氧化铈改性沸石催化氧化工业废气中PH3

宁平1,黄小凤1,周涛1,刘伟文1,范莹莹2,覃扬颂1

(1. 昆明理工大学 环境科学与工程学院,云南 昆明,650500;

2. 昆明理工大学 理学院,云南 昆明,650500)

摘要:为了综合利用泥磷制取次磷酸钠反应尾气中高浓度的PH3,进行了以改性沸石为催化剂催化氧化PH3的研究。考察载气流量、吸收液pH、反应温度、过氧化氢体积分数及催化剂用量对磷化氢吸收及转化效率的影响。结果表明:载气最佳流量为20 mL/min; 较佳的pH为13;较适宜的反应温度为20 ℃;当加入过氧化氢体积分数为6%时对磷化氢的吸收效率最高;催化剂用量达5 g/L时可获得较佳的转化效果。在上述条件下磷化氢吸收率维持73%以上的时间为120 min,磷化氢转化率为40.4%,但因催化活性组分在过氧化氢溶液中溶出,导致催化剂失活,其最多可重复利用3次。

关键词:氧化铈;沸石;催化氧化;磷化氢;次磷酸钠

中图分类号:X701 文献标志码:A 文章编号:1672-7207(2013)11-4753-06

Catalytic oxidation PH3 in industrial waste gas with CeO2-modified zeolite catalyst

NING Ping1, HUANG Xiaofeng1, ZHOU Tao1, LIU Weiwen1, FAN Yingying2, QIN Yangsong1

(1. Faculty of Environmental Science and Engineering, Kunming University of Science and Technology, Kunming 650500, China;

2. Faculty of Science, Kunming University of Science and Technology, Kunming 650500, China)

Abstract: In order to realize the comprehensive utilization of PH3 produced by the preparation of sodium hypophosphite from phosphorous sludge, multiphase catalytic oxidation process of PH3 with mixed solution of model-Ce zeolite as catalyzer was studied. The influence laws of gas flow rate, pH value, temperature, H2O2 concentration and catalyst amount on the absorption and conversion efficiency of PH3 were investigated. The results show that optimal reaction conditions are: pH=13.0, gas flow rate of 20 mL/min, reaction temperature of 20 ℃, H2O2 concentration of 6%, catalyst amount of 5 g/L. Under these conditions, the absorption efficiency of PH3 can reach 73% within 120 min, and the conversion efficiency reaches 40.4%. The active component dissolved in the hydrogen peroxide causes catalyst deactivation and the catalyst just could be reused three times.

Key words: cerium oxide; zeolite; catalytic oxidation; phosphine; sodium hypophosphite

泥磷是黄磷生产过程产生的一种含磷的有害混合物,主要由P4、粉尘杂质和水组成[1]。随着磷化工的发展,泥磷的产量逐年增加,从而引发的堆存问题日益突出。此外,泥磷中含有大量的磷元素,如不加以回收或综合利用,将造成极大的资源浪费,同时泥磷又是一种危险固废,具有腐蚀性,存放在空气中会燃烧,生成有毒的P2O5[2]。因此,妥善有效地处理或处置这种含磷有害物,已成迫在眉睫的问题。前期研究发现:利用泥磷和碱制取次磷酸钠是一种有效的泥磷综合利用方法[3]。此反应过程温度不高,能源消耗低,并且次磷酸钠作为一种还原剂,被广泛应用于化学镀[4-6]、有机合成[7]、食品加工和保鲜[5, 8]及水处理[9]等行业,具有较高的经济附加值。但这种方法会使泥磷中约20%的磷单质转化为磷化氢进入到尾气中[10],如果不加回收利用,则可能引起二次污染。目前,国内外净化磷化氢的方法很多,主要分为燃烧法[11-12]、吸附法[13-14]和化学吸收法[15-18],净化方法的选择根据磷化氢废气的性质及来源而定,对于总量大、浓度高的常采用化学吸收法回收其中的磷资源[19]。泥磷制取次磷酸钠产生的磷化氢废气浓度较高,为了有效回收尾气中的磷,本研究采用多相催化氧化法回收废气中的磷化氢,利用过氧化氢溶液作吸收液,将尾气中的磷化氢氧化成具有较高附加值的次磷酸钠和亚磷酸钠,从而增加了次磷酸钠产率,使资源得到有效利用[10, 20-21]。由于过氧化氢与磷化氢反应速度较慢,吸收率偏低,因此,本文作者利用催化剂以加快反应速度,进而提高吸收效率。采用浸渍法制备了负载5.78%(质量分数)Ce的改性沸石催化剂,在H2O2为氧化剂的条件下,用以催化氧化PH3,探讨各个影响因素对其吸收及转化效率的影响。

