文章编号:1004-0609(2015)12-3300-09

时效前处理对新型Al-Cu-Li-X合金力学性能和显微组织的影响

张 健1,朱瑞华1,李劲风1,马云龙2,刘德博2,郑子樵1

(1. 中南大学 材料科学与工程学院,长沙 410083;

2. 北京宇航系统工程研究所,北京 100076)

摘 要:研究时效前固溶处理、预变形等对一种新型超高强Al-Cu-Li-X合金板材力学性能和显微组织的影响。结果表明:500~540 ℃固溶40 min时,随固溶温度的提高,合金的时效强度呈现先升高后持平的趋势,且在520 ℃时强度略有下降;510 ℃固溶20~180 min时,随固溶时间延长,合金的时效强度则呈现先升高后降低的趋势;(510 ℃, 40 min)固溶处理后的合金具有最高的时效强度。不同固溶处理合金的强度变化主要受固溶阶段第二相粒子的回溶程度、再结晶晶粒形态及长大趋势和过烧的共同影响。合金强化相为大量T1相(Al2CuLi)、部分θ′相(Al2Cu)和少量S′相(Al2CuMg),预变形可促进T1相细小弥散析出,但抑制θ′相及S′相的析出。预变形量小于6%的预变形可有效提高合金的时效强度,但当预变形量大于6%之后,合金强度的增量逐渐减少。

关键词:铝锂合金;固溶处理;预变形;力学性能;显微组织

中图分类号:TG146.2 文献标志码:A

Effect of heat treatment before aging on tensile properties and microstructures of new Al-Cu-Li-X alloy

ZHANG Jian1, ZHU Rui-hua1, LI Jin-feng1, MA Yun-long2, LIU De-bo2, ZHENG Zi-qiao1

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Beijing Institute of Aerospace Systems Engineering, Beijing 100076, China)

Abstract: Effect of solution treatment and pre-deformation before aging on tensile properties and microstructures of a new ultra-high strength Al-Cu-Li-X alloy were investigated. The result shows that, as solution-treated for 40 min at 500-540 ℃, the strength of the aged alloy increases firstly then keeps a relatively same strength with increasing the solution temperature except at 520 ℃. As solution-treated at 510 ℃ for 20-180 min, the strength of the aged alloy increases firstly then decreases. The aged alloy with solution treatment of (510 ℃, 40 min) possesses the highest strength. The strength variation corresponding to various solution treatment is comprehensively affected by the secondary particle dissolution, grain structure, grain growth and overburning. The strengthening precipitates of the aged alloy consist of a large number of T1 phase (Al2CuLi), some θ′ phase (Al2Cu) and a small amount of S′ phase (Al2CuMg). Pre-deformation can promote the precipitation of T1 phase, but restrain the precipitation of θ′ and S′ phases. When the pre-deformation is lower than 6%, the strength increases substantially with increasing pre-deformation. But when the pre-deformation is larger than 6%, the strength increment caused by pre-deformation is reduced.

Key words: Al-Li alloy; solution treatment; pre-deformation; tensile property; microstructure

锂是自然界中密度最低的金属元素,在铝合金中添加1%(质量分数)的锂,可以使铝合金密度降低3%,而弹性模量提高6%[1]。20世纪80年代以来,欧美等国开发了一批具备高综合性能的第三代铝锂合金,如美国研发的具有超高强度、可焊的Weldalite 049系列铝锂合金(2094、2095、2195等),俄罗斯研制的高强可焊1460铝锂合金。这些第三代铝锂合金因其低密度、高弹性模量、良好的焊接性和强韧性能等吸引着航天航空领域的密切关注[2-3]。进入21世纪以来,铝锂合金发展更为迅速,欧美等都致力于开发新型铝锂合金,其中一个重要发展趋势是开发新型超高强铝锂合金[4]。郑子樵课题组[5]通过微量元素Mg、Ag、Zn等的复合添加,促进强化相的析出,自主研发了一种新型超高强铝锂合金。

在固溶处理过程中,合金元素的充分回溶可提高淬火后固溶体的过饱和程度,有利于时效阶段强化相的大量析出,从而大幅度提高合金的强度[6]。而固溶时再结晶则会削弱带状晶粒组织的强化效应,降低合金的强度[7]。人工时效前的预变形可影响强化相的种类、尺寸、体积分数和竞争析出动力学[8]。铝锂合金中析出强化相类型较多,对热处理工艺较为敏感。目前关于铝锂合金的热处理工艺研究主要集中于时效阶段[9-11],而对时效前固溶处理及预变形处理的研究相对较少。基于此,本文作者详细研究了时效前固溶处理的温度和时间、冷却方式及预变形对新型超高强铝锂合金(Al-Cu-Li-X合金)的力学性能和显微组织的影响。

