文章编号:1004-0609(2007)07-1096-05

CVI炭/炭复合材料微观结构和生长模型

谢志勇1,黄启忠1,梁逸曾2,黄伯云1

(1. 中南大学 粉末冶金国家重点实验室,长沙 410083;

2. 中南大学 化学化工学院,长沙 410083)

摘 要:采用自行设计的多元耦合物理场CVI炉增密炭/炭(C/C)复合材料,用炭毡作为纤维增强体,在坯体内部设计特殊的导电发热层,使坯体内部的温度场、气体反应的中间产物浓度场、电磁场等多元物理场实现耦合,实现坯体的快速增密。采用偏光显微镜研究沉积热解炭的组织结构;用X射线衍射仪研究C/C复合材料的石墨化度和微晶尺寸;用扫描电镜观察材料断口和热解炭沉积表面的形貌;并对CVI热解炭的生长方式进行研究。研究表明:获得SL、RL和带状等多种热解炭结构;不同的结构具有不同的形貌特征,其中SL的断口平整,RL的断口呈沟槽构造;并提出前者为小分子平滑生长模型、后者为大分子锥状生长模型。

关键词:多元耦合物理场CVI;炭/炭复合材料;微观结构;生长模型

中图分类号:TB332 文献标识码:A

Microstructure and growth model of C/C composites by

chemical vapor infiltration

XIE Zhi-yong1, HUANG Qi-zhong1, LIANG Yi-zeng2, HUANG Bai-yun1

(1. State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China;

2. School of Chemistry and Chemical Engineering, Central South University, Changsha 410083, China)

Abstract: Using carbon felt as porous performs, installing special electric layer in the performs forming the grads of temperature and electromagnetism, C/C composites were fabricated by chemical vapor infiltration (CVI) in multi-factor coupling physical fields. The textural of pyrolytic carbons were observed by polarized light microscopy(PLM), and the graphitization degree and microcrystal size of these C/C composites was analyzed by XRD. The micromorphology of fracture and deposition surface was observed by SEM. At last, two kinds of growth mode of pyrolytic carbon were put forward. The results show that rough laminar, smooth laminar and banded structure can be obtained, and their micromorphology, graphitization degree and microcrystal size exist different; The fracture appearance of SL is very flat and smooth, but that of RL is rough and more groove exists. The former is deposited by smoothness growth model of smaller molecule, the latter by taper growth model of bigger molecule.

Key words: multi-factor coupling physical fields CVI; carbon/carbon composites; microstructure; growth model

化学气相渗透(CVI)工艺是制备高性能炭/炭(C/C)复合材料的关键工序之一。C/C复合材料是包含炭纤维和热解炭的二元结构。除了炭纤维本身以及纤维坯体编织结构会对C/C复合材料总体结构和性能产生影响之外,热解炭的显微结构也在一定程度上决定整个材料的综合性能。一般将热解炭分为粗糙层(RL)、光滑层(SL)和各向同性(ISO)等3种典型结构,是对问题抽象后的简化认识,具有较好的可操作性[1-2]。其中分布均匀的高织构RL结构具有较好的摩擦磨损性能,适用于高性能的航空刹车材料,也是当今用量最多的一种,但在CVI过程中,此结构又是较难获得的一种,所以成为目前研究最多的一种结构;SL结构具有较好的力学性能,主要用于一些高温结构件、抗烧蚀件等,此结构相对比较容易获得;ISO结构由于其具有较好的各向同性、生物相容性、致密性,一般用于半导体装备、生物材料、密封材料等,此结构获得的条件一般比较苛刻[3-5]。

不同的工艺条件或炉况往往导致不同的热解炭结构,但热解炭结构的差异最终由其生长方式决定。本文作者在研究多元耦合物理场CVI工艺和热解炭结构关系的基础上[6-11],采用PLM、XRD、SEM等手段对RL、SL等典型结构进行综合表征,然后对2种热解炭的生长方式进行探讨。

1 实验

用炭毡作增强体,坯体的初始密度为0.2 g/cm3,尺寸为260 mm×60 mm×20 mm,在纤维内部或表面等设定部位埋置特定形状的导电层,在自制多元耦合物理场CVI炉[12]中增密C/C复合材料,石油液化气作为碳源气体,N2作载气,温度800~1 000 ℃,炉压范围3~15 kPa,碳源气体体积分数25%~75%。所有的样品均为一次性沉积20 h所得。沉积后的样品经 2 300 ℃、2 h石墨化热处理。在MEF3A金相显微镜下观察热解炭的偏光显微结构;用X射线衍射均峰位法[13]测定材料的石墨化度和微晶尺寸;用扫描电镜对材料断口以及热解炭的沉积表面进行形貌观察。

