DOI:10.19476/j.ysxb.1004.0609.2019.01.17

(CH3)3COOH-NaOH体系处理废弃电路板中焊锡技术

郭学益,刘子康,黄国勇

(中南大学 冶金与环境学院,长沙 410083)

摘 要:研究了在(CH3)3COOH-NaOH体系中,废弃电路板焊锡的锡和铅的分离富集行为。系统分析了反应温度、溶液组成、NaOH浓度、(CH3)3COOH滴加速度等因素对焊锡浸出效果的影响,得到最佳工艺参数如下:在溶液组成为85%的氢氧化钠与15%的(CH3)3COOH,反应温度为70 ℃条件下,当氢氧化钠溶液初始浓度为5 mol/L,(CH3)3COOH滴加速度为2.4 mL/min,浸出时间为20 min时,锡的浸出率为96.21%,铅的浸出率为92.36%。往退锡后液中加入理论量1.5倍的Na2S·9H2O,铅的沉淀率为98.79%,可制得纯度为99.23%的PbS产品;往沉淀后液中加入理论量2.5倍的Ca(OH)2,锡的沉淀率达到93.21%,热处理后可得到SnO2产品,产品符合GB/T 26013—2010标准。

关键词:废电路板;焊锡;(CH3)3COOH;NaOH

文章编号:1004-0609(2019)-01-0146-07 中图分类号:TF111 文献标志码:A

近年来,随着经济水平的提高与电子信息技术的迅猛发展,电器及电子产品的生产量与使用量急剧增加,更新换代的速度也在加快,导致电子设备的报废量也在高速增长[1-2]。据统计,2014年全球电子废弃物总量为4180万t,报废量年均增长20%,我国电子废弃物的产生量为603.3万t,约占到全球产生量的15%,仅次于美国位列第二[3]。废弃电路板是电子废弃物的重要组成部分,含有大量的可回收利用的有价金属,如铜、铝、铅、锌、金、银等,具有可观的潜在经济价值[4-5]。

电路板上有大量的电子元器件,通过焊料与电路板基板连接,焊锡在电路板中所占比例约为4%[6]。电路板报废时,其上的电子元器件大多没有到达生命使用周期,进行无损拆解后,元器件仍可继续使用[7-8];另外,如果废弃电路板不拆除元器件直接回收处理,容易造成元器件中的有毒有害物质或贵金属混入电路板废料中,影响后续电路板中金、银、铜、铝、铅、锌等有价金属的提取与富集。同时,分离焊锡也可实现废弃电路板中锡的富集,因此提取废弃电路板中的焊锡可更大程度地实现资源循环,具有较好经济与环境效益[9-10]。

目前,废弃电路板电子元件和焊锡的分离回收主要采用加热与机械联合处理方法,通常是空气被加热后与电路板的焊锡接触,使其达到熔化温度,然后使用工具来拆卸电子元件[11-12]。这种方法虽然对元器件损害较低,但焊锡快速熔化时会产生挥发性的有毒有害物质,且无法回收利用,自动化程度较低,热能利用率不高,能量损耗严重[10]。近年来,湿法回收焊锡成为研究的热点,大部分集中于采用硝酸体系的退锡剂浸泡废弃电路板,剥离废弃电路板中的焊锡,但这种方法对元器件引脚与电路板基板腐蚀严重,且退锡剂成分复杂,从退锡后液中提取有价金属难度较大[13-14]。

本文针对目前工艺中存在的问题,开发了一种从废弃电路板中提取焊锡的新工艺,本工艺在NaOH溶液中缓慢通入(CH3)3COOH,以此作为退锡剂,剥离废弃电路板中的焊锡,在退锡过程中,焊锡中的锡与铅分别以Sn(OH)62-、Pb(OH)42-的形式进入退锡后液,然后依次分别采用Na2S·9H2O与Ca(OH)2沉淀提取退锡后液中的锡与铅,制得PbS产品与CaSn(OH)6,CaSn(OH)6经过盐酸洗涤后热处理可得到SnO2产品。本研究将通过考察退锡工艺中不同工艺参数对退锡效果的影响,得到工艺优化条件,为工业化实验提供依据。