1 实验

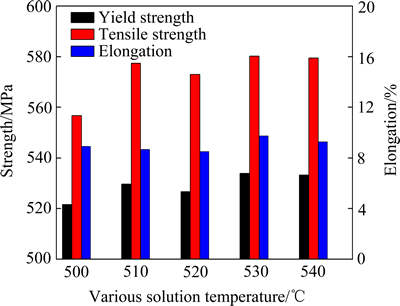

研究用新型超高强Al-Cu-Li-X合金的主要成分如表1所列。铸锭经均匀化处理后,通过热轧和冷轧至约2 mm厚的板材。

将轧制后的合金分成4组,分别进行不同的热处理,其过程及热处理参数如表2所列。其中实验A及B分别研究固溶温度及固溶时间对新型超高强铝锂合金显微组织及力学性能的影响,而实验C和D则研究淬火冷却方式及预变形对超高强铝锂合金力学性能的影响。

表1 新型超高强Al-Cu-Li-X合金化学成分

Table 1 Chemical composition of new ultra-high strength Al-Cu-Li-X alloy (mass fraction, %)

采用MTS 858型拉伸机进行力学性能测试,拉伸速率为2 mm/min;采用Leica DMILM型光学显微镜观察合金晶粒组织。采用FEI Quanta 200型SEM背散射方法进行观察不同固溶处理后合金残余第二相粒子;采用TECNAI G2 20 ST型TEM观察时效后显微组织,其加速电压为200 kV;采用200 F3型差示扫描量热仪测试轧制态合金的差热分析(DSC)曲线。

2 实验结果

2.1 固溶处理对合金力学性能和显微组织的影响

2.1.1 固溶温度的影响

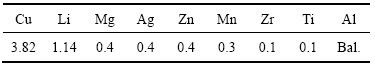

图1所示为合金经500~540 ℃固溶40 min、水淬并进行T6时效(175 ℃,24 h)后的力学性能。由图1可知,合金强度随固溶温度的提高呈现先上升后基本持平的趋势。当固溶温度为500 ℃时,合金T6时效态的强度约为556 MPa;当固溶温度提高至510 ℃时,合金强度增加到578 MPa;随着温度的继续提高至 530 ℃和540 ℃时,合金强度分别为580和579 MPa,与510 ℃的相差不大。但在520 ℃固溶时,合金强度略有降低,为572 MPa。

