文章编号: 1004-0609(2006)09-1527-07

双级固溶处理对7A55铝合金组织与力学性能的影响

张新明, 黄振宝, 刘胜胆, 刘文辉, 张 翀, 杜予晅

(中南大学 材料科学与工程学院, 长沙 410083)

摘 要: 采用光学显微镜、 透射电子衍射和扫描电子衍射显微分析技术, 结合力学性能检测和电导率测定的方法, 研究双级固溶温度和时间对7A55铝合金板材力学性能的影响。 结果表明: 最佳双级固溶制度为450℃, 90min+485℃, 40min。 采用该固溶制度经120℃, 24h时效后, 板材的拉伸力学性能达到σb=648.4MPa, σ0.2=629.6MPa及δ=11.9%。 第一级固溶制度是影响板材力学性能的主要因素, 最佳固溶温度为450℃。 在450℃进行第一级固溶后, 样品发生了较强的回复, 由于降低了再结晶驱动力, 第二级高温固溶在获得较高的合金元素过饱和度的同时, 仅发生较少的再结晶, 从而在随后的时效过程中产生更高的析出强化效应。

关键词: 7A55铝合金; 再结晶; 回复; 双级固溶; 力学性能 中图分类号: TG146

文献标识码: A

Effects of two-stage solution on microstructures and mechanical properties of 7A55 aluminum alloy

ZHANG Xin-ming, HUANG Zhen-bao, LIU Sheng-dan,

LIU Wen-hui, ZHANG Chong, DU Yu-xuan

(School of Materials Science and Engineering, Central South University,

Changsha 410083, China)

Abstract: The effects of temperature and time of two-stage solution on mechanical properties of 7A55 aluminium alloy sheet were investigated by optical microscopy, TEM and SEM analyses and tensile testing and electrical conductivity test. The optimal two-stage solution treatment is 450℃, 90min+485℃, 40min. The mechanical properties σb, σ0.2 and δ reach 648.4MPa, 629.6MPa and 11.9%, respectively, after aging at 120℃ for 24h. The results show that the first stage solution is crucial to the mechanical properties, and the optimal temperature is 450℃. The extensive recovery occurs after the first stage solution at 450℃, which reduces the driving force of recrystallization. Consequently, higher alloying elements supersaturation in matrix is obtained at the second stage high temperature solution and only little recrystallization happens. As a result, a better precipitation strengthening effect in subsequent aging is attained.

Key words: 7A55 aluminum alloy; recrystallization; recovery; two-stage solution; mechanical properties

7A55铝合金具有超高强和高硬等特点, 是新一代优质结构铝合金材料[1]。 固溶是该系合金热处理过程中的关键环节之一, 固溶处理中合金组织的变化、 再结晶和第二相溶解程度将对后续热处理过程产生显著的影响, 从而影响产品的最终性能。 传统的铸锭均匀化温度和变形组织固溶温度均低于非平衡低熔共晶点, 粗大化合物相很难溶解彻底[2-4]。 要使非平衡结晶的粗大化合物相充分溶解, 在不产生过烧的情况下, 应尽可能升高固溶温度, 延长固[CM(22]溶时间。 但随着固溶温度的升高及固溶时间的延[CM)] 长, 又会导致再结晶增多, 使晶粒长大, 从而导致合金的强度降低[5-6]。 因此合金只有在再结晶程度尽量少的前提下, 第二相颗粒充分溶解, 固溶处理才会达到最佳效果[7-8]。 高温短时分级固溶处理可以使再结晶发生程度减小[9], 但由于固溶时间过短, 因而不易于工业应用。 本文作者针对7A55铝合金热轧板, 研究了低温加高温的双级固溶处理对该合金的力学性能及显微组织的影响, 为实际生产制定合理的工艺参数提供依据。

