DOI: 10.11817/j.issn.1672-7207.2019.09.021

方钢管竖向插板加强节点受压承载性能分析

常鸿飞1, 2,徐玮1, 3,左文康1,刘帅鹏1,夏军武1, 2

(1. 中国矿业大学 江苏省土木工程环境灾变与结构可靠性重点实验室,江苏 徐州,221116;

2. 中国矿业大学 深部岩土力学与地下工程国家重点实验室,江苏 徐州,221116;

3. 江苏省建筑设计研究院有限公司,江苏 南京,210019)

摘要:为了研究方钢管竖向插板加强节点(IPT)的受压性能及承载机理,建立未加强及竖向插板加强节点的有限元模型,并采用已有试验结果验证有限元模型的准确性;完成45组IPT节点的受压性能参数分析,得到不同设计参数对节点受压性能的影响规律;最后分析竖向插板对节点的加强机理,提出插板的构造建议。研究结果表明:竖向插板最高可提升方钢管节点受压承载力115.9%;竖向插板加强节点的控制破坏形态有3种,即主管上、下翼缘屈服破坏,主管腹板屈曲破坏以及二者共同控制破坏;支管-主管宽度比、主管高厚比和插板长度对IPT节点受压性能影响显著;竖向插板对节点的加强机理包括2个方面,即插板扩大了主管上翼缘的屈服范围以及将支管轴向压力传递到主管下翼缘并引起主管下翼缘屈服。此外,对插板加强节点的适用范围及插板尺寸构造提出了设计建议。

关键词:方钢管;竖向插板;加强节点;受压性能;有限元分析;承载机理

中图分类号:TU392.3 文献标志码:A 开放科学(资源服务)标识码(OSID)

文章编号:1672-7207(2019)09-2242-10

Compressive characteristics of vertical inner plate reinforced square hollow section tubular joints

CHANG Hongfei1, 2, XU Wei1, 3, ZUO Wenkang1, LIU Shuaipeng1, XIA Junwu1, 2

(1. Jiangsu Key Laboratory of Environmental Impact and Structural Safty in Engineering, China University of Mining & Technology, Xuzhou 221116, China;

2. State Key Laboratory for Geomechanics & Deep Underground Engineering , China University of Mining & Technology, Xuzhou 221116, China;

3. Jiangsu Provincial Architectural Design & Research Institute Ltd Company, Nanjing 210019, China)

Abstract: To study the compressive performance and bearing mechanism of vertical inner plate reinforced square tubular joints, the finite element models of unreinforced and vertical inner plate reinforced joints were established and the accurancy was verified by using existing experimental results. 45 groups of vertical inner plate reinforced T-joints were simulated under brace compression. The load-deformation curves of the joints were studied, and the influence of different parameters on the compressive performance of the joints was investigated. Finally, the mechanism of the vertical inner plate to reinforce the joints on the vertical inserts was analyzed, and the configurations of the vertical inner plate were proposed. The results show that the compressive strength of the joints is improved significantly by the vertical inner plate reinforcement, with the highest increase of 115.9%. The failure modes of the vertical inner plate reinforced joints can be divided into three types, i.e. the yield of the top and bottom flange of the chord, the buckling of the chord web and combination failure of the chord flange and web. Parameters such as the width ratio of brace to chord, the ratio of height to thickness of the chord and the length of the vertical inner plate have significant influence on the compressive behavior of the joints. The mechanism of the vertical inner plate reinforcement can be divided into two aspects, i.e. to enlarge the yielding scope on the top flange of the chord and to transfer the load and drive the yielding on the bottom flange of the chord. The application scope as well as the configuration of the vertical inner plate reinforced joint is proposed.

Key words: square tubular; vertical inner plate; reinforced joint; compressive characteristics; finite element analysis; bearing mechanism