1 实验

1.1 实验原料和设备

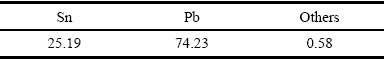

由于各个实际电路板中的焊锡量均不相同,为了定量研究退锡效果,采用焊锡条模拟电路板中焊锡进行实验。本实验中所用的焊锡,直径为1.2 mm,美国世克工具(国际)有限公司生产,将其准确切成32条,长度为4 cm的长条。成分如表1所列。

表1 焊锡的化学组成

Table 1 Chemical composition of solder (mass fraction, %)

实验所用的铜片为电路板制造过程中的覆铜板边角料,准确裁成6 cm×8 cm×0.1 cm。

实验所用氢氧化钠为分析纯,西陇化工股份有限公司生产。

实验所用的65%叔丁基过氧化氢为化学纯,国药集团化学试剂有限公司生产。

主要设备为上海沪西分析仪器厂有限公司生产的HL-2B型恒流泵,金坛市中大仪器长生产DF-1集热式恒温磁力搅拌器,杭州仪表电机有限公司生产JHS恒数数显控制器与JHS-2/90恒速数显搅拌器。

1.2 实验原理

叔丁基过氧化氢是一种易溶于碱性溶液的有机强氧化剂,焊锡的主要成分为铅锡合金,不同种类的焊锡铅与锡的含量不同,由于叔丁基过氧化氢呈弱酸性,配合碱性体系的溶液退锡时,应采用缓慢加入的方式,防止反应过于剧烈,使溶液中游离的[O]生成氧气溢出,退锡过程的主要反应方程式如下[15-16]:

Sn+(CH3)3COOH+NaOH→Na2Sn(OH)6+(CH3)3COH (1)

Pb+(CH3)3COOH+NaOH→Na2Pb(OH)4+(CH3)3COH (2)

焊锡中的锡、铅在碱性强氧化溶液体系下以羟基配子离子形式存在[17],即Sn(OH)62-与Pb(OH)42-。硫化钠是碱性体系中常用的沉淀剂,对铅有良好的沉淀效果,本研究中选用Na2S·9H2O为铅沉淀剂。反应方程式如下:

Na2Pb(OH)4+Na2S→PbS+NaOH (3)

向碱性溶液中加入微溶的Ca(OH)2,沉淀锡的同时可以避免大量Ca2+或其他杂质元素进入溶液体系,可减少对体系的干扰,简化后续金属提取工艺[18]。当溶液pH值高于12.5,沉淀物为CaSn(OH)6[19]。反应方程式如下:

Na2Sn(OH)6+Ca(OH)2→CaSn(OH)6+NaOH (4)

CaSn(OH)6经过盐酸洗涤后热处理可得到SnO2产品[20],反应方程式如下:

CaSn(OH)6+HCl→Sn(OH)4+CaCl2+H2O (5)

Sn(OH)4→SnO2+2H2O (6)

1.3 实验操作与分析方法

电子元件与焊锡湿法分离:配置一定浓度的NaOH溶液,将直径为1.2 mm,长度为4 cm的焊锡加入溶液中,在一定温度下进行机械搅拌,同时利用恒流泵往溶液中缓慢通入叔丁基过氧化氢,反应一定时间后过滤得到退锡后液,通过测定退锡后液中金属离子浓度判断金属的浸出率(R1),计算公式 如下:

(7)

(7)

式中:R1为金属的浸出率,%;ρ为金属离子浓度,g/L;V为溶液体积,L;m为多金属料或低碱浸出渣质量,g;w为该金属在试样中所占质量分数,%。

退锡后液中有价金属的提取:取上述步骤完成之后的退锡后液,在一定温度下加入Na2S,反应后过滤,取滤液在一定温度下加入Ca(OH)2,反应后过滤,将滤渣用稀盐酸重复清洗三次后,在300 ℃的马弗炉中进行热处理,获得产品。通过测定滤液中金属离子浓度判断金属的沉淀率(R2),计算公式如式(7)所示。

(8)

(8)

