Microstructure and properties of Cu/Al joints brazed with Zn-Al filler metals

来源期刊:中国有色金属学报(英文版)2012年第2期

论文作者:姬峰 薛松柏 娄继源 娄银斌 王水庆

文章页码:281 - 287

关键词:Cu/Al钎焊接头;Zn-Al钎料;力学性能;界面层

Key words:Cu/Al brazing joint; Zn-Al filler metals; mechanical property; interface layer

摘 要:

使用不同成分的Zn-Al钎料对铜铝异种金属进行火焰钎焊,研究其力学性能。利用光学显微镜、扫描电镜和能谱研究不同Zn-Al钎料对Cu/Al钎焊接头钎焊性、力学性能及显微组织的影响。结果表明:随着Al含量的增加,Zn-Al钎料在Cu和Al上的铺展面积逐渐增大。当钎料中Al含量为15%时,Cu/Al接头的抗剪强度达到最大值88 MPa;随着组织的变化,钎缝硬度值呈现HV122到HV515不等的分布。另外,钎缝组织的成分主要为富Zn相和富Al相,但是当钎料中Al含量为2%和15%以上时,靠近Cu侧的界面处会分别形成CuZn3和Al2Cu两种完全不同的金属间化合物。研究Zn-Al钎料中铝含量对Cu/Al接头界面化合物类型的影响。

Abstract:

The mechanical properties and microstructural distribution of the Cu/Al brazing joints formed by torch-brazing with different Zn-Al filler metals were investigated. The microstructure of the Zn-Al alloys was studied by optical microscopy and scanning electron microscopy, and the phase constitution of the Cu/Al joints was analyzed by energy dispersion spectrometry. The results show that the spreading area of the Zn-Al filler metals on the Cu and Al substrates increases as the Al content increases. The mechanical results indicate that the shear strength reaches a peak value of 88 MPa when Al and Cu are brazed with Zn-15Al filler metal. Microhardness levels from HV122 to HV515 were produced in the three brazing seam regions corresponding to various microstructure features. The Zn- and Al-rich phases exist in the middle brazing seam regions. However, two interface layers, CuZn3 and Al2Cu are formed on the Cu side when the Al content in the filler metals is 2% and more than 15%, respectively. The relationship between intermetallic compounds on Cu side and Zn-xAl filler metals was investigated.

![]()

Trans. Nonferrous Met. Soc. China 22(2012) 281-287

JI Feng1, XUE Song-bai1, LOU Ji-yuan2, LOU Yin-bin2, WANG Shui-qing2

1. School of Materials Science and Technology, Nanjing University of Aeronautics and Astronautics,Nanjing 210016, China;

2. Zhejiang Xinrui Welding Material Co., Ltd, Shengzhou 312452, China

Received 10 March 2011; accepted 10 June 2011

Abstract: The mechanical properties and microstructural distribution of the Cu/Al brazing joints formed by torch-brazing with different Zn-Al filler metals were investigated. The microstructure of the Zn-Al alloys was studied by optical microscopy and scanning electron microscopy, and the phase constitution of the Cu/Al joints was analyzed by energy dispersion spectrometry. The results show that the spreading area of the Zn-Al filler metals on the Cu and Al substrates increases as the Al content increases. The mechanical results indicate that the shear strength reaches a peak value of 88 MPa when Al and Cu are brazed with Zn-15Al filler metal. Microhardness levels from HV122 to HV515 were produced in the three brazing seam regions corresponding to various microstructure features. The Zn- and Al-rich phases exist in the middle brazing seam regions. However, two interface layers, CuZn3 and Al2Cu are formed on the Cu side when the Al content in the filler metals is 2% and more than 15%, respectively. The relationship between intermetallic compounds on Cu side and Zn-xAl filler metals was investigated.

