使役条件下热暴露对2124-T851铝合金

显微组织与性能的影响

郭加林1,尹志民1,沈 凯2,彭小芒1,王 华1

(1. 中南大学 材料科学与工程学院,湖南 长沙,410083;

2. 南京航空航天大学 材料科学与技术学院,江苏 南京,210016)

摘 要:采用室温拉伸性能测试、金相和透射电子显微分析方法研究热暴露温度和时间对30 mm厚2124-T851铝合金板材组织与力学性能的影响。研究结果表明:在高于板材190 ℃最终时效温度下热暴露,合金强度下降而伸长率上升,温度愈高、时间愈长,强度下降和伸长率上升就愈快,于250 ℃热暴露50 h和100 h时,屈服强度分别降低53%和58%,伸长率分别上升约23%和55%;低于最终时效温度热暴露,若热暴露温度在150 ℃以下,则合金拉伸力学性能变化不大;当热暴露温度接近最终时效温度,如175 ℃时,若热暴露时间在100 h以内,则合金拉伸性能变化也不大;若热暴露时间超过100 h,则合金强度和塑性均有所下降。于175 ℃热暴露500 h屈服强度和伸长率就分别降低14%和9%;于热暴露条件下,2124-T851合金拉伸性能衰退的主要原因是合金固溶体基体内主要强化相S′(Al2CuMg)相粗化以及晶界无沉淀析出带的宽化。

关键词:2124铝合金;热暴露;显微组织;力学性能

中图分类号:TG146.2 文献标识码:A 文章编号:1672-7207(2009)04-0921-05

Effect of thermal exposure during application on microstructure and mechanical properties of 2124-T851 aluminum alloy

GUO Jia-lin1, YIN Zhi-min1, SHEN Kai2, PENG Xiao-mang1, WANG Hua1

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. College of Materials Science and Technology, Nanjing University of Aeronautics and Astronautics,

Nanjing 210016, China)

Abstract: The microstructures and mechanical properties of 2124-T851 aluminum alloy with the thickness of 30 mm under different thermal exposured conditions were investigated by tensile test, optical microscopy and transmitted electron microscopy. The results show that thermal exposured above last aging temperature 190 ℃ of the studied alloy, the strength of the alloy decreases and the elongation of the alloy increases. The higher the temperature and the longer the exposure time, the faster the strength decreases and elongation increases. Thermal exposured at 250 ℃ for 50 h and 100 h, the yield strength decreases by 53% and 58%, and the elongation increases by 23% and 55%, respectively. When thermal exposure is made at below last aging temperature, if the temperature is lower 150℃, the tensile properties of the alloy have no obvious change. When thermal exposure temperature approaches the last aging temperature and exposure time not so long, for example, at 175 ℃ for 100 h, the tensile properties of the alloy have also no large change, but if the exposure time is over 100 h, the strength of the alloy and the elongation of the alloy both decrease. Thermal exposured at 175 ℃ for 100 h and 500 h, the yield strength decreases by 5.5% and 14%, and the elongation decreases by 4% and 9.3%, respectively. The fact that S′ (Al2CuMg) precipitates get coarsen and the precipitate-free-zones (PFZ) get wider are responsible for the decline of the tensile properties of 2124-T851 aluminum alloy under thermal exposure condition.

Key words: 2124 aluminum alloy; thermal exposure; microstructure; mechanical properties

2124铝合金属于Al-Cu-Mg系合金,由20世纪70年代美国铝业公司(Alcoa)研制,它是在传统2024铝合金的基础上,通过调整成分、提高纯度和采用新的热处理工艺而发展起来的航空用高纯高强高韧铝合金[1]。2124合金不仅具有相当于2024合金的强度,而且具有更好的断裂韧性和疲劳性能,2124合金通常以厚板T851状态使用,用于制造要求耐热、耐蚀和 承受较大应力的飞机结构件,使用温度一般不超过175 ℃[2]。近年来,国内外对2124合金的热处理制度、析出相和断裂行为等进行了广泛研究[3-7]。随着航空技术的发展,要求材料具有较好的耐温性能。研究指出,当飞机的飞行速度接近3马赫时,有些零件会受到150~300 ℃的短时热暴露。在很多情况下,短时热暴露的飞机构件大部分时间里仍要在常温下工作,所以,有必要研究热暴露对该铝合金常温性能的影响,以掌握该合金的使用温度极限。目前,对2024和2324铝合金高温下的组织与性能的研究已有报道[8-9],但对高温下2124铝合金微观组织与性能的研究较少,而这又是飞机设计中的重要参考数据。在此,本文作者探讨热暴露对该合金微观组织与性能的影响。