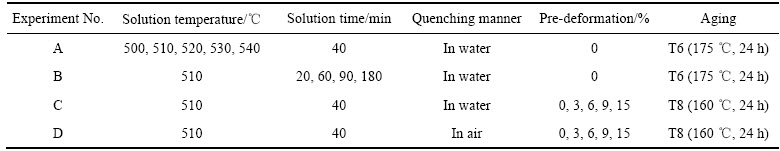

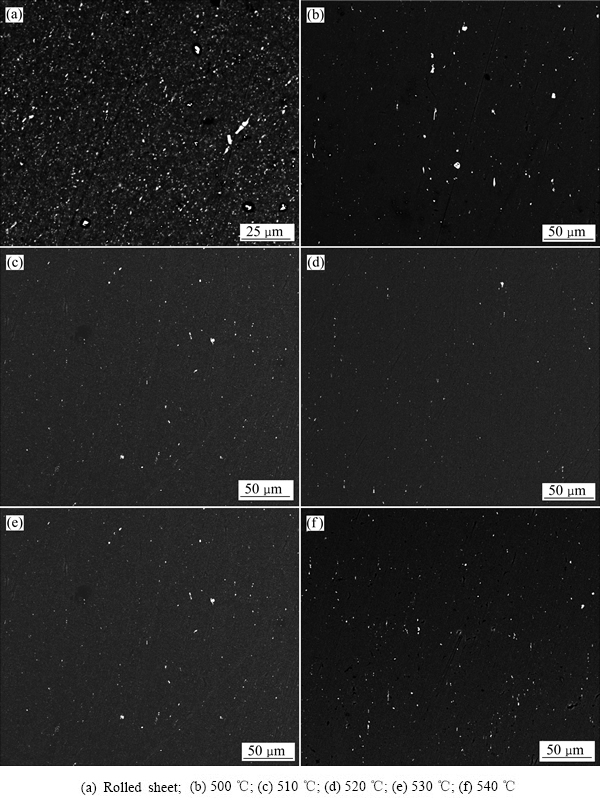

图2所示为合金经500~540 ℃固溶40 min并水淬后的背散射SEM像。由图2可知,相比于冷轧态合金,固溶处理后的残余第二相颗粒数量大幅度减少。

表2 热处理过程及参数

Table 2 Heat treatment process and parameters

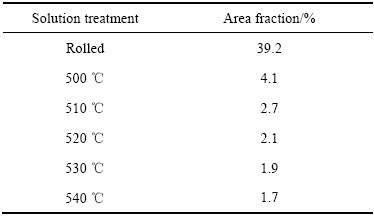

采用Imagepro-plus软件计算SEM像中残余粒子的面积分数;为得到较准确的数据,每个固溶温度均采用3张SEM像统计计算,结果如表3所列。由表3可知,合金经500 ℃固溶后,残余颗粒的面积分数由固溶前的39.2%降低至4.1%;随着固溶温度由510 ℃提高至540 ℃,其面积分数继续降低,但降低幅度很小。

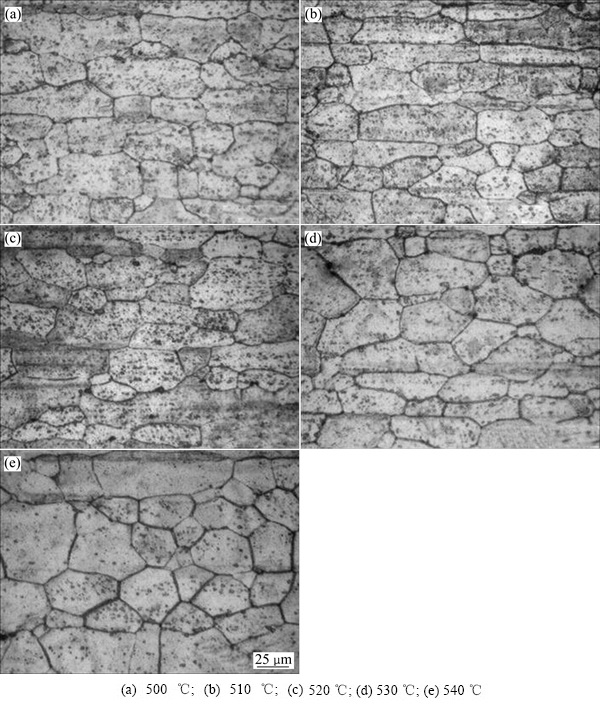

图3所示为合金经500~540 ℃固溶保温40 min、水淬并进行T6时效(175 ℃,24 h)后的金相照片(时效过程不再发生再结晶和晶粒长大)。由图3可知,合金均已发生了再结晶,其中500、510 ℃固溶时仍保持有一定的长条状晶粒组织(见图3(a)和(b))。当温度提高至520 ℃时,部分晶粒已开始趋于等轴状(见图3(c))。随着固溶温度继续升高,趋于等轴状的晶粒数量逐渐增多。在540 ℃时,合金样品中大部分晶粒均呈等轴状且长大趋势较明显(见图3(e))。

图1 不同温度固溶处理40 min并经T6时效(175 ℃, 24 h)后的力学性能

Fig. 1 Tensile properties of T6(175 ℃, 24 h)-aged samples after solution treatment at different temperatures for 40 min

图2 不同温度下固溶处理后合金的背散射SEM像

Fig. 2 Back scattering SEM images of quenched samples after solution treatment at different temperatures

表3 不同温度固溶处理后合金残余第二相粒子的面积分数

Table 3 Area fraction of residual particles after solution treatment at different temperatures

