DOI: 10.11817/j.issn.1672-7207.2019.02.027

单向拉伸应力状态下沥青混合料强度和刚度特性

黄拓1, 2,漆帅2,蒋浩浩2,黄谋英2,李咪2,李亦鹏2

(1. 公路工程教育部重点实验室(长沙理工大学),湖南 长沙,410114;

2. 长沙理工大学 交通运输工程学院,湖南 长沙,410114)

摘要:为了解单向拉伸应力状态下沥青混合料的强度、刚度特性及破坏原因,进行不同加载速度的直接拉伸动回弹模量、静回弹模量及强度试验,揭示沥青混合料强度、回弹模量、破坏应变、应变能等参数随加载速度的变化规律。建立初始开裂对应的各个力学参数与加载速度之间的幂函数关系,并从破坏机理上将材料设计与结构层的设计相统一。研究结果表明:在单轴拉伸试验中,沥青混合料的动、静回弹模量随加载速度的增大而呈幂函数增大,且动回弹模量随着温度的升高而降低;进行不同加载速度的破坏试验时,试件的初始开裂应变基本保持稳定,且表现为拉应变破坏特征,故拉应变是导致沥青混合料发生破坏的原因,用第二强度理论作为直接拉伸条件下的破坏准则较合适。

关键词:沥青混合料;单向拉伸应力状态;强度试验;刚度试验;破坏准则

中图分类号:U416.217 文献标志码:A 文章编号:1672-7207(2019)02-0460-06

Stress and stiffness characteristics of asphalt mixture under uniaxial tensile stress state

HUANG Tuo1, 2, QI Shuai2, JIANG Haohao2, HUANG Mouying2, LI Mi2, LI Yipeng2

(1. Key Laboratory of Highway Engineering of Ministry of Education,Changsha University of Science & Technology, Changsha 410114, China;

2. School of Traffic and Transportation Engineering,Changsha University of Science & Technology, Changsha 410114, China)

Abstract: In order to study stress and stiffness properties, as well as failure reason of asphalt mixture under uniaxial tensile stress state, static resilient modulus tests, dynamic resilient modulus tests and strength tests with various loading rates were carried out. Based on the tests, the change law of mechanics parameters such as strength, modulus, failure strain and strain energy of asphalt mixture with loading rates were revealed. The power function relations among various mechanics parameters corresponding to initial crack and loading rates were established. Material design and structural layer design were unified in failure mechanism. The results show that the dynamic and static resilient modulus increase with the increase of loading rate as power function. Besides, the dynamic modulus decreases with the increase of temperature. The initial cracking strain of specimen almost keeps stable at various loading rates, and presents tensile strain failure. So, tensile strain is the main factor leading to failure, and the second strength theory can be used as failure criterion for direct tensile condition.

Key words: asphalt mixture; uniaxial tensile stress state; strength test; stiffness test; failure criterion

至2018年底,我国已通车高速公路14.25万km,居世界第1位,其中大部分为沥青路面结构。在荷载和环境的共同作用下,沥青面层材料一般处于三维复杂应力状态下工作[1-2]。然而,沥青混合料的力学特性十分复杂,其一维、二维和三维拉、压强度和刚度特性各不相同,且与加载速度和试验温度相关[3-8]。可以从破坏特性出发,将混合料的破坏类型分解成各种简单的应力状态进行研究[9-10]。目前,常用的沥青混合料力学性能试验方法有单轴压缩、单轴拉伸、弯拉、劈裂等[11]。在上述试验方法中,直接拉伸试验的试件处于单向受拉应力状态,能够较好地评价材料的抗拉性能。且JTG D50—2017“公路沥青路面设计规范”[12]以沥青混合料层层底的拉应变作为设计指标来控制沥青层的疲劳开裂。若通过试验研究直接拉伸应力状态下混合料的强度和刚度特性,证明拉应变导致试件破坏,则能从破坏机理上将材料设计与结构层的设计相统一,为沥青路面结构设计的参数取值提供参考,为此,本文对单向拉伸应力状态下沥青混合料强度、刚度特性及破坏原因进行研究。

1 试验与设计

1.1 直接拉伸试验

直接拉伸试验作为评价沥青混合料低温抗裂性能的试验方法,应用较广泛。试件的受力模式如图1所示,试件处于均匀受拉应力状态。为避免试验过程中试件偏心受拉,一方面,在拉拔板成型时制细纹同心圆,以保证试件粘胶时能准确对中;另一方面,在拉拔板两端用球阀连接MTS试验机的加载轴[3]。各力学参数的计算式为:

