基于球形压痕响应的各向异性材料等效应变硬化指数

来源期刊:中国有色金属学报(英文版)2019年第1期

论文作者:惠钰 吴建军 王明智 展学鹏 樊赫

文章页码:77 - 87

关键词:等效应变硬化指数;各向异性材料;球形压痕;残余压痕

Key words:equivalent strain hardening exponent; anisotropic material; spherical indentation; residual imprint

摘 要:针对各向异性材料,讨论单一方向的应变硬化指数对复杂应力问题求解的局限性,提出了一种基于等效能量法计算各向异性材料等效应变硬化指数的新方法。首先,设置一系列有限元仿真实验,得出残余压痕参数与等效应变硬化指数的无量纲函数关系式;其次,使用此无量纲函数建立等效应变硬化指数与残余压痕的数学表达式;最后,通过对比数值试验结果验证该方法的有效性。另外,为了确定各向异性材料的屈服强度,对其Meyer关系进行扩展。通过数值实例及对TC1M钛合金的实际应用验证了该新方法的有效性和可靠性。

Abstract: Uniaxial strain hardening exponent is not suitable for describing the strain hardening behaviors of the anisotropic materials, especially when material deforms in the multi-axial stress states. In this work, a novel method was proposed to estimate the equivalent strain hardening exponent of anisotropic materials based on an equivalent energy method. By performing extensive finite element (FE) simulations of the spherical indentation on anisotropic materials, dimensionless function was proposed to correlate the strain hardening exponent of anisotropic materials with the indentation imprint parameters. And then, a mathematic expression on the strain hardening exponent of anisotropic materials with the indentation imprint was established to estimate the equivalent strain hardening exponent of anisotropic materials by directly solving this dimensionless function. Additionally, Meyer equation was modified to determine the yield stress of anisotropic materials. The effectiveness and reliability of the new method were verified by the numerical examples and by its application on the TC1M engineering material.

Trans. Nonferrous Met. Soc. China 29(2019) 77-87

Yu HUI, Jian-jun WU, Ming-zhi WANG, Xue-peng ZHAN, He FAN

School of Mechanical Engineering, Northwestern Polytechnical University, Xi’an 710072, China

Received 4 August 2017; accepted 17 July 2018

Abstract: Uniaxial strain hardening exponent is not suitable for describing the strain hardening behaviors of the anisotropic materials, especially when material deforms in the multi-axial stress states. In this work, a novel method was proposed to estimate the equivalent strain hardening exponent of anisotropic materials based on an equivalent energy method. By performing extensive finite element (FE) simulations of the spherical indentation on anisotropic materials, dimensionless function was proposed to correlate the strain hardening exponent of anisotropic materials with the indentation imprint parameters. And then, a mathematic expression on the strain hardening exponent of anisotropic materials with the indentation imprint was established to estimate the equivalent strain hardening exponent of anisotropic materials by directly solving this dimensionless function. Additionally, Meyer equation was modified to determine the yield stress of anisotropic materials. The effectiveness and reliability of the new method were verified by the numerical examples and by its application on the TC1M engineering material.

Key words: equivalent strain hardening exponent; anisotropic material; spherical indentation; residual imprint

1 Introduction

Anisotropic plastic properties are widely observed in the industrial materials, especially in the aviation, such as anisotropic alloys, composite materials and coatings [1]. Uniaxial test is one of the classical methods to measure anisotropic properties of materials. However, this testing method is not applicable for the specimens with finite volumes. Nano-indentation, as an alternative approach, has received great attention for its obvious advantages, e.g. easy sample preparation [2]. Nano-indentation has shown the ability to nondestructively measure the local properties of the exceedingly small sub-volumes of specimens [3,4], such as elastic modulus [5], residual stress [6,7], fracture toughness [8,9], as well as the strain hardening exponent in crystal plasticity [10].

TABOR [11] proposed the representative stress and strain method firstly to extract the stress-strain curves from indentation test. MOUSSA et al [12] proposed a method for the determination of strain hardening law of materials using the load-displacement curve of a spherical indentation test. Although some theories and methods have been well established, techniques in the relevant fields are still in the developing stages [13-17].

Strain hardening exponent is an important parameter, which essentially represents the ability of material to resist the further strain hardening in metal forming process. For the anisotropic materials, Hill’48 yield criterion was widely used, for its simple form. However, the strain hardening of the Hill’48 yield criterion is usually assumed as isotropic hardening, using the Hollomon hardening law. Besides, in some conventional FE softwares (e.g. ABAQUS), although the yield stresses along different orthogonal directions are different, the strain hardening of materials was assumed to be isotropic. In fact, the uniaxial strain hardening exponent is suitable for isotropic materials or the anisotropic materials along different uniaxial directions. When dealing with multi-axial stress problems, uniaxial exponent cannot take other directions into consideration. Therefore, an equivalent strain hardening exponent is needed to describe the strain hardening behaviors of the anisotropic materials.

In practice, it is quite difficult to compute the residual imprint in indentation test because the shape cannot be captured accurately [18]. The development of FEM (finite element method) provides a very versatile approach to explore the relationship between the residual imprint and the mechanical properties. It is able to avoid many uncertainties in indentation experiments, e.g. the existence of measuring error [19]. Furthermore, it gives more complete and accurate predictions than the plastic deformation theory [20], such as the complicated multi-axial stress strain states and the pile-up effect [21].