钢管结构建筑效果优美,结构形式合理,广泛应用于大跨结构、桥梁结构中。方钢管节点的研究早期多关注直接焊接节点的静力性能 [1],多基于试验测得[2-3]。随着试验数据的积累,学者们提出了相关设计理论[4],近年来,关于方钢管节点有限元分析的成果逐渐增多[5]。随着钢管结构形式的日趋复杂,学者们提出不同加强方法来保证节点及结构安全[6-7]。钢管节点加强方法可分为外部加强和内部加强2种。外部加强法将加强件直接焊接在主管外表面,便于工厂化生产,但节点附近焊缝过多,疲劳强度不够,同时也影响美观。内部加强法将加强件内嵌于主管内部来提高主管的径向刚度。内置加劲环[8-9]和内置插板 [10-12]属于典型的内部加强方法,可以有效提高节点的承载能力和疲劳强度,而主管竖向插板加强因其施工便利,应用前景广泛[13]。目前,竖向插板已被证实可有效提高圆钢管节点的承载力性能。如王阁等[10]采用有限元分析发现,竖向插板加强对圆钢管相贯节点的极限承载力提高幅度可达22.8%,局部变形最大能降低95%;张巧珍等[14]指出,竖向插板对K型间隙节点的轴向承载力可提高16.1%;ZHU等[15]通过试验发现,竖向加劲板对X型相贯节点极限承载力提高幅度可达86%。影响竖向插板加强节点承载性能的因素较多,李涛等[11-12]指出,插板长度对节点承载性能影响较大,但长度在达到一定的数值后提高效果不明显;插板厚度对节点承载性能影响较小,但插板厚度不宜过小,防止插板先于节点失稳破坏。在承载机理方面,王阁等[10,16]指出竖向插板可扩大主管的屈服范围,改变节点的破坏模式,进而提高节点承载力和刚度。与圆钢管节点相比,竖向插板用于方钢管节点加强时,其承载机理存在差异。例如文献[17]表明,当竖向插板用于宽度比较大的节点时,会引起破坏模式由主管屈服向主管侧壁屈曲转变,但这种转变的条件尚不明确。为此,本文在文献[17]研究的基础上进行有限元参数分析,揭示节点及加强板参数对其承载性能的影响规律,分析竖向插板对节点的加强机理,提出插板的构造建议。

1 试验概况

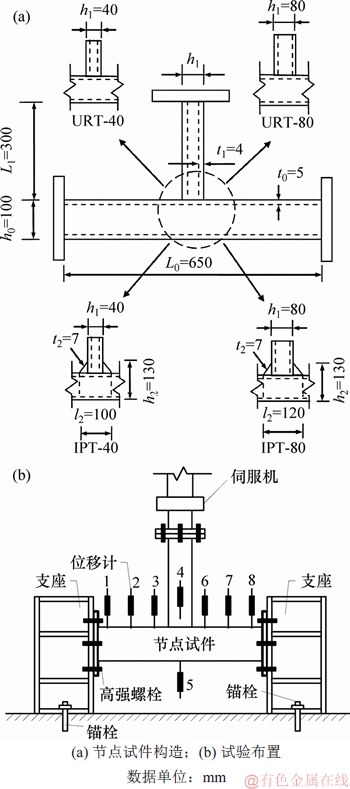

在文献[17]中竖向插板加强节点(IPT)轴压试验的基础上开展研究。文献[17]设计了2组支管-主管宽度比β分别为0.4和0.8的未加强节点作为基准试件,编号分别为URT-40和URT-80;将主管沿轴心切口,插入加强板并与主管和支管焊接形成竖向插板加强节点试件,编号分别为IPT-40和IPT-80。图1所示为试件几何参数和试验加载装置及测点布置,主管两端固定,支管端部通过电液伺服机施加轴向压力。实测材料参数如表1所示,详细试验方案见文献[17]。

图1 节点构造及加载布置图

Fig. 1 Dimensions of specimens and setup of test

2 有限元模型及验证

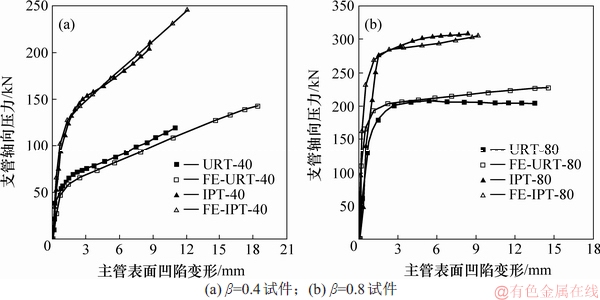

表1 试件材性参数

Table 1 Mechanical properties of specimens

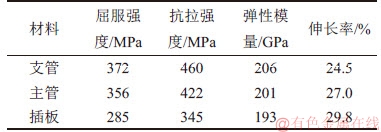

2.1 有限元建模

采用ANSYS软件,建立图1中各试件的有限元模型。节点主管、支管及竖向插板均采用20结点等参单元SOLID95模拟[18],考虑到焊缝会对模型产生影响[19],对焊缝进行建模。考虑到主管与支管交汇处应力梯度较大,对主支管交汇处网格进行局部加密。图2所示为节点有限元模型及破坏形态对比,模型的约束及加载条件与试验条件相同。为方便提取荷载及位移,加载点处采用硬点接触处理。采用多线性随动强化的钢材本构模型、Von-Mises屈服准则及相关流动法则,并根据表1确定相关参数。取材料弹性模量 ,泊松比