(1)

(1)

(2)

(2)

图1 直接拉伸试验示意图

Fig. 1 Schematic diagram of direct tensile test

式中: 为直接拉伸强度,MPa;P为破坏荷载,N;a和b均为试件截面的边长,mm;ε为试件的破坏应变;△L为试件破坏时的变形量,mm;L为试件长度,mm。

为直接拉伸强度,MPa;P为破坏荷载,N;a和b均为试件截面的边长,mm;ε为试件的破坏应变;△L为试件破坏时的变形量,mm;L为试件长度,mm。

1.2 配合比设计

所采用的试件是由欧标轮碾压实仪成型的长为400 mm、宽为300 mm、高为80 mm的车辙板,然后切割成长为250 mm、宽为50 mm、高为50 mm的小梁试件。成型试件的胶结料为东海石油SBS改性沥青,集料为湖南怀芷高速的玄武岩,级配组成为AC-13C,见表1;胶结料和集料的各项指标均满足JTG F40—2004“公路沥青路面施工技术规范”的要求。沥青混合料的最佳油石比由马歇尔试验确定为5.2%,如表2所示[13]。

2 直接拉伸刚度特性

2.1 静态回弹模量

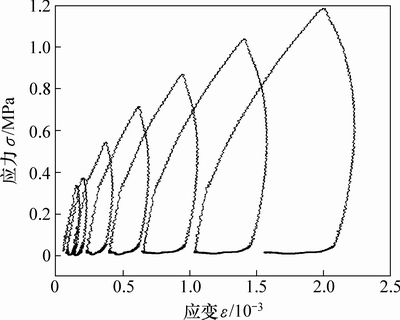

为了解直接拉伸应力状态下沥青混合料的刚度特性,参考JTG E20—2011“公路工程沥青及沥青混合料试验规程”[11]中回弹模量的测试方法,如图2所示,在15 ℃条件下,采用逐级加载、卸载的方法测试各级荷载压强与回弹变形,并取第5级荷载的压强及相应的回弹变形计算沥青混合料的直接拉伸回弹模量:

(3)

(3)

式中:Et为直接拉伸静态回弹模量,MPa;σ5对应于第5级荷载时的应力,MPa;l为试件轴心高度,mm;△L5为第5级荷载时经原点修正后的回弹变形,mm。在试验规程中,沥青混合料静态回弹模量的测试采用控制位移的方式加载。而混合料的刚度特性与加载速度相关[14-16],为了分析加载速度的影响,分别采用0.3,0.4,0.5,0.6和0.7 MPa/s的加载速度测定直接拉伸回弹模量,试验结果见表3和图3。

表1 AC-13C密级配沥青混合料矿料级配

Table 1 Gradation of AC-13C dense grad asphalt mixture

表2 最佳油石比下马歇尔试验结果

Table 2 Marshall test results at optimal asphalt content

图2 直接拉伸静态回弹模量应力-应变曲线

Fig. 2 Stress-strain curve of static resilient modulus in direct tensile test

分析表3中加载速度与沥青混合料直拉静态回弹模量之间的关系,得

,

, (4)

(4)

式中: 为应力加载速度,MPa/s;R为相关系数。

为应力加载速度,MPa/s;R为相关系数。

由式(4)可知:加载速度显著影响着沥青混合料的直拉静态回弹模量,回弹模量与应力加载速度之间呈幂函数关系;随着加载速度增大,直拉静态回弹模量逐渐增大,但增幅逐渐减小。同时,考虑到以控制应力方式加载与常规的控制位移方式加载测得的静态回弹模量应有可比性,而0.3 MPa/s的应力加载速度与规范中2 mm/min的加载速率接近,因此,对于AC-13C沥青混合料,直接拉伸静态回弹模量的控制应力加载速度应选为0.3 MPa/s,其回弹模量为1 435 MPa。

