DOI: 10.11817/j.issn.1672-7207.2017.04.002

二十辊轧机轧制极薄带的板形控制

员征文1, 2,任忠凯1,肖宏1,余超1

(1. 燕山大学 国家冷轧板带装备及工艺工程技术研究中心,河北 秦皇岛,066004;

2. 徐工集团 江苏徐州工程机械研究院,江苏 徐州,221004)

摘要:针对二十辊轧机辊间压扁计算误差较大的问题,将轧辊视为有限长度的半无限体,基于边界积分方程法建立1个精确的辊间压扁模型;基于该辊间压扁模型、耦合轧辊弯曲模型,轧件塑性变形模型、建立更精确的二十辊轧机板形控制耦合模型。基于该二十辊轧机板形控制耦合模型,针对极薄带轧制工况,分析二十辊轧机第一中间辊锥度、轴向移动、不同压下量等因素对带钢出口厚度、轧制力分布、辊间压力分布等的影响规律,并通过实验方法验证该理论模型的正确性。研究结果表明:第一中间辊的锥度和轴向移动对板形控制具有较大的影响,而且辊缝形状的微小改变会引起板形产生较大变化。

关键词:二十辊轧机;辊间压扁;有限长半无限体;边界积分方程;极薄带轧制

中图分类号:TG335.5 文献标志码:A 文章编号:1672-7207(2017)04-0860-07

Plate shape control of ultra thin strip rolling for 20-high mill

YUAN Zhengwen1, 2, REN Zhongkai1, XIAO Hong1, YU Chao1

(1. National Engineering Research Center of Cold Strip Rolling Equipment and Technology,

Yanshan University, Qinhuangdao 066004, China;

2. Jiangsu Xuzhou Construction Machinery Research Institute, XCMG, Xuzhou 221004, China)

Abstract: To improve the accuracy of roll flattening calculation for 20-high mill, a new and more accurate roll flattening model was proposed. In this model, the roll barrel was considered as a finite length semi-infinite body. Based on the boundary integral equation method, an accurate roll flattening model was established. Based on the new roll flattening model, coupled with roll bending model, strip plastic deformation model, a new and more accurate plate control model for 20-high mill was established. Based on the new model, for the particularly thin strip rolling process, the effects of taper angle and axial shift of the first intermediate roll were analyzed, and the accuracy of the new model was certified by rolling test. The results show that the taper angle and axial shift of the first intermediate roll have greater influence on the shape control, and small changes in the shape of the roll gap will cause great changes of flatness.

Key words: 20-high mill; roll flattening; finite length semi-infinite body; boundary integral equation method; ultra thin strip rolling

目前,计算辊间压扁的解析模型主要有费普尔公式[1]和半无限体模型[2]。国内外学者利用这2种模型进行了大量的轧机板形控制方面的分析研究工作。YU等[3-4]利用费普尔公式作为辊间压扁模型,建立了二十辊轧机的辊系变形矩阵,并耦合轧件变形,分析了第一中间辊窜辊量、辊形、工作辊和第二中间被动辊凸度、张力、压下量等因素对带钢边部减薄的影响,并用有限元模型与该解析模型进行了对比分析。CHO 等[5]和SHIN等[6]分别基于有限元模拟结果和接触元法推导了森吉米尔二十辊轧机板形控制模型。HARA等[7]利用费普尔公式计算辊间压扁,建立了二十辊轧机辊系变形模型,分析了第一中间辊窜辊以及轧辊凸度对板形的影响。闫冬[8]基于费普尔公式计算辊间压扁,利用条元变分法分析轧制变形区金属的横向流动,最终利用建立的模型对第一中间辊横移和锥度、工作辊凸度等调控效果进行了仿真。然而,费普尔公式是假设轧辊的弹性压扁为平面应变问题,忽略了轴向应变的影响,所以,在计算辊间压扁时会存在一定的误差,尤其是在轧辊端部误差会更大。半无限体模型是基于弹性力学中半无限体边界受到法向集中力作用问题的布希涅斯克解,该模型假设轧辊为无限长度的半无限体,所以,也会在所计算轧辊的边部区域造成很大误差。针对以上问题,有学者试图通过修正半无限体模型,提高辊间压扁变形的计算精度[9-11]。王崇涛等[12-13]结合现场实际数据,运用有限元软件分析了20辊森吉米尔轧机的板形变化规律。这些工作大部分基于有限元的模拟结果修正半无限体理论模型,得到了更符合实际的辊间压扁模型,具有一定的实际意义,但缺乏理论依据,计算精度不高,适用范围受到限制。为了克服费普尔公式和半无限体模型的误差,本文作者基于边界积分方程法,提出了有限长半无限体压扁理论模型。然后建立二十辊轧机辊系变形影响函数模型,最后耦合带钢塑性变形模型,预测带钢出口板形。