1 实验

7A55铝合金经750~770℃熔炼后, 铜模浇铸。 铸锭名义成分为Al-8.4Zn-2.2Mg-2.4Cu-0.15Zr(质量分数, %)。 铸锭在箱式电阻炉中经460℃, 48h均匀化处理后进行热轧, 热轧温度为350~440℃, 轧制总的变形量为85%, 其组织为典型的长条状组织。 为研究双级固溶处理温度和时间对合金性能的影响, 采用正交设计法, 实验表选定L9(34), 选择一级固溶温度(A)及固溶保温时间(B), 二级固溶温度(C)及固溶保温时间(D)水平参数[10]来研究固溶温度、 时间因素与水平间的搭配关系(表1)。 固溶所用的炉子是箱式电阻炉, 炉温波动在±2℃。 淬火参数为淬火转移时间小于2s, 淬火水温低于25℃, 停放时间少于15min。 淬火后用7501涡流电导仪测试样品的电导率, 随后立即进行T6人工时效(即120℃保温24h)。 采用光学显微镜(OM)观察不同双级固溶时效后合金的金相组织, 观察前用Graff Sargent浸蚀剂(0.5%HF, 15.5%HNO3, 84%H2O(体积分数), 3g CrO3)浸蚀。 通过KYKY 2800扫描电镜对第二相大小、形貌、 分布以及断口进行观察与分析, 并用透射电镜(TEM)观察其组织。 在CSS-44100电子万能实验机上进行时效后样品的拉伸力学性能测试。 使用的拉伸试样按国标GB/6497—14规定进行加工。

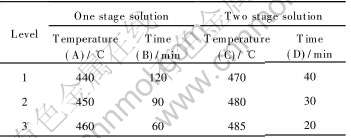

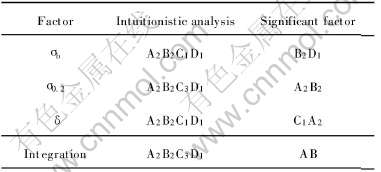

表1 双级固溶的正交设计L9(34)

Table 1 Scheme of two-stage solution heat treatment L9(34)

2 结果及分析

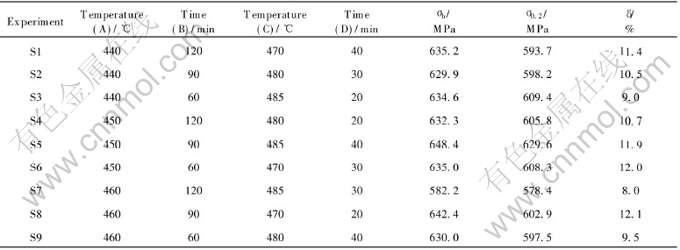

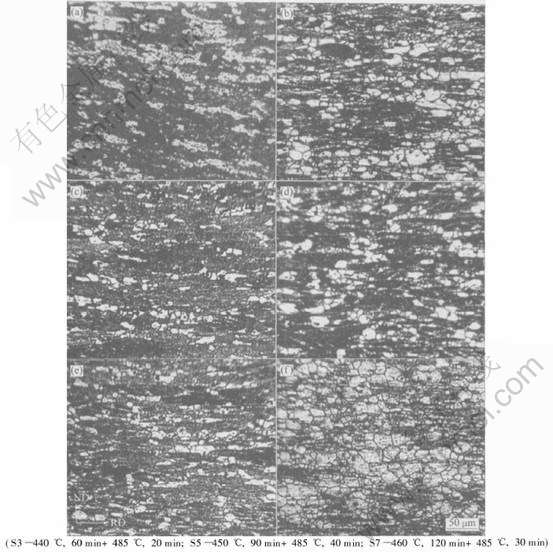

表2和3所列分别为合金经不同双级固溶处理和时效后的力学性能和各因素对性能的影响情况。 图1所示为不同固溶制度后经T6(120℃, 24h)时效的金相组织。 其中图1(a)、 (c)和(e)所示分别为440℃, 60min; 450℃, 60min和460℃, 60min单级固溶后T6时效后的金相组织。