Key words: Cu/Al brazing joint; Zn-Al filler metals; mechanical property; interface layer

1 Introduction

Many emerging applications in power generation, chemistry, petro-chemical, nuclear, aerospace, transportation and electronics industries require the joining of dissimilar materials by various joining methods [1-10]. Cu/Al joints are indispensable in the fabrication of electronic components and solar collectors due to their unique performances such as high electric conductivity, heat conductivity, corrosion resistance and mechanical properties. Thus, the joining of Cu and Al is one of key fabrication techniques for the manufacture of industrial components. However, a sound joint is difficult to make by joining these two metals because of their significantly different melting points, fusion heat and linear expansion, which leads to large misfit strain and residual stress in the joint. Moreover, Cu and Al are incompatible metals because they have a high affinity to each other at temperature higher than 120 °C, which produces intermetallic compounds (IMCs) with brittle, low strength and high electrically resistant natures at their interface [1, 2, 6].

Many investigations have focused on the producing of a stable Cu/Al joint to overcome the difficulties in joining these two dissimilar metals. ABBASI et al [3] studied the growth rate of IMCs in Al/Cu bimetal produced by the cold roll welding process. MAI and SPOWAGE [4] examined the characteristics of Cu/Al joints produced by laser welding. LEE et al [5] discussed the effects of IMCs on the electrical and mechanical properties of friction-welded Cu/Al bimetallic joints. SAHIN [6] joined Al and Cu by means of friction welding, CuAl2, CuAl and Cu9Al4 IMCs were observed in the Cu/Al joint. However, except laser welding, the aforementioned joining methods are all based on the solid diffusion principle, which are not applied to mass production and manufacture parts with complex structures. Brazing technology has been widely used in dissimilar metal joining process. However, copper and brass are not considered that they can be brazed directly to Al [7]. XIA et al [8, 9] attempted to join Cu with Al using vacuum brazing with an eutectic Al-Si filler metal, but this technique cannot produce a Cu/Al joint with desired property.

Various Cu-Al joint forms have been used in power and electric industry. SAHIN [6] and YILBA et al [10] investigated the microstructure and properties of a Cu/Al rod joint. KIM et al [11] studied the bondability of copper wire and an aluminum pad which was used in the chip interconnection. The Cu/Al butt connector was used in the friction stir welding and laser welding process [1, 4] while the overlap joints were widely used in brazing and diffusion bonding process [8, 9, 12]. In the present study, a Cu/Al overlap joint was brazed by oxy-acetylene torch brazing. Three Zn-Al filler metals with melting points far lower than that of Al-Si filler metal were employed to braze Cu and Al. The effects of Al contents on the joint reliability were investigated by measuring the shear strength of joints. The microhardness and microstructural distribution of the brazing seam zone were also investigated.

2 Experimental

2.1 Materials

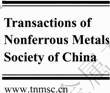

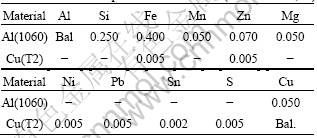

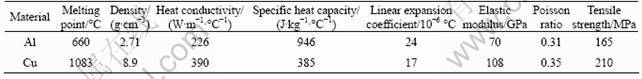

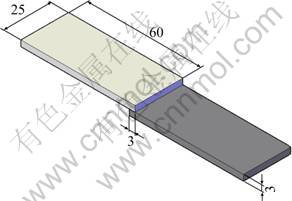

The materials used in the present study were industrial pure Al and Cu. The chemical compositions and main thermo-physical properties of the metals are shown in Tables 1 and 2, respectively. Although some composition and properties are temperature-dependent, the data provide a basic reference for assessing the differences in brazability between Al and Cu. The compositions of the Zn-Al filler metals used for the spreadability test are listed in Table 3. All the cast ingots were drawn into a wire with diameter of 2 mm during the torch brazing process. The Cu and Al samples supplied for the spreadability test and brazing were machined into plates with dimensions of 40 mm×40 mm×2 mm and 60 mm×25 mm×3 mm, respectively. The bonding strength of brazed Cu/Al joint with an overlap length of 3 mm was evaluated. Figure 1 shows the geometry and dimensions of the brazing specimens subjected to shear testing.

