF-(SiO2) molten salt system[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(5): 929-933.

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51001057)

收稿日期:2010-12-06;修订日期:2011-03-02

通信作者:贾建刚,讲师,博士;电话:13919809312;E-mail: lzhjiajiangang@163.com