1 实验

1.1 催化剂的制备

将载体4A沸石经多次洗涤后于110 ℃下干燥,去除其中的机械及可溶性杂质。预处理后的4A沸石按质量比1:20加入到配制好的0.1 mol/L Ce(NO3)3溶液中,常温下搅拌6 h,浸渍18 h,过滤后滤饼烘干,于450~500 ℃焙烧3 h,待冷却后筛分125 μm,焙烧后催化剂活性组分以氧化铈的形式存在于载体表面,得到实验用催化剂。

1.2 磷化氢催化氧化实验

磷化氢催化氧化实验流程如图1所示。实验以泥磷为原料制取次磷酸钠,反应尾气中含有大量高浓度PH3,以N2为保护气,由钢瓶压力提供动力。 按一定配比将泥磷、氢氧化钙、氢氧化钠等加入到隔氧及带搅拌装置的反应器中,用电热套加热至一定温度,进行次磷酸钠的制取反应,反应过程产生的尾气先经缓冲瓶调节流量混合均匀,接着进入装有85%(质量分数)浓磷酸的洗气瓶,起到去除尾气中的杂质、降低尾气温度的作用,然后在装有过氧化氢溶液和催化剂的吸收瓶中进行催化转化,利用恒温水浴锅控制反应温度,催化氧化后的气体经含浓硫酸的尾端吸收瓶进一步吸收后排空。由于进口PH3浓度变化较大,为了准确有效地监控磷化氢吸收效果,在吸收瓶前后分别设采样点,利用钼酸铵分光光度法测定PH3的浓度。

碱性条件下,吸收瓶中反应如下[9]:

2H2O2+PH3+OH-=H2PO2-+3H2O (1)

3H2O2+PH3+2OH-=HPO32-+5H2O (2)

图1 实验装置流程图

Fig.1 Flow sheet of experiment

1.3 评价指标

以过氧化氢对磷化氢的吸收率、磷化氢中磷元素转化为产物次磷酸钠及亚磷酸钠的转化率作为评价催化剂性能的重要指标,其中,产物次磷酸钠及亚磷酸钠用碘量法进行分析测定。磷化氢吸收率计算见式(1),磷化氢转化率计算见式(2)。

δ=[(ρ0-ρe)/ρ0]×100% (1)

η=(n1/n2)×100% (2)

式中:δ为磷化氢的吸收率;ρ0为磷化氢进口质量浓度,mg/m3;ρe为磷化氢出口质量浓度,mg/m3;η为磷化氢的转化率;n1为次磷酸钠或亚磷酸钠中的磷质量,g;n2为磷化氢中磷质量,g。

