DOI: 10.11817/j.issn.1672-7207.2017.12.023

单楔形掏槽爆破腔体时空演化及应用

胡建华1, 2,杨春1, 2,周科平1, 2,周炳任3,张绍国3

(1. 中南大学 资源与安全工程学院,湖南 长沙,410083;

2. 湖南省深部金属矿开发与灾害控制重点实验室,湖南 长沙,410083;

3. 广西华锡集团股份有限公司,广西 河池,547200)

摘要:为改善矿山巷道掘进掏槽爆破现状,采用AUTO CAD与ANSYS联合建模技术构建垂直单楔形掏槽爆破数值模型,运用显式动力分析软件LS-DYNA定义岩石单元失效获得掏槽腔体扩展演化过程。通过多方位剖视掏槽腔体,从时空演化角度研究垂直单楔形掏槽在铜坑矿阶段运输巷道掘进工程中的适用性。研究结果表明:AUTO CAD与ANSYS联合建模技术可克服ANSYS对于复杂模型构建的缺点,实现巷道掏槽精细化数字建模;定义岩石单元失效使得掏槽腔体演化过程更直观,整体上形成双向主次的喇叭状掏槽腔体结构,腔体空间上X和Y向呈三角形分布,Z向不同段表现出不同的形态;应力波叠加作用对孔底附近掏槽腔体形状影响显著,靠近掌子面附近腔体形态主要受炮孔空间布置方式影响,为提高爆破的效果,辅助爆破可以适当倾斜布置;垂直单楔形掏槽体积比直孔桶形掏槽体积明显增大,其有效掘进进尺2 m,效率比达91%;辅助孔与掏槽孔起爆时间应控制在毫秒级范围内。

关键词:掏槽爆破;巷道掘进;时空演化;联合建模;数值模拟

中图分类号:TD235 文献标志码:A 文章编号:1672-7207(2017)12-3309-07

Temporal-spatial evolution and application of blasting cavity of single wedge cutting

HU Jianhua1, 2, YANG Chun1, 2, ZHOU Keping1, 2, ZHOU Bingren3, ZHANG Shaoguo3

(1. School of Resources and Safety Engineering, Central South University, Changsha 410083,China;

2. Hunan Key Laboratory of Mineral Resources Exploitation and Hazard Control for Deep Metal Mines,Changsha 410083, China;

3. Guangxi Huaxi Group Co. Ltd., Hechi 547200, China)

Abstract: In order to change the present situation of narrow cutting cavity, the model of single wedge cutting blasting was established by combining AUTO CAD with ANSYS. The explicit dynamic software LS-DYNA was used to simulate cavity extension. From the aspects of temporal and spatial evolution with multi-direction cutaway views, the applicability of vertical single wedge cutting blasting for TONGKENG mine haulage roadway excavation was researched. The results show that joint modeling with AUTO CAD and ANSYS can overcome the shortcomings of ANSYS for complex model modeling, and achieve refined digital modeling for roadway. Cavity extension is more intuitive when elements failure is defined, which contributes to the analysis of cutting effect. The bidirectional primary and secondary trumpet-shaped cavity is formed with the outlines of triangle in horizontal and longitudinal sections. Meanwhile, there is different outlines in different vertical sections. The superposition of blasting stress waves has remarkable effect on the shape of cavity that is close to the hole bottom, and the shape of cavity near excavating face is influenced by the layout of blast holes markedly. For improving the blasting effect, the layout of auxiliary holes can be adjusted to sloping appropriately. The volume of this cavity is larger than that of the cylinder cutting. Therefore, the vertical single wedge cutting blasting is capable of improving the cutting present situation. Its footage keeps 2 m and efficiency ratio is 91%. Furthermore, the time lag between the denotations of auxiliary holes and cutting holes should be kept in the scope of milliseconds.