Table 1 Chemical composition of Al and Cu (mass fraction, %)

2.2 Experimental procedure

To produce a satisfactory metallurgical bond by torch brazing, contaminants layers (oxides, absorbed ions, grease and dust particles) adhered to the surfaces of the two metals should be removed. The surface precleaning process involved the following steps: 1) The assembly was degreased using a vapor; 2) It was immersed in 10% HNO3 and 0.25% HF at room temperature for 5 min; 3) The assembly was rinsed in cold water and subsequently dried.

The spreading experiments were performed according to China’s National Standard GB/T11346— 2008. The filler metal (0.2 g) was placed on the specimens with a non-corrosion KAlF4-CsAlF4 flux. Afterward, the specimens were heated at (500±5) °C for 1 min in an electrical resistance furnace. The spreading area was photographed by a digital camera and calculated using Image-Pro plus, and the average of five samples was reported. Finally, the Cu and Al specimens were joined with three kinds of filler metals, namely, Zn-2Al, Zn-15Al and Zn-22Al by an automatic oxy-acetylene torch (DIL, DESVER2500). The oxygen and acetylene flow rates were 12 L/min.

Metallographic samples of the filler metals and Cu/Al brazing joints were ground and polished using a series of different SiC papers and Al2O3 powders, and then etched with an HNO3 alcohol solution. An optical microscope and Hitachi S-4800 field emission scanning electron microscopes were used to observe the microstructure of the filler metals and the morphology of the brazing interface, respectively. Shear tests were conducted using a universal tensile test machine. The microhardness distribution and composition of the brazing interface were measured by a Wilson-wlopert microsclerometer (Wilson 401 mvA) and an energy dispersion spectrometer, respectively.

3 Results and discussion

3.1 Brazability and microstructure of filler metals

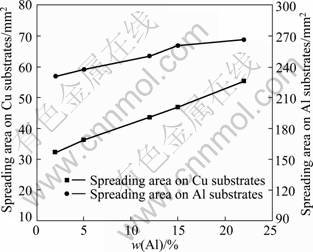

Figure 2 shows the spreading area of different Zn-Al filler metals with Al and Cu substrates at 500 °C. The spreading area of the filler metals increases linearly with the increase of Al content. The important factors to the extent of wetting can be illustrated by the phase relationship between the filler metal and base metals. The filler metals are easily spread on the base metals if they have the appropriate mutual solubility or can form an IMC. According to the Zn-Al binary phase diagram, Zn and Al have a high degree of mutual solubility at 500 °C, which may lessen the fluidity of the brazing alloy on the Al substrates. However, the dissolution rate of a filler metal in the Al substrates is lowered when the Al content is increased, which may favor the spreadability of the brazing alloys. Al and Cu can generate new phases easily, and the free energy formed during the process which is resulted from the diffusion between Cu and Al atoms is one of the driving forces behind wetting and capillary action. Consequently, the spreading area of filler metals on the Cu substrates also increases with a corresponding increase of Al content.

Table 2 Thermophysical properties of Al and Cu

Table 3 Composition of Zn-Al filler metals used in spreadability test (mass fraction, %)

Fig.1 Schematic representation of brazed specimens for shear testing (Unit: mm)