2.2 动态回弹模量

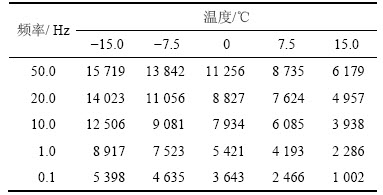

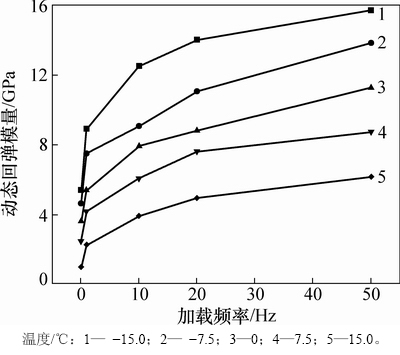

动态回弹模量测试参照美国ASMT D 3497中的方法,并结合我国“公路工程沥青及沥青混合料试验规程”中动模量测试方法的规定,在弹性范围内,按一定加载频率对试件施加半正矢波轴向拉应力。应力幅值取0.7 MPa,测量最后5次加载循环中试件的可恢复轴向变形,以计算直接拉伸动态回弹模量。在测试动模量时,试验温度分别为15.0,-7.5,0,7.5和15.0 ℃;加载频率分别为0.1,1.0,10.0,20.0和50.0 Hz,试验结果见表4。不同温度下直接拉伸动态回弹模量与加载频率的关系见图4。

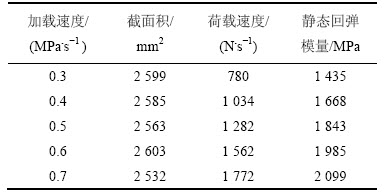

表3 不同加载速度时沥青混合料直拉静态回弹模量

Table 3 Static resilient modulus of asphalt mixture in direct tensile test at various loading rates

图3 直接拉伸静态回弹模量与加载速度的关系

Fig. 3 Relationship between static resilient modulus in direct tensile test and loading rate

表4 沥青混合料直拉动态回弹模量

Table 4 Dynamic resilient modulus of asphalt mixture in direct tensile test MPa

表4中,动态模量与频率和加载速度之间的关系为

(5)

(5)

图4 不同温度下直接拉伸动态回弹模量与加载频率的关系

Fig. 4 Relationship between dynamic resilient modulus in direct tensile test and loading frequencies at various temperatures

式中:Ed为直接拉伸动态回弹模量,MPa;f为加载频率,Hz;t为试验温度,℃。

由式(5)可知:加载频率与试验温度显著影响沥青混合料的直拉动态回弹模量;动态回弹模量与加载频率之间同样呈幂函数关系,其值随加载频率的增大而增大,但增幅逐渐减小;动态模量增幅最大的区间对应的频率范围为0.1~1.0 Hz。在相同频率下,动态回弹模量随温度降低而升高。考虑到公路沥青路面设计规范JTG D50—2017中动态回弹模量的测试频率为10 Hz,建议对于AC-13C型沥青混合料直接拉伸动态回弹模量的加载频率宜定为10 Hz,在15 ℃时动态回弹模量为静态回弹模量的2.74倍。

3 强度特性及破坏准则

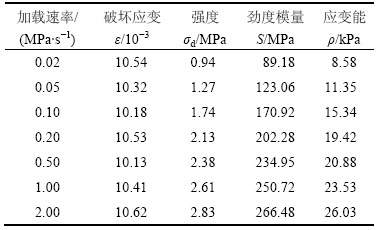

为了解直接拉伸应力状态下沥青混合料的强度特性,在15 ℃时,采用控制应力模式,进行加载速度分别为0.02,0.05,0.10,0.20,0.50,1.00和2.00 MPa/s的强度试验。在直接拉伸破坏试验中,试件受力均匀,理论上将在长度方向上均匀变形。但作为一种非均质的多相材料,沥青混合料不可避免地存在相对薄弱的位置。因此,试件将在薄弱位置最先发生破坏,而不可能在长度方向上产生均匀变形而破坏。故参照文献[17]中方法,以初始开裂定义破坏,在试件长度方向上首尾顺次相连地粘贴应变片,测试破坏时的局部应变,以获得实测破坏应变对应的强度、劲度模量和应变能,如表5所示。

表5 以初始开裂作为破坏准则对应的力学参数

Table 5 Mechanical parameters by taking initial crack as failure criterion

表5中,强度σd和破坏应变ε的计算公式分别见式(1)和式(2);劲度模量S和应变能ρ的计算式分别为:

S=σd/ε (6)

(7)

(7)