2 结果与讨论

2.1 载气流速对多相催化氧化反应的影响

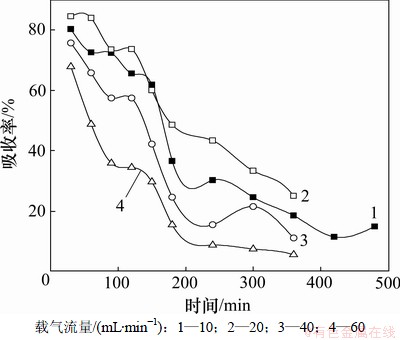

当反应温度为20 ℃,不同载气流量对PH3吸收及转化效率的影响分别见图2和图3。

由图2和图3可知,在载气流速为20 mL/min时PH3吸收及转化效率皆最高,随着载气流速的增大,PH3吸收及转化效率降低,当载气流速增大到40 mL/min时吸收及转化效率迅速下降,这是因为随着气体流量的增加,气体在吸收液中的停留时间缩短,PH3的溶解和氧化反应不完全,降低了吸收及转化的效率。

图2 不同载气流量对磷化氢吸收率的影响

Fig.2 Effect of different carrier gas flow rate on absorption rate of PH3

图3 不同载气流量下磷化氢的转化率

Fig.3 Conversion rate of PH3 at different carrier gas flow rate

随着载气流速的不断减小,气液接触的时间逐渐延长,PH3的吸收效率提高,而当在气流速控制在20 mL/min时,吸收液对PH3吸收效率高于85%且可维持60 min。当流速为10 mL/min时,PH3吸收及转化效率皆低于20 mL/min时,据此确定适宜的载气流速为20 mL/min。

2.2 pH对多相催化氧化反应的影响

在磷化氢的多相催化氧化反应中,溶液的pH是重要的控制参数。实验考察了pH对磷化氢吸收率和转化率的影响,结果见图4和5。

从图4和5可看出,吸收液的pH对PH3的吸收及转化效率有较大影响, PH3的吸收转化效率随pH的增大有大幅度的提高,当吸收液pH为13时,PH3的吸收及转化效率最高,可见强碱有利于PH3的吸收及转化。因为OH-在反应中参与由H2O2 解离出的·OH自由基的链反应,在酸性及弱碱条件下,H+浓度高,链反应以及H2O2的解离皆受到抑制,产生的·OH数量少,吸收PH3的有效基团变少,致使PH3直接与H2O2作用,反应速率减慢,PH3的吸收及转化效率较低。pH升高,反应液中的OH-含量增多,参与反应并促进·OH的生成,使得低选择性且高氧化性的·OH数量增多,以·OH间接氧化反应所占比例增大,反应速率加快,吸收及转化效率随着升高[22]。此外,PH3在氧化过程中会产生大量的中间产物,在酸性或中性条件下会以分子形态(如H3PO2和H3PO3)存在。各分子内部或分子之间存在氢键作用,造成反应阻力大,反应速率小;而在碱性条件下主要以离子形态存在,反应阻力小,反应速率大[9]。因此确定适宜的吸收pH为13。

图4 不同pH对磷化氢吸收率的影响

Fig.4 Effect of different pH on absorption rate of PH3

图5 不同pH下磷化氢的转化率

Fig.5 Conversion rate of PH3 at different pH

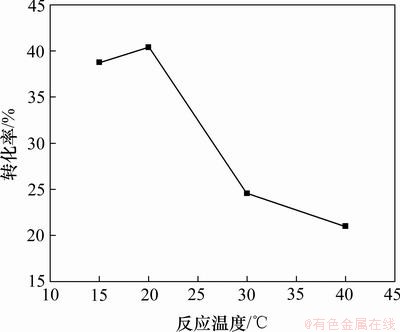

2.3 温度对多相催化氧化反应的影响

升高温度,有利于提高化学反应速率,但不利于化学传质过程。温度对PH3吸收转化效率的影响如图6和7所示。从图6和7可以看出,当温度从15 ℃升至20 ℃后,吸收液对PH3的吸收转化作用明显增强,说明温度升高有利于提高反应速率,化学反应速率为此时的控制步骤,当温度为20~40 ℃时,吸收液对PH3的吸收效率及PH3的转化效率随温度的升高而逐渐降低,其原因可能是因为,随着温度升高,PH3的物理溶解过程会变弱,PH3的溶解度降低,从而降低了气体从气相向液相传质的速率,气液接触时间减少,最终使PH3的吸收转化效率降低。因此可以看出化学传质是此反应的控制步骤,而化学反应速率对此反应影响不大,低温对磷化氢的吸收较为有利。故较佳的反应温度为20 ℃。