Fig. 2 Spreading area of filler metals with different components

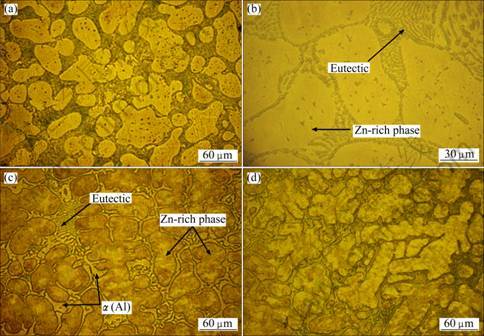

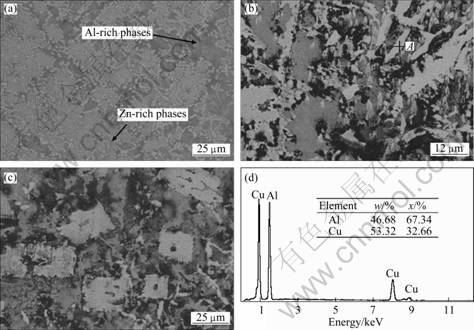

The increasing Al content in Zn-Al alloys also results in a more complicated microstructure. Figure 3 shows the as-cast microstructures of the Zn-2Al, Zn-15Al and Zn-22Al alloys melted at 500 °C and slowly cooled. The Zn-2Al alloy is composed of tow phases, the Zn-rich phases as well as a certain quantity of Zn-Al eutectic structure which can be seen in Figs. 3(a) and (b). When the total content of Al is 15%, as shown in Fig. 3(c), the Zn-Al solidified microstructure exhibits a typical hypereutectic structure. At higher Al content, the α(Al) phases precipitate from the molten liquid and uniformly surround the Zn-rich phases. Figure 3(c) presents the optical micrographs of the Zn-22Al alloy, in which a typical eutectoid microstructure is apparent.

Fig. 3 Optical micrographs of Zn-2Al (a, b), Zn-15Al (c) and Zn-22Al (d)

3.2 Microhardness and mechanical property of brazing joint

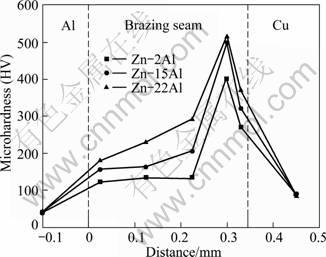

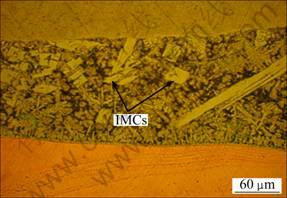

Hardness is an important index for evaluating the mechanical properties and physical performance of a brazing joint. Figure 4 shows the line scan analysis profile of the microhardness values of the Cu/Al brazing joints with different Zn-Al filler metals. The test parameters were a 0.245 N loading and loading time of 10 s. The average hardness was calculated from five indentations. The brazing seam region has a higher hardness value than those of the Cu and Al substrates, and significantly increases to HV515 near the Cu side. Figure 4 also shows that the microhardness of the Cu/Al brazing seam linearly increases with increasing Al content in the filler metals. This could be attributed to the formation of the Cu/Al IMCs caused by the various reactions between the two metals during the brazing process. Disordered distribution of IMCs in the brazing seam, as can be seen in Fig. 5, might result in higher hardness values. The distinctively higher hardness values on the Cu side are attributable to the formation of IMC layers as well.

Fig. 4 Microhardness of Cu/Al brazing joints with different Zn-Al filler metals

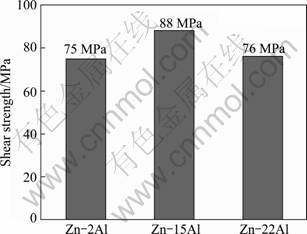

The shear strengths of the Cu/Al joints brazed with three kinds of Zn-Al filler metals are shown in Fig. 6. The joint shares almost equal shear strength when the Cu/Al substrates are brazed with Zn-2Al and Zn-22Al. Additionally, the shear strength of the Cu/Al joint reaches the peak value of 88 MPa when Al content is 15%, which is an improvement of 17% compared with those brazed with the other two filler metals.