,泊松比 ,强化阶段切线模量

,强化阶段切线模量 [20]。

[20]。

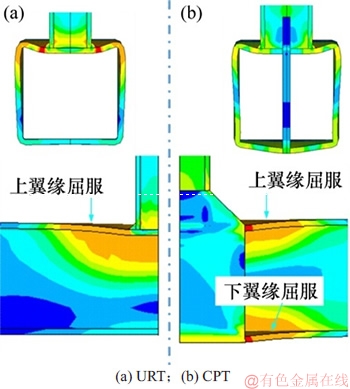

2.2 模型验证

从节点破坏形态以及荷载-位移曲线2方面验证有限元模型的准确性。节点破坏形态的模拟结果与文献[17]中试验对比如图2(b)所示。由图2(b)可见:模拟破坏形态与试验相符,现有模型较好地模拟了主管的上、下翼缘屈服以及主管腹板屈曲破坏。

图2 方钢管焊接T型节点有限元模型及破坏形态对比

Fig. 2 Finite element models of welded square tubular T-joint and comparison of failure modes by FEA and test

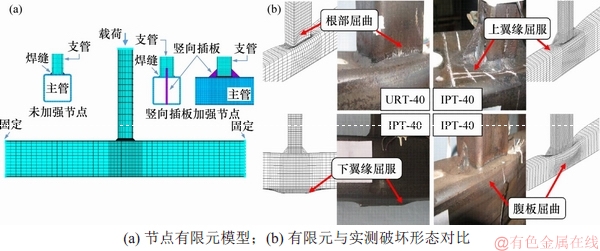

图3 有限元与实测荷载-位移曲线对比

Fig. 3 Comparison of load-displacement curves by FEA and test

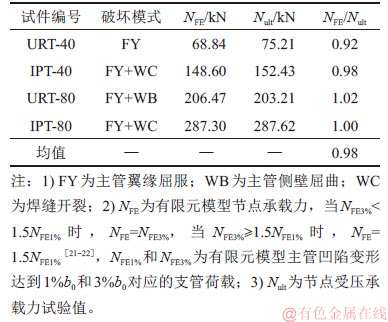

表2 轴压有限元承载力与试验结果对比

Table 2 Comparison of compressive strength by FEA and test

节点荷载-位移模拟曲线与实测曲线的对比如图3所示。由图3可见:模拟曲线与试验曲线较吻合。试验和有限元模拟的节点承载力对比如表2所示[21-22],由表2可见:试件IPT-40和试件IPT-80的有限元模拟承载力比对应未加强试件分别提高115.9%和39.1%;试验承载力则分别提高102.7%和41.5%,表明插板对节点的加强作用明显。模拟承载力平均为试验值的0.98倍,模型在模拟竖向插板加强节点的荷载-位移曲线及承载力方面有较高的准确度。

3 节点参数分析

3.1 参数分析方案

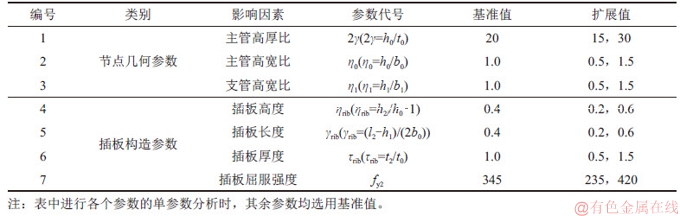

方钢管焊接节点受压性能受支管-主管宽度比β、主管高厚比的影响明显[23]。文献[24]给出了方钢管未加强节点支管-主管宽度比β、主管高厚比、主管高宽比等参数的构造建议。参考现有研究成果,本文对参数进行分析时,将IPT节点受压性能的影响因素分成2组,即第1组为节点的几何参数为主管高厚比 ,主管高宽比