式中:σd为试件初始开裂对应的强度,MPa;ε为应变分量;εmax为破坏应变即临界应变。材料破坏时的应变能ρ通过应力应变曲线下方的包络线面积确定。

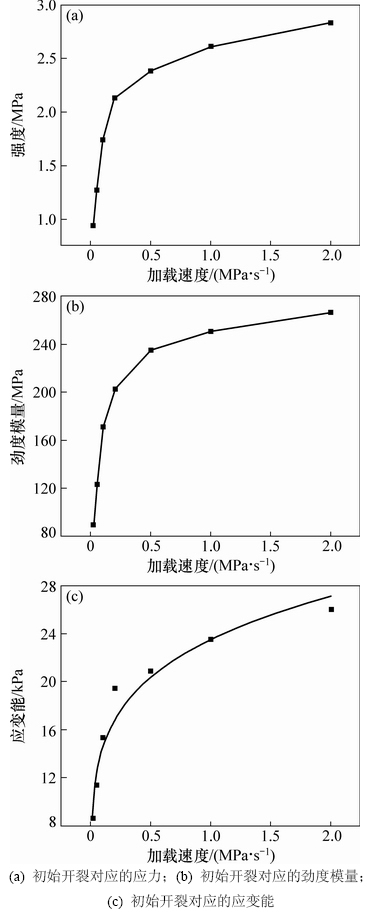

分析表5中强度、劲度模量、应变能与加载速度之间的关系,可得:

,

, (8)

(8)

,

, (9)

(9)

,

, (10)

(10)

式中:S为试件初始开裂对应的劲度模量,MPa;ρ为试件初始开裂对应的应变能,kPa。试样初始开裂对应的各力学参数与加载速度的关系见图5。

第二强度理论认为,断裂是由最大拉应变引起的,当最大拉应变达到极限值时材料就发生断裂。由上述分析可知:在直接拉伸试验中,试件破坏时,极限拉应变基本保持稳定,其均值为0.010 39,且表现为拉应变破坏特征,可见拉应变是导致沥青混合料发生破坏的原因,用第二强度理论作为破坏准则较合理。若以试件初裂定义破坏,则直接拉伸试验中破坏状态对应的力学参数包括强度、劲度模量和应变能均与加载速度呈幂函数关系,且其幂指数相同,表明各力学参数随加载速度的增长规律基本一致。在新版JTG D50—2017“公路沥青路面设计规范”中,以沥青混合料层层底的拉应变作为设计指标来控制沥青层的疲劳开裂;本试验以最大拉应变理论作为破坏准则,与规范的设计指标沥青层底拉应变一致,这样,可从破坏机理上统一材料设计与结构层设计,为沥青路面结构设计参数的合理取值提供试验及理论参考。

图5 试件初始开裂对应的各力学参数与加载速度的关系

Fig. 5 Relationship between mechanical parameters and loading rate in initial crack

4 结论

1) 通过直接拉伸刚度试验研究,揭示了沥青混合料直接拉伸动态回弹模量的速度相关性和温度相关性,建立了直拉动态和静态回弹模量随加载速度的幂函数关系。

2) 以试件初裂定义破坏,在不同加载速度条件下,混合料破坏时的破坏拉应变基本保持稳定,其均值为0.010 39,且试件表现为拉应变破坏特征。这表明拉应变是导致沥青混合料发生破坏的原因,用最大拉应力理论作为破坏准则较合理,这样,就从破坏机理上统一了材料设计和结构层的设计。据此建立的强度、劲度模量和应变能参数与加载速度之间的幂函数关系,可为沥青路面结构设计参数的取值提供试验及理论参考。

参考文献:

[1] 黄晓明. 路基路面工程[M]. 北京: 人民交通出版社, 2014: 1-15.

HUANG Xiaoming. Road subgrade and pavement engineering[M]. Beijing: China Communication Press, 2014: 1-15

[2] 罗增杰. 三向独立加载条件下沥青混合料强度特性[D]. 长沙: 长沙理工大学交通运输工程学院, 2012: 21-30.

LUO Zengjie. Strength characteristics of asphalt mixture under three-direction independent load[D]. Changsha: Changsha University of Science and Technology. School of Traffic and Transportation Engineering, 2012: 21-30.

[3] 黄拓. 沥青混合料三轴试验方法及破坏准则研究[D]. 长沙: 长沙理工大学交通运输工程学院, 2013: 2-11.

HUANG Tuo. Study on triaxial test method and failure criterion of asphalt mixture[D]. Changsha: Changsha University of Science and Technology. School of Traffic and Transportation Engineering, 2013: 2-11.

[4] ZHENG Jianlong, HUANG Tuo. Study on triaxial test method and failure criterion of asphalt mixture[J]. Journal of Traffic and Transportation Engineering(English Edition), 2015, 2(2): 93-106.

[5] WANG L B, HOYOS L R, WANG J, et al. Anisotropic properties of asphalt concrete: characterization and implications for pavement design and analysis[J]. Journal of Materials in Civil Engineering, 2015, 17(5): 535-543.

