DOI: 10.11817/j.issn.1672-7207.2018.04.001

鞍山式赤铁矿预选粗精矿悬浮态磁化焙烧—磁选试验研究

余建文,韩跃新,李艳军,高鹏

(东北大学 资源与土木工程学院,辽宁 沈阳,110819)

摘要:采用实验室间歇式悬浮态反应炉作为磁化焙烧装置,以高纯N2和H2的混合气体作为还原气体,考察450~700 ℃下某鞍山式赤铁矿预选粗精矿磁化焙烧—磁选的影响因素。研究结果表明:在气体流量为8 m3/h、反应温度为650 ℃、H2体积分数为40%及物料循环3次的条件下,焙烧物料经磁场强度80 kA/m的戴维斯磁选管分选后,可获得Fe质量分数为65.46%、回收率88.10%的优质铁精矿。

关键词:鞍山式赤铁矿;预选精矿;悬浮态磁化焙烧;磁选

中图分类号:TD925.7 文献标志码:A 文章编号:1672-7207(2018)04-0771-08

Experimental study on utilization of crude concentrate from an Anshan-type hematite ore by suspension magnetization roasting-magnetic separation

YU Jianwen, HAN Yuexin, LI Yanjun, GAO Peng

(School of Resources and Civil Engineering, Northeastern University, Shenyang 110819, China)

Abstract: Magnetization roasting via a laboratory-batch scale fluidized reactor was carried out for the utilization of crude concentrate from an Anshan-type hematite ore, which was performed at 450-700 ℃ in mixed H2 and N2 atmosphere. The results show that the gas flow is 8 m3/h, the roasting temperature is 650 ℃, the hydrogen volume fraction is 40% and the material cycles is 3, and a high grade concentrate containing 65.46% iron with an iron recovery of 88.10% is achieved by magnetic separation with a magnetic field strength of 80 kA/m under above conditions.

Key words: Anshan-type hematite iron ores; preconcentrate; suspension magnetization roasting; magnetic separation