由表2可看出, 经不同的双级固溶工艺后, 试样的性能差异说明优化固溶处理可以改善合金的力学性能。 7A55铝合金在进行双级固溶处理时, 第一级固溶温度为450℃的各项力学性能均好于440和460℃的。 其中450℃, 90min+485℃, 40min双级固溶经120℃, 24h时效的试样的拉伸性能最好, 其σb 、 σ0.2和δ分别达到648.4MPa、 629.6MPa和11.9%。 从正交实验数据处理的结果(表3)

表2 双级固溶对合金力学性能的影响

Table 2 Influence of two-stage solution on mechanical properties of 7A55 alloy

图1 440℃, 60min; 450℃, 60min; 460℃, 60min和S3, S5, S7固溶后经T6(120℃, 24h)时效的金相组织

Fig.1 Optical micrographs of specimens aged at 120℃ for 24h after solution treatment at

440℃, 60min(a); S3(b); 450℃, 60min(c); S5(d); 460℃, 60min(e) and S7(f)

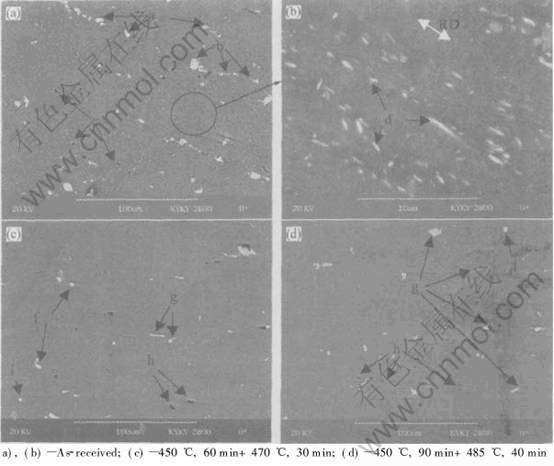

图2 固溶处理前后7A55合金的SEM像

Fig.2 SEM images of 7A55 alloy after and before solution treatment

表3 各因素对合金性能的影响

Table 3 Effect of factors on

mechanical properties of studied alloy

可知, 因素AB(一级固溶温度和时间)对合金性能的影响非常显著, 且综合直观分析影响最佳的固溶处理制度为450℃, 90min+485℃, 40min。

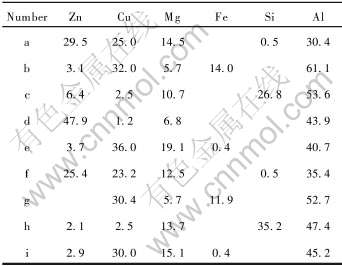

固溶处理前后7A55合金的SEM像和相应能谱分析结果分别如图2和表4所示。 SEM观察及能谱分析结果表明: 在图2(a)和(b)(固溶前的)中存在两种尺寸的相, 粗大的为一些初生相沿着轧向分布, 这些相主要为AlZnMgCu相及含Fe、 Si的杂质相; 一些较细小的为轧制过程和冷却过程析出的AlZnMgCu相。 7×××铝合金固溶处理的目的是让Zn、 Mg和Cu溶质原子尽量溶解于铝基体中, 以提高固溶体的过饱和程度, 使时效过程中能够产生足够高的析出强化效应。 从图2(c)(450℃, 60min+470℃, 30min)中发现, 固溶后的初生相已绝大部分固溶进基体中, 但仍有少量的残留相AlZnMgCu相及难溶的含杂质Fe和Si的杂质相。 而在图2(d)(450℃, 90min+485℃, 40min)中只发现了难溶的含杂质Fe、 Si的杂质相, 几乎没有观察到AlZnMgCu相。 电导率可以判断固溶处理时铝合金固溶体的过饱和程度[11]。

表4 第二相EDX分析结果

Table 4 EDX analysis of second phase

particles (mass fraction, %)