式中:R2为金属的沉淀率,%;ρ1为沉淀前金属离子的浓度,g/L;ρ2为沉淀后离子的浓度,g/L;V1为沉淀前溶液体积,L;V2为沉淀后溶液体积,L。

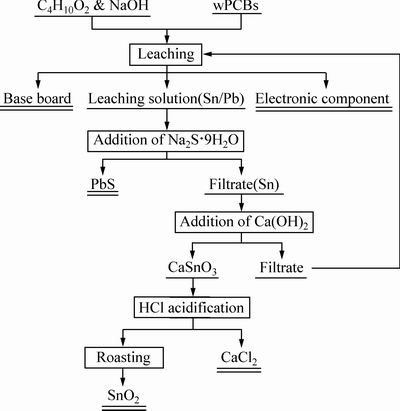

滤液采用用电感耦合等离子体-原子发射光谱仪(Optimal 5300DV,Perkin-Elmer Instruments)检测铅、锡浓度,实验流程如图1所示。

图1 实验流程图

Fig. 1 Schematic diagram of experimental flow sheet

2 结果与分析

2.1 电子元件与焊锡湿法分离

2.1.1 浸出温度对浸出率的影响

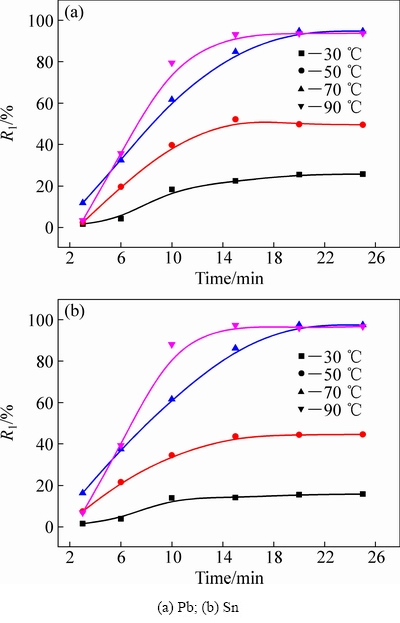

在NaOH浓度为5 mol/L,体系溶液(85%的碱溶液+15%的(CH3)3COOH溶液)与焊锡液固比(mL/g)为20:1,(CH3)3COOH溶液滴加速度2 mL/min,浸出时间25 min条件下,考察浸出温度对金属浸出率的影响,实验结果如图2所示。

由图2可以看出,在反应同一时间下,随着温度的升高,铅锡的浸出率均在上升,这是因为温度升高有利于强化浸出传质过程;铅锡浸出率变化趋势一致,在90 ℃下浸出率最高,70 ℃下铅锡的浸出率与90 ℃接近,且在反应20 min后,70 ℃与90 ℃浸出率基本一致,铅的浸出率为94.83%,锡的浸出率为97.60%,考虑能耗、溶液蒸发等因素,选取70 ℃为合适的反应温度。

2.1.2 (CH3)3COOH体积分数对浸出率的影响

在NaOH浓度为5 mol/L,反应温度为70 ℃,体系溶液与焊锡液固比为20:1,(CH3)3COOH溶液滴加速度2 mL/min,浸出时间25 min条件下,考察(CH3)3COOH体积分数对金属浸出率的影响,实验结果如图3所示。

图2 浸出温度对金属浸出率的影响

Fig. 2 Effect of leaching temperature on leaching efficiency of metals

图3 (CH3)3COOH体积分数对金属转化率的影响

Fig. 3 Effect of volume fraction of (CH3)3COOH on leaching efficiency of metals

由图3可以看出,当(CH3)3COOH体积分数小于15%,铅锡的浸出率随(CH3)3COOH体积分数的增加而增加,当(CH3)3COOH体积分数大于15%。铅锡的浸出率随(CH3)3COOH体积分数的增加变化不明显,在体系中,金属与碱及氧化剂之间的反应,可认为是(CH3)3COOH在碱中分解,释放活性氧[O][21],金属先被氧化生成金属氧化物,氧化物再与碱反应生成钠盐的过程。增加(CH3)3COOH用量,会产生更多[O]参与金属反应过程,有助于金属在碱中溶解,提高金属浸出率,但当(CH3)3COOH体积分数较大时,碱溶液体积分数较少,料浆密度增加,减少了传质速率[22],同时用恒流泵将(CH3)3COOH不断加入过程中,会降低碱溶液浓度,导致金属浸出率降低。选择(CH3)3COOH体积分数为15%较为合适。

2.1.3 碱浓度对浸出率的影响

反应温度为70 ℃,体系溶液(85%的碱溶液+15%的(CH3)3COOH溶液)与焊锡液固比为20:1,(CH3)3COOH溶液滴加速度2 mL/min,浸出时间25 min条件下,考察碱浓度对金属浸出率的影响,实验结果如图4所示。