In this work, a new method is suggested to estimate the equivalent hardening exponent n by only using the residual imprint of spherical indentation. The advantage of this method is that it does not need to know the entire indentation loading history [22]. The residual imprint profile contains the essential deformation characteristics of a material, and it is closely related to the material hardening exponent [21]. When a rigid spherical indenter is penetrated into the surface of in-plane anisotropic specimens, the residual imprint is different among orthogonal directions. Inspirited by that, dimensionless function between mechanical properties parameters and residual imprint is established [2]. Because it only considers in-plane anisotropy and uses dimensionless function, this approach is quite simple. Furthermore, the effectiveness of the method is verified by the numerical experiment and the effectiveness of the equivalent strain hardening exponent is verified by the experimental results of TC1M anisotropic materials.

2 Numerical approach

2.1 Material model

The anisotropic theory used in the indentation simulation is introduced. There are many criteria to describe the plastic deformation behaviors of anisotropic materials. Here, the Hill’48 criterion [23] is considered, for its simple form. Hill’s theory is expressed as Eq. (1):

F(σy-σz)2+G(σx-σy)2+H(σx-σy)2+ =1 (1)

=1 (1)

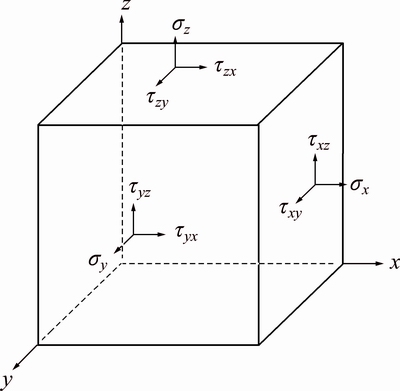

where F, G, H, L, M and N are anisotropic parameters, σx, σy, σz, τzy, τxy and τzx are the normal stresses and shear stresses along three axes. The material coordinate is shown in Fig. 1.

Figure 1 describes the material coordinate used in the present work, xy plane is the in-plane that characterizes the anisotropic properties. Three normal stresses and three shear yield stresses along the orthogonal axes (x, y, z), are defined as τxy, τyz, τzx and σyx, σyy, σyz, respectively.

Since the materials exhibit in-plane anisotropic properties, their stress strain curve is expressed as

σy =σyy =σyz <σyx (2)

where σy is the yield strength.

(3)

(3)

And m is defined as the ratio σyx/σyy, that is,

σyx=mσyy (4)

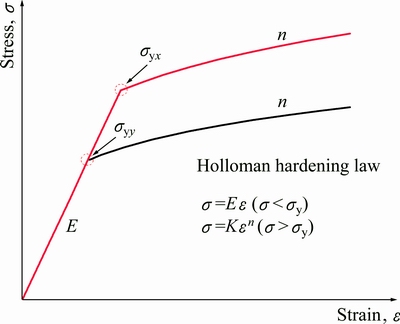

The present work considers the materials which obey Holloman hardening law, as shown in the following equations:

σ=Eε (σ<σy) (5)

σ=Kεn (σ>σy) (6)

n is the strain hardening exponent, E is the elastic modulus and K is the work-hardening strength.

(7)

(7)

Holloman hardening law is able to describe the hardening behavior of most materials [24-26]. Figure 2 shows the stress-strain curves of anisotropic materials that obey the Holloman hardening law. When E is known in advance, two parameters need to be identified, which are σy and n. In the present work, we focus on the strain hardening exponent n, independently, and we also extend the approach to estimate the yield stress in anisotropic materials.

Fig. 1 Material coordinate system

Fig. 2 Stress-strain curves of anisotropic materials

2.2 Finite element model in spherical indentation of anisotropic materials

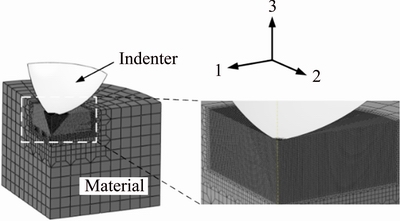

The one-quarter finite element (FE) model of spherical indentation test is built with ABAQUS software [27], as shown in Fig. 3. The longitudinal direction is along 1-direction, transverse direction is along 2-direction, and 3-direction is the indenter loading-unloading direction.

Fig. 3 FE model used in indentation simulation

This model comprises 17200 elements, and refined meshes are created around the local contact region between indenter and specimen, as shown in Fig. 3. The specimen is modeled using C3D8R element type. Contact friction coefficient between the surfaces of these two bodies is defined to be 0.1 [28]. Because the contact friction coefficient between diamond and metals is around this value, and it is a minor factor in indentation [29,30]. The displacement of bottom nodes of specimen is fixed, and the axisymmetric boundary constraints are applied on the center axis of specimen. The surfaces of the specimens are assumed as a planar plate and the indenter load can only move vertically to penetrate the specimen, and the ratios between maximum indentation depth and indenter radius hm/R are fixed to be 0.1.