合金进行双级固溶处理时, 第一级低温固溶处理发生的过程主要是回复和再结晶的过程。 回复与再结晶都是由变形储能来驱动的, 它们是一个竞争的过程。 一旦发生再结晶, 就不可能产生进一步的回复, 回复的程度又取决于再结晶发生的难易。 相反, 由于回复消耗了变形储能, 降低了再结晶的驱动力[12]。 第一级固溶时发生大量回复, 第二级固溶处理时再结晶程度小。 同时, 在第一级低温固溶时, 低熔点共晶组织先行溶解, 使得合金中剩余相的共晶温度提高。 这样, 第二级温度就可以突破单级固溶温度的上限, 进行第二级高温固溶处理, 在不引起过烧的情况下可使合金组织中粗大共晶相的溶解速度和固溶程度大幅度增加, 达到基本消除粗大的第二相的目的[13-15]。 因此第一级固溶制度对合金的性能起关键性的作用。 在固溶处理过程中, 变形组织将会发生回复和再结晶。 由于时效温度很低, 不可能再进一步发生再结晶, 因而晶粒组织将会保留至最终的产品[16]。 再结晶晶粒中几乎不含有亚晶组织, 从而存在统一亮度, 因此在图1中再结晶区域很容易区分, 且再结晶区域呈白色; 未再结晶区域含大量亚结构, 腐蚀后呈黑色 [17]。 由图1(a)、 (c)和(e)可看出, 经450℃, 60min固溶后, 回复组织最多, 再结晶程度较小, 因此当第一级固溶温度为450℃时, 回复过程消耗了大部分变形储能, 从而大大降低了再结晶驱动力, 为第二级高温固溶处理起了很好的控制再结晶作用, 结果如图1(d)所示。 图1(d)(S5)中的再结晶程度是最小的, 且含最多的回复组织。

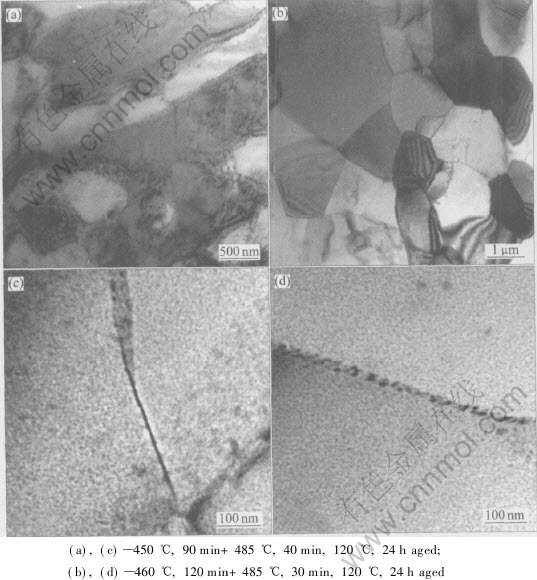

图3所示为450℃, 90min+485℃, 40min后经120℃, 24h时效和460℃, 120min+485℃, 30min后经120℃, 24h时效热处理后样品的TEM像。 由图3可看出, S5固溶时效后含有多边形回复组织(图3(a)); S7固溶时效后含有部分再结晶组织(图3(b)), 由于回复组织的能量高于再结晶组织的, 因此回复组织较再结晶组织更易析出, 典型结果如图3(c)和(d)所示。 图3(c)中S5固溶时效后比图3(d)中S7固溶时效后的晶界较完整且呈连续状, 析出相多而细密, 这就达到很好的时效强化效果。 由此可见, 当第一级固溶温度为450℃时, 回复组织最多、 亚晶尺寸小, 对抑制第二级固溶时的再结晶起了很好的作用。 结合表2的力学性能结果, 可知第一级最佳固溶温度为450℃。