2.1.2 固溶时间的影响

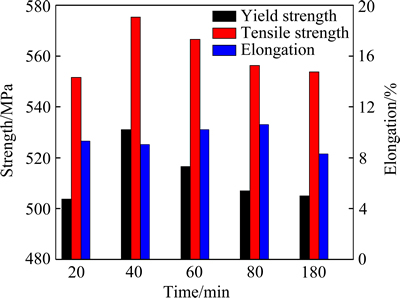

图4所示为合金在510 ℃固溶保温不同时间、水淬并经T6时效(175 ℃,24 h)后的力学性能。由图4可知,随固溶时间延长,合金强度呈现先上升后降低的趋势。固溶20 min时,T6时效合金的抗拉强度仅为551 MPa。当固溶时间延长到40 min时,合金抗拉强度提高到578 MPa。随着固溶时间的继续延长至60、90和180 min时,T6时效态抗拉强度分别为567、554和553 MPa,其强度逐渐降低。

图3 不同温度下固溶40 min并经T6时效后合金的金相照片

Fig. 3 Optical micrographs of T6-aged samples after solution treatment at different temperatures

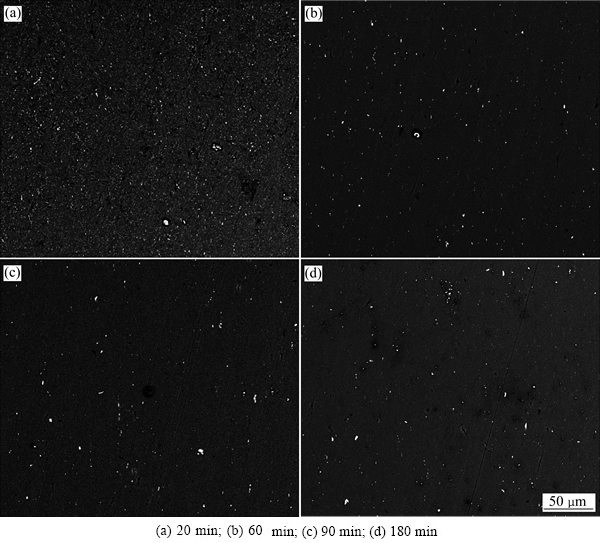

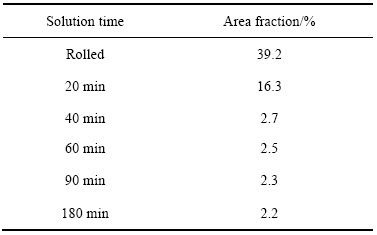

图5所示为合金在510 ℃固溶保温不同时间并水淬后的背散射SEM像。在固溶时间为20 min样品中(见图5(a)),观察到大量未溶解的残余第二相颗粒。当时间延长到40 min时(见图2(c)),残余第二相粒子回溶较为充分。随着固溶时间的继续延长(见图5(c)和(d)),残余第二相颗粒继续回溶,但程度并不明显。采用Imagepro-plus软件统计计算残余第二相粒子的面积分数,计算结果如表4所列。合金在510 ℃固溶20 min后,残余第二相颗粒的面积分数由固溶前的39.2%降低至16.3%。当时间延长到40 min时,其面积分数降低至2.7%;随固溶时间的继续延长,其面积分数进一步降低,但降低的幅度很小。

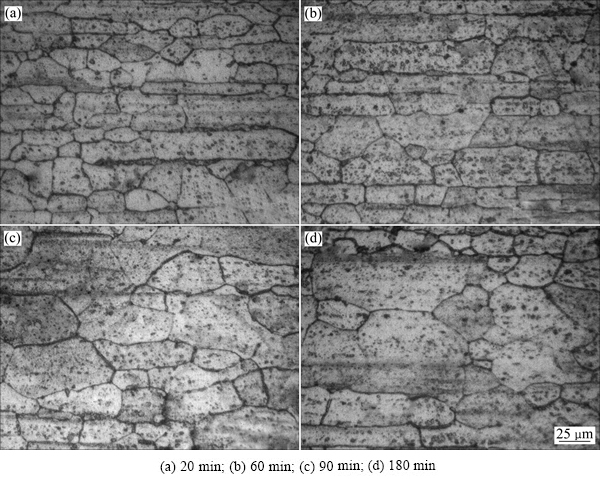

图6所示为合金经510 ℃固溶保温不同时间淬火,并在175 ℃时效24 h的金相照片。结合图3(b)可知,合金在510℃固溶保温20~60 min后,晶粒大部分保持为一定长条状的晶粒形态;但固溶保温90和180 min后(见图6(d)和(e)),晶粒明显长大,等轴状晶粒数量增加。