[6] 延西利, 吕嵩巍, 陶家朴. 沥青混合料内在参数的实验研究[J]. 西安公路交通大学学报, 1997, 17(3): 9-13.

YAN Xili, LU Songwei, TAO Jiapu. Experimental study on the intrinsic parameters of bituminous mixtures[J]. Journal of Xi 'an Highway University, 1997, 17(3): 9-13.

[7] HUANG Tuo, PAN Qinxue, JIN Jiao, et al. Continuous constitutive model for bimodulus materials with meshless approach[J]. Applied Mathematical Modelling, 2019(66): 41-58.

[8] 黄拓, 郑健龙, 钱国平. 沥青混合料实测拉应变的试验研究[J]. 中外公路, 2013, 33(1): 209-211.

HUANG Tuo, ZHENG Jianlong, QIAN Guoping. Experimental study for the measured tensile strain of asphalt mixture[J]. Chinese and Foreign Highway, 2013, 33(1): 209-211.

[9] 钱国平, 刘宏富, 郑健龙, 等. 不同受力模式下沥青混合料强度的速度特性试验研究[J]. 中南大学学报(自然科学版), 2012, 43(2): 681-687.

QIAN Guoping, LIU Hongfu, ZHENG Jianlong, et al. Strength experiment of speed characteristic of asphalt mixtures in different force modes[J]. Journal of Central South University(Science and Technology), 2012, 43(2): 681-687.

[10] 李帅. 不同受力模式下沥青混合料变形与破坏特征研究[D]. 长沙: 长沙理工大学交通运输工程学院, 2011: 1-2.

LI Shuai. Research on deformation characteristics and damage characteristics of asphalt mixture under different stress patterns[D]. Changsha: Changsha University of Science & Technology. School of Traffic and Transportation Engineering, 2011: 1-2.

[11] JTG E20—2011, 公路工程沥青及沥青混合料试验规程[S].

JTG E20—2011, Standard test methods of bitumen and bituminous mixtures for highway engineering[S].

[12] JTG D50—2017, 公路沥青路面设计规范[S].

JTG D50—2017, Specifications for design of highway asphalt pavement[S].

[13] 李亦鹏. 不同应力状态下沥青混合料强度与刚度特性研究[D]. 长沙: 长沙理工大学交通运输工程学院, 2017: 10-15.

LI Yipeng. Research on strength and stiffness features of asphalt mixture under different stress states[D]. Changsha: Changsha University of Science and Technology. School of Traffic and Transportation Engineering, 2017: 10-15.

[14] 吕松涛. 考虑加载速度影响的沥青混合料疲劳方程[J]. 工程力学, 2012, 29(8): 276-281.

LU Songtao. Fatigue equation of asphalt mixture considering the influence of loading rate[J]. Engineering Mechanics, 2012, 29(8): 276-281.

[15] HUANG Tuo, QI Shuai, YANG Ming, et al. Strength criterion of asphalt mixtures in three-dimensional stress states under freeze-thaw conditions[J]. Applied Sciences, 2018, 8(8): 1302-1316.

[16] HUANG Tuo, ZHENG Jianlong, LU Songtao, et al. Failure criterion of an asphalt mixture under three-dimensional stress state[J]. Construction and Building Materials, 2018, 170, 708-715.

[17] 黄拓, 郑健龙. 不同试验方法的沥青混合料强度特性[J]. 中南大学学报(自然科学版), 2016, 47(8): 2820-2827.

HUANG Tuo, ZHENG Jianlong. Strength characteristics of asphalt mixture with various loading modes[J]. Journal of Central South University(Science and Technology), 2016, 47(8): 2820-2827.

(编辑 陈灿华)

收稿日期:2018-03-11;修回日期:2018-05-12

基金项目(Foundation item):国家自然科学基金资助项目(51608055);湖南省自然科学基金资助项目(2019JJ40297);湖南省教育厅项目(16C0051);交通运输部建设科技项目(2015318825120);公路工程教育部重点实验室开放基金资助项目(长沙理工大学)(kfj160201)(Project(51608055) supported by the National Natural Science Foundation of China; Project(2019JJ40297) supported by the Natural Science Foundation of Hunan Province; Project(16C0051) supported by the Education Department of Hunan Province; Project(2015318825120) supported by Construction Program of Science and Technology of Ministry of Transport; Project(kfj160201) supported by Open Fund of the Key Laboratory of Highway Engineering of Ministry of Education (Changsha University of Science & Technology))

通信作者:黄拓,博士,从事道路结构设计与路面力学研究;E-mail:huangtuomao@163.com