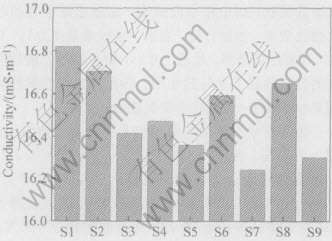

图4所示为不同固溶制度下合金的电导率。 由图4可看出, 经S5(450℃, 90min+485℃, 40min)处理后合金的电导率明显小于经S6(450℃, 60min+470℃, 30min)处理后合金的。 说明经450℃, 90min+485℃, 40min时效比经450℃, 60min+470℃, 30min时效固溶更充分。

图3 不同热处理后的7A55合金TEM像

Fig.3 TEM images of samples after different heat treatments

图5所示为经450℃, 60min+470℃, 30min和450℃, 90min+485℃, 40min双级固溶后再经120℃, 24h时效试样的拉伸断口形貌。 由图5可看出, 7A55合金断裂是第二相引起的晶内断裂与晶界断裂的混合型断裂。 图5(b)中经450℃, 90min+485℃, 40min时效的韧窝多于图5(a)中经450℃, 60min+470℃, 30min时效的, 且图5(b)中的韧窝更细小均匀, 说明经450℃, 90min+485℃, 40min时效固溶较充分, 从另一角度验证了图2和4所得出的结果。

图4 不同固溶制度下合金的电导率

Fig.4 Conductivity of studied alloy after different solution treatments

图5 不同固溶处理制度后在120℃时效24h后的

7A55合金断口形貌

Fig.5 Tensile fractographs of studied 7A55 alloy aged at 120℃ for 24h after different solution treatments

综合以上分析可得: 本研究中的最佳双级固溶制度为450℃, 90min+485℃, 40min, 能在较小的再结晶程度下, 产生较高的溶质原子过饱和度, 使时效过程能够获得足够高的析出强化效应。

3结论

1) 在7A55铝合金板材双级固溶中, 第一级固溶制度是影响板材力学性能的主要因素。 在450℃进行第一级固溶后的样品发生了比较强的回复, 由于降低了再结晶驱动力, 第二级高温固溶在获得了很高的合金元素过饱和度的同时, 仅发生较少的再结晶, 从而在随后的时效过程中产生更高的析出强化效应。

2) 第一级固溶温度在450℃时发生较大的回复, 再结晶程度较小, 因此第一级最佳固溶温度为450℃。

3) 7A55铝合金板材的最佳双级固溶制度为450℃, 90min+485℃, 40min。 采用该双级固溶及120℃, 24h时效后, 其室温拉伸力学性能达到了σb=648.4MPa, σ0.2=629.6MPa和δ=11.9%。

REFERENCES

[1]曾渝, 尹志民, 潘青林, 等. 超高强铝合金的研究现状及发展趋势[J]. 中南工业大学学报, 2002, 33(6): 592-596.

ZENG Yu, YIN Zhi-min, PAN Qing-lin, et al. Present research and developing trends of ultra high strength aluminum alloys[J]. Journal of Central South University(Natural Science), 2002, 33(6): 592-596.

[2]李红英, 郑子樵. 高性能航空铝合金结构材料的动态研究[J]. 湖南有色金属, 2001(7): 34-38.

LI Hong-yin, ZHEN Zi-qiao. Research on developing high properties aluminum alloy[J]. Hunan Nonferrous Metals, 2001(7): 34-38.

[3]曾苏民. 影响铝合金固溶保温时间的多因素相关规律[J]. 中国有色金属学报, 1999, 9(1): 79-86.

ZENG Su-min. Disciplines of multiple factors affecting solution treating of aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 1999, 9(1): 79-86.

[4]Hahn G T, Rosenfield A R. Metallurgical factors affecting fracture toughness of aluminum alloys[J]. Metall Trans A, 1975, A6: 653-658.

[5]Deshpasde N Q, Gorhale A M, Denzer D K, et al. Relationship between fracture toughness, fracture path and microstructure of 7050 aluminum alloy (Part Ⅰ): Quantitative characterization[J]. Metall Trans A, 1998, 29(4): 1191-1201.