1 实 验

研究用的合金为30 mm厚2124-T851合金板材,合金成分见表1。2124-T851热处理工艺为498 ℃固溶水淬—2%冷变形—190 ℃/8 h时效。拉伸性能试样直径为12 mm、标距为50 mm的棒状试样,沿板材纵向(LT)截取,在不同温度和时间条件下热暴露(表2),热暴露后的样品在室温下拉伸,拉伸速率为2 mm/min。对力学性能乾地测试后,对显微组织结构演变进行观察和分析。金相显微分析在POLYVER- MET显微镜上进行,样品采用Keller试剂腐蚀。透射电镜薄膜样品经机械预减薄后采用双喷电解减薄,电解液为硝酸与甲醇混合液(体积比为1?3),电解减薄温度低于-20 ℃。透射电子显微组织观察在TECNAI G220电镜上进行,加速电压为200 kV。

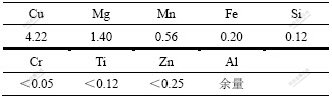

表1 2124合金化学成分

Table 1 Chemical composition of 2124 alloy 质量分数/%

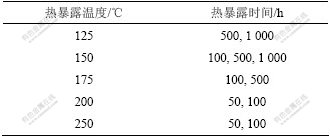

表2 热暴露处理制度

Table 2 Processing of thermal exposure

2 实验结果

2.1 热暴露对合金力学性能的影响

热暴露温度和时间对合金拉伸力学性能的影响见表3。可以看出,在高于板材190 ℃最终时效温度热暴露时,合金强度下降而伸长率上升,温度愈高、时间愈长,强度下降和伸长率上升就愈快,如于200 ℃热暴露50 h和100 h时,合金的屈服强度分别降低16%和19%,伸长率分别上升约14.6%和23%,而在250 ℃热暴露50 h和100 h时,屈服强度则分别降低53%和58%,伸长率分别上升约23%和55%;低于最终时效温度热暴露,若热暴露温度在150 ℃以下,则合金强度和塑性变化不大;当热暴露温度接近最终时效温度,如175 ℃时,若热暴露时间在100 h以内,则合金力学性能变化也不大, 屈服强度只降低5.5%,伸长率只降低4%;若热暴露时间超过100 h,合金强度和塑性均会下降,如于175 ℃热暴露500 h,合金的屈服强度和伸长率就分别降低14%和9.3%。

表3 热暴露对合金力学性能的影响

Table 3 Effects of thermal exposure on mechanical properties of alloy

2.2 热暴露对合金微观组织的影响

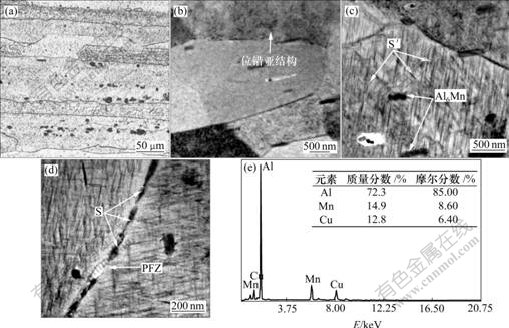

2.2.1 热暴露试验前原板材的微观组织

图1所示为热暴露试验前30 mm厚原板材的微观组织。可以看出,2124-T851合金晶粒结构呈沿轧制方向延展的扁平状(图1(a)),固溶体基体内除位错亚 结构外(图1(b)),还有许多沿轧向排列的微米级短棒状相和针片状析出相,晶界上有不连续的粗大相和晶界无沉淀析出带PFZ(图1(c)~(d))。电子衍射分析表明,针片状析出相为S′(Al2CuMg),晶界上平衡相为S(Al2CuMg),微区成分分析表明,微米级短棒状相为Al6Mn相(图1(e))。