2 结果和讨论

2.1 组织结构

图1所示为4种典型热解炭的偏光显微结构像。样品A为光滑层结构,其显著特征是视觉效果光滑、呈灰色、裂纹显著、消光十字清晰(图1(a));样品B视觉效果粗糙、呈银灰色、无裂纹、消光十字开叉(图1(b));样品C和D均属于2种以上结构复合形成的带状结构(图1(c)、1(d)),二者的相似之处在于:靠近纤维表面都出现一小圈亮色区,其余大部分区域为颜色较暗的灰色;二者在形貌上则相差较大,前者的表面光滑,后者的结构较为复杂,除了表面粗糙外,在圆环的周边分布有许多凸起的生长锥,还具有炭微树热解炭结构的某些特征[14]。

2.2 XRD分析

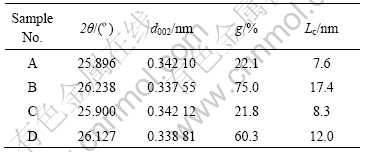

表1所列为图1所示的4个CVI典型样品的XRD均峰位法所得的结构参数。以单晶硅作内标,取C/C

图1 4种典型热解炭结构的偏光显微结构像

Fig.1 Four typical polarized optical micrographs of samples from infiltrations: (a) Sample A, smooth laminar; (b) Sample B, rough laminar; (c) Sample C, binary banded structure; (d) Sample D, ternary banded structure

表1 4种典型C/C复合材料的XRD结构参数

Table 1 XRD structure parameters of four typical C/C composites

复合材料的粉末样品,用日本制造的Rigaku-D/ max-3C型X射线衍射仪扫描C/C复合材料的d002峰,按XRD谱线的峰顶位、重心位和半高宽的中心位所对应的位置得到3个衍射角,根据公式 G=(0.344 0- d002)/(0.344 0-0.335 4)×100%计算d002对应的3个石墨化度值(g),取三者的平均值作为该材料的石墨化度。根据布拉格公式算出晶粒大小Lc的平均值。X射线衍射仪采用铜靶,工作电压为40 kV,工作电流为20 mA[15]。

样品经过2 300 ℃、2 h石墨化处理后,样品A、B、C、D的石墨化度分别为20%、75%、20%和60%左右。可见,偏光下热解炭的亮度是判断高织构热解炭的重要标准,样品B整个热解炭的圆环呈银灰色,其石墨化度一般在75%以上。其次,偏光形貌是判断带状织构高低的重要标准,同为带状结构的样品C和样品D,而且二者亮色和暗色的比例也相近,但其石墨化度也存在显著的差别,如前者为20%,与单一光滑层结构样品A相差无几,后者可达60%以上,比较接近单一的粗糙层结构样品B,二者在偏光下形貌的主要差别是,后者的粗糙度明显高于前者,所以粗糙度越高,其织构也越高。可见,XRD和PLM分析的结果有着较好的对应性。

2.3 SEM断口和沉积表面形貌

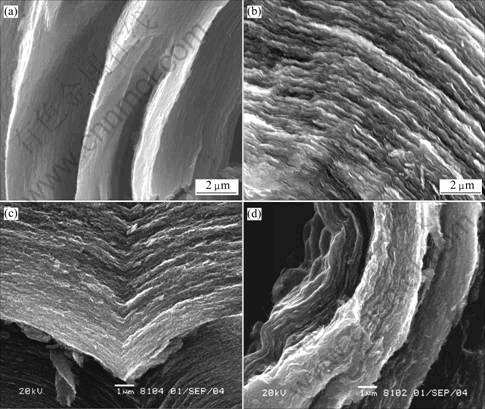

图2所示为本实验中获得的4种典型结构CVI热解炭断口的SEM像(分别对应于图1中的4种结构)。可以看出,光滑层热解炭的断口(图2(a))的显著特点就是光滑、平齐、致密,似层状的构造非常细腻、模糊、层间结合致密;粗糙层结构的断面(图2(b))则非常粗糙,片层构造显而易见,片层的厚度一般在纳米级的范畴,锯齿状或沟壑形貌显著;带状结构主要表现为多元结构,如图2(c)中的二元结构与上述偏光照片形

图2 4种典型结构断口的SEM像

Fig.2 SEM images of fracture morphologies of four typical pyrolytic carbon from infiltrations: (a) Sample A, smooth laminar; (b) Sample B, rough laminar; (c) Sample C, binary banded structure; (d) Sample D, ternary banded structure

成较好的吻合。但在偏光中亮色部分在SEM像中并没有表现明显的锯齿状构造,而图2(d)中则表现出明显的三元结构,内侧片层结构明显,具有粗糙层的特征,中间与外层结构差别不是很明显。

