文章编号:1004-0609(2008)08-1566-05

表面改性剂对铜锌粉末表面润湿性和漂浮性的影响

冯拉俊,徐大鹏,雷阿利

(西安理工大学 材料科学与工程学院,西安 710048)

摘 要:采用湿法表面包覆将5种单一表面改性剂按不同的比例包覆于铜锌粉末的表面,测试包覆后铜锌粉末的润湿性、漂浮性以及印刷光泽度,并且分析了改性剂对铜锌粉末润湿性和漂浮性的影响机理。结果表明,经 1%月桂酸钠包覆的铜锌粉末的润湿性降低最多,经2%吐温-80包覆的铜锌粉末的漂浮性升高最多,2%吐温-80对铜锌粉末润湿性的降低和漂浮性的升高都有较大的改善,包覆后的铜锌粉末印刷光泽度由原来的54.4提高到75.5,基本可以满足印刷对铜锌粉末的要求。

关键词:铜锌粉末;表面活性剂;漂浮性;润湿性

中图分类号:TF 12 文献标识码:A

Influences of surfactants on wettability and floating property of bronze powders

FENG La-jun, XU Da-peng, LEI A-li

(School of Materials Science and Engineering, Xi’an University of Technology, Xi’an 710048, China)

Abstract: Five kinds of single surfactant were coated on the surface of bronze powder by wet method in different proportions, the wettability, floating property and gloss of the coated bronze powders were measured, and the influence mechanisms of the surfactants on the wettability and floating property of the bronze powders were analyzed as well. The results show that the wettability of the bronze powders coated by 1% sodium laurate has the largest decrease and the floating property of the bronze powders coated by 2% tween-80 has the largest increase. 2% tween-80 has significant improvement on the decrease of the wettability and the increase of the floating property of bronze powders. The gloss of the coated bronze powders increases from 54.5 to 75.5, thus can meet the printing requirements for bronze powders.

Key words: bronze powder; surfactant; floating property; wettability

含有铜锌粉末的金油墨除具有闪亮的金属光泽,印刷适应性强,能满足平、凸、凹、丝印刷工艺的要求外[1?3],还具有油墨不退色,附着力强的特点。因此在印刷行业中得到了广泛的应用。但是,印刷行业要求铜锌粉末不仅要有很高的径厚比,而且要求在油墨中有较好的漂浮性和较低的润湿性,使得铜锌粉末在油墨中分散均匀、不团聚。粉体的表面包覆按处理的工艺可分为湿法和干法两种。湿法相对干法具有包覆均匀和包覆效果好等优点[4],常规的包覆是在铜锌粉球磨加工时加入硬脂酸钙等试剂,使球磨和包覆同时完成,这样包覆的粉末在后处理时,容易破坏包覆层,因此包覆效果差。我国生产的铜锌粉末粒径虽然能达到要求,但由于润湿性高,分散性和漂浮性较差,出现了我国铜锌粉末生产过剩,而印刷用的铜锌粉末还需进口的局面[5?7]。针对这一实际,本文作者用表面活性剂月桂酸钠、油酸、聚乙二醇、吐温-80和聚乙烯醇对铜锌粉末表面包覆,以便提高铜锌粉末在粘结料中的漂浮性,降低铜锌粉末的润湿性,从而满足印刷行业对铜锌粉末的要求。

1 实验

1.1 试剂与仪器

表面活性剂:月桂酸钠、油酸、吐温-80;高分子聚合物:聚乙二醇、聚乙烯醇;乙酸乙酯(分析纯),铜锌粉末(1 000目),101印金油。1801 v50电子天平,KGZ?1C型光泽度仪,DGB2003台式干燥箱。

1.2 实验方法

把称量好的30 g(33.26 mL)乙酸乙酯倒入100 mL烧杯中,加入表面改性剂,用玻璃棒搅拌10 min,之后加入20 g铜锌粉末并用玻璃棒搅拌20 min。铜锌粉末在乙酸乙酯中具有良好的分散性,表面改性剂吸附力强,通过刮样检测,搅拌20 min,表面改性剂已充分包覆到铜锌粉末表面。过滤上述包覆后的铜锌粉末,并置于干燥箱内70 ℃干燥10 h。