(a) 金相显微组织; (b)~(d) 晶内和晶界析出相透射电镜显微组织; (e) 短棒状相Al6Mn能谱分析

图1 热暴露试验前2124-T851合金板材的显微观组织

Fig.1 Microstructures of 2124-T851 alloy plates before thermal exposure

2.2.2 热暴露对合金显微组织的影响

图2所示为2124-T851合金在不同热暴露条件下的透射电子显微组织。与热暴露前原板材的微观组织相比较,可以看出,低于最终时效温度(190 ℃)热暴露,若热暴露温度在150 ℃以下,则晶内析出相和晶界特征变化不大(图2(a))。当热暴露温度接近最终时效温度如175 ℃时,若热暴露时间在100 h以内,则合金的显微组织还是没有明显的变化(图2(b));若热暴露时间超过100 h,则晶内析出相S′粗化(图2(c))。在高于板材190 ℃最终时效温度下热暴露,合金晶内析出相S′相和晶界平衡相S明显粗化,S′析出相密度降低,晶界无沉淀析出带显著宽化。热暴露温度愈高、热暴露时间愈长,晶内析出相和晶界平衡相粗化以及无沉淀析出带也愈严重(图2(d)~(f));特别是当热暴露温度为250 ℃时,晶内析出相已由针片状变成条带状和板条状[10-11],析出相密度也显著降低(图2(e)~(f))。

(a) 150 ℃/100 h; (b) 175 ℃/100 h; (c) 175 ℃/500 h; (d) 200 ℃/100 h; (e) 250 ℃/50 h; (f) 250 ℃/100 h

图2 热暴露对2124-T851合金显微组织的影响

Fig.2 Effects of thermal exposure on microstructures of 2124-T851 alloy

3 分析与讨论

3.1 热暴露对弥散相Al6Mn和基体固溶体组织性能的影响

2124-T851铝合金中Mn含量比较高,Mn是以Al6Mn的形式存在,它是铸锭在485 ℃/12 h均匀化过程中析出的,Al6Mn相弥散分布在合金的晶内和晶界,主要作用是提高合金抗再结晶的能力。热暴露最高温度只有250 ℃,远低于Al6Mn的析出温度,实验结果表明,热暴露对Al6Mn相的形态和尺寸影响不大。基体固溶体组织结构包括基体固溶度、基体再结晶程度和基体中的位错密度,2124-T851铝合金原始板材的热处理工艺为498 ℃固溶水淬—2%冷变形—190 ℃/ 8 h时效。基体起始固溶温度约为400 ℃,合金再结晶开始温度为270~275 ℃,若热暴露实验温度达到再结晶开始温度,则合金会开始再结晶;若热暴露实验温度在再结晶温度以下、最终时效温度以上,则合金虽然不会再结晶,但是,位错亚结构会发生变化;若高出最终时效温度很多或者在最终时效温度附近热暴露时间很长,则位错亚结构会消失。本实验中热暴露实验温度最高只有250 ℃,在热暴露过程中,基体固溶度不会有多大变化;热暴露也没有达到该合金的再结晶起始温度,因此,热暴露下合金的晶粒粒径和形貌不会有明显变化。金相组织观察结果表明,热暴露前、后,合金晶粒结构没有明显变化也证实了这一点。但是,实验中有几个热暴露实验点已经高出最终时效温度,而且热暴露实验时间长,基体中的位错亚结构发生了变化,表现为位错密度大大降低。综上所述,在热暴露过程中,虽然基体固溶体晶粒粒径变化不会影响合金的力学性能,但是,基体位错亚结构变化和消失会降低固溶体基体的力学性能。