,主管高宽比 ,支管高宽比

,支管高宽比 ,支管-主管宽度比

,支管-主管宽度比 ;第2组为竖向插板的几何量纲一参数或材料参数,即插板高度

;第2组为竖向插板的几何量纲一参数或材料参数,即插板高度 ,插板长度

,插板长度 ,插板厚度

,插板厚度 ,插板屈服强度

,插板屈服强度 。

。

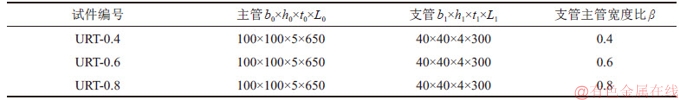

选取β分别为0.4,0.6和0.8的未加强节点(URT-0.4,URT-0.6和URT-0.8)为基准试件,对应的几何参数如表3所示。对基准试件进行竖向插板加强,通过改变参数 ,

, ,

, ,

, ,

, ,

, 和

和 ,分析各参数变化对插板加强节点受压性能的影响规律,详细参数如表4所示。为分析各参数对加强节点的影响规律,本文仅进行单参数分析,即分析某参数的影响时,其他参数均选用基准值。共对3个未加强节点和45个竖向插板加强节点参数进行分析。

,分析各参数变化对插板加强节点受压性能的影响规律,详细参数如表4所示。为分析各参数对加强节点的影响规律,本文仅进行单参数分析,即分析某参数的影响时,其他参数均选用基准值。共对3个未加强节点和45个竖向插板加强节点参数进行分析。

表3 基准试件几何参数

Table 3 Geometries of benchmark specimens mm

表4 竖向插板加强节点影响参数

Table 4 Influence parameters of IPT T-joints

进行有限元建模时,单元类型选择及网格划分与前面的相同,选用理想的弹塑性材料模型,主管材料取Q345钢材,并取弹性模量 ,泊松比

,泊松比 ;为消除主管附加弯矩和附加变形的影响,约束条件取为主管下翼缘角部连续支承。

;为消除主管附加弯矩和附加变形的影响,约束条件取为主管下翼缘角部连续支承。

为方便对比,对荷载-位移曲线的横纵坐标均进行量纲一处理,取荷载因子 和变形因子

和变形因子 分别为:

分别为:

(1)

(1)

(2)

(2)

式中:Nu为支管轴向压力;fy0为主管屈服强度;t0为主管壁厚; 为主管表面凹陷变形;b0为主管宽度。IPT节点受压承载力设计值根据文献[17-18]中方法确定。