1.3 样品检测

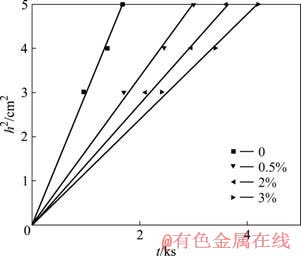

采用平衡润湿法检测粉末的润湿性,粉末润湿性的直接表征参数是界面接触角,接触角越大,润湿性越低。实验中使用的液相为乙酸乙酯,由于乙酸乙酯可作为铜锌粉末的连接料,铜锌粉末在乙酸乙酯中有很好的分散性,因此乙酸乙酯可以作为检验铜锌粉末润湿性的液相。通过平衡润湿检测法测定液体在固定装填密度的粉体柱中液面上升高度h所用的时间t,作h2—t曲线,制得相应的直线。该直线的斜率越小,接触角越大,粉末越难被润湿。

采用小刀漂浮法检测粉末的漂浮性,将专用金属小刀插入铜锌粉末和乙酸乙酯的混合物中并转动一定的时间,再将小刀抽出,静止悬挂,保持一段时间,测定小刀两边的浸入长度和完全漂浮长度,铜锌粉末的漂浮长度以亮膜连续出现处为准,并按下式计算其漂浮值:

漂浮值=(完全漂浮的长度÷浸润长度)×100%

2 结果与分析

2.1 表面改性剂对铜锌粉末包覆机理

表面改性剂是一种能吸附在表(界)面上,在加入量很少时即可显著改变表(界)面的物理化学性质的物质。表面改性剂分子由亲水基和憎水基两部分组成[8]。本文采用的表面改性剂是均匀分散在乙酸乙酯溶液中,表面改性剂的憎水基向外,当铜锌粉末与含表面改性剂的乙酸乙酯混合时,表面改性剂的憎水基与铜锌粉末接触,达到定向吸附,在乙酸乙酯溶液中形成表面改性剂的浓度差,随着吸附时间的延长,表面改性剂扩散,使铜锌粉末表面形成改性剂吸附层。表面改性剂浓度低于某一数值时,表面改性剂以单个离子或分子的形式吸附在铜锌粉末表面;超过某一浓度时,已吸附的表面改性剂可以因其疏水效应而形成二维缔和物,也可因同样的效应使体相溶液中的表面改性剂参与二维缔和物的形成,这将导致吸附量的急剧增加。