3.2 热暴露对S′析出相、晶界平衡相S相和晶界无沉淀析出带及其合金性能的影响

研究表明[12-13],Al-Cu-Mg系合金的时效序列为GPA—GPB—S′(Al2CuMg)—S(Al2CuMg),其中,GPA为面心正方晶格,GPB为有序化结构,S′相是亚稳相,该相为正交结构,是合金的主要强化相,弥散细小的S′相在固溶体基体中析出,S相是平衡相,是时效后期析出的,主要是在晶界上析出,晶界上除了S(Al2CuMg)外,还伴随着无沉淀析出带(PFZ)。2124-T851铝合金于190 ℃时效后再进行热暴露实验,实际上就是对合金进行再次时效。在热暴露过程中,热暴露温度和时间不同,对S′过渡相、S平衡相和晶界无沉淀析出带(PFZ)影响的程度也不同。当热暴露温度超过190 ℃时,S′过渡相、S平衡相和晶界无沉淀析出带(PFZ)发生明显变化,S′相粗化,S平衡相数量增加,晶界无沉淀析出带(PFZ)加宽。当热暴露温度低于190 ℃时,若温度较低或热暴露时间比较短,则S′过渡相、S平衡相和晶界无沉淀析出带(PFZ)变化不大,但是,若热暴露时间很长,则S′过渡相形貌大小和晶界无沉淀析出带(PFZ)宽度也会有明显的变化。实验结果说明了这一点。

位错理论指出,析出相对合金强度的影响主要取决于位错与析出相之间的交互作用。当析出相细小并且与基体共格时,位错与析出相切割,当析出相达到一定尺寸并且与基体失去共格时,位错与析出相绕过。在较高的热暴露温度和较长的热暴露时间条件下析出相粗化,合金的析出强度取决于析出相的尺寸及分布,反比于析出相粒子间距,因此,粒子粗化屈服应力就降低[14]。与此同时,较高的热暴露温度和较长的热暴露时间导致无沉淀析出带宽化,PFZ是强度较小的地方,变形很容易集中在这些区域,其强度也会下降而塑性有所提高。

4 结 论

a. 2124-T851合金原板材高于最终时效温度 (190 ℃)热暴露,合金强度下降而伸长率上升,温度愈高、时间愈长,强度下降和伸长率上升愈快。当合金在250 ℃热暴露50 h和100 h时,其σ0.2降低 260 MPa和280 MPa,伸长率上升约23%和55%。当合金在低于最终时效温度热暴露时,若热暴露温度在150 ℃以下,则合金力学性能变化不大;当热暴露温度低于最终时效温度但高于150 ℃时,若热暴露时间在100 h以内,合金力学性能变化也不大,但是,若热暴露时间超过100 h,则合金强度和塑性均下降。于175 ℃热暴露100 h和500 h后,合金强度分别下降0.95%和3.2%,于150 ℃热暴露100 h和500 h后,合金强度分别下降11.4%和19%。

b. 在热暴露条件下,2124-T851合金力学性能衰退的主要原因是晶内主要强化相S′相长大和粗化以及晶界附近的无沉淀析出带的宽化。在175 ℃以下热暴露,合金的显微组织变化不大;在175 ℃热暴露,析出相S′相有所粗化、无沉淀析出带加宽;在200 ℃以上热暴露,S′相明显粗化,晶界平衡相聚集长大,无沉淀析出带明显加宽,特别是热暴露温度升高到 250 ℃时,晶内析出相由针片状变成条带状或板条状,析出相密度也显著降低。

参考文献:

[1] 王祝堂, 田荣璋. 铝合金及其加工手册[M]. 长沙: 中南大学出版社, 2005: 323-325.

WANG Zhu-tang, TIAN Rong-zhang. Manual for aluminium alloys and its processing[M]. Changsha: Central South University Press, 2005: 323-325.

[2] 林 纲, 林慧国, 赵玉涛. 铝合金应用手册[M]. 北京: 机械工业出版社, 2006: 280-290.

LIN Gang, LIN Hui-guo, ZHAO Yu-tao. Manual for application of aluminium alloys[M]. Beijing: Mechanical Industry Press, 2006: 280-290.

[3] 梁忠华. 2124铝合金铸锭及厚板的显微组织分析[J]. 黑龙江大学自然科学学报, 1995, 12(2): 72-76.

LIANG Zhong-hua. Microscopical structures analysis of cast constitution and plant in 2124 aluminum alloy[J]. Journal of Natural Science of Heilongjiang University, 1995, 12(2): 72-76.