3.3 Phase constitution of Cu/Al brazing joints

Micrographs of the Cu/Al samples at the brazing seam zone display four layers between Cu and Al, namely, the transition region on the Al side, the middle brazing seam region, the IMC layer and the intermediate layer of saturated solid solution on the Cu side. The morphology and distribution regularities of the brazing seam microstructure severely affect the shear strength of the Cu/Al brazing joint. The brazing seam zones of the Cu/Al joints bonded with Zn-2Al, Zn-15Al and Zn-22Al are shown in Fig. 7. The Zn- and Al-rich phases constitute the entire middle brazing seam region when the Cu and Al substrates are joined with Zn-2Al filler metal. In Fig. 7(a), the bright bulks regions are the Zn-rich phases, whereas the dark microstructures are the Al-rich phases. The IMC particles are formed during brazing seam solidification process when the content of Al reaches 15%. The IMCs consist of Cu and Al, as shown by energy-dispersive spectrometry (EDS) in Fig. 7(d). According to the Cu/Al binary phase diagram and the EDS result, the IMC at point A is θ (Al2Cu) phase. When these IMC particles are uniformly distributed in the brazing seam, as shown in Fig. 7(b), an intensive particulate-reinforced Cu/Al is produced. Consequently, the uniform distribution of these Al2Cu particles may be partly responsible for the increase of shear strength. Moreover, the increased microhardness of the joint is large due to the formation of the Al2Cu IMC particles. However, these IMC particles are hard, brittle and can easily become the stress concentration areas in the brazing process when they appear in bulk shape as seen in Fig. 7(c), which may become the source of crack initiation and expansion. Thus, the Cu/Al joint brazed with Zn-22Al has lower shear strength than that brazed with Zn-15Al filler metal.

Fig. 5 SEM image of brazing seam zone in Cu/Al joined with Zn-22Al

Fig. 6 Shear strengths of Cu/Al brazing joints using different Zn-Al filler metals

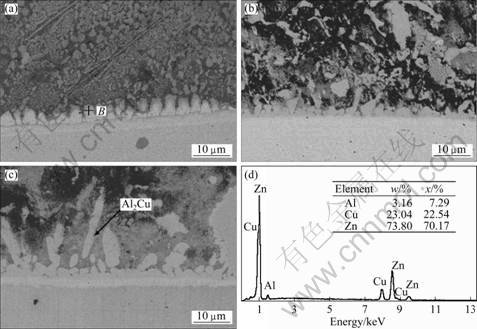

Engineering brazing joints require stable microstructures to prevent failure such as fracture fatigue crack formation and propagation [13-16]. Numerous similar investigations show that the type and morphology of interface microstructures determine the mechanical property of the Cu/Al brazing joint. An interface layer with an appropriate thickness and fine distribution is beneficial to the strength of the dissimilar metal joint [17-20]. The intermetallic layers of different joints on the Cu side observed by scanning electron microscope are shown in Fig. 8. The IMCs are present as islands with serrated edges and develop perpendicularly to the interface layer when the joints are brazed with Zn-2Al and Zn-15Al. Zn-based filler metals with high plasticity are uniformly distributed among the islands. The IMC and middle brazing seam region could be associated by the interdigitated characteristic, which prevents the growth and expansion of cracks. However, the IMC is in a bulky strip form when the Al content in the filler metals is 22%, which can be attributed to the relatively high brazing temperature compared with that of Zn-2Al and Zn-15Al. Thus, the IMC is thicker than others due to the more severe reaction between the melted filler metals and the Cu substrates. Moreover, the bulk-like IMC may fracture because of the scouring action of the melted filler metals which further weakens the performance of the brazing joint.

Fig. 7 Microstructures (a-c) and EDS analysis (d) of Cu/Al brazing joints: (a) Zn-2Al; (b) Zn-15Al; (c) Zn-22Al; (d) EDS analysis of position A

Fig. 8 Microstructures (a-c) and EDS analysis (d) of interface layer on Cu side: (a) Zn-2Al; (b) Zn-15Al; (c) Zn-22Al; (d) EDS analysis of position B

Aside from the morphology of the IMC, the type and character of the IMC also significantly influence the joint properties. The interface layers on the Cu side change with increasing Al content. Figure 8(d) shows the result of the EDS analysis of point B in the Zn-2Al joint. According to the Cu-Zn binary phase diagram and Al-Cu-Zn ternary phase diagram, the interface in Fig. 8(a) is composed of Al particles and CuZn3. However, the IMCs produced at the interface, the joints of which are brazed with Zn-15Al and Zn-22Al (Figs. 8(b) and (c)) are Al2Cu phase, which is the same as that found in the middle brazing seam region. Thus, the type of interface layer is another factor that leads to the variations in mechanical properties of the joint.