由图4可知,当碱浓度为5 mol/L时,铅锡的浸出率最高,当碱浓度小于5 mol/L时,铅锡的浸出率随碱浓度的增加而增加,当碱浓度大于5 mol/L时,铅锡的浸出率随碱浓度的增加而降低。在碱溶液中,Pb、Sn分别以PbO2-、SnO32-的形式存在于溶液中[22],当碱浓度为5 mol/L时,OH-浓度不断增加,增加了金属与活性氢氧根离子的有效接触面积,导致金属的浸出率逐渐增加。由于当碱浓度大于5 mol/L时,PbO2-、SnO32-在碱中的溶解度随碱浓度的增加而迅速降低[22],且碱浓度的增加,会使溶液黏度增加,减少传质速率,制约了金属的浸出。综合考虑,选择碱浓度为5 mol/L为合适的用量。

图4 碱浓度对金属浸出率的影响

Fig. 4 Effect of alkali concentration on leaching efficiency of metals

2.1.4 (CH3)3COOH滴加速度对浸出率的影响

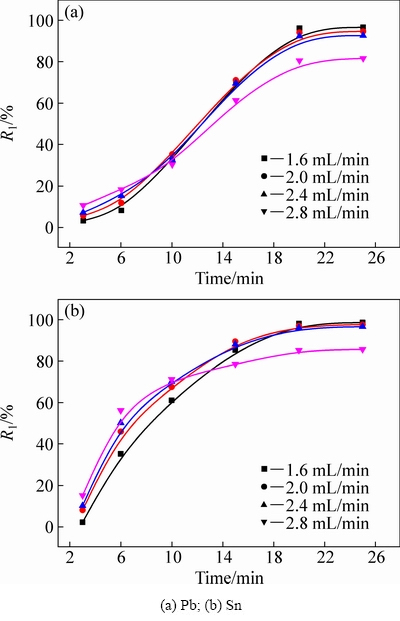

NaOH浓度为5 mol/L,反应温度为70 ℃,体系溶液(85%的碱溶液+15%的(CH3)3COOH溶液)与焊锡液固比为20:1,浸出时间25 min条件下,考察(CH3)3COOH溶液滴加速度对金属浸出率的影响,实验结果如图5所示。

图5 (CH3)3COOH滴加速度对金属浸出率的影响

Fig. 5 Effect of dropping speed of (CH3)3COOH on leaching efficiency of metals

由图5可知,在考察的(CH3)3COOH滴加速度范围内,Pb、Sn的浸出率变化不明显。当滴加速度较大时,浸出率在10 min之前提升较快,10 min之后浸出率增速较缓。(CH3)3COOH溶液在碱中分解速度较快,释放活性氧[O][21],反应前期,由于溶液中活性氧[O]含量较低,滴加速度越快,浸出率越高;反应后期,由于溶液中的活性氧远超过了其在溶液中的溶解量,大部分活性氧溢出体系外不参与反应,且溶液体积增加,降低了NaOH溶液浓度,因此滴加速度越快,浸出率越低。当滴加速度过慢时,反应时间也会延长。由于滴加的(CH3)3COOH溶液体积保持固定,当滴加速度为2.8 mL/min时,(CH3)3COOH溶液在反应10.7 min时就已经滴加完毕,溶液中活性氧[O]大量溢出,后续反应时间溶液中活性氧[O]不足,因此浸出率明显下降。综合考虑,选择(CH3)3COOH滴加速度为2.4 mL/min较为合适。

(CH3)3COOH溶液按2.4 mL/min滴加速度计算,双氧水加入时间为12.5 min;当浸出时间达20 min后,随着浸出时间的增加,铅与锡的浸出率基本保持不变,分别稳定在92.36%与96.21%。这是因为随着反应的不断进行,(CH3)3COOH分解速率逐渐加快,产生的活性氧促进金属的浸出,反应过程速度较快,未在溶液中溶解的活性氧溢出体系外不参与反应,反应后期体系中氧化性较弱,延长反应时间,金属的浸出率不发生改变,因此选择20 min作为最佳的浸出时间。

2.2 退锡后液中有价金属的提取

2.2.1 铅的提取工艺研究

将电路板制造过程中的覆铜板边角料准确裁成6 cm×8 cm×0.1 cm,质量为487.3 g,以此模拟废弃电路板基板;将直径为1.2 mm的焊锡准确切成32条,长度为4 cm的长条,质量为10.7 g,以此模拟废弃电路板中的焊锡。取上述退锡过程最佳实验条件,处理模拟废弃电路板基板与焊锡,反应后得到的浸出液成分如表2所列。