[4] 李满良, 初春溪, 许晨玲. 组元含量和T851参数对2124合金厚板组织和性能的影响[J]. 轻合金加工技术, 1991, 19(1): 20-25.

LI Man-liang, CHU Chun-xi, XU Chen-ling. Effect of component content and parameter of T851 on microstructure and tensile properties of the thick hot-rolled plate of 2124 alloy[J]. Light Alloy Fabrication Technology, 1991, 19(1): 20-25.

[5] 宁爱林. 固溶处理对高纯高强铝合金组织和性能的影响[J]. 金属热处理, 2004, 29(4): 13-16.

NING Ai-lin. Effect of solution treatment on microstructure and properties of high-purity and high-strength aluminum alloy[J]. Heat Treatment of Metals, 2004, 29(4): 13-16.

[6] 郑玉珍, 刘存玉, 刘金凤. 影响 2124 铝合金断裂韧性的因素[J]. 航空材料, 1989, 9(4): 16-23.

ZHENG Yu-zhen, LIU Cun-yu, LIU Jin-feng. Influence of some factors on fracture toughness of 2124 aluminium alloy[J]. Aeronautical Materials, 1989, 9(4): 16-23.

[7] 王昌臻, 潘清林, 何运斌, 等. 2124铝合金热扎厚板的热处理制度[J]. 中南大学学报: 自然科学版, 2007, 38(3): 386-373.

WANG Chang-zhen, PAN Qing-lin, HE Yun-bin, et al. Heat treatment of thick hot-rolled plate of 2124 alloy[J]. Journal of Central South University: Science and Technology, 2007, 38(3): 386-373.

[8] 王顺才, 李春志, 石 健, 等. 高温瞬时和热暴露对2024铝合金组织和性能的影响[J]. 航空材料学报, 1991, 11(1): 32-38.

WANG Shun-cai, LI Chun-zhi, SHI jian, et al. Effect of high temperature instant and thermal exposure on microstructure and mechanical property of 2024 aluminium alloy[J]. Journal of Aeronautical Materials, 1991, 11(1): 32-38.

[9] 郑 鹏, 郑玉珍, 魏 晖, 等. 稳定化对新型2324高纯铝合金组织性能的影响[J]. 航空材料学报, 1994, 14(4): 15-20.

ZHENG Peng, ZHENG Yu-zhen, WEI Hui, et al. Effect of stablizition on microstructure and mechanical property of new style 2324 high purity aluminium alloy[J]. Journal of Aeronautical Materials, 1994, 14(4): 15-20.

[10] Radmilovic V, Kilaas R, Dahmen U, et al. Structure and morphology of S-phase precipitates in aluminium[J]. Acta Mater, 1999, 47(15/16): 3987-3997.

[11] 刘禹门. Al-Cu-Mg合金中位错与S相的相互作用[J]. 兵器材料科学与工程, 2005, 28(5): 1-4.

LIN Yu-men. Interaction between dislocation and S-phase precipitates in Al-Cu-Mg alloy[J]. Ordnance Material Science and Engineering, 2005, 28(5): 1-4.

[12] 王莉梅. Al-Cu-Mg系铝合金时效过程的电镜观察[J]. 轻合金加工技术, 1995, 23(6): 15-20.

WANG Li-mei. Microscope observation of aging in Al-Cu-Mg alloy[J]. Alminium Fabrication, 1995, 23(6): 15-20.

[13] 谷亦杰, 陈 荣, 张永刚, 等. 预变形对463k人工时效Al-Cu-Mg合金显微组织的影响[J]. 中国有色金属学报, 2001, 11(1): 31-33.

GU Yi-jie, CHEN Rong, ZHANG Yong-gang, et al. Effect of pre-deformation on microstructures of Al-Cu-Mg alloy aged at 463 K[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(1): 31-33.

[14] Honycombe R W K. The plastic deformation of metals[R]. W1Z8LL. London: Edwad Arnold, 1984.

收稿日期:2008-09-04;修回日期:2008-11-18

基金项目:国家“973”重点基础研究项目(G2005CB623705)

通信作者:尹志民(1946-),男,湖南湘乡人,教授,博士生导师,从事金属材料结构与性能研究;电话:0731-88830262;E-mail: yin-grp@csu.edu.cn