1 有限长半无限体辊间压扁模型的建立

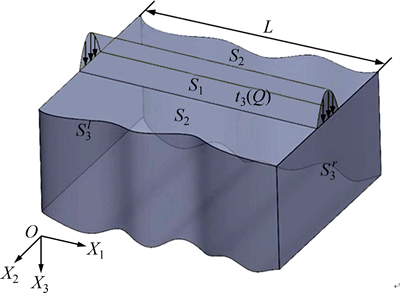

求解辊间压扁,首先要建立1个有限长的半无限体模型,然后求其在分布力作用下的位移场。受分布载荷作用下的有限长半导体模型如图1所示,欲求的是1个长度为L的半无限体在分布力t3(Q)作用下的表面位移场。该半无限体沿X3轴正向和X2轴无限大,沿X1轴长度为L。

针对该有限长半无限体模型,XIAO等[14-16]进行了推导,在辊系变形计算中,由于两圆柱体接触的特性,分布力t3(Q)沿X2方向假设为二次分布,但沿X1方向分布较为复杂,不易求解,所以,一般将其离散化。将分布力沿X1轴分成n个相等的单元,用Tj(X2) (j=1,2,…,n)表示。在每个单元上Tj(X2)沿X1轴均匀分布,沿X2轴二次分布[17]。离散后所求的是Pi点处的位移矢量u3(Pi)(i=1,2,…)。

图1 受分布载荷作用下的有限长半无限体模型

Fig. 1 Finite length semi-infinite body under distributed force

(1)

(1)

式中:i和j分别取1,2和3(1,2和3分别代表X1,X2和X3方向);P和Q分别为场点和源点;uj(Q)和tj(Q)分别为表面上的位移和面力矢量; 和

和 分别为在无限大空间或者半无限空间作用单位载荷的位移和面力基本解,它们表示在P点i方向作用单位载荷在Q点j方向产生的位移和面力;

分别为在无限大空间或者半无限空间作用单位载荷的位移和面力基本解,它们表示在P点i方向作用单位载荷在Q点j方向产生的位移和面力; 表示在

表示在 和

和 上的点沿X3方向的位移衰减函数,

上的点沿X3方向的位移衰减函数, 表示在

表示在 和

和 上的点沿X1方向的位移衰减函数。位移衰减函数

上的点沿X1方向的位移衰减函数。位移衰减函数 和

和 表征轧辊边部位移点与轧辊侧面位移场之间的关系,可以基于有限元法模拟得到[14-15]。

表征轧辊边部位移点与轧辊侧面位移场之间的关系,可以基于有限元法模拟得到[14-15]。

式(1)中有 ,

, ,

, n+2个未知量,但是只有n个方程。故根据边界积分方程(1),需补充下式,其实质是利用边界积分方程求得P1和Pn这2点沿X1方向的位移:

n+2个未知量,但是只有n个方程。故根据边界积分方程(1),需补充下式,其实质是利用边界积分方程求得P1和Pn这2点沿X1方向的位移:

(2)

(2)