为主管表面凹陷变形;b0为主管宽度。IPT节点受压承载力设计值根据文献[17-18]中方法确定。

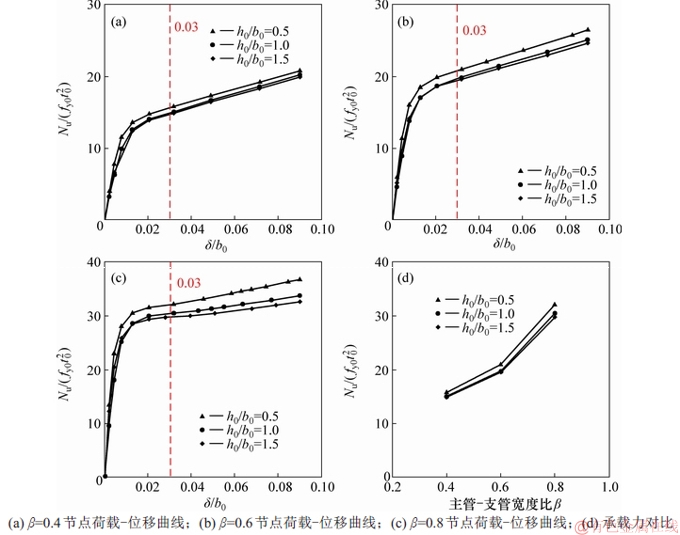

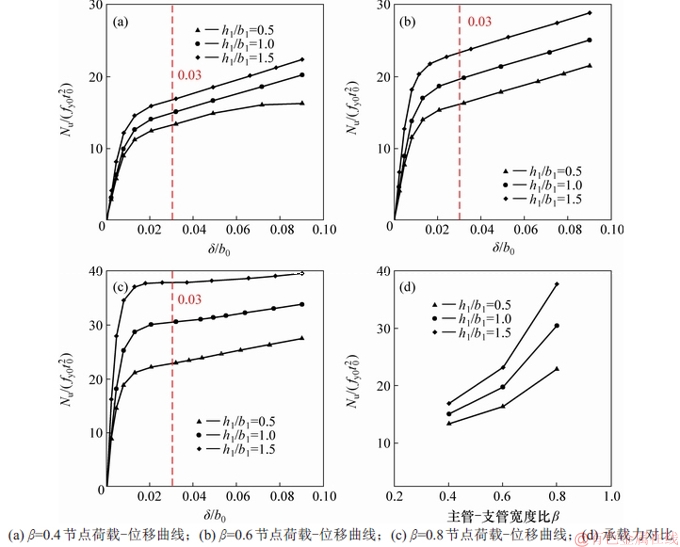

3.2 主管高厚比影响

图4所示为IPT节点主管高厚比变化时的量纲一荷载-位移曲线和承载力变化趋势图。由图4可见:IPT节点的受压性能受到主管高厚比影响较大,随着主管高厚比的减小,节点受压强度及刚度明显提高,这与未加强节点情况一致。例如当主管高厚比由30减小为15时,β为0.4,0.6和0.8的IPT节点受压承载力分别增加16.5%,18.9%和11.0%;当β增大时,IPT节点荷载-位移曲线逐渐接近,主管高厚比对IPT节点的影响逐渐减弱,节点破坏形态由上、下翼缘屈服控制向腹板屈曲控制转化。因此,为提高IPT节点受压强度和刚度,建议主管高厚比不超过35。

3.3 主管高宽比影响

图5所示为IPT节点主管高宽比变化时的量纲一荷载-位移曲线和承载力变化趋势图。由图5可见:IPT节点的受压性能受到主管高宽比影响较小,随着主管高宽比的减小,节点受压强度及刚度略有提高。例如主管高宽比由1.5减小到0.5时,β为0.4,0.6及0.8的IPT节点受压承载力分别增加5.8%,6.7%和7.5%;当β增大时,主管高宽比对IPT节点的影响逐渐增加,即主管侧壁对IPT节点受压性能的影响越加明显。因此,IPT节点主管高宽比可参照未加强节点确定[24]。

3.4 支管高宽比影响

图6所示为IPT节点支管高宽比变化时的量纲一荷载-位移曲线和承载力变化趋势图。由图6可见:IPT节点的受压性能受到支管高宽比影响较大,随着支管高宽比的减小,节点受压强度及刚度明显降低。例如当支管高宽比由1.5减小到0.5时,β为0.4,0.6及0.8的IPT节点受压承载力分别减小21.1%,30.8%和39.6%;当β=0.8时, 的IPT节点荷载-位移曲线趋于有拐点。这说明随着β增大,插板对节点可能过度加强,节点的破坏形态也由表面屈服控制向侧壁屈曲控制变化,这与文献[13]中结果一致。为保证竖向插板的加强效果且防止插板对节点过度加强,建议IPT节点支管高宽比取0.5≤h1/b1≤2.0。

的IPT节点荷载-位移曲线趋于有拐点。这说明随着β增大,插板对节点可能过度加强,节点的破坏形态也由表面屈服控制向侧壁屈曲控制变化,这与文献[13]中结果一致。为保证竖向插板的加强效果且防止插板对节点过度加强,建议IPT节点支管高宽比取0.5≤h1/b1≤2.0。

图4 主管高厚比对IPT节点受压性能的影响

Fig. 4 Influence of chord width-thickness ratio on IPT joints

图5 主管高宽比对IPT节点受压性能的影响

Fig. 5 Influence of chord height-width ratio on IPT joints

图6 支管高宽比对IPT节点受压性能的影响

Fig. 6 Influence of brace height-width ratio on IPT joints

3.5 插板尺寸影响

图7所示为 时插板尺寸及屈服强度影响的IPT节点受压荷载-位移曲线。由图7(a)可见:当插板高度参数

时插板尺寸及屈服强度影响的IPT节点受压荷载-位移曲线。由图7(a)可见:当插板高度参数 从0.6减小到0.4和0.2时,各节点的荷载-位移曲线重合,说明插板高度对IPT节点的受压性能没有影响。可见IPT节点插板高度无需太高,考虑到焊接方便,建议竖向插板高度取为主管高度的1.2~1.5倍。

从0.6减小到0.4和0.2时,各节点的荷载-位移曲线重合,说明插板高度对IPT节点的受压性能没有影响。可见IPT节点插板高度无需太高,考虑到焊接方便,建议竖向插板高度取为主管高度的1.2~1.5倍。