我国鞍山式赤铁矿资源储量巨大,现已探明储量50多亿t,主要集中在辽宁、山西、河北、湖南等地。其中典型代表性的鞍山式赤铁矿资源有东鞍山铁矿、齐大山铁矿及司家营铁矿。自1958年以来,我国选矿科技工作者就对东鞍山铁矿石进行了长期的科技攻关试验。最初,东鞍山铁矿石的选别工艺流程为“连续磨矿—单一碱性正浮选”,在原矿品位为32.74%(质量分数)的条件下,获得了精矿品位为59.98%、回收率为72.49%的技术指标[1-6]。针对齐大山铁矿石的开发利用,其早期采用的选别工艺流程为“阶段磨矿—重选—磁选—浮选”及“竖炉磁化焙烧—磁选”。在原矿品位分别为28.49%和29.26%的条件下,分别获得精矿品位为63.60%和63.26%及回收率为73.20%和77.03%的选别指标[4-5, 7-8]。1988年,我国选矿工作者围绕提高齐大山铁矿石选矿技术指标进行了大量的研究。其中,典型的研究成果有长沙矿冶研究院的“连续磨矿—弱磁—强磁—阴离子反浮选”、马鞍山矿山研究院的“连续磨矿—弱磁—强磁—酸性正浮选”及鞍钢集团矿山公司的“连续磨矿—弱磁—强磁—阳离子反浮选”工艺[4-5, 8-9]。2001年,鞍钢矿山研究所总结齐大山选矿厂工艺改造的成功经验,对东鞍山铁矿进行了“连续磨矿—重选—磁选—阴离子反浮选”及“连续磨矿—磁选—重选—阴离子反浮选”工艺流程对比试验,在原矿品位分别为31.38%及32.94%的条件下,取得了精矿品位为64.08%和64.74%及回收率为71.47%和71.69%的技术指标。在此基础上,2002年东鞍山烧结厂按“连续磨矿—重选—磁选—阴离子反浮选”工艺流程完成了工业化改造,并于2004年实现了原矿品位为32.26%、精矿品位为64.80%、尾矿品位为16.06%及回收率为66.76%的工业技术指标[8]。2002年,针对司家营赤铁矿的开发利用,唐钢委托鞍钢矿山研究所进行了阶段磨矿—粗细分级—重选—磁选—阴离子反浮选和阶段磨矿—粗细分级—磁选—重选—阴离子反浮选工艺对比研究。在原矿品位为29.14%的条件下,分别获得了精矿品位为66.57%和66.40%,尾矿品位为8.87%和9.08%及回收率为80.24%和79.75%的技术指标。根据上述试验结果,唐钢司家营铁矿采用阶段磨矿—粗细分级—重选—磁选—阴离子反浮选工艺建设生产,并一直使用至今[8, 10-11]。近年来,随着东鞍山铁矿开采深度的增加,矿石性质发生变化。所采铁矿石中碳酸盐(菱铁矿及铁白云石)含量显著增加,对分选过程构成极大的影响。当碳酸铁质量分数大于8%时,甚至出现精、尾不分现象。针对东鞍山含碳酸盐铁矿石无法利用的技术难题,东北大学针进行了系统的分选试验研究,发现细粒菱铁矿在赤铁矿和石英表面的吸附罩盖是难以实现分选的本质原因[12-16],并据此创造性提出“分步浮选”技术,即第1步在中性条件下采用正浮选预先分离出菱铁矿,以消除其对后续赤铁矿与石英矿物分离的影响;第2步在强碱性条件下采用反浮选使石英等脉石矿物与赤铁矿分离,实验室获得了铁精矿品位为66.34%,铁回收率为71.60%的优异指标,并于2010年在东鞍山烧结厂成功应用,获得了铁精矿品位为63.03%、回收率为63.77%的工业技术指标,使含碳酸盐铁矿石获得了工业利用。但“分步浮选”技术的铁回收率低,造成铁矿资源的极大浪费。综上所述,采用常规选矿方法无法实现鞍山式赤铁矿资源的高效利用。在当前技术经济条件下,磁化焙烧—弱磁分选技术是处理低品位难选铁矿石典型和最有效的方法,因悬浮态焙烧具有传热传质效率高、能耗低等突出优点,悬浮态磁化焙烧成为近年来的研究热点。本文作者基于复杂难选铁矿“预富集—悬浮态磁化焙烧—磁选”新技术,采用自制实验室型间歇式悬浮态磁化反应焙烧炉,对东鞍山赤铁矿石预选粗精矿进行了系统的悬浮态磁化焙烧—磁选试验,以期为此类鞍山式赤铁矿资源的高效开发利用提供一种新途径。

1 试验

1.1 试样性质

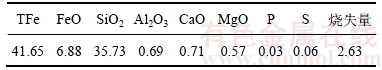

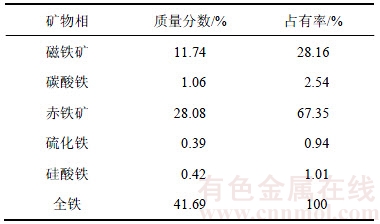

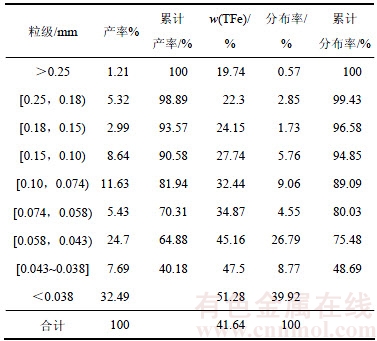

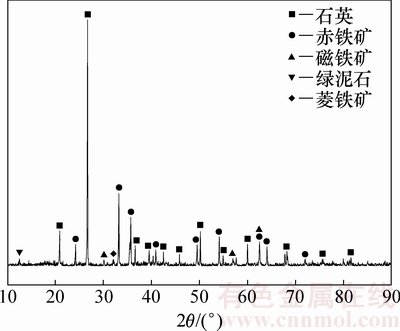

试验所用原料为东鞍山铁矿磁选预选精矿,试样经混匀、取样、分别进行原矿化学多元素分析、铁物相分析、XRD分析及粒度组成分析,结果见表1~3和图1。

据表1~3可知:原矿铁品位(质量分数)为41.65%,且以赤铁矿形式存在为主,占有率为67.35%;矿石中SiO2质量分数为35.73%,有害元素P和S质量分数较低;原料细度小于0.074 mm的质量分数占70.31%,铁主要分布于小于0.038 mm粒级中。由图1可知:该预选精矿主要由石英、赤铁矿、和磁铁矿组成,另外含有少量的菱铁矿和绿泥石。