联立式(1)和(2)即可求解辊间压扁。通过式(1)可以发现,如果方程右侧只保留第一项 ,那么转化为半无限体模型。新压扁模型的实质是对原半无限体模型的一种修正模型,后面4个积分项其实质是对半无限体有限长度状态的修正。

,那么转化为半无限体模型。新压扁模型的实质是对原半无限体模型的一种修正模型,后面4个积分项其实质是对半无限体有限长度状态的修正。

将本文建立的压扁模型应用到轧辊压扁计算中,并分别与原半无限体模型、费普尔公式、有限元计算结果对比,从而验证了该压扁模型的正确性[14-16]。

2 二十辊轧机板形控制模型的建立

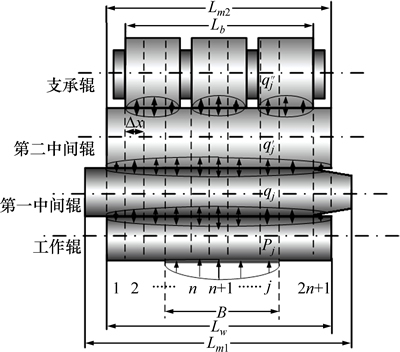

为了将上述辊间压扁模型应用到二十辊轧机辊系变形计算中,首先要建立二十辊轧机辊系变形解析模型。轧机辊系变形包括轧辊的挠曲变形,辊间压扁变形以及工作辊与带钢压扁变形。工作辊与带钢之间、工作辊与第一中间辊之间、第一中间辊与第二中间辊之间以及第二中间辊与支承辊之间的弹性压扁均采用有限长半无限体压扁模型。由于辊系受力的复杂性,求解轧机的辊系变形时需要将辊系沿轧辊轴线方向离散成若干个小单元,然后对每个单元单独分析。轧机辊系变形的离散化模型如图2所示。

图2 二十辊轧机辊系离散化模型

Fig. 2 Discrete model of roll deformation for 20-high mill

图2中:Pj为离散后j单元上的轧制力;qj, 和

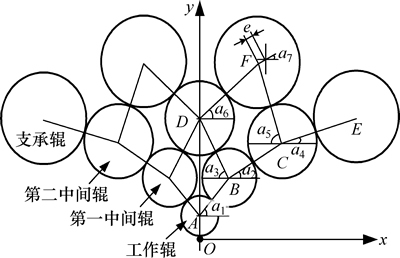

和 分别为离散后j单元上第一、二层和第三层辊间压力。计算支承辊、中间辊和工作辊挠度采用邵特提出的基于悬臂梁模型的影响函数法[17]。为了研究辊系变形,必须对其空间结构进行受力分析,并分别沿辊心连线方向建立力平衡、挠度、力矩平衡、位移协调方程。图3中:α1~α7分别为轧辊辊心连线与水平方向的夹角;e为偏心距。

分别为离散后j单元上第一、二层和第三层辊间压力。计算支承辊、中间辊和工作辊挠度采用邵特提出的基于悬臂梁模型的影响函数法[17]。为了研究辊系变形,必须对其空间结构进行受力分析,并分别沿辊心连线方向建立力平衡、挠度、力矩平衡、位移协调方程。图3中:α1~α7分别为轧辊辊心连线与水平方向的夹角;e为偏心距。

图3 二十辊轧机辊系布置示意图

Fig. 3 20-high mill rolls arrangement

下面以B辊A-B方向为例,分别列出力平衡方程、力矩平衡方程、挠度方程。B辊其他方向及其余轧辊的分析过程与B辊A-B方向分析过程类似。根据上述辊系布置几何关系,B辊A-B方向受力平衡关系式如下:

(3)

(3)

式中:q为辊间压力;下角标表示辊号。

B辊与其相邻的A辊辊心连线方向A-B的力矩平衡关系式如下:

(4)

(4)

根据辊系受力平衡关系,可以得到B辊任意点i处沿A-B方向的挠度方程为

(5)

(5)

式中: 为B轧辊左半部分的弯曲影响系数,轧机右侧的挠度方程与左侧的相类似,只是单元编号不同;