由图7(b)可见:IPT节点的受压性能受到插板长度影响较大;随着插板长度减小,节点受压强度及刚度明显降低,这是因为插板长度增大,主管上下翼缘的屈服范围增加。例如插板长度参数 由0.6降低到0.4和0.2时, IPT节点受压承载力分别减少14.6%和26.5%。因此,为增加主管屈服范围,建议插板长度宜超过主管上下翼缘塑性铰线之间的距离,但不宜超过主管宽度的2.0倍,即

由0.6降低到0.4和0.2时, IPT节点受压承载力分别减少14.6%和26.5%。因此,为增加主管屈服范围,建议插板长度宜超过主管上下翼缘塑性铰线之间的距离,但不宜超过主管宽度的2.0倍,即 。

。

由图7(c)可见:插板厚度对IPT节点的受压性能有影响,但其灵敏度远小于插板长度的灵敏度,随着插板厚度减小,节点受压强度及刚度有所降低。例如,插板厚度参数 由1.5降低到1.0和0.5时,IPT节点受压承载力分别减少4.5%和8.6%。由此可知:插板厚度并非IPT节点受压性能主要影响因素,建议插板厚度宜与主管壁厚相同。

由1.5降低到1.0和0.5时,IPT节点受压承载力分别减少4.5%和8.6%。由此可知:插板厚度并非IPT节点受压性能主要影响因素,建议插板厚度宜与主管壁厚相同。

3.6 插板屈服强度影响

由图7(d)可见:IPT节点的受压性能受到插板屈服强度影响较小,随着插板屈服强度减小,节点受压强度及刚度略有降低。例如,当插板屈服强度由420 MPa减小到345 MPa和235 MPa时, IPT节点受压承载力分别减小1.9%和5.0%。为防止插板过早屈服而影响加强效果,建议插板屈服强度宜与主管屈服强度相同。

图7 插板尺寸及屈服强度对IPT节点受压性能的影响

Fig. 7 Influence of inner plate dimension and strength on IPT joints

图8 URT及IPT节点应力图

Fig. 8 Stress graph of URT joint and IPT joint

4 承载机理分析与构造建议

图8所示为URT节点和IPT节点的应力分布。为方便观察,将URT节点和IPT节点对称布置。由图8可见:支管轴向受压时,IPT节点的主管上翼缘沿支管和纵向加劲肋周边出现凹陷变形,载荷通过插板传递至主管下翼缘,引起下翼缘凸出变形;IPT节点应力达到屈服值主要在主管上、下翼缘以及主管腹板靠近上翼缘处,由此可知竖向插板对节点承载力的加强来自2个方面,即扩大主管上翼缘屈服范围以及插板将轴压力传递到主管下翼缘,引起主管下翼缘屈服。

竖向插板加强节点的控制破坏形态包括3种,即主管上下翼缘屈服(模式I)、主管腹板屈曲(模式II)以及二者共同控制的破坏(模式III)。其中,模式I主要发生在β≤0.6的分析节点处,模式III主要发生于β=0.8的分析节点处,模式II则发生于β>0.8的分析节点处。

考虑到当β>0.8时插板对节点存在过度加强,导致IPT节点破坏形态由主管翼缘表面屈服控制转变为主管侧壁屈曲控制,无法充分发挥插板的作用,此外,当β<0.3时IPT节点支管强度较弱,不需要采用插板加强,因此,建议插板加强的适用范围为0.3<β≤0.8。

基于参数及受压承载机理分析,对插板的构造给出如下建议:

1) 插板高度对IPT节点的受压性能没有影响,考虑到焊接的方便,建议取为主管高度的1.2~1.5倍。

2) 插板长度对IPT节点的受压性能影响较大,为增加主管屈服范围,建议插板长度宜超过主管翼缘塑性铰线范围;另外,为减少对主管的削弱,插板长度不宜超过主管宽度的2.0倍,即 ,其中b0和b1分别为主管和支管宽度。

,其中b0和b1分别为主管和支管宽度。

3) 插板厚度对IPT节点受压性能影响较小,建议插板厚度与主管壁厚相同,即 。

。

4) 插板屈服强度对IPT节点的受压性能影响较小,建议插板屈服强度与主管的相同。

5 结论

1) 竖向插板对节点的加强效果明显,节点承载力提高幅度最高可达115.9%。IPT节点的破坏形态为主管上、下翼缘表面屈服破坏;随着β增大,节点的破坏模式由上下翼缘屈服控制向腹板屈曲控制转化。