Key words: cutting blasting; roadway excavation; temporal and spatial evolution; joint modeling; numerical simulation

在地下金属矿山钻爆法巷道掘进过程中,掏槽腔为辅助孔起爆提供了新的自由面,进而削弱了岩体内部夹制作用,对改善辅助孔起爆条件极为有利[1]。针对掏槽孔起爆仅有1个自由面、碎岩条件差的现状,需探求一种高效掏槽方法。戴俊等[2-5]采用工程试验或数值模拟等方法对三角柱直眼掏槽、双螺旋直眼掏槽、楔形掏槽、锥形掏槽等掏槽方式进行了研究。黄宝龙[6]对目前国内外岩巷掘进掏槽爆破研究现状进行了综述,归纳了岩巷掏槽爆破的理论与试验研究状况及掏槽技术的工程应用情况,介绍了一种新的掏槽技术即准直孔掏槽技术。单仁亮等[7-8]运用相似理论建立了准直眼掏槽爆破实验模型,确定了最优爆破参数,并将现场试验方案应用于工程实践,效果良好。徐刚等[9]在楔形掏槽眼中间增加一组辅助掏槽眼,以扩大掏槽眼自由面,减小抵抗线。优化后的参数在工程实践中不仅提高了掘进循环进尺,而且降低了巷道材料消耗。巷道掘进掏槽爆破的工程试验研究成本较高,采用相似模型试验研究受尺寸效应影响具有一定的局限性,且耗时耗力[10-11]。显式动力分析软件LS-DYNA在爆破参数优化及爆破方案适用性研究方面应用广泛[12]。于蕾等[13]对2种不同装药的桶形掏槽爆破方式进行了数值模拟对比分析,在此基础上结合现场条件对这2种掏槽爆破方式的模拟结果进行了试验验证,为矿山高效掘进提供了技术支持。潘先峰等[14]利用有限元软件 LS-DYNA 对掏槽爆破扩腔过程进行了数值仿真,根据不同时刻炸药物质的膨胀过程分析了爆破空腔的形成过程,数值模拟计算结果与现有的理论分析结果基本相符。在工程实践中,掏槽腔体是在炸药爆破作用下岩体中原岩裂隙及爆生裂隙互相贯通,岩体发生破碎并向掌子面抛掷的结果。许多研究者采用数值模拟方法在研究掏槽扩腔过程中未考虑岩石单元失效,仅从爆生物质膨胀过程或应力应变角度分析掏槽效果,实际掏槽空间形成过程无法直观展示。为此,本文作者采用显式动力分析软件LS-DYNA通过定义单元失效,对巷道掘进过程中的掏槽腔形成过程直观显现,以探究垂直单楔形掏槽的效果,分析单楔形掏槽爆破的工程效果,以便为矿山巷道工程提供高效、适用的掏槽工艺参数。

1 工程背景

铜坑矿是广西华锡集团股份有限责任公司的主要矿山企业之一,年产近200万t。井下主要采用Simba-261潜孔钻机以及国内先进的宣化钻机、 CTX-6B铲运机以及井下卡车出矿等大型设备生产工艺。为满足井下大型无轨运输设备运行条件要求,采用大断面阶段运输巷道,断面长×宽为4 500 mm×3 800 mm。目前,生产主要集中在92号矿体405水平及以下水平,围岩多为层状硅质灰岩体,岩石抗压强度最大达153 MPa;坚固岩石的普氏系数为I和II级,凿岩性差,爆破性好且崩落围岩块度均匀。但受到层状结构的影响,岩体爆破效果差。为控制巷道拱顶断面轮廓,在阶段运输巷道延伸工程中,在拱顶预留厚度为800 mm的光爆层,层内采用二步精细爆破法施工。巷道掘进循环进尺2 200 mm,装药孔径42 mm。