为B轧辊左半部分的弯曲影响系数,轧机右侧的挠度方程与左侧的相类似,只是单元编号不同; ,

, 和

和 分别表示B轧辊与A,C和D轧辊之间单元i处的辊间压力。

分别表示B轧辊与A,C和D轧辊之间单元i处的辊间压力。

根据辊系的空间几何布置,沿各辊心连线方向,建立相邻轧辊的变形协调关系。相邻两轧辊的协调方程如下:

(6)

(6)

式中:Ym(i)和Yn(i)分别为相邻轧辊m和n上i点的挠度;Zmn(mid)和Zmn(i)分别为两轧辊在中点和i点的压扁,在此模型中辊间压扁应用本文的有限长半无限体压扁模型;βmn为相邻轧辊m和n轧制中心线截面在发生变形后相对偏转的角度;x(i)为i点的轧辊坐标;△Dmn为相邻两轧辊的凸度差。

二十辊轧机计算工作辊出口辊缝时,需要考虑上下工作辊轴线的弯曲变形 和

和 和辊面相对于板带压扁变形

和辊面相对于板带压扁变形 ,上下轧辊凸度

,上下轧辊凸度 ,

, 等几何量的协调关系。工作辊i单元出口辊缝协调方程为

等几何量的协调关系。工作辊i单元出口辊缝协调方程为

(7)

(7)

3 计算和实验结果分析

为了分析带钢轧后的板形状况,需要同时考虑轧机的辊系变形和轧件的塑性变形。轧件的塑性变形采用LIAN[18]提出的变分法求解金属横向流动模型计算轧件的前后张力横向分布。根据最小能量原理,在轧制过程中,总变形功应该最小。这就转换成了1个以出口横向位移函数u(y)为未知量的最简变分问题,总变形功率表达式以F(y,u,u′)为基本函数,u(y)则需要使下述欧拉方程成立,即

(8)

(8)

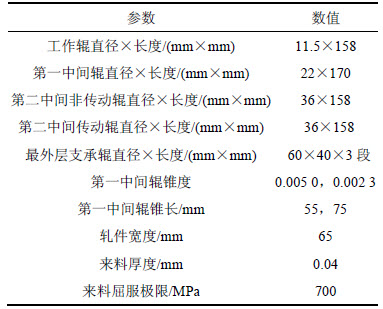

横向位移函数确定后,根据轧后带材相对长度差方程,得到考虑金属横向流动的前后张力公式[15]。得到前后张力分布值后,采用Hill公式计算轧制力横向分布。采用本文给出的模型,以实验室二十辊轧机为例分析实际轧制过程中的力能参数变化规律,计算条件如表1所示。通过实验结果验证该模型的准确性。由于二十辊轧机轧制极薄带的过程中张力横向分布及总的轧制力不易准确测量,所以,通过实验直接来验证该模型所计算的张力、轧制力的准确性比较困难。但是,张力的横向分布可以通过轧后带材的板形来宏观体现,所以,本文通过观察轧后带材宏观表现出的板形来验证该计算模型的准确性。