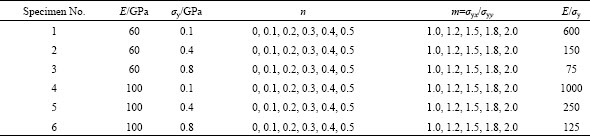

The elastic-plastic properties used for the extensive FE simulations are listed in Table 1. Poisson ratio v was fixed at 0.3 because its influence on the inden-tation response was small [31-34]. The ratio range of 75

2.3 Effect of anisotropic plasticity on residual imprint

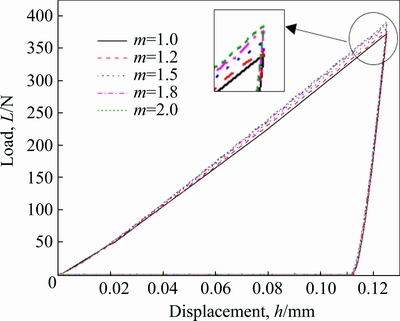

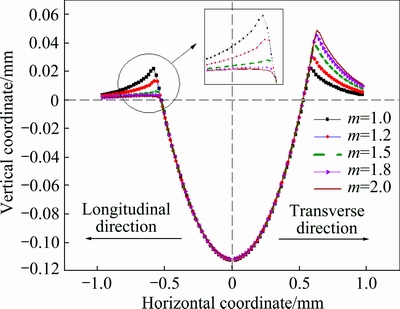

Figure 5 shows the indentation response of in-plane anisotropic materials, of which E=100 GPa, σy=400 MPa and n=0.1, anisotropic parameter m varies from 1.0, 1.2, 1.5, 1.8 to 2.0. The maximum load increases as m increases, but the differences are small. This indicates that it is difficult to evaluate the anisotropy of in-plane anisotropic materials using solely the load-displacement curves. So, we suggested here to use the residual imprint as useful indentation information. When the spherical indenter penetrates into the specimen, the specimen will deform as the indenter moves, and an imprint will be left after indenter withdrawal. Figure 6 shows the simulated residual imprints of specimens with different m values. The maximum pile-up value varies obviously as m value changes. The pile-up height in the low yield stress direction becomes larger than that in the high yield stress direction, which is coincident with the results of YONEZU et al [2]. This indicates that, the shape of the residual imprint relies on the plastic anisotropic properties. Consequently, the relationship between residual imprint and the hardening exponent n should be investigated.

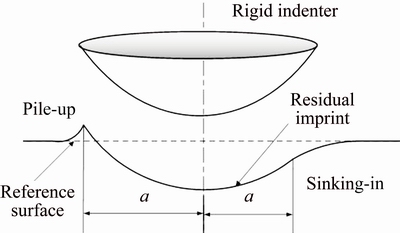

The schematic diagram of the residual imprint is shown in Fig. 7. a is defined as the contact radius under the fully unloaded state. The contact radii along different directions are equal for isotropic materials while the contact radii are different for anisotropic materials. Different contact radii are influenced by the pile-up or the sinking-in effect. Actually, these differences are caused by the plastic anisotropy, such as the yield stress and strain hardening exponent in different directions. So, it is reasonable to connect the residual imprint with plastic properties.

Further, the influence of strain hardening exponent on the shape of the residual imprint was investigated.

Table 1 Elastic-plastic properties used in FE simulations

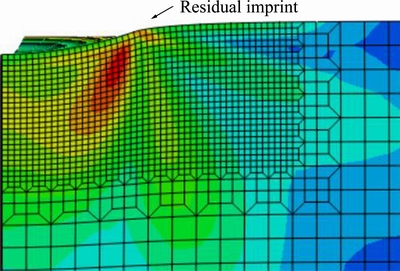

Fig. 4 Residual imprint after spherical indentation

Fig. 5 Indentation curves of five materials

Fig. 6 Residual imprints of specimens with different m values after indenter withdrawal

Fig. 7 Schematic diagram of residual imprint in spherical indentation

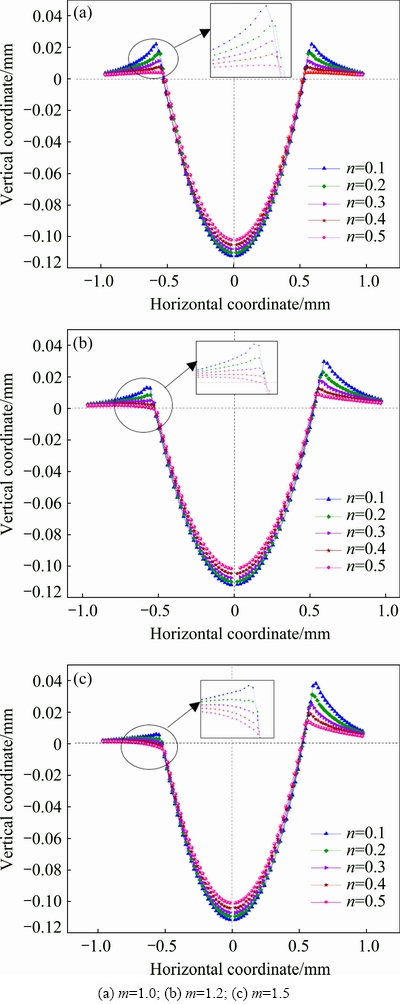

Figure 8 shows the changes of the residual imprints at different n and m values. The height of pile-up and the contact radius decrease as n increases and then the mathematic relationship between contact radius a and hardening exponent n is explored.