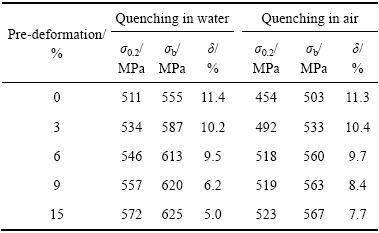

2.2 冷却方式及预变形对合金力学性能的影响

表5所列为510 ℃固溶处理40 min,采用不同的方式淬火冷却并进行不同预变形量的T8态时效(160 ℃,24 h)后合金的力学性能。由表5可知,相同淬火冷却方式的前提下,时效前进行预变形,可明显提高合金的强度。时效前施加3%~6%的预变形,合金抗拉强度可较大程度提高;而当预变形量进一步提高至9%~15%,合金强度可进一步提高,但幅度很小,而且伸长率有较明显降低。这说明合金能通过T8态时效提高其力学性能,但其预变形量应控制低于6%。

另外,在相同的预变形量条件下,采用冷水淬火及空冷淬火时,合金时效后的强度差别非常明显,冷水淬火并时效后的合金强度比空冷淬火的相应强度提高约50~60 MPa。

图4 510 ℃固溶保温不同时间并经T6时效后的力学性能

Fig. 4 Tensile properties of T6-aged samples after solution treatment at 510 ℃ for different time

图5 510 ℃固溶保温不同时间后的SEM背散射像

Fig. 5 Back scattering SEM images of quenched samples after solution treatment at 510 ℃ for different time

图6 510 ℃固溶保温不同时间并经T6时效后合金的金相照片

Fig. 6 Optical micrographs of T6-aged samples after solution treatment at 510 ℃ for different time

表4 510 ℃固溶不同时间后合金残余第二相粒子的面积分数

Table 4 Area fractions of residual particles after solution treatment at 510 ℃ for different time

3 分析与讨论

析出相强化是铝锂合金最主要的强化方式之一。固溶过程中将发生第二相粒子的回溶,即大量第二相粒子中的Cu、Li、Mg、Ag、Zn等原子回溶到基体中,并在随后淬火时形成过饱和固溶体。这些固溶原子在时效阶段以细小第二相形式析出,进而提高了铝锂合金的力学性能。当固溶温度较低、固溶时间较短时,第二相粒子回溶程度较低(见图2(a)和5(a)),仍存在较多残余第二相粒子,因此固溶体过饱和程度较低,导致时效后力学性能偏低。随固溶温度提高以及固溶时间延长,第二相粒子回溶程度增加,相应的固溶体过饱和程度提高,有利于提高合金的时效强化效果。

表5 不同淬火冷却方式及预变形处理的T8态时效合金的力学性能

Table 5 Tensile properties of T8-aged samples with various pre-deformation and different quenching manners

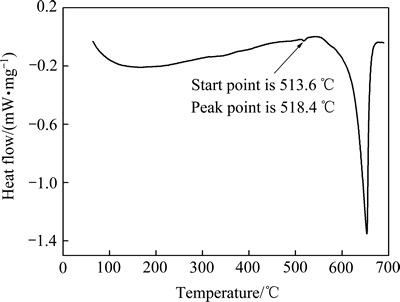

提高固溶温度和延长固溶时间也可能导致合金再结晶晶粒组织形态变化,甚至产生过烧。如(520~540 ℃,40 min)固溶及(510 ℃,90~180 min)固溶时晶粒长大及等轴状再结晶晶粒数量增加。有研究表明[6],铝锂合金的晶粒组织形态对强度有很大的影响。一定长条状的晶粒具有组织强化效应,强化机理主要包括薄带强化和分层强化。而等轴状再结晶晶粒间的大角度晶界不容易被位错穿过,在晶界处出现位错塞积,容易导致应力集中。另外,晶界过烧将导致晶界弱化,合金强度降低[13]。从本研究轧制态铝锂合金升温过程的差热分析(DSC)曲线可观察到两个吸热峰(见图7)。518 ℃呈现出一个较小的吸热峰,表明合金在518 ℃产生了轻微过烧;而653 ℃的吸热峰则为基体的大规模熔化造成的。晶界轻微过烧应该是该铝锂合金520 ℃固溶后时效强度略有降低的主要原因。