1.2 试验方法

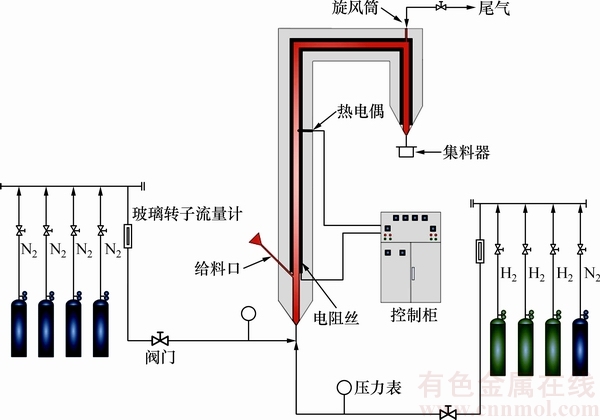

试验中所使用的间歇式悬浮焙烧炉是由东北大学与沈阳鑫博工业技术股份有限公司共同研制。该悬浮焙烧装置由给料系统、电加热与温度控制系统、气固分离系统、物料收集系统等组成,其结构示意图如图2所示。

表1 原料的化学多元素分析(质量分数)

Table 1 Multi-element analysis of raw ore %

表2 铁物相分析结果

Table 2 Analysis results of iron phase

试验过程中,当温度升至预定值时,首先将N2由炉膛底部引入到焙烧炉腔内以排空炉腔内的空气,然后通过调节气体阀门控制和调整一定流量的N2和H2通入焙烧炉内,并将准备好的细粒原料(100 g/份)由给料装置给入到焙烧炉中进行磁化焙烧,完成焙烧后关闭加热系统并向焙烧炉内通入N2以排空炉内残留的还原性气体H2,待焙烧物料冷却至350°C以下时取出空冷至室温。

表3 原料粒度组成及Fe在各粒级的分布率

Table 3 Particle size composition of raw ore and distribution of Fe

图1 原料XRD分析图谱

Fig. 1 XRD pattern of raw ore

焙烧、冷却物料经实验室小型锥形球磨机(XMQ- 150×50)磨细至小于0.038 mm粒级质量分数占85%后,缩分出10.0 g子样本进行戴维斯磁选管(XCGS-50)试验,磁场强度为80 kA/m。磁选精矿和尾矿分别烘干、称量和化验Fe质量分数以计算铁回收率。

150×50)磨细至小于0.038 mm粒级质量分数占85%后,缩分出10.0 g子样本进行戴维斯磁选管(XCGS-50)试验,磁场强度为80 kA/m。磁选精矿和尾矿分别烘干、称量和化验Fe质量分数以计算铁回收率。

图2 悬浮焙烧炉结构示意图

Fig. 2 Structure diagram of suspension roasting furnace

2 磁化焙烧热力学分析

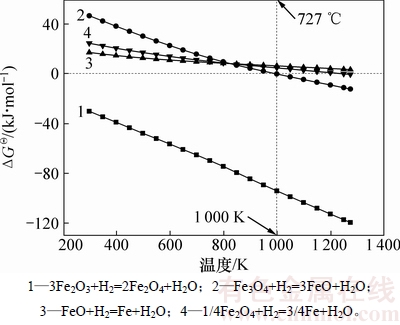

在本次磁化焙烧试验过程中,采用的还原剂为H2,因此,可能发生的反应有:

3Fe2O3+H2=2Fe3O4+H2O (1)

Fe3O4+H2=3FeO+H2O (2)

FeO+H2=Fe+H2O (3)

1/4Fe3O4+H2=3/4Fe+H2O (4)