2.2 润湿性检测结果

铜锌粉末润湿性研究结果如图1~5所示。

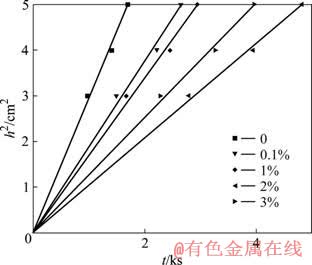

图1 油酸对铜锌粉末润湿性的影响

Fig.1 Influences of oleic acid on wettability of bronze powders

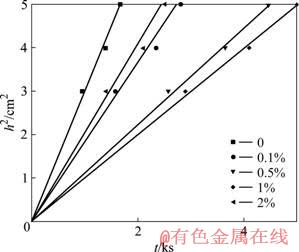

图2 月桂酸钠对铜锌粉末润湿性的影响

Fig.2 Influences of sodium laurate on wettability of bronze powders

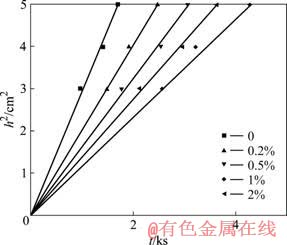

图3 聚乙二醇对铜锌粉末润湿性的影响

Fig.3 Influences of polyethylene glycol on wettability of bronze powders

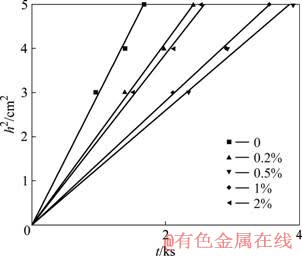

图4 聚乙烯醇对铜锌粉末润湿性的影响

Fig.4 Influences of polyvinyl alcohol on wettability of bronze powders

图5 吐温-80对铜锌粉末润湿性的影响

Fig.5 Influences of Tween-80 on wettability of bronze powders

由图1~5可见,未包覆的铜锌粉末的润湿性最好,即h2—t曲线中的斜率最大,用不同表面改性剂包覆后,润湿性不同程度降低。由图1可见,用油酸包覆铜锌粉末随着油酸浓度增加,铜锌粉末的润湿性变差,即斜率变小,油酸包覆铜锌粉末润湿性变差的顺序依次为0.1%、1%、3%、2%。图2所示为月桂酸钠对铜锌粉末润湿性影响的测试结果,出现与图1相同的规律,但月桂酸钠的用量明显减少。月桂酸钠的用量为1%时,直线的斜率最小,即铜锌粉末的润湿性最差。图3和4所示分别为聚乙二醇和聚乙烯醇对铜锌粉末润湿性影响的测试结果。由图3可见,聚乙二醇含量增加时,润湿性随之降低,当含量为1%时,润湿性最差;由图4可见,聚乙烯醇含量在0~0.5%之间变化时,随着聚乙烯醇含量的增加润湿性变差;当聚乙烯醇含量超过0.5%时,润湿性随着聚乙烯醇含量的增加而变好,因此聚乙烯醇含量在0.5%时,铜锌粉末润湿性最差。图5所示为吐温-80对铜锌粉末润湿性影响的测试结果,由图5可见,随着吐温-80浓度的增大,润湿性变差,当吐温-80的浓度达到3%以后,由于表面活性剂浓度过大,会在印刷过程中产生气泡,因此研究中吐温-80的浓度最高为3%。

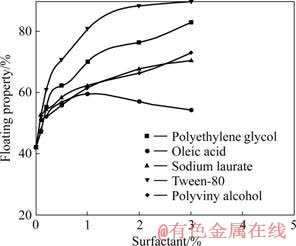

2.3 漂浮性检测结果

漂浮性检测结果如图6所示。由图6可见,铜锌粉末经月桂酸钠、油酸、聚乙二醇、吐温-80、聚乙烯醇包覆后完全漂浮长度与浸润长度之比明显提高,说明铜锌粉末的漂浮性变好,降低了铜锌粉末在油墨中的沉降速度。经月桂酸钠、聚乙二醇、吐温-80、聚乙烯醇包覆的铜锌粉末随着表面改性剂含量的增加,粉末的漂浮性能呈上升趋势。经油酸包覆的铜锌粉末的漂浮性随着表面改性剂含量的增加,先升高后降低,当油酸的含量为1%时,漂浮性最好。吐温-80的浓度大于2%以后,铜锌粉末的漂浮值基本不变,因此,吐温-80的添加量为2%较适宜。

图6 表面改性剂对铜锌粉末漂浮性的影响

Fig.6 Influences of surfactants on floating property of bronze powders

2.4 表面改性剂对润湿性的影响

铜锌粉末经乙酸乙酯处理后,除去了表面的污渍,使粉末表面具有OHˉ等活性基团 [9?14]。一方面,铜锌粉末比表面积大,它的表面能比较高,这使得粉末粒子之间容易相互吸引,粒子之间易发生团聚现象;另一方面,如果铜锌粉末表面没有吸附表面活性剂,则很容易被大多数有机溶剂所润湿而失去漂浮能力。在铜锌粉末的表面改性过程中,粒子表面吸附了有机物分子,使改性剂的极性基团朝向铜锌粉末的表面,而改性剂的非极性基团朝向气相,从而使铜锌粉末的表面性质发生了变化,由原始的高能表面变为低能表面,粒子处于稳定状态,颗粒之间较为分散,相应的铜锌粉末的润湿性也发生变化,由易于润湿向难于润湿转变[15]。

油酸(Oleic acid)的分子式为C18H34O2,结构式为CH3(CH2)7CH=CH(CH2)7COOH,是一种含有一个双键的不饱和脂肪酸[16]。其分子链中一端为极性基团—COOH,另一端为非极性的直链状烃链。在铜锌粉末的表面改性过程中,粉体表面所带有的OHˉ等活性基团与油酸分子能以化学氢键的形式结合,这种结合方式比较牢固。而氢键形成时,只有OHˉ与O原子相距比较近时才能发生。由于油酸分子较大,且为不对称结构,只有羧基可能与粉体表面的OHˉ形成氢键,从而以单分子层包覆颜料表面。由图1可分析,当油酸浓度较低时,尽管油酸的分子数不足以完全包覆铜锌粉末表面,但粉末的表面能已经大大降低,粉末的润湿性也发生变化;随着改性剂浓度的增加,油酸的极性基团吸附在粉末表面,而非极性基团开始向液相伸展,当油酸的浓度为2%时,油酸分子在铜锌粉末表面形成单分子层定向排列,粉末的润湿性达到最低;随着改性剂含量的继续增加,油酸分子在铜锌粉末表面形成双层吸附,第二层所吸附的油酸分子的非极性基与第一层油酸分子的非极性基相连,而极性基团羧基排列在最外层,从而又使铜锌粉末的表面能升高,更容易被润湿。