表1 二十辊轧机主要计算参数

Table 1 Primary calculating parameters of 20-high mill

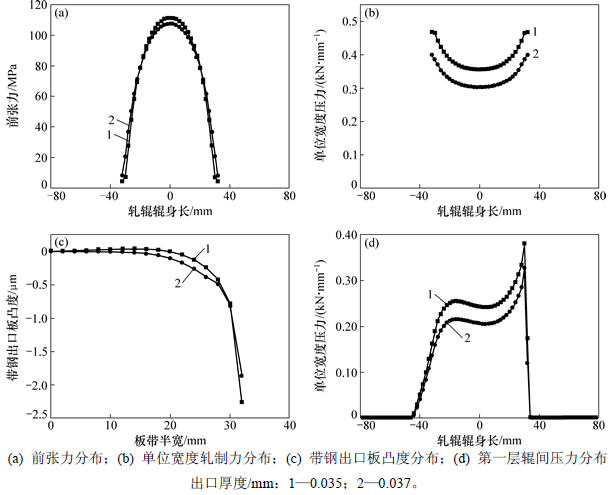

为了进行板形控制,通常第一中间辊一端加工成一定的锥度和锥长,并可轴向移动以适合不同宽度带钢轧制板形控制的需要,且上下辊系和第一中间辊轴向移动为反对称。图4所示是锥长为55 mm,锥度为0.005,前后张力分别为80 MPa和100 MPa时,得到出口厚度分别为0.037 mm和0.035 mm的计算结果。

由上述计算结果可知:当锥长为55 mm时,带钢边缘只有2.5 mm进入第一中间辊锥度段与工作辊的接触区,第一中间辊锥度段开始位置与工作辊的接触点出现较大的接触压力突变,说明此锥度较大,在轧制力的作用下锥度段大部分没有参与接触。同时,由于在带钢宽度范围的边缘附近工作辊与第一中间辊接触压力相对较大,这导致工作辊正向挠度增大,致使带钢边部压下量大于中部,容易出现边浪。如图4所示,板带板凸度、轧制力和前张力横向分布均表现出边浪特征,且出口厚度为0.035 mm时更加明显。因此,采用上述轧制条件轧制厚度小于0.035 mm的带材是非常困难的。

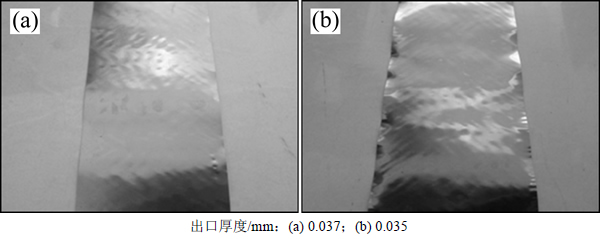

取与上述相同工况进行轧制实验,所得结果如图5所示。从图5可见:当出口厚度为0.037 mm时,带材表现出轻微的双边浪;当出口厚度进一步减小到0.035 mm时,带材表现出较为严重的双边浪。通过实验结果发现:轧后所表现出的板形情况与该模型张力计算结果基本吻合,从而证明了该模型可以较为准确地预测极薄带轧制过程中的板形。

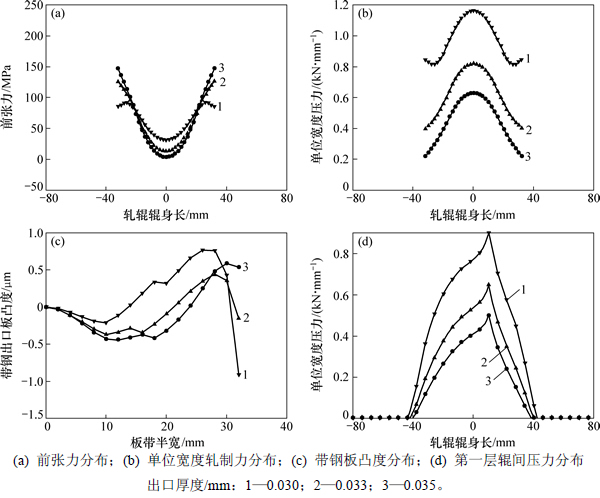

为了进一步分析锥度和第一中间辊移动对板形控制的影响,将第一中间辊的锥度改为0.002 3,并将锥度向带钢中心移动20 mm,其他计算条件同上,采用上述模型分别计算出口厚度为0.035,0.033和0.030 mm时轧制过程板形相关参数的变化,计算结果如图6所示。