图3所示温度为1 000 ℃以内反应(1)~(4)的标准吉布斯自由能(△GΘ)与温度(T)之间的线性关系。从图3可知:温度在450~700 ℃范围内,反应(1)的标准吉布斯自由能为负数,表明赤铁矿很容易被H2还原为磁铁矿。随着温度的升高,反应(1)的标准吉布斯自由能越小(负),说明升高温度有助于反应(1)的发生。但是当温度超过727 ℃(1 000 K)时,新生磁铁矿可能发生过还原转化为弱磁性的富士体(FeO),如反应(2)所示。进一步提高反应温度,金属铁也有可能出现,如反应(3)和(4)所示。因此,为选择性地将赤铁矿还原为磁铁矿,实现磁化焙烧的目的,应选择合理的温度范围 (727 ℃以下)。

图3 反应(1)~(4)的标准反应吉布斯自由能与温度之间的关系

Fig. 3 Relations between standard Gibbs free energy and temperatures for reactions (1)~(4)

图4所示为温度在1 000 ℃ 以内H2还原铁氧化物的平衡组分相图。由图4可知:温度在450~700 ℃范围内,将赤铁矿还原为磁铁矿所需的氢气体积分数φ(H2)非常小(约0.001%)。图4表明:在H2还原性气氛中,赤铁矿还原转化为磁铁矿的反应(1)非常容易发生,这与图3所得结论一致。理论上,在570 ℃以下也有可能还原出金属铁(Fe),如反应(4)所示,但此时所需的还原剂H2体积分数φ(H2)非常高(>76.8%)。温度在570~700 ℃范围内,也可能还原出弱磁性的富士体(φ(H2)>52.93%)和金属铁(φ(H2)>69.42%)。因此,在试验过程中为防止新生磁铁矿过还原为金属铁或富士体,还原剂H2的体积分数φ(H2)应控制在52.93%以下。但是,通常情况下由于动力学因素的影响,理论分析与实际生产有很大的区别。因此,有必要对影响赤铁矿磁化焙烧过程的影响因素进行全面考察与分析。

图4 氢气还原铁氧化物的平衡组分

Fig. 4 Equilibrium phase compositions for reduction of iron oxides by H2

3 结果与讨论

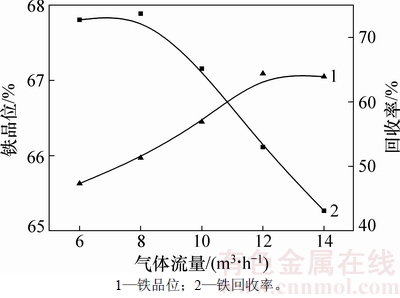

3.1 气体流量对磁化焙烧过程的影响

悬浮态磁化焙烧试验过程中,首先在焙烧温度为600 ℃,物料循环次数为1次,H2体积分数为20%(还原气体中H2与N2的体积流量比( )为1:4)的条件下,分别考察气体流量为6,8,10,12和14 m3/h时对焙烧效果的影响,对不同气体流量下焙烧后的物料进行磁选,结果如图5所示。

)为1:4)的条件下,分别考察气体流量为6,8,10,12和14 m3/h时对焙烧效果的影响,对不同气体流量下焙烧后的物料进行磁选,结果如图5所示。

由图5可知:在气体流量为6~8 m3/h范围内,磁选精矿铁品位及回收率均随着气体流量的增大而升高;当气体流量为8 m3/h时,铁回收率达最大值73.75%;继续增大气体流量至14 m3/h时,铁回收率则呈现急剧下降的趋势;当气体流量为14 m3/h时,铁回收率降至43.12%。磁选精矿铁品位变化规律较简单,随着气体流量的不断增大,品位总体上呈现不断升高的趋势;当气体流量为12 m3/h时,铁回收率升至最大值67.09%;进一步增大气体流量至14 m3/h时铁品位几乎保持不变。这主要是由于气体流量增大,相应的气体表观流速变大,物料在悬浮焙烧炉内停留时间短,磁化反应不完全,回收率逐渐降低。综上分析,适宜的气体流量确定为8 m3/h。