月桂酸钠(Sodium laurate)的分子式为C12H23O2Na,结构式为CH3(CH2)10 COONa,其分子键中极性基团为—COONa,非极性基团中带有双烃链结构[16]。月桂酸钠的吸附机理与油酸类似。由图2可分析,随着月桂酸钠浓度的增加,铜锌粉末的润湿性先逐渐降低,又逐渐升高,月桂酸钠浓度为1%时被包覆的铜锌粉末的润湿性最低。

聚乙二醇(Polyethylene glycol)和聚乙烯醇(Polyvinyl alcohol)的结构式分别为HOCH2[CH2OCH2]nCH2OH和[CH2CH(OH)]n,它们都属于高分子聚合物表面活性 剂[16]。高分子表面活性剂分子量较大,由于醇羟基中的氧是SP3杂化,导致聚乙二醇和聚乙烯醇有较大的极性,因此也很容易地吸附在铜锌粉末的表面。聚乙二醇和聚乙烯醇的含量对铜锌粉末润湿性的影响机理与油酸类似,随着含量的增加同样出现了不完全包覆、完全包覆、定向排列、双层吸附等情况。由图3、图4可见,聚乙二醇浓度为1%、聚乙烯醇浓度为0.5%时,改性剂分子在铜锌粉末表面形成单分子层定向排列,粉末的润湿性达到最低;随着改性剂含量的继续增加,改性剂分子在铜锌粉末表面形成双层吸附,铜锌粉末更容易被润湿。

吐温-80(Tween-80)属于非离子表面活性剂。非离子表面活性剂是一种在水中不离解成离子状态的两亲结构的化合物。其分子链中的极性基团由聚乙二醇基即聚氧乙烯基—(C2H4O)—构成,非极性基团带有苯环结构,靠物理吸附而附集在铜锌粉末上[16]。由图5分析可见,随着吐温-80改性剂含量的增加铜锌粉末出现了不完全包覆、完全包覆、定向排列,吐温-80的浓度为3%时改性剂分子在铜锌粉末表面形成单分子层定向排列,粉末的润湿性达到最低。虽然表面活性剂浓度越大,吸附量越多,但是表面活性剂浓度过大会在印刷过程中产生气泡,影响印刷效果,因此,研究过程中吐温-80的浓度大到3%为止。

2.5 润湿性与漂浮性之间的关系

铜锌粉末的漂浮性是指铜锌粉末在稀料中能够漂浮在液体表面上并形成光亮金属膜的性质。其实质是铜锌粉末与稀料产生的一种界面行为,与润湿性存在着某种必然的联系。一般来讲,润湿性差,漂浮性好,铜锌粉末的表面处理原则是降低其在稀料中的润湿性,从而提高铜锌粉末的漂浮性。但通过实验结果分析可以看出,铜锌粉末润湿性最差,虽然漂浮性增大,但不是最大。

例如油酸对铜锌粉末的表面处理,经2%油酸包覆的铜锌粉末的润湿性最差,而经1%油酸包覆的铜锌粉末的漂浮性最好,这主要是表面活性剂对漂浮性与润湿性的作用原理不同。

在上述研究结果的基础上,综合表面改性剂对于铜锌粉末的润湿性和漂浮性的影响得出,2%吐温-80、1%聚乙二醇、1%月桂酸钠、0.5%聚乙烯醇对铜锌粉末润湿性的降低和漂浮性的升高都有较大的影响作用。对实验用的铜锌粉末进行了包覆与未包覆的油墨印刷实验,连接料选取101印金油,未被包覆的铜锌粉末印刷后经KGZ-1C型光泽度仪检测光泽度仅为54.4,而经2%吐温-80包覆的铜锌粉末的光泽度可提高到77.5,用1%聚乙二醇、1%月桂酸钠和0.5%聚乙烯醇包覆的铜锌粉末印刷后的光泽度分别达到72.7、72.5和75.3,基本满足工业印刷要求,说明表面改性剂对铜锌粉末的表面改性有较大的作用。

3 结论

1) 表面包覆能有效地改变铜锌粉末的润湿性,实验中几种改性剂使铜锌粉末润湿性依次变差及最差时的最佳添加量为:聚乙烯醇0.5%,吐温-80为3%,聚乙二醇为1%,油酸为2%,月桂酸钠为1%。