Fig. 8 Residual imprints for materials with three m values

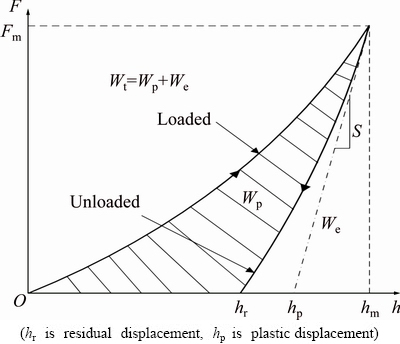

The equivalent indentation work was used to characterize the anisotropic parameters of materials, of which the elastic deformation was assumed in the unloaded stage. The load-depth curve in indentation test is shown in Fig. 9, where hm is the maximum indentation depth, Fm is the maximum indentation force. The area surrounded by loading curve and x-axis is defined as the total work Wt, the area surrounded by unloading curve and x-axis is the elastic recover work We, and the difference of Wt and We is plastic work Wp.

Fig. 9 Schematic diagram of relation curve between indentation force and depth

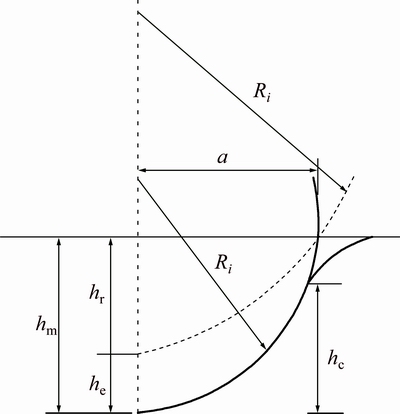

Important displacement variables include the maximum displacement hm, the contact depth hc, the elastic displacement he, and the residual displacement hr. In the indentation test, the materials are assumed that only elastic deformation happens in the unloading stage. The profile of the imprint is shown in Fig. 10. According to Hertz’s contact theory [35], for rigid spherical indenter and flat non-rigid specimen, the indentation depths can be described as

(8)

(8)

In current literature, the relationship between indentation work and depth in the dimensionless form is described as [36]

(9)

(9)

According to the indentation geometry, the relationship between contact depth h and contact radius can be described as

(10)

(10)

where R is the radius of rigid indenter.

So Eq. (9) can be rewritten as

(11)

(11)

Fig. 10 Schematic diagram of geometrical relationships among contact radius and characteristic depths

Anisotropic materials are also assumed to obey Eq. (11), but a2 should be written as  . As for orthogonal anisotropic materials, there are two different directions. And the projection of the residual imprint is ellipse, which has two contact radii.

. As for orthogonal anisotropic materials, there are two different directions. And the projection of the residual imprint is ellipse, which has two contact radii.  is defined and described as

is defined and described as

(12)

(12)

When the indentation depth is fixed, the maximum contact radius and the indenter radius are constant parameters. The equivalent expression can be described as

(13)

(13)

(14)

(14)

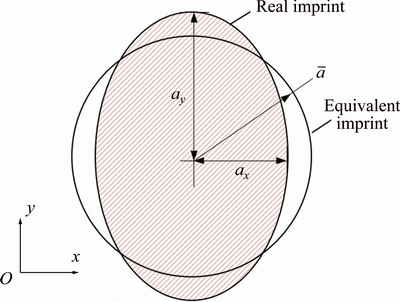

Equation (14) can be regarded as the same proportion of the normal imprint for isotropic and anisotropic materials. Here,  represents the area of the ellipse in Fig. 11.

represents the area of the ellipse in Fig. 11.

As for anisotropic materials, the nominal imprint after indenter withdrawal is ellipse while it is a circle for isotropic materials. For further illustration, the contact radii in orthogonal direction are different, ax , which is regarded as the representative radius of the two axis (x-axis and y-axis) of the ellipse.

, which is regarded as the representative radius of the two axis (x-axis and y-axis) of the ellipse.

Fig. 11 Schematic diagram of equivalent imprint

3 Dimensionless analysis and numerical computation

In this section, the method is proposed to evaluate the in-plane strain hardening exponent n based on dimensional analysis and numerical computation. Dimensionless function is explored which can correlate the exponent n with the impression geometry.  theorem [37] is a useful tool to establish functional relation between independent parameters. Contact radius can be expressed by the following

theorem [37] is a useful tool to establish functional relation between independent parameters. Contact radius can be expressed by the following function:

function:

(15)

(15)

where subscript i refers to the corresponding indenter, and  is the Poisson ratio.

is the Poisson ratio.

The reduced elastic modulus E* can be expressed as

(16)

(16)

Indenter is regarded as rigid body, and the elastic modulus of indenter is infinite. So, Eq. (16) can be rewritten as

(17)

(17)

When R, h and  are fixed,

are fixed,  and

and  functions can be simplified to

functions can be simplified to  and

and  functions, as shown in the following equation:

functions, as shown in the following equation:

(18)

(18)

As stated in Section 2.3, the residual imprint strongly depends on the strain hardening exponent n, and the function is established based on this relation. Contact radius contains all the characters, such as load depth, and pile-up or sinking-in effects. The values of the contact radius are different by changing the material characters, such as yield stress σy, anisotropic parameter m, elastic modulus E and strain hardening exponent n.