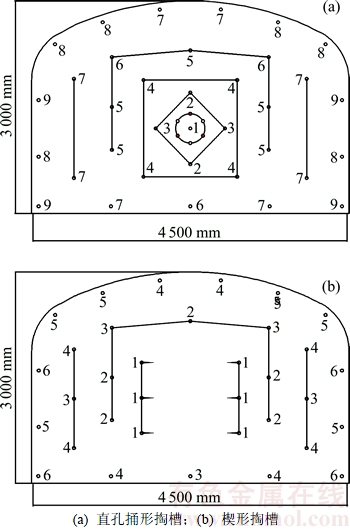

在巷道掘进中采用直孔桶形掏槽技术,该法掏槽孔与大孔径诱导空孔间隔布置,根据岩体性质,掏槽孔一般为3~6个。桶形掏槽特点是炮孔均垂直于掌子面,施工方便,炮孔布置方式如图1所示。中央预留1个诱导空孔,外围3个装药孔与诱导空孔间隔布置,1次掏槽体积受限,后续辅助孔爆破自由面较小,需进行2次爆破扩槽。随着矿山生产强度增大,开拓和采准工程的滞后性更加突出,改进矿山掘进掏槽工艺、提高矿山巷道工程的效率已经成为矿山发展的必然 选择。

拟改用垂直单楔形掏槽方式提高矿山巷道掘进效率。垂直单楔形掏槽孔由左、右对称的2排炮孔组成,炮孔与掌子面呈一定角度,这种结构对掏槽腔内岩石抛掷极有利。其优点是:所需掏槽孔数少,掏槽体积大;当巷道断面一定时,减少了矿山爆破钻孔数量,有利于提高爆破凿岩效率,提高掘进工效。运用LS-DYNA分析掏槽腔形成过程,分析铜坑矿采用垂直单楔形掏槽爆破的可行性。

图1 直孔桶形掏槽和单楔形掏槽爆破设计方案图

Fig. 1 Layout of cylinder cutting and single wedge blasting holes

2 数值模型构建

2.1 数值模型联合构建

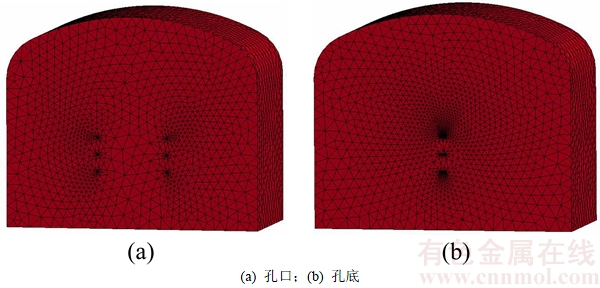

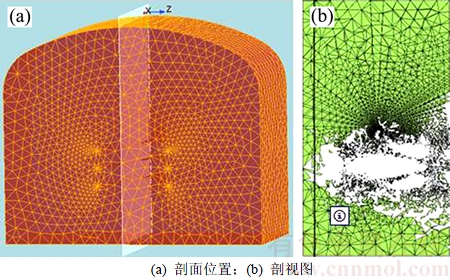

沿巷道走向取1个循环进尺长度作为研究域,根据铜坑矿455水平岩体性质并结合楔形掏槽主要参数,在AUTO CAD中建立垂直单楔形掏槽爆破炮孔布置方式三维模型。模型中的巷道边界为曲面样条曲线,难以实现ANSYS精细构建。将炮孔及巷道模型CAD文件输出为“*.sat”格式导入ANSYS进行模型修复[15-16],以实现巷道拱顶弧形轮廓样条曲线的精细化数字建模。通过MAT_ADD_EROSION关键字[17-18]定义岩石单元失效来直观展现掏槽腔体扩展时空演化过程。考虑到单元尺寸过大将导致模拟结果精度降低,而小尺寸单元会导致单元数量剧增,大幅增加计算成本的现状,采用模型框线定长分段的方法,经过多次调试最终确定图2所示网格模型。模型由3 320 667个四面体单元构成,单元类型为3D SOLID164。除掌子面定义为自由面外,其他边界均为无反射边界条件。