图5 气体流量对磁化焙烧效果的影响

Fig. 5 Effect of gas flow rate on magnetization roasting

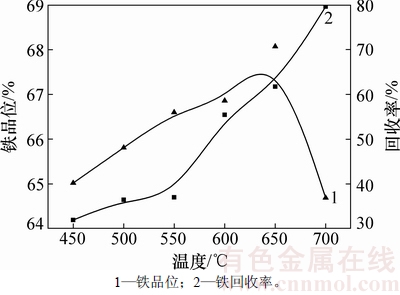

3.2 焙烧温度对磁化焙烧过程的影响

试验确定适宜的气体流量为8 m3/h,在物料循环次数为1次,H2体积分数为20%( =1:4)的条件下,分别考察了焙烧温度450,500,550,600,650和700 ℃对焙烧效果的影响,对不同焙烧温度下焙烧后的物料进行磁选,结果如图6所示。

=1:4)的条件下,分别考察了焙烧温度450,500,550,600,650和700 ℃对焙烧效果的影响,对不同焙烧温度下焙烧后的物料进行磁选,结果如图6所示。

图6 焙烧温度对磁化焙烧效果的影响

Fig. 6 Effect of roasting temperature on magnetization roasting

由图6可知:在焙烧温度为450~650 ℃范围内,磁选精矿的铁品位及回收率均随着焙烧温度的升高而逐渐增大;当温度为650 ℃时,精矿铁品位达最大值68.07%;继续升高温度至700 ℃时,铁品位则急剧下降至64.69%,铁回收率则进一步提高至79.59%。这主要是由于温度越高,物料的磁化反应速率越快,赤铁矿等向磁铁矿转化率越高,因而铁回收率逐步提高;但当温度升高至700 ℃时,原料中的含铁绿泥石在还原性气氛下可转变为橄榄石包裹型的磁铁矿[17],在后续磁选过程中进入精矿中从而降低精矿铁品位。因此,确定适宜的焙烧温度为650 ℃。

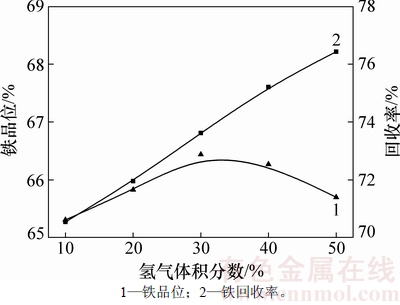

3.3 氢气体积分数对磁化焙烧过程的影响

试验确定了适宜的气体流量为8 m3/h,焙烧温度为650 ℃,在物料循环次数为1次的条件下,分别考察氢气体积分数为10%,20%,30%,40%和50%对磁化焙烧效果的影响,对不同氢气体积分数下焙烧后的物料进行磁选,结果如图7所示。

图7 氢气体积分数对磁化焙烧效果的影响

Fig. 7 Effect of hydrogen volume fraction on magnetization roasting

由图7可知:在氢气体积分数为10%~30%范围内,磁选精矿铁品位及回收率均随着氢气体积分数的升高而逐渐增大;当氢气体积分数为30%时,精矿铁品位为66.44%,回收率为73.62%;继续升高氢气体积分数至40%时,精矿铁品位降低为66.27%,回收率则提高至75.21%,进一步升高氢气体积分数至50%时,精矿铁品位则进一步降为65.70%,回收率缓慢提高至76.43%,提高幅度较小。这主要是由于氢气体积分数的提高,促进了还原性气体H2向原料中赤铁矿等含铁矿物颗粒表面的扩散,从而提高了磁化反应效率,相应地磁选铁精矿中铁的回收率逐步提高。因此,确定适宜的氢气体积分数为40%。

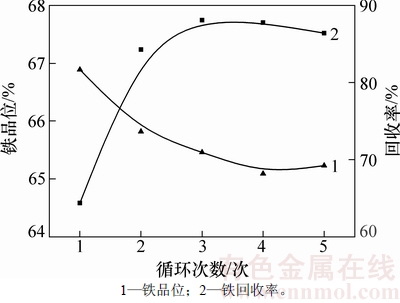

3.4 物料循环次数对磁化焙烧过程的影响

试验在气体流量为8 m3/h、焙烧温度为650 ℃及氢气体积分数为40%的条件下,分别考察物料循环1次、2次、3次、4次和5次对磁化焙烧效果的影响,对不同物料循环次数下焙烧后的物料进行磁选,结果如图8所示。