In order to establish the relationship between the imprint and material properties, indentation depth is fixed as hm/R=0.1. By using the  theorem, the parameter

theorem, the parameter  can be expressed as

can be expressed as

(19)

(19)

In Eq. (19),  reveals that the value of

reveals that the value of  depends on the plastic properties (E/σy, m, n).

depends on the plastic properties (E/σy, m, n).

TABOR [11] suggested the following relationship between flow stress and strain in uniaxial tension and the parameters in spherical indentation:

(20)

(20)

(21)

(21)

where σt and εt are flow stress and strain in uniaxial tension, respectively, ψ is the plastic constraint factor (taken as 3 in Tabor’s work). Inserting Eqs. (20) and (21) into Eq. (6) gives

(22)

(22)

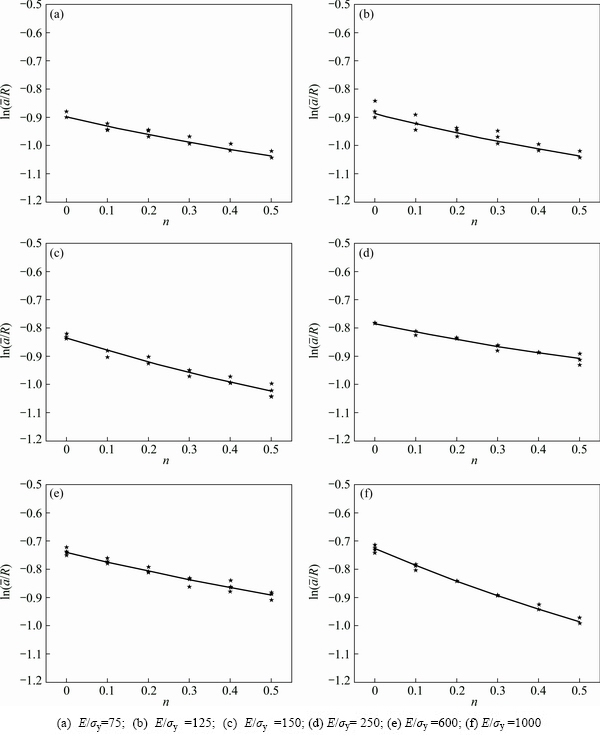

When the test condition (load depth) is fixed, the indentation load F is a constant. The relationship between  and hardening exponent n at different plastic strains is shown in Fig. 12. From the results in all the FEM data, Fig. 12 shows a close relationship between

and hardening exponent n at different plastic strains is shown in Fig. 12. From the results in all the FEM data, Fig. 12 shows a close relationship between  and hardening exponent n, in spite of the small deviation in anisotropic parameters m from 1.0 to 2.0. For simple mathematical expressions, FEM data are fitted as

and hardening exponent n, in spite of the small deviation in anisotropic parameters m from 1.0 to 2.0. For simple mathematical expressions, FEM data are fitted as

=An2+Bn+C (23)

=An2+Bn+C (23)

where A, B and C are regression coefficients.

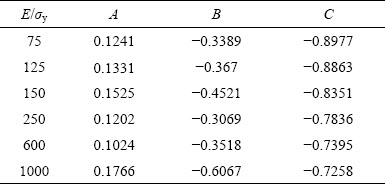

In Fig. 12, the curves are similar under different strains.  is linearly related to the strain hardening exponent n. The values of coefficients A, B and C used in Eq. (23) are listed in Table 2.

is linearly related to the strain hardening exponent n. The values of coefficients A, B and C used in Eq. (23) are listed in Table 2.

Coefficients A, B and C are strongly denpendent on the strain value. Their relationships are fitted by Eq. (24), (25) and (26), respectively:

(24)

(24)

(25)

(25)

(26)

(26)

Fig. 12 Dimensionless function of  at hm/R=0.1 and different E/σy values

at hm/R=0.1 and different E/σy values

Table 2 Coefficients A, B and C used in Eq. (23)

4 Results and discussion

4.1 Numerical verification

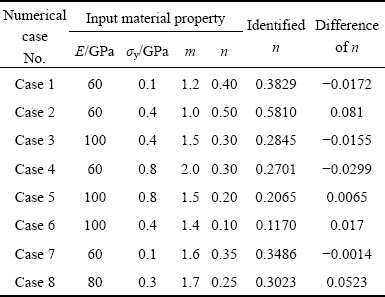

In this section, the new approach will be employed to estimate the strain hardening exponent of anisotropic materials using several numerical cases, and results are shown in Table 3. The effectiveness of the approach is verified by comparing the “input” hardening exponent in the FE simulation with those identified by the established numerical method.

Table 3 Representative numerical cases for effectiveness verification of strain hardening exponent of anisotropic materials

It can be seen from Table 3 that the strain hardening exponent identified by the present method shows good agreement with the FE “input” hardening exponent values, and the maximum difference is 0.081. This indicates that the new approach is reliable and has satisfactory accuracy.