图2 单楔形掏槽爆破数值计算网格模型

Fig. 2 Element models of single wedge cutting blasting

2.2 算法选择

LS-DYNA提供了爆破大变形动力学问题共节点、接触和流固耦合的3种算法[19]。前2种算法在模型构建及网格划分方面并无太大差异,而流固耦合算法要求流体与固体之间需有一定范围的网格重叠区域,模型构建及网格划分相对耗时耗力。共节点算法与接触算法都属于Lagrange算法,前者不同材料间相互作用通过材料边界共用节点传递,后者需通过修改关键字定义接触实现载荷传递。基于网格数量较多,综合考虑各算法优缺点,采用共节点算法进行模拟可节省计算成本。模拟药卷直径为25 mm,通过试算调整网格分布解决了网格畸变所引起的计算终止现象。求解时间参数设定为3 ms。

2.3 材料属性

2.3.1 岩石材料

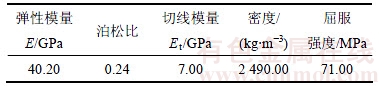

为提高计算的精确性,岩体介质材料选取连续、均匀、各向同性的弹塑性材料塑性,在k文件中采用MAT_PLASTIC_KINEMATIC材料模型[20]定义岩体,岩石材料参数如表1所示。

表1 岩石物理力学参数

Table 1 Mechanical properties of rock

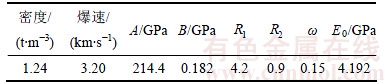

2.3.2 炸药材料

在地下坑道开挖过程中采用2号岩石炸药。材料参数如表2所示。炸药状态方程(JWL方程)[21]如下:

式中:P为爆轰压力;V为相对体积;E为单位体积比内能;ω,A,B,R1和R2为材料常数。

表2 2号岩石炸药材料及JWL状态方程参数

Table 2 Properties of No. 2 explosive and JWL equations

3 掏槽腔体时空演化过程分析

3.1 腔体时间演化过程

为了解掏槽爆破的炸药与岩体相互作用及其相应时空演化过程,对炸药起爆后的初始状态及其掏槽腔体的最终形态进行分析,分别见图3和图4。

由图3可知:药卷在起爆零时刻由孔底迅速向掌子面方向传爆,炸药单元应力极值随时间快速增大,并在一定的时间段内维持高应力状态。这种高应力的膨胀单元将炸药爆生能量传递并作用于岩石单元,靠近孔底区域岩石单元在高能应力作用下率先失效破坏,掏槽腔随之扩展和成形。

图3 药卷初始起爆时刻的单元膨胀图

Fig. 3 Explosive elements swelling at time of explosive detonation

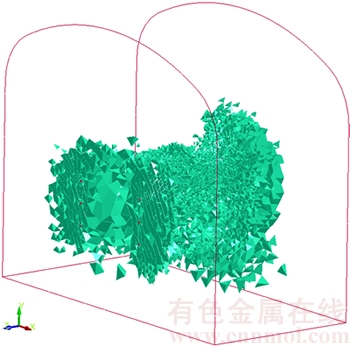

图4 最终形成的掏槽腔体形态图

Fig. 4 Form of cavity formed finally

由图4可知:掏槽腔的最终形态呈双向的主次喇叭状结构,受孔底炸药的直接作用和孔底无反射边界条件约束,炸药起爆后在孔底形成了喇叭状开口形状,这与工程实际有一定差距。在工程实际中,受岩石的夹持作用,孔底岩石破碎程度低,难以形成腔体。但随着炸药直接作用减弱,腔体收缩并重新向自由面端扩展,形成主要的喇叭口状掏槽腔。

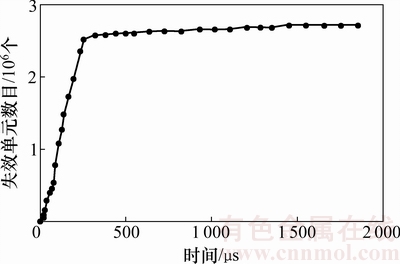

LS-DYNA的输出文件系统详细记录了模型运算信息,据此,通过提取模型信息输出文件中的单元失效时间及对应时刻的失效单元数目,统计得腔体内失效单元共2 717 817个,得图5所示失效单元时程曲线。