图4 第一中间辊锥度0.005无横移的计算结果

Fig. 4 Calculation results with taper angle 0.005 and no shift of the 1st IMR

图5 第一中间辊锥度0.005无横移的实验结果

Fig. 5 Experimental results with taper angle 0.005 and no shift of the 1st IMR

与第一中间辊锥度0.005无轴向移动相比,带钢边缘已有较大的区域进入第一中间辊锥度段与工作辊的接触区,当出口厚度为0.035 mm时,第一中间辊锥度段大部分区域没有进入接触状态,意味着带钢边部部分区域的工作辊未与第一中间辊接触,处于悬空状态,这将导致工作辊正向挠度减小,出现明显的中浪特征,如图6所示。从图6可见:随着出口厚度的减小,轧制力不断增大,锥度段与工作辊的接触长度逐渐增加,导致带钢边缘附近工作辊与第一中间辊接触压力逐渐增大,工作辊正向挠度逐渐增大;随着压下量的增加,板形由中浪特征转变为边浪特征。

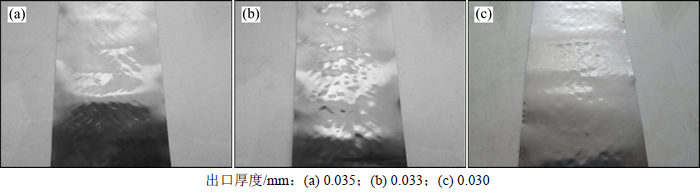

取与上述相同工况进行轧制实验,所得结果如图7所示。从图7可见:当出口厚度为0.035 mm时,带材表现出较严重的中浪;当出口厚度减小到0.033 mm时,带材中浪在逐渐减小;当出口厚度进一步减小到0.030 mm时,带材表现为轻微的中边浪。通过实验结果发现:轧后所表现出的板形情况与该模型张力计算结果基本吻合,进一步证明了该模型可以较准确地预测极薄带轧制过程中的板形。

图6 第一中间辊锥度0.002 3和横移20 mm的板形计算结果

Fig. 6 Calculation results with taper angle 0.002 3 and shift 20 mm of the 1st IMR

图7 第一中间辊锥度0.002 3横移20 mm的板形实验结果

Fig. 7 Experimental results with taper angle 0.002 3 and shift 20 mm of the 1st IMR

4 结论

1) 基于有限长度半无限体模型,建立二十辊轧机的板形分析模型,该分析模型具有较高的计算精度和计算效率,相比半无限体模型和费普尔公式更适宜计算多辊轧机辊间压扁变形。

2) 通常二十辊轧机AS-U-Roll(支承辊凸度分段调整)辊形调整要通过二中间辊、一中间辊传到工作辊上,导致有限的AS-U-Roll凸度调整量对工作辊形状影响较小,因此,不同锥度的第一中间辊及其横移作为20辊轧机板形控制的主要手段。

3) 轧制极薄带材时辊缝形状的微小改变会引起板形的较大变化,如压下量的微小改变引起板形由中浪变成边浪。因此,对于极薄带的板形控制,提高辊系变形模型的计算精度尤为重要。

参考文献:

[1] YOUNG W C, BUDYNAS R G. Roark’s Formulas for stress and strain[M]. New York: McGraw-Hill, 2002: 213-221.

[2] TOZAWA Y, UEDA M. Analysis to obtain the pressure and distribution from the contour of deformed roll[J]. Journal of the Japan Society for Technology of Plasticity, 1970, 108(11): 29-37.

[3] YU H L, LIU X H, LEE G T, et al. Numerical analysis of roll deflection for sendzimir mill[J]. Journal of Manufacturing Science and Engineering, 2008, 130(1): 0110161-0110167.

[4] YU H L, LIU X H, LEE G T. Contact element method with two relative coordinations and its application of prediction for strip profile for a sendzimir mill[J]. ISIJ International, 2007, 47(7): 996-1005.

[5] CHO J H, HWANG S M. A new model for the prediction of roll deformation in a 20-high sendzimir mill[J]. Journal of Manufacturing Science and Engineering Transactions of the ASME, 2014, 136(1): 204-226.

[6] SHIN J M, HAN S I, KIM J S. Development and experimental evaluation of strip shape prediction model for sendzimir rolling mills[J]. Journal of Iron and Steel Research, International, 2013, 20(12): 25-32.