2) 表面包覆能有效地改变铜锌粉末的表面漂浮性,防止铜锌粉末在连接料中下沉结垢,漂浮性由高到低及最高时最佳添加量依次为:吐温-80 2%,聚乙二醇3%,聚乙烯醇3%,月桂酸钠3%,油酸1%。

3) 随着改性剂含量的增加,铜锌粉末表面出现了不完全包覆、完全包覆、定向排列、双层吸附等情况,改性剂定向排列于铜锌粉末表面时,粉体的润湿性最低。

4) 在印刷用的铜锌粉末表面改性时,同时兼顾润湿性最差和漂浮性最好来选取活性剂的用量,2%吐温-80、1%聚乙二醇、1%月桂酸钠、0.5%聚乙烯醇对铜锌粉末润湿性的降低和漂浮性的升高都有较大的改善,基本可以满足工业印刷的要求。

REFERENCES

[1] 钱军浩. 油墨配方设计与印刷手册[M]. 北京: 中国轻工业出版社, 2004: 558?560.

QIAN Jun-hao. The handbook of printing ink’s prescription and printing[M]. Beijing: Chinese Light Industry Press, 2004: 558?560.

[2] AKIFUMI I, YOSHINORI K, MASATO I. Fine flake copper powder and its production[M]. New York: Wiley, 1996: 124?127.

[3] 李荣兴. 油墨[M]. 北京: 印刷工业出版社, 1988: 55?58.

LI Rong-xing. Printing oil[M]. Beijing: Printing Industry Press, 1988: 55?58.

[4] BELL G. Advance in powder coating technology automotive applications[J]. Pigment & Technology, 1997, 26(4): 229?234.

[5] 朱晓云. 铜锌合金粉在凹版印刷中的应用[J]. 云南冶金, 2000, 29(6): 34?36.

ZHU Xiao-yun. The application of bronze powder in intaglio printing[J]. Yun Nan Metallurgy,2000, 29(6): 34?36.

[6] 陈振兴. 特种粉体[M]. 北京: 化学工业出版社, 2004: 384?388.

CHEN Zhen-xin. Special type powder[M]. Beijing: Chemical Industry Press, 2004: 384?388.

[7] 周锦鑫, 郑裕生, 黄永昌. 我国铜金粉生产技术的现状与存在的问题浅析[J]. 化学世界, 1999, 56(9): 498?500.

ZHOU Jin-xin, ZHENG Yu-sheng, HUANG Yong-chang. Analysis on manufacturing circumstance and existing problem of the domestic bronze powder[J]. Chemistry World, 1999, 56(9): 498?500.

[8] GODDARD E D. Interactant of surfactants with polymers and proteins[M]. Boca Raton, FL: CRC Press, 1993: 23?26.

[9] KWAK J C T. Ploymer-surfactant systems, surfactant science series[M]. New York: Marcel Dekker, 1998: 56?62.

[10] JONSSON B, LINDMANN B, HOLMBERG K, KRONBERG B. Surfactants and polymers in aqueous solution[M]. New York: John Wiley & Sons Ltd, 1998: 65?78.

[11] 肖进新, 赵振国. 表面活性剂应用原理[M]. 北京: 化学工业出版社, 2003: 4?5.

XIAO Jin-xin, ZHAO Zhen-guo. The applications theory of surfactants[M]. Beijing: Chemical Industry Press, 2003: 4?5.

[12] FROES F H, SENKOV O N, BABURAJ E G. Synthesis of nanocrystalline materials—An overview [M]. New York: Marcel Dekker, 2001: 44?53.

[13] RANDOM T S. Heterogeneous material: Microstructure and macroscopic properties[M]. New York: Springer Verlag, 2002: 42?50.

[14] KISSA E. Fluorinated surfactants: Synthesis properties applications[M]. New York: Marcel Dekker, 1994: 23?27.

[15] ADAMSON A W. Physical chemistry of surfaces[M]. New York: John & Sons, 1990: 12?19.

[16] 刘 云. 日用化学品原材料技术手册[M]. 北京: 化学工业出版社, 2003: 332?460.

LIU Yun. The handbook of chemistry commodity raw and processed materials[M]. Beijing: Chemical Industry Press, 2003: 332?460.

收稿日期:2007-10-10;修订日期:2008-03-27

通讯作者:冯拉俊,教授;电话:13072968541;E-mail: fenglajun@xaut.edu.cn

(编辑 何学锋)