图5 失效单元时程曲线

Fig. 5 Time-history curve of elements failure

从图5可以看出:失效单元数目在260 μs内处于急速增长阶段,260 μs后增长速度明显减小,1 545 μs后失效单元数不再发生变化。结合LS-PREPOST后处理器中掏槽扩腔动画演示可发现:起爆初期高能应力作用于岩石单元,腔体扩展速度较快,1 545 μs前腔体处于扩展状态;随着炸药能量不断耗散,后期腔体体积增长速度明显减小,掏槽爆破在1 545 μs内完成。为提高爆破的效果,辅助孔的爆破应该与掏槽孔爆破的时间差达到毫秒级。

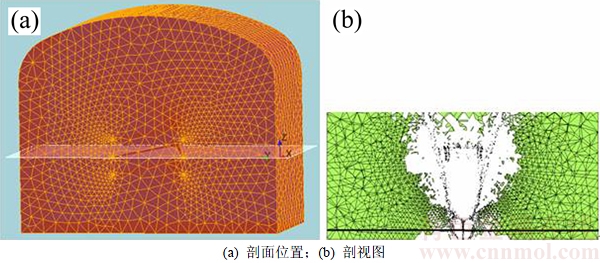

3.2 腔体空间形态表征分析

从掏槽的时间演化可以发现,掏槽腔的形态演化有利于形成爆破的后续空腔自由面及其补偿体积空间。为充分研究掏槽腔体在空间演化上的特征,利用LS-PREPOST后处理器中提供的强大“切片”剖视功能,从X,Y和Z这3个方向剖视掏槽腔体内部结构,充分分析在空间的演化上腔体形成和演化的空间表征,论证腔体形成的空间特征与掏槽效果及其爆破控制间的关系。