图6 不同温度对磷化氢吸收率的影响

Fig.6 Effect of different temperatures on absorption rate of PH3

图7 不同反应温度下磷化氢的转化率

Fig.7 Conversion rate of PH3 at different temperatures

2.4 催化剂用量对多相催化氧化反应的影响

实验考察了不同催化剂用量(催化剂用量为催化剂质量与H2O2的体积比)对磷化氢吸收率和转化率的影响,结果见图8和图9。由图8和9可知,实验范围内最佳的催化剂用量为5 g/L,催化剂用量过高或过低都不利于PH3的催化转化。催化剂用量过低,催化剂活性中心与吸收液接触面积有限,不利于催化作用的产生;催化剂用量过高,催化剂催化分解H2O2速率过快,消耗过多的H2O2,使后续实验有效的H2O2浓度减小,不利于催化作用的进行,进而使PH3的吸收及转化效率也相应减少,故适宜的催化剂加入量为5 g/L。

图8 不同催化剂用量对磷化氢吸收率的影响

Fig.8 Effect of different catalyst amounts on absorption rate of PH3

图9 不同催化剂用量下磷化氢的转化率

Fig.9 Conversion rate of PH3 with different catalyst amounts

2.5 过氧化氢体积分数的影响

H2O2作为此反应的氧化剂,H2O2含量极大的影响反应的进行。实验考查了不同H2O2含量对PH3吸收及转化效率的影响,结果见图10和图11。

图10 不同过氧化氢体积分数对磷化氢吸收率的影响

Fig.10 Effect of different volume fraction of H2O2 on absorption rate of PH3

图11 不同过氧化氢体积分数下磷化氢的转化率

Fig.11 Conversion rate of PH3 with different volumes fraction of H2O2

由图10和11可知,实验范围内最佳的H2O2含量(体积分数)为6%,H2O2含量过高或过低对吸收及转化反应都不利。当H2O2含量为3%时,PH3的吸收及转化效果最差,由于H2O2含量过低会使大量的PH3分子得不到氧化,不利于PH3的转化及吸收。H2O2含量过高,H2O2分子会占据大量活性中心位,与PH3分子发生竞争,也不利于催化剂表面PH3的氧化,从而不利于PH3的吸收及转化反应。而图10中,120 min后,H2O2含量为6%时的PH3吸收率下降趋势较H2O2含量为9%及12%时的快,这可能与H2O2的消耗有关,据此确定适宜的H2O2含量为6%,此外,在实际应用时应及时补充H2O2,使其含量维持在6%。

2.6 催化剂的重复使用对催化氧化的影响

负载型催化剂在溶液中使用,会有活性组分溶出的问题。活性组分溶出后,催化剂催化性能将受到很大的影响。实验考察了催化剂的重复使用情况,结果见图12。由图12可以看出,重复使用催化剂3次后,PH3的转化率由最初的40.4%下降到25.7%,已经接近空白4A沸石作用时的转化率23.7%;说明催化剂重复使用3次后,活性组分接近全部溶出。

图12 催化剂重复使用对转化率的影响

Fig.12 Effect of repeat-used catalyst on conversion rate of PH3

3 结论

(1) 氧化铈改性沸石(铈负载量为5.78%)催化氧化磷化氢的最佳反应条件为:载气流量20 mL/min, pH 13,反应温度20 ℃,过氧化氢体积分数6%,催化剂用量5 g/L。在此条件下磷化氢吸收率维持在73%以上的时间为120 min,磷化氢转化率为40.4%。

(2) 催化剂可重复利用3次,由于活性组分的溶出,导致催化剂催化活性降低。

参考文献:

[1] 胡若鹏, 黄小凤, 宁平, 等. 分散剂十二烷基苯磺酸钠对泥磷制取次磷酸钠的影响[J]. 资源开发与市场, 2008, 24(5): 388-389.