表2 模拟废弃电路板退锡后液化学组成

Table 2 Chemical composition of leaching liquid from oxidative alkali leaching of simulated waste printed circuit board (mass concentration, g/L)

由表2可知,溶液体系基本不腐蚀电路板基板中的Cu,溶液在200 mL的退锡后液中加入1.5倍理论量的Na2S·9H2O,即13.81 g,温度为20 ℃,搅拌速度为200 r/min,反应时间为15 min,铅的沉淀率达到98.79%。将溶液真空过滤后,得到的产物置于120 ℃烘箱中干燥8 h,得到黑色粉末,对其进行XRD分析,其结果如图6所示,结果表明物相为PbS。通过X射线荧光光谱分析(X Ray Fluorescence)所得检测结果如表3所列,其中PbS的纯度可达99.23%,后续高纯化后可作为半导体材料。

图6 沉淀产物XRD谱

Fig. 6 XRD pattern of evaporation precipitation product

表3 沉淀产物化学成分

Table 3 Chemical composition of precipitation product (mass fraction, %)

2.2.2 锡的提取工艺研究

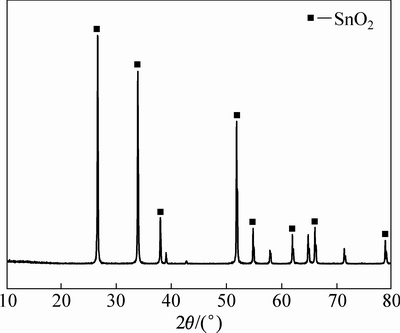

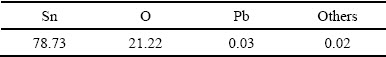

往上述200 mL的沉淀后液中加入理论量2.5倍的Ca(OH)2,即4.20 g,控制反应温度为70 ℃,反应时间为60 min,搅拌速度为200 r/min,锡的沉淀率达到93.21%,将溶液真空过滤后,将过滤产物置于pH=1的稀盐酸条件下洗涤,洗涤产物干燥后,置于400 ℃的马弗炉中热处理2 h得到白色粉末,XRD分析结果表明物相为SnO2,如图7所示。通过电感耦合等离子体-原子发射光谱仪(ICP-AES)所得检测结果如表4 所列,产品符合GB/T 26013—2010标准。

图7 沉淀产物XRD谱

Fig. 7 XRD pattern of evaporation precipitation product

表4 沉淀产物化学成分

Table 4 Chemical composition of precipitation product (mass fraction, %)

3 结论

1) 利用(CH3)3COOH-NaOH体系处理废弃电路板中的焊锡,可高效浸出焊锡中的铅和锡,且基本不腐蚀电路板基板中的Cu;在溶液中,铅锡分别以Pb(OH)42-、Sn(OH)62-形式存在,分别采用Na2S·9H2O与Ca(OH)2沉淀提取退锡后液中的铅与锡,制得PbS产品与CaSn(OH)6,CaSn(OH)6经过盐酸洗涤后热处理可得到SnO2产品。

2) 通过考察(CH3)3COOH-NaOH体系退锡过程各因素对金属转化率的影响,得到了最佳工艺条件:反应温度为70 ℃,体系溶液组成为85%的碱溶液+15%的(CH3)3COOH溶液,初始NaOH溶液为5 mol/L,(CH3)3COOH滴加速度为2.4 mL/min,浸出时间为20 min,在此条件下,铅的浸出率为92.36%,锡的浸出率为96.21%。

3) 往退锡后液中加入1.5倍理论量的Na2S·9H2O,,铅的沉淀率为98.79%,可制得纯度为99.23%的PbS产品;往沉淀后液中加入理论量2.5倍的Ca(OH)2,后,锡的沉淀率达到93.21%,得到SnO2产品,产品符合GB/T 26013—2010标准。

4) 本工艺实现废弃电路板中焊锡的高效提取回收,解决了目前湿法退锡工艺过程中溶液成分复杂、硝酸对元器件与基板腐蚀严重、后续过程金属提取难度大的问题,为工业化实验提供借鉴。

REFERENCES

[1] TSYDENOVA O, BENGTSSON M. Chemical hazards associated with treatment of waste electrical and electronic equipment[J]. Waste Management, 2011, 31(1): 45-58.