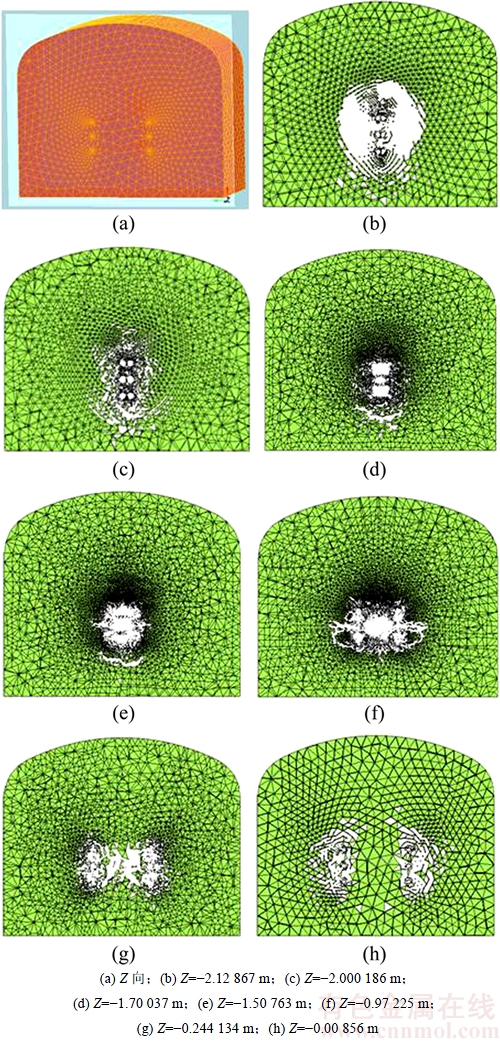

3.2.1 Z向剖面

截面位置及其切片分布如图6所示。平面法向与Z轴平行,沿着坐标Z轴间隔一定步距获取剖面视图,并根据巷道掘进中的炮孔利用系数经验值在2 m处获取切片。

受炮孔布置方式等因素影响,掏槽腔体竖直断面形状沿巷道走向不断变化,越靠近掌子面断面面积越大,与炮孔外扩结构一致。巷道作业面与孔底断面腔体截面形状差异较大,孔底位置腔体截面形状近似为1个长轴与Y轴平行的椭圆形,长轴约2.15 m,短轴约1.80 m。掌子面左右两排炮孔间距最大,掏槽腔体腔体断面水平方向最大破坏范围约2.80 m,垂直方向约1.60 m。2排炮孔围成区域为最小预计掏槽空间,该域内岩石单元几乎完全失效,掏槽腔体贯通研究域内2个端面。从图6(h)可以看出:2排炮孔中央有近似矩形区域(长约1.50 m,宽约0.70 m)岩石单元仍有保留,但相邻存留单元之间已经产生明显分离。在进一步辅助孔爆破中将直接破坏,形成有效的辅助爆破空腔自由面及补偿空间。在2.00 m位置处,腔体收缩变最窄,空腔的破坏单元数量少,与经验的有效进尺一致,掘进中的炮孔利用系数为91%。

图6 腔体Z向及其不同位置的剖面切片图

Fig. 6 Different section views of cavity at Z direction

不同位置断面横向尺寸与竖向尺寸差异较大且不断变化,孔底区域炮孔间距小,应力波叠加作用明显,导致近孔底区域腔体断面竖向尺寸大于横向尺寸;断面位置越靠近孔口,2排炮孔间距增大应力波叠加作用弱化,腔体断面形状受炮孔布置方式影响更加显著,断面横向尺寸大于竖向尺寸。

3.2.2 X向剖面

沿巷道中轴线所在竖直平面剖视,腔体断面形状近似为1个等腰三角形,如图7所示。但在2.00 m附近有明显的未破坏发生的岩石存在。该剖面位于2排炮孔中央,为左右炮孔应力波叠加作用最显著区域,腔体上下边界内岩体单元大部分失效,腔内少量存留单元均已与原岩完全分离。同时,为提高矿山巷道工程的爆破效果,可以适当对辅助爆破的炮孔布置进行适当倾斜,提高底部爆破的效果。

图7 腔体剖面视图(X=0 m)

Fig. 7 Section views of cavity(X=0 m)

3.2.3 Y向剖面

沿过炮孔中心的水平面进行剖视,腔体断面如图8所示。掘进现场孔底区域受到原岩约束,爆破条件较差,通常只能在较小范围内破碎岩石。在模拟过程中,为了节省计算成本,仅取1个循环进尺作为研究域,因此,模拟过程中未考虑后方原岩约束作用,孔底区域腔体形成了1个反向“喇叭口”,深度约为20.00 cm。根据模拟结果可以看出:软件算法本身具有一定的局限性,无反射边界条件只能大幅度降低边界应力波反射作用,不能将其完全消除。起爆点与端面距离较近,故反射应力波对近腔体形成仍有一定影响,这也验证了在矿山生产中,受底部的夹持作用,爆破的有效进尺一般在2.00 m左右,即图8(b)中黑色分界线上方区域。

图8 腔体剖面视图(Y=1.3 m)

Fig. 8 Section views of cavity (Y=1.3 m)

受围岩约束,腔体中部位置炸药能量耗散较少,集中作用于岩体,故腔体中部破碎范围较大。距掌子面约20.00 cm腔体轮廓局部收缩。该区域炮孔间距较大,岩石破碎效果略有下降。掌子面是巷道掘进唯一自由面,应力波传至自由面后产生反射拉伸波折回岩体,掌子面附近腔体轮廓较上述收缩区域略增大。

4 结论

1) 运用AUTO CAD对复杂三维模型进行初步构建,导入ANSYS进行模型修复,克服了ANSYS对于复杂模型构建的缺点。AUTO CAD与ANSYS联合建模技术实现了巷道掘进掏槽爆破精细化建模。

2) 通过定义岩石单元失效更加直观地展示了掏槽腔体形成过程,使得对掏槽效果分析更直接;获得了掏槽爆破腔体的时间和空间的演化特征和规律,表现为底部爆破起爆快速形成高能爆炸气体破岩,整体上形成了双向主次的喇叭状掏槽腔体结构,空间上X和Y向呈三角形分布,Z向不同段表现出不同的形态。