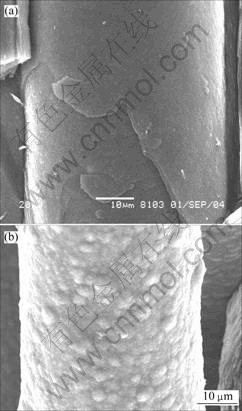

图3所示为2种典型结构热解炭(SL和RL)沉积表面的SEM像。此照片的取样部位均位于沉积坯体的核部围绕单根纤维周围沉积的热解炭(放大倍数相同)。SL结构的沉积表面光滑,RL结构沉积表面是以凸起或粒状的形貌为主。

图3 2种典型结构沉积表面的SEM像

Fig.3 SEM morphologies of deposition surface: (a) Smooth laminar; (b) Rough laminar

光滑层和粗糙层的断口和沉积表面的形貌均存在较大差异,从一个侧面揭示了2种热解炭沉积的过程和特征。首先,2种结构都是以炭纤维为核心均匀沉积,形成如同树木年轮的层状生长模式。其次,光滑层主要是小分子堆积,形成较小尺寸的微晶,小微晶具有较大表面能,相互之间具有较大结合能,无序地堆积使材料具有较大的各向同性度,所以断口和沉积表面光滑、层理细致,层与层之间是紧密化学键结合;粗糙层主要由片层状的大分子堆积,一般由锥状方式生长,即,大分子首先在生长平面的活性位上堆积成锥,锥堆积到一定高度以后,其相互之间的凹部的表明能会逐渐增大,直到超过锥的顶部,于是,凹部的沉积速度随之加快,锥体在平面延伸连接成层,层内的结合强度大,层间相对较弱,断裂时容易形成沟壑构造,而且层越厚,沟壑越深,织构也越高。

以上SEM结果说明,断口和沉积表面的形貌也可作为判断热解炭结构的重要标准。高织构的热解炭一般具有清晰的层状构造和沟壑形貌,而且沟壑越深或层的厚度越大预示着其织构愈高;相反断面愈平滑,则织构愈低。

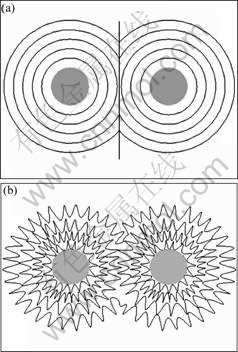

2.4 热解炭的生长模型

通过采用PLM、SEM等手段对热解炭微观结构的观察和分析可知,CVI热解炭的生长模型主要有2种:平滑生长和锥状生长。其生长模型示意图如图4所示。前者的生长表面光滑,生长均匀,生长界面围绕纤维呈规则的同心圆沿着纤维的径向生长,垂直纤维的截面上相邻纤维周围热解炭的交线为直线;该生长方式沉积的热解炭一般为低织构的SL结构,其宏观上一般表现为规则层状生长,但其微观上,石墨微晶的有序度较差、微晶尺寸小、缺陷多;此生长方式的增密速度较快。后者的生长表面呈锥状形貌,在纤维不同径向的生长不是非常均匀,类似炭微树结构的生长模式[16],垂直纤维截面上相邻纤维周围的热解炭也不是直线相交,说明沉积面上的各个点位的沉积速

图4 2种典型CVI热解炭的生长模型

Fig.4 Two typical growth models of pyrolytic carbon by CVI: (a) Smooth growth model; (b) Taper growth model

度不等,高能量的点位出现优先生长,所以表现出不规则的接触线,其增密的速度一般较慢;该生长方式沉积的热解炭,其宏观上生长的规则性较差,但各生长锥都是高有序度、大尺寸微晶的堆积,所以一般为高织构的热解炭,而且随着生长锥高度的增大,热解炭的织构越高。

总之,平滑生长方式所需活化能较低,在沉积表面上能满足生长的活性位数量多,所以其生长速度快、且均匀,但热解炭的织构较低,一般为小分子沉积;锥状生长方式则刚好相反。

3 结论

1) 通过采用PLM、XRD、SEM等手段对多元耦合物理场CVI工艺制备的C/C复合材料的结构进行综合表征,可知,本工艺可以获得SL、RL、炭微树等多种热解炭结构。

2) 提出CVI热解炭的2种典型的生长模型,即平滑生长模型和锥状生长模型。前者一般只能获得低织构热解炭,但沉积速度较快,相邻纤维周围的热解炭为线接触;后者可获得高织构热解炭,但沉积速度较慢,相邻纤维周围热解炭为非线性接触。

REFERENCES

[1] 邹林华, 黄 勇, 黄伯云, 黄启忠. C/C复合材料的显微结构及其与工艺、性能的关系[J]. 新型炭材料, 2001, 16(4): 63-70.