图7 轧制态合金的DSC曲线

Fig. 7 DSC curve of rolled sample

虽然合金在较高温度(530、540 ℃)固溶时过饱和程度更高,但此时的轻微过烧和晶粒组织形态对合金的强度有不利的影响。3个因素的综合效果导致合金在530和540 ℃固溶的时效态强度与510 ℃固溶时相当。此外,510 ℃固溶时间延长至60 min后,合金部分晶粒显著长大,等轴状再结晶晶粒数量增加,导致合金强度逐渐降低。

固溶处理后的淬火冷却方式对合金强度的影响来源于冷却过程中是否析出第二相。有研究表明[14],在Al-Cu-Li系合金中,固溶后空冷时冷却速度较慢,高温停留时间长,会析出T1相(Al2CuLi)和δ′相(Al3Li)等第二相;而水淬时冷却速度非常快,高温停留时间短,几乎不析出第二相。上述因素将导致空冷后固溶体的过饱和程度低,削弱强化相的时效析出,导致合金强度的降低。

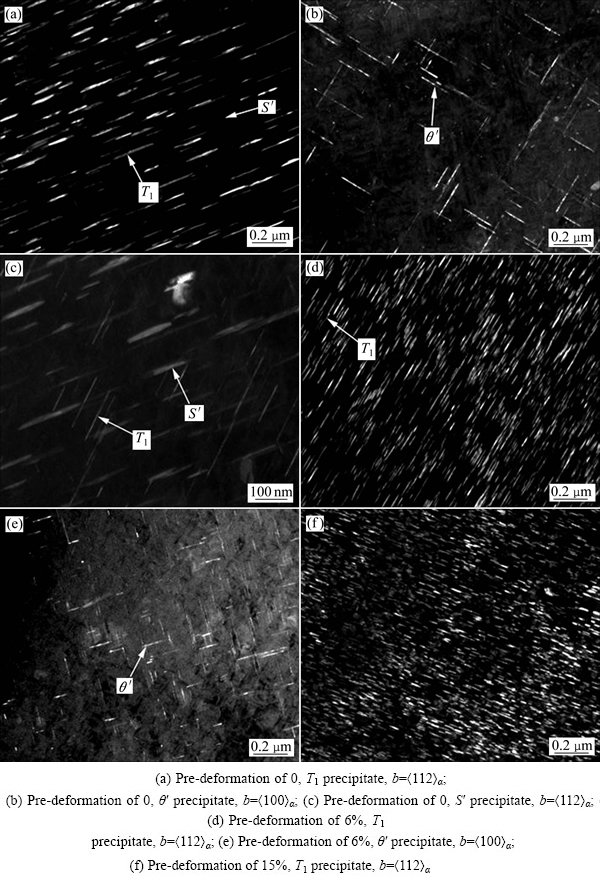

预变形量对合金强度的影响主要来源于时效析出相分布的差异。图8所示为合金经(510 ℃,40 min)固溶水淬后,分别进行0、6%、15%预变形,并于160 ℃时效24 h后的TEM暗场像。由图8可知,预变形量为0的时效样品中,观察到大量T1相、部分θ′相(Al2Cu)和少量S′相(Al2CuMg)(见图8(a)~(c))。在预变形量为6%的时效样品中,析出相为大量T1相和少量θ′相,S′相消失;另外,相比于0预变形量时效样品,T1相数量大幅度增多,而且尺寸更加细小、分布更加弥散(见图8(d)和(e))。当预变形量增加至15%时(见图8(f)),时效样品中只观察到T1相,其数量进一步增加,尺寸减小,特别是长度明显降低,其长宽比相应地大幅度下降。由此可知,随着预变形量的增大,时效时T1相的数量增多且尺寸减小,而θ′相和S′相则逐渐减少甚至消失。有研究表明[15],人工时效前的预变形在基体中形成大量的位错,可作为强化相的形核位置,促进强化相在晶内细小弥散析出。并且在铝锂合金的沉淀强化相中,预变形对T1相的形核促进作用最为显著[16]。T1相数量越多、尺寸越细小、分布越弥散,其强化效果越大。因此,合金的时效强度随着预变形量的提高而逐渐增加。

当预变形量较大时(>6%),合金中位错密度较高,但由于合金中过饱和固溶体中的溶质原子的浓度一定,析出相体积分数基本保持不变。由于片状相(盘状相)T1相的长宽比大幅度下降(见图8(f)),将导致T1相的强化效果下降[17],因而即使预变形量大(>6%)可导致T1相数量增加,但其强化效果的增量反而降低。而且当预变形量过大(15%)时,可能产生位错缠结,形成胞状位错组织,对T1相的析出形态和分布反而不利,造成合金塑性的降低[18]。