3) 应力波叠加作用对孔底掏槽腔体断面形状影响显著,靠近掌子面附近腔体形态主要受炮孔布置方式影响,为提高爆破的效果,辅助爆破可以适当进行倾斜布置。

4) 垂直单楔形掏掏槽体积较直孔桶形掏槽明显增大,可以改善铜坑矿阶段开拓运输巷道的掘进效果,其有效掘进进尺为2.00 m,效率比达91%,辅助孔与掏槽孔起爆时间应控制在毫秒级。

参考文献:

[1] 李夕兵. 凿岩爆破工程[M]. 长沙: 中南大学出版社, 2011: 184-185.

LI Xibing. Drilling blasting engineering[M]. Changsha: Central South University Press, 2011: 184-185.

[2] 戴俊, 杨永琦. 三角柱直眼掏槽爆破参数研究[J]. 爆炸与冲击, 2000, 20(4): 364-368.

DAI Jun, YANG Yongqi. Researches on blasting parameters of triangle burn cut[J]. Explosion and Shock Waves, 2000, 20(4): 364-368.

[3] 刘医硕. 双螺旋直眼掏槽参数优化研究[D]. 湘潭: 湖南科技大学资源环境与安全工程学院, 2013: 12-16.

LIU Yishuo. Double-spiral cutting parameters optimization[D]. Xiangtan: Hunan University of Science and Technology. School of Resource Environment and Safety Engineering, 2013: 12-16.

[4] 袁晓龙. 隧道楔形掏槽爆破技术研究[D]. 合肥: 安徽理工大学土木建筑学院, 2014: 21-23.

YUAN Xiaolong. Research on blasting technology of wedge-shaped cutting for rock tunnel[D]. Hefei: Anhui University of Science and Technology. School of Civil and Architectural Engineering, 2014: 21-23.

[5] 黄永辉. 立井硬岩深孔锥形掏槽爆破技术研究[D]. 北京: 中国矿业大学(北京)力学与土木工裎学院, 2013: 9-27.

HUANG Yonghui. The technology study on long-hole pyramid cut blasting in hard rock vertical shaft[D]. Beijing: China University of Mining & Technology (Beijing). School of Mechanics and Civil Engineering, 2013: 9-27.

[6] 黄宝龙. 岩巷掘进掏槽爆破理论与技术研究进展[J]. 中国矿业, 2014, 23(10): 103-106.

HUANG Baolong. Progress on theory and technique of cutting blasting in rock drivage[J]. China Mining Magazine, 2014, 23(10): 103-106.

[7] 单仁亮, 黄宝龙, 蔚振廷, 等. 岩巷掘进准直眼掏槽爆破模型试验研究[J]. 岩石力学与工程学报, 2015, 31(2): 256-264.

SHAN Renliang, HUANG Baolong, WEI Zhenting, et al. Model test of quasi-parallel cut blasting in rock drivage[J]. Chinese Journal of Rock Mechanics and Engineering, 2015, 31(2): 256-264.

[8] 单仁亮, 黄宝龙, 高文蛟, 等. 岩巷掘进准直眼掏槽爆破新技术应用实例分析[J]. 岩石力学与工程学报, 2011, 30(2): 224-232.

SHAN Renliang, HUANG Baolong, GAO Wenjiao, et al. Case studies of new technology application of quasi-parallel cut blasting in rock roadway drivage[J]. Chinese Journal of Rock Mechanics and Engineering, 2011, 30(2): 224-232.

[9] 徐刚, 陈国才. 硬岩掘进掏槽方式及参数优化研究及应用[J]. 煤炭工程, 2014, 46(12): 45-46.

XU Gang, CHEN Guocai. Study and application of cutting mode and parameter optimization of hard work heading[J]. Coal Engineering, 2014, 46(12): 45-46.

[10] 袁文华, 马芹永, 黄伟. 楔形掏槽微差爆破模型试验与分析[J]. 岩石力学与工程学报, 2012, 31(S1): 3352-3356.