[6]Morere B, Ehrstrom J C, Gregson P J, et al. Microstructural effects on fracture toughness in AA7010 plate[J]. Metall Trans A, 2000, 21: 2503-2509.

[7]王洪斌, 刘慧敏. 热处理对喷射成形超高强Al-Zn-Mg-Cu系铝合金的影响[J]. 中国有色金属学报, 2004, 14(3): 398-404.

WANG Hong-bin, LIU Hui-min. Effects of heat treatment on microstructure and mechanical properties of ultra-high strength spray deposited Al-Zn-Mg-Cu aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(3): 398-404.

[8]王洪斌, 黄进峰. 喷射成形Al-Zn-Mg-Cu合金的显微组织演变[J]. 金属学报, 2004, 40(8): 827-832.

WANG Hong-bin, HUANG Jin-feng. Microstructure evolution of ultrahigh strength spray deposited Al-Zn-Mg-Cu alloy[J]. Acta Metallurgica Sinica, 2004, 40(8): 827-832.

[9]宁爱林, 刘志义, 郑青春, 等. 分级固溶对7A04铝合金组织与性能的影响[J]. 中国有色金属学报, 2004, 14(7): 1211-1216.

NING Ai-lin, LIU Zhi-yi, ZHENG Qing-chun, et al. Effects of progressive solution treatment on microstructure and mechanical properties of 7A04 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(7): 1211-1216.

[10]郑艳玲, 刘静, 李子微. 7049A铝合金锻件T6状态热处理工艺制度研究[J]. 轻合金加工技术, 2003, 31(1): 25-27.

ZHENG Yan-ling, LIU Jing, LI Zi-wei. Study about T6 temper heat treatment institution of 7049A aluminium alloy forgings[J]. Light Alloy Fabrication Technology, 2003, 31(1): 25-27.

[11]宁爱林, 蒋寿生, 彭北山. 铝合金的力学性能及其电导率[J]. 轻金属, 2005(6): 34-36.

NING Ai- lin, JIANG Shou-sheng, PENG Bei-shan. Mechanical properties and electrical conductivity of aluminum alloys[J]. Light Metals, 2005(6): 34-36.

[12]李松瑞, 周善初. 金属热处理[M]. 长沙: 中南大学出版社, 2003: 30-46.

LI Song-rui, ZHOU Shan-chu. Metal Heat Treatment[M]. Changsha: Central South University Press, 2003: 30-46.

[13]Zwickan E C, Freiberg U T. Possibilities for the calculation for the heat treatment diagrams for industrial AlZnMg(Cu) alloys[J]. Aluminium, 1999, 75: 90-96.

[14]刘卫红, 陈康华. 强化固溶对7075铝合金组织与性能的影响[J]. 金属热处理, 2000(9): 16-20.

LIU Wei-hong, CHEN Kang-hua.The effect of promotiveIy-solutionizing treatment on the mechanical properties and structure of 7075 aluminum alloy[J]. Heat Treatment of Metals, 2000(9): 16-20.

[15]Ludtka G M, Laughlin D E. The influence of microstructure and strength on the fracture mode and toughness of 7××× series aluminum alloys[J]. Metall Trans A, 1982, 13(3): 411-414.

[16]Robson J D. Predicting recrystallised volume fraction in aluminum alloy 7050 hot rolled plate[J]. Materials Science and Technology, 2002, 18(6): 607-619.

[17]Robson J D. Microstructural evolution in aluminum alloy 7050 during processing[J].Mater Sci Eng A, 2004, 382: 112-121.

基金项目: 国家重点基础研究发展规划资助项目(2005CB623700)

收稿日期: 2005-11-29; 修订日期: 2006-03-21

通讯作者: 张新明, 教授, 博士; 电话: 0731-8830265; E-mail: xmzhang@mail.csu.edu.cn

(编辑李艳红)