4 结论

1) 在500~540 ℃固溶处理40 min时,随固溶温度提高至520 ℃,未回溶残余第二相粒子分数降低;但在520 ℃以上温度固溶时,再结晶晶粒尺寸增加且趋于呈等轴状。

2) 在510 ℃固溶处理时,随固溶时间延长至40 min,第二相粒子固溶过程基本完成,时效后强度随固溶时间延长而提高;继续延长固溶时间,再结晶晶粒尺寸增加且趋于呈等轴状,时效后强度相应地降低。

3) 合金的时效析出相包括大量T1相、部分θ′相和少量S′相;预变形可促进时效时T1相细小、弥散析出,而抑制θ′相和S′相析出;随预变形量增加至6%及15%,S′相及θ′相消失,T1相数量大幅度增加,长宽比急剧下降。

图8 不同预变形量T8时效合金的TEM暗场像

Fig. 8 Dark field TEM images of T8-aged alloy with various pre-deformations

4) 预变形量在6%以下预变形,随预变形量增加,合金时效后强度明显提高;预变形量在6%以上预变形时,强化效果的增量降低。

REFERENCES

[1] RIOJA R J, LIU J. The evolution of Al-Li base products for aerospace and space applications[J]. Metallurgical & Materials Transactions A, 2012, 43(9): 3325-3337.

[2] 程晓宇, 王晓梅. 铝锂合金研究与发展[J]. 中国有色金属, 2008(12): 72-73.

CHENG Xiao-yu, WANG Xiao-mei. Research and development of Al-Li alloy[J]. China Nonferrous Metals, 2008(12): 72-73.

[3] RIOJA R J, DENZER D K, MOOY D, VENEMA G B. Lighter and stiffer materials for use in space vehicles[C]// Proceedings of the 13th International Conference on Aluminum Alloys (ICAA13). Pittsburg: John Wiley & Sons, Inc, 2012: 593-598.

[4] DENZER D K, RIOJA R J, BRAY G H, VENEMA G B, COLVIN E L. The evolution of plate and extruded products with high strength and fracture toughness[C]// Proceedings of the 13th International Conference on Aluminum Alloys (ICAA13). Pittsburg: John Wiley & Sons, Inc, 2012: 587-592.

[5] 罗先甫, 郑子樵, 钟继发, 张海锋, 钟 警, 李世晨, 李劲风. Mg、Ag、Zn多元微合金化对新型Al-Cu-Li合金时效行为的影响[J]. 中国有色金属学报, 2013, 23(7): 1833-1842.

LUO Xian-fu, ZHENG Zi-qiao, ZHONG Ji-fa, ZHANG Hai-Feng, ZHONG Jing, LI Shi-chen, LI Jin-feng. Effects of Mg, Ag and Zn multi-alloying on aging behavior of new Al-Cu-Li alloy[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(7): 1833-1842.

[6] MAZIBUKO N E, CURLE U A. Effect of solution heat treatment time on a rheocast Al-Zn-Mg-Cu alloy[J]. Materials Science Forum, 2011, 690: 343-346.

[7] 谢绍俊. CP276铝-锂合金的固溶温度研究[J]. 轻合金加工技术, 2001, 29(1): 35-37.

XIE Shao-jun. Study on solid solution treatment temperature for Al-Li alloy[J]. Light Alloy Fabrication Technology, 2001, 29(1): 35-37.

[8] 张新明, 刘颖维, 叶凌英, 唐建国. 预变形和过时效对AA2195铝锂合金晶粒的细化[J]. 中国有色金属学报, 2009, 19(4): 633-638.

ZHANG Xin-ming, LIU Ying-wei, YE Ling-ying, TANG Jian-guo. Grain refinement of AA2195 Al-Li alloy by pre-deformation and overaging[J]. Chinese Journal of Nonferrous Metals, 2009, 19(4): 633-638.

[9] 刘平礼, 张 健, 李劲风, 陈永来, 张绪虎. 二次时效对微合金化的Al-Cu-Li微观组织及力学性能的影响[J]. 宇航材料工艺, 2014, 44(5): 50-60.

LIU Ping-li, ZHANG Jian, LI Jin-feng, CHEN Yong-lai, ZHANG Xu-hu. Effect of secondary aging on microstructure and mechanical strength of micro-alloyed Al-Cu-Li alloy[J]. Aerospace Materials & Technology, 2014, 44(5): 50-60.