2) IPT节点受压性能影响程度由强到弱依次为:支管-主管宽度比β,主管高厚比 ,插板长度

,插板长度 ,支管高宽比

,支管高宽比 和插板厚度

和插板厚度 。主管高宽比、插板高度和插板屈服强度对IPT节点受压性能的影响不明显。

。主管高宽比、插板高度和插板屈服强度对IPT节点受压性能的影响不明显。

3) 竖向插板对节点的加强机理为:插板将荷载由上翼缘传递至下翼缘,扩大了主管翼缘的屈服范围,并使上、下翼缘共同屈服。

4) 插板加强的适用范围为0.3<β≤0.8;插板高度宜为主管高度的1.2~1.5倍;插板厚度宜与主管壁厚相同;插板长度建议取值范围为: ;插板屈服强度宜与主管屈服强度相同。

;插板屈服强度宜与主管屈服强度相同。

参考文献:

[1] 武振宇, 张耀春. 直接焊接钢管节点静力工作性能的研究现状[J]. 哈尔滨建筑大学学报, 1996(6): 102-109.

WU Zhenyu, ZHANG Yaochun. State of the art in the static behavior of directly welded tubular connections[J]. Journal of Harbin University of Civil Engineering and Architecture, 1996(6): 102-109.

[2] 武振宇, 张耀春. 直接焊接T型钢管节点性能的试验研究[J]. 钢结构, 1999, 14(2): 36-40.

WU Zhenyu, ZHANG Yaochun. Experimental study of directly welded T-type steel tubular joints[J]. Steel Construction, 1999, 14(2): 36-40.

[3] KOSTESKI N, PACKER J A. Welded tee-to-HSS connections[J]. Journal of Structural Engineering, 2003, 129(2): 151-159.

[4] WARDENIER J. Hollow section joints[M]. Delft: Delft University Press, 1982: 42-51.

[5] FENG R, YOUNG B. Experimental investigation of cold-formed stainless steel tubular T-joints[J]. Thin-Walled Structures, 2008, 46(10): 1129-1142.

[6] 高春彦, 史治宇, 牛丽华, 等. 圆钢管混凝土K型焊接管板节点试验研究和有限元分析[J]. 中南大学学报(自然科学版), 2017, 48(3): 769-778.

GAO Chunyan, SHI Zhiyu, NIU Lihua, et al. Experimental study and finite element analysis of concrete-filled circular steel tubular K-type welded tube-gusset joints[J]. Journal of Central South University(Science and Technology), 2017, 48(3): 769-778.

[7] 别雪梦, 李召, 管文强, 等. 方钢管混凝土柱-钢梁外环板式节点抗剪性能[J]. 中南大学学报(自然科学版), 2018, 49(1): 226-237.

BIE Xuemeng, LI Zhao, GUAN Wenqiang, et al. Shear performance of square concrete-filled steel tubular column to steel beam joint with external diaphragm[J]. Journal of Central South University(Science and Technology), 2018, 49(1): 226-237.

[8] 方小丹, 韩小雷, 韦宏, 等. 广州西塔巨型斜交网格平面相贯节点试验研究[J]. 建筑结构学报, 2010, 31(1): 56-62.

FANG Xiaodan, HAN Xiaolei, WEI Hong, et al. Experimental study on plannar intersecting connections used in obliquely crossing mega lattice of the Guangzhou West Tower[J]. Journal of Building Structures, 2010, 31(1): 56-62.

[9] 张峰, 陈扬骥, 陈以一, 等. 内加劲环的设置对钢管节点性能的影响[J]. 空间结构, 2004, 10(1): 51-56.

ZHANG Feng, CHEN Yangji, CHEN Yiyi, et al. Effects of ring-stiffeners on the behaviour steel tubular joints[J]. Spatial Structures, 2004, 10(1): 51-56.

[10] 王阁, 张季超. 内置加强板空间相贯圆钢管节点在广东科学中心工程中的应用研究[J]. 工业建筑, 2007, 37(10): 93-97.

WANG Ge, ZHANG Jichao. Study on application of igp-stiffen chs joints in Guangdong science center[J]. Industrial Construction, 2007, 37(10): 93-97.

[11] 李涛, 邵永波, 张季超. 内置竖向插板加强型管节点静力强度研究[J]. 工程力学, 2010, 27(4): 133-140.

LI Tao, SHAO Yongbo, ZHANG Jichao. Study on static strength of tubular joints reinforced with vertical inner plate[J]. Engineering Mechanics, 2010, 27(4): 133-140.