由图8可知:在物料循环次数为1~3次范围内,磁选精矿铁回收率随着循环次数(焙烧时间)的增加而逐渐升高,当物料循环3次时,精矿铁回收率达到最佳值88.10%;磁选精矿铁品位随着物料循环次数的增加而逐渐下降,当物料循环3次时,精矿铁品位由循环1次时的66.89%降低至65.46%。继续增加循环次数,精矿铁回收率呈现缓慢下降的趋势;当循环5次时,精矿铁回收率降至86.40%,精矿铁品位基本维持在常数65.0%以上不变。这主要是由于适当地增加物料循环次数(焙烧时间),原料中赤铁矿等含铁矿物向磁铁矿转化反应越充分,但物料循环次数超过3次后,由于物料在焙烧炉内停留时间过长,可能导致新生磁铁矿发生过还原向弱磁性的富士体(FeO)转变,从而降低了铁的回收率。综上分析,适宜的物料循环次数确定为3次。此时,所得磁选精矿铁品位为65.46%,铁回收率达88.10%。

图8 循环次数对磁化焙烧效果的影响

Fig. 8 Effect of cycles on magnetization roasting

3.5 焙烧物料产品物相及结构分析

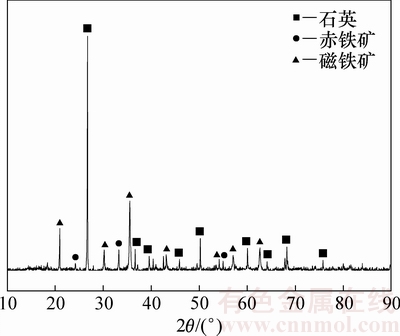

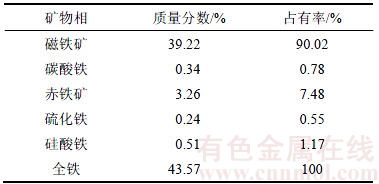

为探明焙烧过程中铁矿物的物相转化规律,对最佳焙烧条件下(气体流量为8 m3/h,焙烧温度为650 ℃,氢气体积分数为40%及物料循环3次)的焙烧物料产品进行了XRD分析、铁物相分析及光学显微结构分析。

图9所示为焙烧后物料的XRD分析图谱,与焙烧前物料的XRD图谱(图1)相比,可知经悬浮磁化焙烧后,原料中的赤铁矿已经大部分转化为磁铁矿,但仍残留未反应完全的赤铁矿。

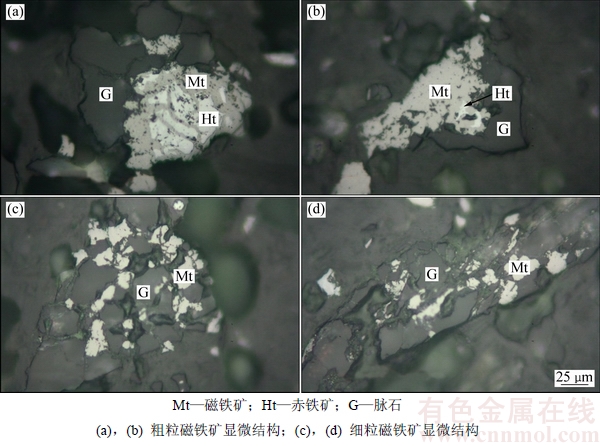

表4所示为焙烧后的物料铁物相分析结果,与原料的铁物相分析结果(表2)相比,经悬浮磁化焙烧后物料的铁质量分数由焙烧前的41.69%提高至43.57%,相应的赤铁矿的占有率由67.35%降低至7.48%、磁铁矿的占有率由28.16%提高至90.02%。结果表明:仍有部分残留的赤铁矿未完成向磁铁矿转化,这与上述XRD图谱分析结果是一致的。这极大的可能是由于部分粗粒赤铁矿仅表面发生了磁化反应转变为磁铁矿,但颗粒内部仍保留为赤铁矿的晶格所致。为验证上述分析结果,对焙烧后物料进行了光学显微结构分析,结果如图10所示。