[2] TERAZONO A, MURAKAMI S, ABE N, INANC B, MORIGUCHI Y. Current status and research on E-waste issues in Asia[J]. Journal of Material Cycles and Waste Management, 2006, 8(1): 1-12.

[3] HICKS C, DIETMAR R, EUGSTER M. The recycling and disposal of electrical and electronic waste in China: Legislative and market responses[J]. Environmental Impact Assessment Review, 2005, 25(5): 459-471.

[4] 郭学益, 刘静欣, 田庆华. 废弃电路板多金属粉末低温碱性熔炼过程的元素行为[J]. 中国有色金属学报, 2013, 23(6): 1757-1763.

GUO Xue-yi, LIU Jing-xin, TIAN Qing-hua. Element behavior of low temperature alkaline melting process of waste printed circuit boards[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(6): 1757-1763.

[5] 刘 旸, 刘静欣, 郭学益. 电子废弃物处理技术研究进展[J]. 金属材料与冶金工程, 2014, 42(2): 44-49.

LIU Yang, LIU Jing-xin, GUO Xue-yi. Progress of electronic waste treatment[J]. Metal Materials and Metallurgy Engineering, 2014, 42(2): 44-49.

[6] 周益辉, 曾毅夫, 龙桂花, 湛志华. 废弃电路板电子元件和焊锡的分离回收技术[J]. 资源再生, 2011(2): 64-67.

ZHOU Yi-hui, ZENG Yi-fu, LONG Gui-hua, ZHAN Zhi-hua. Separating and recycling of electronic components and solder from waste printed circuit boards[J]. Resource Recycling, 2011(2): 64-67.

[7] YOO J M, JEONG J, YOO K, LEE J C, KIM W. Enrichment of the metallic components from waste printed circuit boards by a mechanical separation process using a stamp mill[J]. Waste Management, 2009, 29(3):1132-1137.

[8] ZHOU Yi-hui, Qiu Ke-qiang. A new technology for recycling materials from waste printed circuit boards[J]. Journal of Hazardous Materials, 2010, 175(1): 823-828.

[9] 周益辉, 丘克强. 回收废弃印刷电路板焊锡的新技术[J]. 中南大学学报(自然科学版), 2011, 42(7): 1883-1889.

ZHOU Yi-hui, QIU Ke-qiang. A new technology for recycling solder from waste printed circuit boards[J]. Journal of Central South University(Science and Technology), 2011, 42(7): 1883-1889.

[10] DUAN Hua-bo, HOU Kun, LI Jin-hui, ZHU Xiao-dong. Examining the technology acceptance for dismantling of waste printed circuit boards in light of recycling and environmental concerns[J]. Journal of Environmental Management, 2011, 92(3): 392-399.

[11] LI Jia, LU Hong-zhou, GUO Jie, XU Zhen-ming, Zhou Yao-he. Recycle technology for recovering resources and products from waste printed circuit boards[J]. Environmental Science & Technology, 2007, 41(6): 1995-2000.

[12] HUANG Kui, GUO Jie, XU Zhen-ming. Recycling of waste printed circuit boards: A review of current technologies and treatment status in China[J]. Journal of Hazardous Materials, 2009, 164(2): 399-408.

[13] JHA M K, KUMARI A, CHOUBEY P K, LEE J, KUMAR V, JEONG J. Leaching of lead from solder material of waste printed circuit boards (PCBs)[J]. Hydrometallurgy, 2012, 121: 28-34.

[14] MECUCCI A, SCOTT K. Leaching and electrochemical recovery of copper, lead and tin from scrap printed circuit boards[J]. Journal of Chemical Technology and Biotechnology, 2002, 77(4): 449-457.

[15] 赵由才, 张承龙, 蒋家超. 碱介质湿法冶金技术[M]. 北京: 冶金工业出版社, 2009: 98-100.

ZHAO You-cai, ZHANG Cheng-long, JIANG Jia-chao. Alkali medium hydrometallurgy technology[M]. Beijing: Metallurgical Industry Press, 2009: 98-100.

[16] 刘伟锋. 碱性氧化法处理铜、铅阳极泥的研究[D]. 长沙: 中南大学, 2011: 68-70.

LIU Wei-feng. Study on copper/lead anode slimes treated by alkaline oxidative leaching[D]. Changsha: Central South University, 2011: 68-70.