4.2 Modified Mayer’s relationship for estimation of yield strength of anisotropic materials

In Section 3, we have established the method to directly estimate the strain hardening exponent of anisotropic materials, but the yield stress is still unknown. In this section, the modified Mayer’s relationship will be proposed to estimate the yield strength of anisotropic materials. In the spherical indentation, the relationship between the indentation contact force and the depth was obtained [38]:

(27)

(27)

where d is the contact diameter, A1 is a regression coefficient, D is the diameter of the rigid indenter, and k is the fitting exponent. However, this equation is only suitable for the isotropic materials. Here, the equation for the anisotropic material is rewritten, as shown in the following forms:

(28)

(28)

GEORGE et al [39] proposed the following equation to correlate the constant A1 with yield stress

σy=cA1 (29)

where c is a constant that varies with the specific material class. In this study, the c value of Ti alloys was known to be 0.3 [40]. Similarly, Eq. (29) can also be extended to Eq. (30):

(30)

(30)

Equations (24)-(26) require a single yield stress to calculate the fitting coefficients A, B and C. While for the anisotropic materials considered in the present study, there are two yield stress values along different orthogonal directions, and they can be obtained from Eq. (30). Here, we defined the equivalent yield stress  , for the anisotropic materials, by using the concept of equivalent contact diameter

, for the anisotropic materials, by using the concept of equivalent contact diameter  , which are written as follows:

, which are written as follows:

(31)

(31)

(32)

(32)

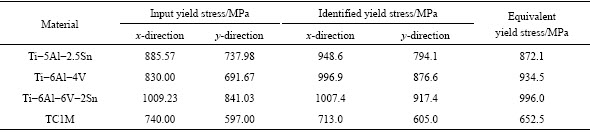

Table 4 shows the comparison of the equivalent yield stress estimated by using spherical indentation with those from the tensile tests. From Table 4, it can be seen that good agreement can be found, indicating that the modified Mayer’s relation in the present study is effective.

Table 4 Equivalent yield stress estimated from spherical indentation and those from tensile tests

4.3 Application of equivalent strain hardening exponent in multi-axial stress fields

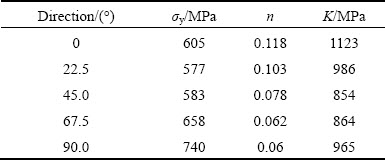

In this section, the effectiveness of the equivalent strain hardening exponent is verified by its application in the TC1M anisotropic material. The multi-axial stress strain field is calculated by separately using the uniaxial direction strain hardening exponent and equivalent strain hardening exponent. The material parameters of TC1M titanium alloys in five different directions are listed in Table 5.

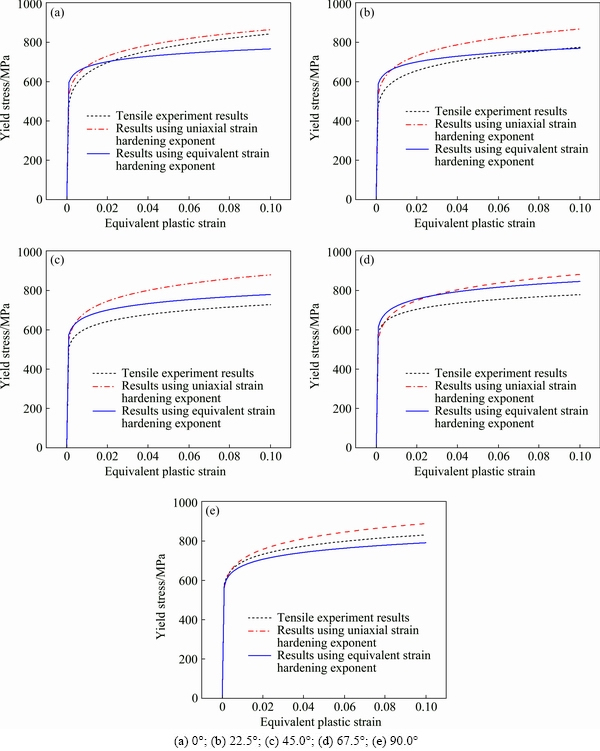

The equivalent strain hardening exponent of TC1M material calculated by Eq. (25) is 0.078. Figure 13 shows the comparison of FE simulation results using different directions of the strain hardening exponent. The stress-strain curves are extracted from the representative point beneath the indenter. This representative data acquisition point is defined as the optimal data acquisition point, r/a=0.8 and l/D=10%, at which the frictional effect can be ignored and the maximum strain for a given indentation depth can be obtained [41].

Table 5 Tensile experimental data of TC1M titanium alloys

Fig. 13 Comparison of stress-strain curves of TC1M between uniaxial tests and those calculated by using equivalent strain hardening exponent, respectively, in different directions

Figure 13 shows three stress-strain curves that are separately calculated by using the uniaxial strain hardening exponent along different reference directions (the longitudinal direction is regarded as the reference direction in this work), the equivalent strain hardening exponent, and the tensile experimental data. It can be seen from Fig. 13 that, the stress-strain curves calculated by equivalent strain hardening exponent show better agreement than those calculated by uniaxial strain hardening exponent in the four directions (22.5°, 45.0°, 67.5° and 90.0° (except 0° direction). This is because the uniaxial strain hardening exponent can only give relatively accurate results in its own direction, while it gives coarse results in other directions. For the anisotropic materials, the equivalent strain hardening exponent is calculated by the parameters in different directions, thus it takes into account the strain hardening in all the directions. This explains why the equivalent strain hardening exponent gives more accurate results.