图9 焙烧后物料的XRD分析图谱

Fig. 9 XRD pattern of roasted ore sample

表4 焙烧后物料铁物相分析

Table 4 Distribution of Fe contained in roasted ore sample with different phases

由图10(c)和(d)可知:焙烧后物料中细粒赤铁矿已经全部转化为磁铁矿,表明原料中赤铁矿粒度小,比表面积大,气固接触反应充分;但粒度相对较大的新生磁铁矿颗粒内核中仍能发现部分残留未反应的赤铁矿(见图10(a)和(b)),表明原料中粒度相对较大的赤铁矿由于比表面积小,气固反应不充分,仅颗粒表面转化为磁铁矿,颗粒内部难以完全转化为磁铁矿,仍残留着部分赤铁矿。但是这种内核仍为赤铁矿的新生磁铁矿颗粒磁性依然很强,经磨矿与脉石矿物解离后,在后续磁选过程中会进入铁精矿产品中,并不会影响铁的回收率和品位。

图10 焙烧后物料的光学显微结构图

Fig. 10 Optical microstructure images of roasted ore sample

4 结论

1) 东鞍山铁矿预选精矿中铁质量分数为41.65%,其中铁主要以赤铁矿和磁铁矿的形式存在,部分以菱铁矿的形式存在;主要脉石矿物为石英,绿泥石等。

2) 对于东鞍山铁矿预选精矿,以高纯H2和N2混合气体为还原剂,在适宜的气体流量为8 m3/h、焙烧温度为650 ℃、H2体积分数为40%及物料循环3次的工艺条件下,焙烧物料通过磁选可获得铁品位65.46%、回收率88.10%的优质铁精矿。

3) 采用“预富集—悬浮态磁化焙烧—磁选”技术处理鞍山式赤铁矿资源是一项全新的尝试,并取得了优异的技术指标,为我国其他类型难选铁矿资源的高效开发利用具有借鉴意义。

参考文献:

[1] 蒋有义, 杨永革. 东鞍山难选矿石工艺矿物学研究[J]. 金属矿山, 2006(7): 40-43.

JIANG Youyi, YANG Yongge. Study on technological mineralogy of Donganshan refractory ores[J]. Metal Mine, 2006(7): 40-43.

[2] 李维兵, 刘保平, 陈占金, 等. 我国红铁矿选矿技术研究现状及发展方向[J]. 金属矿山, 2005(3): 1-6.

LI Weibing, LIU Baoping, CHEN Zhanjin, et al. Present status and development orientation of China’s red iron ore beneficiation technology research[J]. Metal Mine, 2005(3): 1-6.

[3] 张锦瑞, 胡力可, 梁银英. 我国难选铁矿石的研究现状及利用途径[J]. 金属矿山, 2007(11): 6-9.

ZHANG Jinrui, HU Like, LIANG Yinying. Status quo of utilization way research of refractory iron ore in China[J]. Metal Mine, 2007(11): 6-9.

[4] 李维兵, 陈志华. 鞍山地区红铁矿选矿工艺的进展及建议[J]. 国外金属矿山, 2002(3): 40-46.

LI Weibing, CHEN Zhihua. Advances and recommendations on the beneficiation of Anshan red iron ores[J]. Foreign Metal Mining Magazine, 2002(3): 40-46.

[5] 陈国荣. 东鞍山赤铁矿选矿技术研究[D]. 沈阳:东北大学资源与土木工程学院, 2008: 1-4.

CHEN Guorong. Study on separation technology for Donganshan hematite ore[D]. Shenyang: Northeastern University. College of Resources and Civil Engineering, 2008: 1-4.

[6] 刘动, 李维兵. 东鞍山铁矿石工艺矿物学及选矿工艺研究与建议[J]. 金属矿山, 2004(7): 27-31.

LIU Dong, LI Weibing. Research of technological mineralogy and mineral processing technology of Donganshan iron ores and suggestion[J]. Metal Mine, 2004(7): 27-31.

[7] 鲁荣林. 东鞍山铁矿矿石工艺矿物学研究[J].金属矿山, 2004(9): 40-41.

LU Ronglin. Study on characteristics of technological mineralogy of Donganshan iron mine’s ore[J]. Metal Mine, 2004(9): 40-41.