4 Conclusions

1) The spreading area of the Zn-Al filler metals exhibits a linear increasing trend on the Al and Cu substrates with increasing Al content. The main microstructure of the Zn-2Al filler metal consists of a Zn-rich phase and Zn-Al eutectic structure, whereas Zn-15Al and Zn-22Al show a typical hyper-eutectic and eutectoid microstructure.

2) A peak value of 88 MPa for the shear strength is obtained when the Zn-15Al filler metal is employed to braze the Cu and Al substrates, and the Cu/Al joints have almost identical shear strengths when brazed with Zn-2Al and Zn-22Al. The microhardness of the brazing seam zone is higher than those of the substrates, the interface layers on the Cu side have the maximum hardness value.

3) The middle brazing seam zone encompasses the Zn- and Al-rich phases when the Cu/Al joints are bonded with Zn-2Al. The Al2Cu phase is formed in the middle brazing seam when the Al content in the filler metals is more than 15%. The Al2Cu phase appears in the shape of particles and bulks when the joints are brazed with Zn-15Al and Zn-22Al, respectively. Furthermore, CuZn3 and Al2Cu layers are found on the Cu sides for the first time when Al content of filler metals is 2% and more than 15%, respectively.

References

[1] OUYANG J H, YARRAPAREDDY E, KOVACEVIC R. Microstructural evolution in the friction stir welded 6061 aluminum alloy (T6-temper condition) to copper [J]. Journal of Materials Processing Technology, 2006, 172(1): 110-112.

[2] XUE Song-bai, DONG Jian, LV Xiao-chun, QIAN Yi-yu. Brazing technology of LY12 Al-alloy at middle temperature [J]. Transactions of the China Welding Institution, 2003, 24(3): 21-23. (in Chinese)

[3] ABBASIA M, TAHERIB A K, SALEHI M T. Growth rate of intermetallic compounds in Al/Cu bimetal produced by cold roll welding process [J]. Journal of Alloys and Compounds, 2001, 319(1-2): 233-241.

[4] MAI T A, SPOWAGE A C. Characterisation of dissimilar joints in laser welding of steel–kovar, copper–steel and copper–aluminium [J]. Materials Science and Engineering A, 2004, 374(1-2): 224-233.

[5] LEE W B, BANG K S, JUNG S B. Effects of intermetallic compound on the electrical and mechanical properties of friction welded Cu/Al bimetallic joints during annealing [J]. Journal of Alloys and Compounds, 2005, 390(1-2): 212-219.

[6] SAHIN M. Joining of aluminium and copper materials with friction welding [J]. The International Journal of Advanced Manufacturing Technology, 2010, 49(5-8): 527-534.

[7] Brazing handbook [M]. USA: American Welding Society, 2007: 378-379.

[8] XIA C Z, LI Y J, PUCHKOV U A, GERASIMOVB S A, WANG J. Microstructure and phase constitution near the interface of Cu/Al vacuum brazing using Al–Si filler metal [J]. Vacuum, 2008, 82(8): 799-804.

[9] XIA C Z, Li Y J, PUCHKOV U A, GERASIMOV S A, WANG J. Crack analysis near vacuum brazing interface of Cu/Al dissimilar materials using Al–Si brazing alloy [J]. Materials Science and Technology, 2009, 25(3): 383-387.

[10] YILBA B S, SAHIN A Z, KAHRAMAN N, AL-GARNIAHMED Z. Friction welding of St-A1 and A1-Cu materials [J]. Journal of Materials Processing Technology, 1995, 49(3-4): 431-443.

[11] KIM H J, LEE J Y, PAIK K W, KOH K W, WON J H, CHOE S, LEE J, MOON J T, PARK Y J. Effects of Cu/Al intermetallic compound (IMC) on copper wire and aluminum pad bondability [J]. IEEE Transactions on Components and Packaging Technologies, 2003, 26(2): 367-374.