HU Ruopeng, HUANG Xiaofeng, NING Ping, et al. Effect of SDBS on producing sodium hypophosphite by phosphorous sludge[J]. Resource Development & Market, 2008, 24(5): 388-389.

[2] 吴江. 一种从泥磷中回收黄磷的工艺: 中国, CN95106266.2[P]. 1995-05-24.

WU Jiang. A process for yellow phosphoric recovery from phosphorous sludge: China, CN95106266.2[P]. 1995-05-24.

[3] 高慧敏, 宁平, 黄小凤, 等. 泥磷制取次磷酸钠实验研究[J]. 云南化工, 2004, 31(5): 15-17.

GAO Huimin, NING Ping, HUANG Xiaofeng, et al. Experimental study on the preparation of sodium hypophosphite from phosphorus sludge[J]. Yunnan Chemical Technology, 2004, 31(5): 15-17.

[4] Mimani T, Mayanna S M. Study of the role of sodium hypophosphite in electroless nickel bath solution[J]. Journal of Chemical Sciences, 1997, 109(3): 203-209.

[5] 黎德育, 李宁, 戴长松. 次磷酸钠性质与应用[C]// 第十届全国化学镀会议, 长沙, 2010: 74-80.

LI Deyu, LI Ning, DAI Changsong. Properties and application of sodium hypophosphite[C]// 10th National Conference on Electroless Plating. Changsha, 2010: 74-80.

[6] Hsu H F, Tsai C L, Lee C W, et al. Mechanism of immersion deposition of Ni-P films on Si(100) in an aqueous alkaline solution containing sodium hypophosphite[J]. Thin Solid Films, 2009, 517(17): 4786-4791.

[7] 范德明, 曾广建, 徐社阳, 等. 一种复合催化剂及其在制备浅色松香酯中的应用: 中国, CN200810026951.0[P]. 2008-03-2l.

FAN Deming, ZENG Guangjian, XU Sheyang, et al. Application of composite catalyst in preparation of light-colored rosin ester: China, CN200810026951.0[P]. 2008-03-2l.

[8] 傅生. 食用菌、果蔬保鲜袋的制作及使用[J]. 吉林农业, 2006(4): 31.

FU Sheng. Fabrication of storage bags and application in edible fungi, fruit and vegetable preservation[J]. Jilin Agricultural, 2006(4): 31.

[9] 吴洪特, 于兵川, 盛锡军. 新型低磷水处理剂的合成及性能研究[J]. 工业水处理, 2005, 25(7): 20-22.

WU Hongte, YU Bingchuan, SHENG Xijun. Study on the synthesis and performance of low phosphate content water treatment agent[J]. Industrial Water Treatment, 2005, 25(7): 20-22.

[10] 王成俊, 郭爱红, 王福生, 等. 次磷酸钠工业生产过程中PH3尾气处理技术[J]. 天津化工, 2003, 17(5): 37-38.

WANG Chenjun, GUO Aihong, WANG Fusheng, et al. Treatmental technology of PH3 wastegas in the process of industrial sodium hypophosphite production[J]. Tianjin Chemical Industry, 2003, 17(5): 37-38.

[11] Elliant B, Balma F, Johnson F. Exhaust gas incineration and the combustion of arsine and phosphine[J]. Solid State Technology, 1990, 33(1): 89-92.

[12] 王惠平, 唐忠松. 次磷酸钠生产中“三废”的综合治理[J]. 化学世界, 1999(3): 159-162.

WANG Huiping, TANG Zhongsong. Comprehensive management of waste materials in the production process of sodium hypophosphite[J]. Chemical World, 1999(3): 159-162.

[13] Juergen W. Absorbent mass for phosphine. WO 00/21644 A3[P]. 2000-04-02.