5 Conclusions

(1) Equivalent strain hardening exponent is suitable for describing the anisotropic materials in the multi-axial stress states.

(2) The established dimensionless function effectively correlates the equivalent strain hardening exponent with the residual contact radius of the anisotropic materials. The effectiveness of the proposed approach is numerically verified by its application on a series of numerical cases.

(3) The application of the equivalent strain hardening exponent is verified by its application in the TC1M engineering material.

References

[1] YONEZU A, TANAKA M, KUSANO R, CHEN X. Probing out-of- plane anisotropic plasticity using spherical indentation: A numerical approach [J]. Computational Materials Science, 2013, 79: 336-344.

[2] YONEZU A, YONEDA K, HIRAKATA H, SAKIHARA M, MINOSHIMA K. A simple method to evaluate anisotropic plastic properties based on dimensionless function of single spherical indentation—Application to SiC whisker-reinforced aluminum alloy [J]. Materials Science and Engineering A, 2010, 527(29): 7646-7657.

[3] ZHANG H, SCHUSTER B E, WEI Q, RAMESH K T. The design of accurate micro-compression experiments [J]. Scripta Materialia, 2006, 54(2): 181-186.

[4] WANG M, WU J, ZHAN X, GUO R, HUI Y, FAN H. On the determination of the anisotropic plasticity of metal materials by using instrumented indentation [J]. Materials & Design, 2016, 111: 98-107.

[5] OLIVER W C, PHARR G M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments [J]. Journal of Materials Research, 1992, 7(6): 1564-1583.

[6] DAO M, CHOLLACOOP N V, VANVLIET K J, VENKATESH T A, SURESH S. Computational modeling of the forward and reverse problems in instrumented sharp indentation [J]. Acta Materialia, 2001, 49(19): 3899-3918.

[7] MOUSSA C, HERNOT X, BARTIER O, DELATTRE G, MAUVOISIN G. Evaluation of the tensile properties of a material through spherical indentation: Definition of an average representative strain and a confidence domain [J]. Journal of Materials Science, 2014, 49(2): 592-603.

[8] ROY T K. Assessing hardness and fracture toughness in sintered zinc oxide ceramics through indentation technique [J]. Materials Science and Engineering A, 2015, 640: 267-274.

[9] WANG X, WANG C, ATKINSON A. Interface fracture toughness in thermal barrier coatings by cross-sectional indentation [J]. Acta Materialia, 2012, 60(17): 6152-6163.

[10] PETRYK H, STUPKIEWICZ S, KUCHARSKI S. On direct estimation of hardening exponent in crystal plasticity from the spherical indentation test [J]. International Journal of Solids and Structures, 2017, 112: 209-221.

[11] TABOR D. The hardness of metals [M]. London: Oxford University Press, 1951.

[12] MOUSSA C, HERNOTX, BARTIER O, DELATTRE G, MAUVOISIN G. Identification of the hardening law of materials with spherical indentation using the average representative strain for several penetration depths [J]. Materials Science and Engineering A, 2014, 606: 409-416.

[13] YONEDA K, YONEZU A, HIRAKATA H, MINOSHIMA K. Estimation of anisotropic plastic properties of engineering steels from spherical impressions [J]. International Journal of Applied Mechanics, 2010, 2(2): 355-379.

[14] BOCCIARELLI M, BOLZON G, MAIER G. Parameter identification in anisotropic elastoplasticity by indentation and imprint mapping [J]. Mechanics of Materials, 2005, 37(8): 855-868.

[15] YONEZU A, KUWAHARA Y, YONEDA K, HIRAKATA H, MINOSHIMA K. Estimation of the anisotropic plastic property using single spherical indentation—An FEM study [J]. Computational Materials Science, 2009, 47(2): 611-619.

[16] VLASSAK J J, NIX W D. Measuring the elastic properties of anisotropic materials by means of indentation experiments [J]. Journal of the Mechanics and Physics of Solids, 1994, 42(8): 1223-1245.

[17] NAKAMURA T, GU Y. Identification of elastic–plastic anisotropic parameters using instrumented indentation and inverse analysis [J]. Mechanics of Materials, 2007, 39(4): 340-356.

[18] PATEL D K, KALIDINDI S R. Correlation of spherical nanoindentation stress-strain curves to simple compression stress-strain curves for elastic-plastic isotropic materials using finite element models [J]. Acta Materialia, 2016, 112: 295-302.

[19] DONOHUE B R, AMBRUS A, KALIDINDI S R. Critical evaluation of the indentation data analyses methods for the extraction of isotropic uniaxial mechanical properties using finite element models [J]. Acta Materialia, 2012, 60: 3943-3952.