[10] 程 彬, 郑子樵, 范春平, 钟继发, 韩 烨, 孙景峰. 时效制度对新型Al-Cu-Li合金组织与性能的影响[J]. 中国有色金属学报, 2014, 24(4): 926-933.

CHEN Bin, ZHENG Zi-qiao, FAN Chun-ping, ZHONG Ji-fa, HAN Ye, SUN Jing-feng. Effect of aging treatments on microstructures and properties of new Al-Cu-Li alloy[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(4): 926-933.

[11] 李红英, 张孝军, 张建飞, 郑子樵. 分级时效对新型Al-Cu-Li合金组织与性能的影响[J]. 中国有色金属学报, 2008, 18(3): 426-432.

LI Hong-ying, ZHANG Xiao-jun, ZHANG Jian-fei, ZHENG Zi-qiao. Effect of multi-stage ageing treatments on microstructures and mechanical properties of new-type Al-Cu-Li alloy[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(3): 426-432.

[12] 朱小辉, 郑子樵, 钟 申. Mg和Zn对2099合金时效组织与拉伸性能的影响[J]. 中国有色金属学报, 2010,20(10): 1861-1867.

ZHU Xiao-hui, ZHENG Zi-qiao, ZHONG Shen. Effect of Mg and Zn on microstructure and tensile properties of 2099 alloy[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(10): 1861-1867.

[13] 陈小明, 宋仁国, 张 宇, 李 杰. 过烧对7003铝合金组织与性能的影响[J]. 轻合金加工技术, 2009, 37(2): 48-52.

CHEN Xiao-ming, SONG Ren-guo, ZHANG Yu, LI Jie. Effects of overfire on microstructure and properties of 7003 aluminum alloy[J]. Light Alloy Fabrication Technology, 2009, 37(2): 48-52.

[14] 李红英, 张建飞, 耿进峰, 郑子樵. 冷却速度对Al-Cu-Li系合金析出相及其硬度的影响[J]. 热加工工艺, 2006, 35(18): 38-40.

LI Hong-ying, ZHANG Jian-fei, GENG Jin-feng, ZHENG Zi-qiao. Effect of cooling rate on precipitation phases and hardness of Al-Cu-Li alloy[J]. Hot Working Technology, 2006, 35(18): 38-40.

[15] 李慧中, 张新明, 陈明安, 周卓平, 龚敏如. 预变形对2519铝合金组织与力学性能的影响[J]. 中国有色金属学报, 2004, 14(12): 1990-1994.

LI Hui-zhong, ZHANG Xin-ming, CHEN Ming-an, ZHOU Zhuo-ping, GONG Min-ru. Effect of pre-deformation on microstructures and mechanical properties of 2519 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(12): 1990-1994.

[16] 魏修宇, 郑子樵, 潘峥嵘, 陈圆圆, 李世晨, 陈秋妮. 预变形对2197铝锂合金显微组织和力学性能的影响[J]. 稀有金属材料与工程, 2008, 37(11): 1996-1999.

WEI Xiu-yu, ZHENG Zi-qiao, PAN Zheng-rong, CHEN Yuan-yuan, LI Shi-chen, CHEN Qiu-ni. The role of plastic deformation on microstructure and mechanical properties of 2197 Al-Li alloy[J]. Rare Metal Materials and Engineering, 2008, 37(11): 1996-1999.

[17] NIE J F, MUDDLE B C. Microstructural design of high-strength aluminum alloys[J]. J Phase Equilibria, 1998, 19(6): 543-551.

[18] 蒋 呐, 向曙光, 郑子樵. CP276铝锂合金的应变时效工艺[J]. 中国有色金属学报, 1999, 9(4): 694-699.

JIANG Na, XIANG Shu-guang, ZHENG Zi-qiao. Strain-ageing process for Al-Li alloy CP276[J]. The Chinese Journal of Nonferrous Metals, 1999, 9(4): 694-699.

(编辑 王 超)

基金项目:国家高技术研究发展计划资助项目(2013AA032401);中南大学教师研究基金资助项目(2013JSJJ0001)

收稿日期:2015-02-09;修订日期:2015-10-29

通信作者:李劲风,教授,博士;电话:13278861206;E-mail: lijinfeng@csu.edu.cn