[12] ZHU Lei, ZHAO Yan, LI Shuwen, et al. Numerical analysis of the axial strength of CHS T-joints reinforced with external stiffeners[J]. Thin-Walled Structures, 2014, 85: 481-488.

[13] 陈以一, 陈扬骥. 钢管结构相贯节点的研究现状[J]. 建筑结构, 2002, 32(7): 52-55, 31.

CHEN Yiyi, CHEN Yangji. Research status of tubular joints of steel tubular structure[J]. Building Structure, 2002, 32(7): 52-55, 31.

[14] 张巧珍, 周洪彬, 张明莉. 插板加强K型间隙圆钢管相贯节点的极限承载能力非线性有限元分析[J]. 钢结构, 2006, 21(1): 54-57.

ZHANG Qiaozhen, ZHOU Hongbin, ZHANG Mingli. Nonlinear finite element analysis of the ultimate bearing capacity of reinforced circular tubular gapped k-joints with a flashboard[J]. Steel Construction, 2006, 21(1): 54-57.

[15] ZHU Lei, YANG Kai, BAI Yu, et al. Capacity of steel CHS X-joints strengthened with external stiffening rings in compression[J]. Thin-Walled Structures, 2017, 115: 110-118.

[16] ZHU Lei, SONG Qiming, BAI Yu, et al. Capacity of steel CHS T-Joints strengthened with external stiffeners under axial compression[J]. Thin-Walled Structures, 2017, 113: 39-46.

[17] 常鸿飞, 夏军武, 段晓牧, 等. 方钢管覆板及竖向插板加强T形节点受压静力试验[J]. 建筑结构学报, 2013, 34(10): 57-63.

CHANG Hongfei, XIA Junwu, DUAN Xiaomu, et al. Experimental study on compression capacity of doubler or vertical inner plate reinforced square tubular T-joints[J]. Journal of Building Structures, 2013, 34(10): 57-63.

[18] XIA Junwu, CHANG Hongfei, HELEN M G, et al. Axial hysteretic test of doubler-plate reinforced square hollow section tubular T-joints[J]. Marine Struct 2017; 55(5): 162-181.

[19] 祝磊, 叶桢翔, 赵岩. 焊缝建模对T型圆钢管节点轴压承载力计算的影响[J]. 建筑结构, 2013, 43(S2): 498-501.

ZHU Lei, YE Zhenxiang, ZHAO Yan. Effect of weld modeling on computation of axial compressive strength of circular steel tubular T-joints[J]. Building Structure, 2013, 43(S2): 498-501.

[20] 常鸿飞, 夏军武, 常虹, 等. 方钢管覆板加强T型节点的受压承载机理[J]. 华南理工大学学报(自然科学版), 2013, 41(6): 77-83.

CHANG Hongfei, XIA Junwu, CHANG Hong, et al. Bearing mechanism of doubling plate-reinforced square tubular T-joints under compression[J]. Journal of South China University of Technology(Natural Science Edition), 2013, 41(6): 77-83.

[21] ZHAO Xiaoling. Deformation limit and ultimate strength of welded T-joints in cold-formed RHS sections[J]. Journal of Constructional Steel Research, 2000, 53(2): 149-165.

[22] LH Lu , GD Winkel , Y Yu ,et al. Deformation limit for the ultimate strength of hollow section joints[C]// 6th International Symposium on Tubular Structures. Melbourne, Austria, 1994: 341-347.

[23] 武振宇, 张耀春. 等宽T型方管节点静力工作性能与设计[J]. 土木工程学报, 2004, 37(4): 23-28.

WU Zhenyu, ZHANG Yaochun. Static behavior and design of full-width T-type rhs joints[J]. China Civil Engineering Journal, 2004, 37(4): 23-28.

[24] GB 50017—2017. 钢结构设计标准[S].

GB50017—2017. Code for design of steel structures[S].

(编辑 秦明阳)

收稿日期: 2018 -10 -18; 修回日期: 2018 -12 -25

基金项目(Foundation item):国家自然科学基金资助项目(51408596, 51978657);江苏省自然科学基金资助项目(BK20140195)(Projects(51408596, 51978657) supported by the National Natural Science Foundation of China; Project(BK20140195) supported by the Natural Science Foundation of Jiangsu Province)

通信作者:常鸿飞,博士,副教授,硕士生导师,从事装配式钢结构研究;E-mail:honfee@126.com