[20] LEE H, LEE J H, PHARR M. A numerical approach to spherical indentation techniques for material property evaluation [J]. Journal of the Mechanics and Physics of Solids, 2005, 53: 2037-2069.

[21] KIND N, BERTHEL B, FOUVRY S, POUPON C, JAUBERT O. Plasma-sprayed coatings: Identification of plastic properties using macro-indentation and an inverse Levenberg–Marquardt method [J]. Mechanics of Materials, 2016, 98: 22-35.

[22] WANG M, WU J, HUI Y, ZHANG Z, ZHAN X, GUO R. Identification of elastic-plastic properties of metal materials by using the residual imprint of spherical indentation [J]. Materials Science and Engineering A, 2017, 679: 143-154.

[23] HELWANY S. Applied soil mechanics with ABAQUS applications [M]. New York: John Wiley & Sons, 2007.

[24] HILL R. A theory of the yielding and plastic flow of anisotropic metals [J]. Proceedings of the Royal Society of London, 1948, 193: 281-297.

[25] DIETER G E. Mechanical metallurgy [M]. New York: McGraw-Hill, 1961.

[26] LUBLINER J, MORAN B. Plasticity theory [J]. Journal of Applied Mechanics, 1990, 59(1): 245-246.

[27] HIBBIT K. Abaqus/standard users manual [M]. Providence: Abaqus Inc, 1995.

[28] SCHMALING B, HARTMAIER A. Determination of plastic material properties by analysis of residual imprint geometry of indentation [J]. Journal of Materials Research, 2012, 27(16): 2167-2177.

[29] BOWDEN F P, TABOR D, PALMER F. The friction and lubrication of solids [M]. London: Clarendon Press, 1964.

[30] BUCAILLE J L, STAUSS S, FELDER E, MICHLER J. Determination of plastic properties of metals by instrumented indentation using different sharp indenters [J]. Acta Materialia, 2003, 51(6): 1663-1678.

[31] PHADIKAR J K, BOGETTI T A, KARLSSON A M. On the uniqueness and sensitivity of indentation testing of isotropic materials [J]. International Journal of Solids and Structures, 2013, 50(20): 3242-3253.

[32] ZHAO M, OGASAWARA N, CHIBA N, CHEN X. A new approach to measure the elastic–plastic properties of bulk materials using spherical indentation [J]. Acta Materialia, 2006, 54(1): 23-32.

[33] HERNOT X, MOUSSA C, BARTIER O. Study of the concept of representative strain and constraint factor introduced by Vickers indentation [J]. Mechanics of Materials, 2014, 68: 1-14.

[34] FLECK N A. Spherical indentation of elastic-plastic solids [J]. Proceedings of Mathematical Physical & Engineering Sciences, 1999, 455: 2707-2728.

[35] FISCHER-CRIPPS A C, JOHNSON K L. Introduction to contact mechanics: Mechanical engineering series [J]. Applied Mechanics Reviews, 2002, 55(3): B51.

[36] NI W, CHENG Y T, CHENG C M, GRUMMON D S. An energy- based method for analyzing instrumented spherical indentation experiments [J]. Journal of Materials Research, 2004, 19(1): 149-157.

[37] BOWDEN F P, TABOR D, PALMER F. The friction and lubrication of solids [M]. London: Clarendon Press, 1954.

[38] RICHMOND O, MORRISON H L, DEVENPECK M L. Sphere indentation with application to the Brinell hardness test [J]. International Journal of Mechanical Sciences, 1974, 16(1): 75-82.

[39] GEORGE R A, DINDA S, KASPER A S. Estimating yield strength from hardness data [J]. Metal Progress, 1976, 109(5): 30-33.

[40] KIM K H, KIM Y C, JEON E C, KWON D. Evaluation of indentation tensile properties of Ti alloys by considering plastic constraint effect [J]. Materials Science and Engineering A, 2011, 528(15): 5259-5263.

[41] LEE H, LEE J H, PHARR G M. A numerical approach to spherical indentation techniques for material property evaluation [J]. Journal of the Mechanics and Physics of Solids, 2005, 53(9): 2037-2069.

惠 钰,吴建军,王明智,展学鹏,樊 赫

西北工业大学 机电学院,西安 710072

摘 要:针对各向异性材料,讨论单一方向的应变硬化指数对复杂应力问题求解的局限性,提出了一种基于等效能量法计算各向异性材料等效应变硬化指数的新方法。首先,设置一系列有限元仿真实验,得出残余压痕参数与等效应变硬化指数的无量纲函数关系式;其次,使用此无量纲函数建立等效应变硬化指数与残余压痕的数学表达式;最后,通过对比数值试验结果验证该方法的有效性。另外,为了确定各向异性材料的屈服强度,对其Meyer关系进行扩展。通过数值实例及对TC1M钛合金的实际应用验证了该新方法的有效性和可靠性。

关键词:等效应变硬化指数;各向异性材料;球形压痕;残余压痕

(Edited by Wei-ping CHEN)

Foundation item: Project (51675431) supported by the National Natural Science Foundation of China

Corresponding author: Jian-jun WU; Tel: +86-29-88493101; E-mail: wujj@nwpu.edu.cn

DOI: 10.1016/S1003-6326(18)64917-9