[17] 郭学益, 江晓健, 刘静欣, 刘 旸, 刘子康. 梯级碱溶分步提取废弃电路板中有价金属[J]. 中国有色金属学报, 2017, 27(2): 406-413.

GUO Xue-yi, JIANG Xiao-jian, LIU Jing-xin, LIU Yang, LIU Zi-kang. Recovery of metal values from waste printed circuit boards using a cascading alkali leaching process[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(2): 406-413.

[18] HE Ze-qiang, LI Xin-hai, LIU En-hui, HOU Zhao-hui, DENG Ling-feng, HU Chuan-yue. Preparation of calcium stannate by modified wet chemical method[J]. Journal of Central South University of Technology, 2003, 10(3): 195-197.

[19] OCHS M, VIELLE-PETIT L, WANG LIAN, MALLANTS D, LETERME B. Additional sorption parameters for the cementitious barriers of a near-surface repository[R]. NIROND-TR, 2010.

[20] 汪秋雨, 蔡 琥, 何 强, 韩亚丽, 胡意文, 王 日. 分银渣中锡提取工艺[J]. 有色金属(冶炼部分), 2016(7): 22-25.

WANG Qiu-yu, CAI Hu, HE Qiang, HAN Ya-li, HU Yi-wen, WANG Ri. Tin extraction process from silver separating residue[J]. Nonferrous Metal(Smelting Part), 2016(7): 22-25.

[21] AUGUST J, BROUARD M, DOCKER M P, SIMONS J P. Vector correlations in molecular photodissociation: H2O2, HONO2 and (CH3)3COOH[J]. Zeitschrift Für Elektrochemie Berichte Der Bunsengesellschaft Für Physikalische Chemie, 1988, 92(3): 264-273.

[22] 刘静欣, 郭学益, 刘 旸, 江晓健. NaOH-Na2SnO3-Na2PbO2-H2O四元水盐体系相平衡研究[J]. 有色金属科学与工程, 2016, 7(1): 13-16.

LIU Jing-xin, GUO Xue-yi, LIU Yang, JIANG Xiao-jian. Study on the phase equilibrium of quaternary saline system NaOH-Na2SnO3-Na2PbO2-H2O[J]. Nonferrous Metals Science and Engineering, 2006, 7(1): 13-16.

Recovery of solder from waste printed circuit boards in (CH3)3COOH-NaOH system

GUO Xue-yi, LIU Zi-kang, HUANG Guo-yong

(School of Metallurgy and Environment, Central South University, Changsha 410083, China)

Abstract: In the (CH3)3COOH-NaOH system, the separation and enrichment of tin and lead in solder in waste circuit board are studied. The impacts of leaching temperature, solution composition, NaOH concentration and dropping speed of (CH3)3COOH on solder extraction were systematically analysed. The optimum parameters for leaching are as follows: under the conditions of the solution consisting 85% of NaOH and 15% of (CH3)3COOH and leaching temperature of 70 ℃, when NaOH concentration is 5 mol/L, dropping speed of (CH3)3COOH is 2.4 mL/min and leaching time is 20 min, the leaching rates of lead and tin reach 98.79% and 99.23% respectively. After adding 1.5 times the theoretical amount of Na2S 9H2O to the solution, the precipitation rate of lead reaches 98.79%, the purity of 99.23% of PbS products are obtained. After adding 2.5 times the theoretical amount of Ca(OH)2 to the solution, the precipitation rate of tin reaches 93.21%, SnO2 products can be obtained after the heat treatment, which meet the GB / T 26013—2010 standard.

Key words: waste printed circuit board; solder; tert-butyl hydroperoxide; sodium hydroxide

Foundation item: Project(2014DFA90520) supported by the International S&T Cooperation Program of China; Project(2013A090100003) supported by the Special Project on the Integration of Industry, Education and Research of Guangdong Province, China

Received date: 2017-12-18; Accepted date: 2018-04-17

Corresponding author: GUO Xue-yi; Tel: +86-731- 88876255; E-mail: xyguo@csu.edu.cn

(编辑 何学锋)

基金项目:国家国际合作专项项目(2014DFA90520);广东省产学研项目(2013A090100003)

收稿日期:2017-12-18;修订日期:2018-04-17

通信作者:郭学益,教授,博士;电话:0731- 88876255;E-mail:xyguo@csu.edu.cn