[7] HARA K, YAMADA T, TAKAGI K. Shape controllability for quarter buckles of strip in 20-high sendzimir mills[J]. ISIJ International, 1991, 31(6): 607-613.

[8] 闫冬. 森吉米尔20辊轧机板形控制特性研究[D]. 秦皇岛: 燕山大学机械工程学院, 2011: 18-73.

YAN Dong. The study about shape control characteristics of sendzimir 20-high mill[D]. Qinhuangdao: Yanshan University. College of Mechanical Engineering, 2011: 18-73.

[9] 麻永林, 宫美娜, 邢淑清, 等. 304不锈钢带板形控制的有限元分析[J]. 钢铁, 2015, 50(2): 48-53.

MA Yonglin, GONG Meina, XING Shuqing, et al. FEM analysis of 304 stainless steel strip flatness control[J]. Iron and Steel, 2015, 50(2): 48-53.

[10] ZHOU Shunxin, FUNKE P, ZHONG Jue. Influence of roll geometry and strip width on flattening in flat rolling[J]. Steel Research, 1996, 67(5): 200-204.

[11] ZHOU Shunxin, FUNKE P, ZHONG Jue, et al. Modification of a classical Formula for determination of roll flattening in flat rolling[J]. Steel Research, 1996, 67(11): 491-494.

[12] 王崇涛, 方康玲. 森吉米尔轧机的板形控制[J]. 轧钢, 2005, 22(4): 14-16.

WANG Chongtao, FANG Kangling. Shape control on sendzimir mill[J]. Steel Rolling, 2005, 22(4): 14-16.

[13] 杨光辉, 张杰, 曹建国, 等. 20辊森吉米尔轧机辊系变形的有限元分析[C]//第七届中国钢铁年会大会论文集. 北京: 冶金工业出版社, 2009: 227-231.

YANG Guanghui, ZHANG Jie, CAO Jianguo, et al. Analysis of elastic deformation of roll system on 20-hi sendzimir mill by finite element method[C]//Proceedings of the 7th CSM Steel Congress. Beijing: Metallurgical Industry Press, 2009: 227-231.

[14] XIAO Hong, YUAN Zhengwen, WANG Tao. Roll flattening analytical model in flat rolling by boundary integral equation method[J]. Journal of Iron and Steel Research, International, 2013, 20(10): 39-45.

[15] YUAN Zhengwen, XIAO Hong, XIE Hongbiao. Practice of improving roll deformation theory in strip rolling process based on boundary integral equation method[J]. Metallurgical and Materials Transactions A, 2014, 45(2): 1019-1026.

[16] 员征文, 肖宏, 谢红飙. 基于边界积分方程法的六辊轧机辊系变形分析[J]. 机械工程学报, 2013, 49(18): 125-131.

YUAN Zhengwen, XIAO Hong, XIE Hongbiao. 6-Hi mill deformation analysis based on boundary integral equation method[J]. Journal of Mechanical Engineering, 2013, 49(18): 125-131.

[17] 王国栋. 板形控制和板形理论[M]. 北京: 冶金工业出版社, 1986: 439-441.

WANG Guodong. Control and theory of plate shapes[M]. Beijing: Metallurgical Industry Press, 1986: 439-441.

[18] LIAN Jiachuang. Analysis of profile and shape control in flat rolling[C]//Proceeding of the First International Conference on Steel Rolling. Tokyo, Japan, 1980: 713-717.

(编辑 杨幼平)

收稿日期:2016-04-30;修回日期:2016-06-28

基金项目(Foundation item):国家自然科学基金资助项目(51474190);河北省自然科学基金资助项目(E2015203311)(Project (51474190) supported by the National Natural Science Foundation of China; Project (E2015203311) supported by the Natural Science Foundation of Hebei Province)

通信作者:肖宏,博士,教授,从事金属塑性成形过程计算机模拟及轧制理论研究;E-mail:xhh@ysu.edu.cn