[12] WU H Y, LEE S Y, WANG J Y. Solid state bonding of iron-base alloy, steel-brass and aluminum alloy [J]. Journal of Material Processing Technology, 1998, 75(1-3): 173-179.

[13] YAO C W, XU B S, ZHANG X C, HUANG J, FU J, WU Y X. Interface microstructure and mechanical properties of laser welding copper–steel dissimilar joint [J]. Optics and Lasers in Engineering, 2009, 47(7-8): 808-814.

[14] RAMIREZ A G, MAVOORI H, JIN S. Bonding nature of rare-earth-containing lead-free solders [J]. Applied Physics Letters, 2002, 80(3): 398-400.

[15] CHANG S Y, TSAO L C, LI T Y, CHUANG T H. Joining 6061 aluminum alloy with Al–Si–Cu filler metals [J]. Journal of Alloys and Compounds, 2009, 488(1): 174-180.

[16] LEE W B, SCHMUECKER M, MERCARDO U A, BIALLAS G. Interfacial reaction in steel–aluminum joints made by friction stir welding [J]. Scripta Materialia, 2006, 55(4): 355-358.

[17] UZUN H, DONNE C D, ARGAGNOTTO A, GHIDINIA T, GAMBAROB C. Friction stir welding of dissimilar Al 6013-T4 to X5CrNi18-10 stainless steel [J]. Materials and Design, 2005, 26(1): 41-46.

[18] PANG H L J, TAN K H, SHI X Q, WANG Z P. Microstructure and intermetallic growth effects on shear and fatigue strength of solder joints subjected to thermal cycling aging [J]. Materials Science and Engineering A, 2001, 307(1-2): 42-50.

[19] SONG J M, LAN G F, LUI T S, CHEN L H. Microstructure and tensile properties of Sn–9Zn–xAg lead-free solder alloys [J]. Scripta Materialia, 2003, 48(8): 1047-1051.

[20] LIN San-bao, SONG Jian-ling, YANG Chun-li, MA Guang-chao. Microstructure analysis of interfacial layer with tungsten inert gas welding-brazing joint of aluminum alloy/stainless steel [J]. Acta Metallurgica Sinica, 2009, 45(10): 1211-1216.(in Chinese)

姬 峰1, 薛松柏1, 娄继源2, 娄银斌2, 王水庆2

1. 南京航空航天大学 材料科学与技术学院,南京 210016;

2. 浙江新锐焊接材料有限公司,嵊州 312452

摘 要:使用不同成分的Zn-Al钎料对铜铝异种金属进行火焰钎焊,研究其力学性能。利用光学显微镜、扫描电镜和能谱研究不同Zn-Al钎料对Cu/Al钎焊接头钎焊性、力学性能及显微组织的影响。结果表明:随着Al含量的增加,Zn-Al钎料在Cu和Al上的铺展面积逐渐增大。当钎料中Al含量为15%时,Cu/Al接头的抗剪强度达到最大值88 MPa;随着组织的变化,钎缝硬度值呈现HV122到HV515不等的分布。另外,钎缝组织的成分主要为富Zn相和富Al相,但是当钎料中Al含量为2%和15%以上时,靠近Cu侧的界面处会分别形成CuZn3和Al2Cu两种完全不同的金属间化合物。研究Zn-Al钎料中铝含量对Cu/Al接头界面化合物类型的影响。

关键词:Cu/Al钎焊接头;Zn-Al钎料;力学性能;界面层

(Edited by FANG Jing-hua)

Foundation item: Project (2009GJC20040) supported by the Scientist and Technician Serve the Enterprise, MOST, China

Corresponding author: XUE Song-bai; Tel: +86-25-84896070; Fax: +86-25-52112626; E-mail: xuesb@nuaa.edu.cn

DOI: 10.1016/S1003-6326(11)61172-2