[8] 张明. 东鞍山含碳酸盐铁矿石浮选行为研究[D]. 沈阳:东北大学资源与土木工程学院, 2009: 3-5.

ZHANG Ming. Study on the floatation behavior for Donganshan carbonate-containing iron ore [D]. Shenyang: Northeastern University. College of Resources and Civil Engineering, 2009: 3-5.

[9] 吕建华. 齐大山矿石矿物学特性及选矿厂工艺特点[J]. 矿业工程, 2004, 2(3): 23-26.

L Jianhua. Mineralogical features of Qidashan iron ore and properties of Qidashan dressing plant[J]. Mining Engineering, 2004, 2 (3): 23-26.

Jianhua. Mineralogical features of Qidashan iron ore and properties of Qidashan dressing plant[J]. Mining Engineering, 2004, 2 (3): 23-26.

[10] 李俊华. 浅谈开发河北司家营铁矿的难点及对策[J]. 矿业快报, 2004(7): 27-29.

LI Junhua.Difficulties and countermeasures in the development of Hebei Sijiaying iron ore[J]. Express Information of Mining Industry, 2004(7): 27-29.

[11] 张久甲, 候吉林. 唐钢司家营氧化铁矿石选矿试验研究[J]. 金属矿山, 2004(4): 28-31.

ZHANG Jiujia, HOU Jilin. Experiment research on beneficiation of oxidized iron ore of Sijiaying Mine, Tang Steel[J]. Metal Mine, 2004(4): 28-31.

[12] 张兆元, 吕振福, 印万忠, 等. 东鞍山铁矿石中菱镁铁矿对反浮选的影响[J]. 金属矿山, 2008(10): 52-55.

ZHANG Zhaoyuan, LU Zhengfu, YIN Wanzhong, et al. Influence of the siderite in Donganshan iron ore on reverse flotation[J]. Metal Mine, 2008(10): 52-55.

[13] 冀秀荣, 纪振明, 田鹏杰, 等. 东鞍山含碳酸盐铁矿石分步浮选中矿的试验研究[J]. 现代矿业, 2010(7): 30-32.

JI Xiurong, JI Zhenming, TIAN Pengjie, et al. Experimental study of middling ore branch flotation from iron ore containing carbonate at Donganshan[J]. Modern Mining, 2010(7): 30-32.

[14] YIN Wanzhong,YANG Xiaosheng, ZHOU Dapeng, et al. Shear hydrophobic flocculation and flotation of ultrafine Anshan hematite using sodium oleate[J]. Trans Nonferrous Met Soc China, 2011, 21(3): 652-664.

[15] 李丽匣, 印万忠, 王玉斌, 等. 菱铁矿对假象赤铁矿与石英混合矿浮选的影响[J]. 东北大学学报(自然科学版), 2012, 33(3): 431-434.

LI Lixia, YIN Wanzhong, WANG Yubin, et al. Effect of siderite on flotation separation of martite and quartz[J]. Journal of Northeastern University: Natural Science, 2012, 33(3): 431-434.

[16] 邵安林. 东鞍山含碳酸盐赤铁矿石浮选试验[J]. 中南大学学报(自然科学版), 2013, 44(2): 456-460.

SHAO Anlin. Flotation separation of Donganshan carbonates-containing hematite ore[J]. Journal of Central South University (Science and Technology), 2013, 44(2): 456-460.

[17] LIU Xinghua, YU Yongfu, CHEN Wen, et al. Phase change of chlorite in reducing atmosphere[J]. Physicochemical Problems of Mineral Processing, 2014, 50: 607-614.

(编辑 杨幼平)

收稿日期:2017-04-20;修回日期:2017-07-06

基金项目(Foundation item):国家自然科学基金资助项目(51674064,51674065);中央高校基本科研业务费项目(N140108001,N150106003) (Projects(51674064, 51674065) supported by the National Natural Science Foundation of China; Projects(N140108001, N150106003) supported by the Fundamental Research Funds for the Central Universities)

通信作者:韩跃新,博士,教授,从事复杂难选矿产资源高效利用研究;E-mail:dongdafulong@mail.neu.edu.cn