[14] 陈中明, 武立新, 魏玺群, 等. 变温和变压吸附法从黄磷尾气净化回收一氧化碳[J]. 天然气化工, 2001, 26(4): 24-26, 39.

CHEN Zhongming, WU Lixin, WEI Xiqun, et a1. Purification and recovering of CO from yellow phosphorus tail gas by TSA and PSA[J]. Natural Gas Chemical Industry, 2001, 26(4): 24-26, 39.

[15] 程建忠, 张英喆, 张宝贵. 次磷酸钠生产中磷化氢尾气处理技术的研究[J]. 南开大学学报: 自然科学版, 2001, 34(2): 31-34

CHENG Jianzhong, ZHANG Yingzhe, ZHANG Baogui. Study on the treatment of PH3 in the process of making sodium hypophosphite[J]. Acta Scientiarum Naturalium Universitatis Nankaiensis, 2001, 34(2): 3l-34.

[16] 张建华. 硫化氢、磷化氢脱除新工艺[J]. 河南化工, 1995(10): 21-22.

ZHANG Jianhua. A new technics wipe of PH3 and H2S[J]. Henan Chemical Industry, 1995(10): 2l-22.

[17] TimHerman, Soden S. Efficiently handing effluent gases through chemical scrubbing[J]. AIP ConfPro, 1988, l66: 99-108.

[18] 熊辉, 杨晓利, 李光兴. 次磷酸钠氧化脱出黄磷尾气中的硫、磷杂质[J]. 化工环保, 2002, 22(3): 161-164.

XIONG Hui, YANG Xiaoli, LI Guangxing. Removal of sulfur and phosphorus from tail gas in yellow phosphorus production by sodium hypochlorite oxidation process[J]. Environmental Protection of Chemical Industry, 2002, 22(3): 161-164.

[19] 张永. 黄磷尾气催化氧化净化系列催化剂开发研究[D]. 昆明: 昆明理工大学环境科学与工程学院, 2006: 14.

ZHANG Yong. Explotation and research of series catalysts for purifying yellow phosphoric tail gas by catalytic oxidation[D]. Kunming: Kunming University of Science and Technology. School of Environmental Science and Engineering, 2006: 14.

[20] 丁百全, 徐周, 房鼎业, 等. 熏蒸杀虫余气PH3的吸收净化研究[J]. 环境污染治理技术及设备, 2003, 4(1): 29-32.

D1NG Baiquan, XU Zhou, FANG Dingye, et al. Study of absorbing purification for phosphine from fumigated disinfestation of pests[J]. Techniques and Equipment for Environmental Pollution Control, 2003, 4(1): 29-32.

[21] 卡尔L·约斯. Matheson气体数据手册[M]. 陶万鹏, 黄建彬, 朱大方, 译. 北京: 化学工业出版社, 2003: 5-60.

Jos C L. Matheson gas date book[M]. TAO Pengwan, HUANG Jianbin, ZHU Dafang, Trans. Beijing: Chemical Industry Press, 2003: 5-60.

[22] 王楠. 纳米级TiO2/沸石/UV催化臭氧化处理水中硝基苯的研究[D]. 苏州: 苏州科技学院环境科学与工程学院, 2008: 43-44.

WANG Nan. Degradation of phenol by nano-TiO2/zeolite/UV catalyzed ozonation in aqueous solution[D]. Suzhou: Suzhou University of Science and Technology. Faculty of Environmental Science and Engineering, 2008: 43-44.

(编辑 赵俊)

收稿日期:2012-12-10;修回日期:2013-03-01

基金项目:云南省教育厅科学研究基金资助项目(2010Z011);昆明理工大学分析测试基金资助项目(2010160,2011316)

通信作者:宁平(1958-),男,山西太原人,教授,博士生导师,从事环境污染控制研究;电话:13708409187;E-mail: hxfkm@sina.com,ningping58@sina.com