ZOU Lin-hua, HUANG Yong, HUANG Bai-yun, HUANG Qi-zhong. The relationship among microstructures, processing parameters and properties for carbon-carbon composites[J]. New Carbon Materials, 2001, 16(4): 63-70.

[2] Oberlin A. Pyrocarbons[J]. Carbon, 2002, 40: 7-24.

[3] Fitzer E. The future of carbon-carbon composites[J]. Carbon, 1987, 25: 163-167.

[4] Buckley J D, Edie D D. Carbon-carbon materials and composites[M]. Park Ridge, NJ: Noyes Publication, 1993: 12-14.

[5] Buckley J D. Carbon-carbon overview[J]. Ceramic Bulletin, 1988, 67(2): 364-368.

[6] Hu Z J, Zhang W G, Huttinger K J, Reznik B, Gerthsen D. Influence of pressure, temperature and surface area/volume ratio on the texture of pyrolytic carbon deposited from methane[J]. Carbon, 2003, 41: 749-758.

[7] 谢志勇, 黄启忠, 苏哲安, 等. 毡体密度对C/C复合材料增密和结构的影响[J]. 湖南科技大学学报(自然科学版), 2005, 20(2): 41-44.

XIE Zhi-yong, HUANG Qi-zhong, SU Zhe-an, et al. Effects of perform density on CVI rate and microstructure of carbon/carbon composites[J]. Journal of Hunan University of Science and Technology, 2005, 20(2): 41-44.

[8] 谢志勇, 黄启忠, 苏哲安, 等. 碳源对CVI炭/炭复合材料致密和结构的影响[J]. 新型炭材料, 2005, 20(2): 171-177.

XIE Zhi-yong, HUANG Qi-zhong, SU Zhe-an, et al. The influence of hydrocarbon gas on the density and microstructure of C/C composites formed by chemical vapor infiltration[J]. New Carbon Materials, 2005, 20(2): 171-177.

[9] 谢志勇, 黄启忠, 苏哲安, 等. 耦合物理场CVI制备炭/炭复合材料及其机理[J]. 无机材料学报, 2005, 20(5): 1201-1207.

XIE Zhi-yong, HUANG Qi-zhong, SU Zhe-an, et al. Preparation of C/C composites by CVI with multi-factor coupling physical fields and deposition mechanism[J]. Journal of Inorganic Materials, 2005, 20(5): 1201-1207.

[10] 谢志勇, 黄启忠, 苏哲安, 等. 耦合物理场CVI快速增密C/C复合材料及其动力学研究[J]. 复合材料学报, 2005, 22(4): 47-52.

XIE Zhi-yong, HUANG Qi-zhong, SU Zhe-an, et al. Preparing C/C composites by CVI with multi-factor coupling physical fields and discussing the dynamic process[J]. Acta Material Composites Sinica, 2005, 22(4): 47-52.

[11] Zhang W G, Hu Z J, Hüttinger K J. Chemical vapor infiltration of carbon fiber felt: optimization of densification and carbon microstructure[J]. Carbon, 2002, 40: 2529-2545.

[12] 黄启忠, 谢志勇, 苏哲安, 等. 多元耦合物理场作用下化学气相沉积快速制备炭/炭复合材料的方法[P]. 中国专利, 200410029034X, 2004.

HUANG Qi-zhong, XIE Zhi-yong, SU Zhe-an, et al. A rapid densification method of chemical vapor infiltration for the fabrication of carbon/carbon composites by multi-factor coupling physical fields CN 200410029034X[P]. 2004.

[13] 汤中华, 周桂芝, 熊 杰, 等. 炭/炭复合材料石墨化度的XRD均峰位法测定[J]. 中国有色金属学报, 2003, 13(6): 1435-1440.

TANG Zhong-hua, ZHOU Gui-zhi, XIONG Jie, et al. Measurement of graphitization degree of carbon-carbon composites by average X-ray diffraction angle method[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(6): 1435-1440.

[14] Ajayan P M, Nugent J M, Siegel R W, Wei B, Kohler-Redlich P H. Growth of carbon micro-trees[J]. Nature, 2000, 404: 243.

[15] 张福勤. 航空刹车用C/C复合材料石墨化度的研究[D]. 长沙: 中南大学, 2002.

ZHANG Fu-qin. The study on graphitization degree of C/C composites used for aircraft brakes[D]. Changsha: Central South University, 2002.

[16] Jung Y J, WEI Bing-qing, Nugent J, Ajayan P M. Controlling growth of carbon microtrees[J]. Carbon, 2001, 39: 2195-2201.

(编辑 陈爱华)

基金项目:国家重点基础研究发展计划资助项目(2006CB600901)

收稿日期:2006-10-17;修订日期:2007-04-02

通讯作者:谢志勇,博士;电话:0731-8877671;E-mail: xiezhiyong310@tom.com