YUAN Wenhua, MA Qinyong, HUANG Wei. Model experiment and analysis of wedge-shaped cutting millisecond blasting[J]. Chinese Journal of Rock Mechanics and Engineering, 2012, 31(S1): 3352-3356.

[11] 黄永辉, 程志彬, 沈慰安, 等. 立井 4.9 m 深孔锥形掏槽爆破试验研究[J]. 工程爆破, 2013, 19(3): 23-25.

HUANG Yonghui, CHENG Zhibin, SHEN Weian, et al. Research on blasting experiments of 4.9 m long-hole pyramid cut in vertical shaft[J]. Engineering Blasting, 2013, 19(3): 23-25.

[12] BERNARD T, DOZOLME P. The digital simulation of blasts: a major challenge for mines in the 21st century[J]. Procedia Engineering, 2014, 83: 100-110.

[13] 于蕾, 李祥龙, 邓光茂. 云锡 1360 基础平台桶形掏槽数值模拟研究[J]. 爆破, 2014, 31(3): 103-109.

YU Lei, LI Xianglong, DENG Guangmao. Numerical simulation of cylinder cutting on 1360 fundamental platform of Yunnan Tin Group[J]. China Blasting, 2014, 31(3): 103-109.

[14] 潘先峰, 毛艳锋. 基于 ANSYS/LS-DYNA 的井巷掘进掏槽爆破扩腔过程的数值模拟[J]. 煤矿爆破, 2014(4): 19-24.

PANG Xianfeng, MAO Yanfeng. The numerical simulation of shaft excavation blasting cavity expansion process based on ANSYS/LS-DYNA[J]. Coal Mine Blasting, 2014(4): 19-24.

[15] 徐惠琳, 杨帆, 谢波. ANSYS 与 CAD 联合建模时的数据接口及数据转换[J]. 山西建筑, 2007, 33(33): 366-367.

XU Huilin, YANG Fan, XIE Bo. Data interface and conversion technology in model building combined with ANSYS and CAD[J]. Shanxi Architecture, 2007, 33(33): 366-367.

[16] 黄小华, 金艳丽. 岩土工程中 CAD 与 ANSYS 联合建模的数据交换[J]. 西部探矿工程, 2009, 21(12): 9-12.

HAUNG Xiaohua, JIN Yanli. Data conversion of models using ANSYS and CAD in geological engineering[J]. West-China Exploration Engineering, 2009, 21(12): 9-12.

[17] 周科平. 采矿过程模拟与仿真[M]. 长沙: 中南大学出版社, 2012: 166-167.

ZHOU Keping. Mining process modeling and simulation[M]. Changsha: Central South University Press, 2012: 166-167.

[18] MA G W, AN X M. Numerical simulation of blasting-induced rock fractures[J]. International Journal of Rock Mechanics and Mining Sciences, 2008, 45(6): 966-975.

[19] 白金泽. LS-DYNA3D理论基础与实例分析[M]. 北京: 科学出版社, 2005: 74-99.

BAI Jinze. Theoretical basis and case analysis of LS-DYNA3D[M]. Beijing: Science Press, 2005: 74-99.

[20] 王鹏, 周传波, 耿雪峰, 等. 多孔同段爆破漏斗形成机理的数值模拟研究[J]. 岩土力学, 2010, 31(3): 993-997.

WANG Peng, ZHOU Chuanbo, GENG Xuefeng, et al. Numerical simulation of formation mechanism of multi hole and same delay time of blasting crater[J]. Rock and Soil Mechanics, 2010, 31(3): 993-997.

[21] 赵铮, 陶钢, 杜长星. 爆轰产物 JWL 状态方程应用研究[J]. 高压物理学报, 2009, 23(4): 277-282.

ZHAO Zheng, TAO Gang, DU Changxing. Application research on JWL equation of state of detonation products[J]. Chinese Journal of High Pressure Physics, 2009, 23(4): 277-282.

(编辑 陈灿华)

收稿日期:2016-12-16;修回日期:2017-03-07

基金项目(Foundation item):国家“十二五”科技支撑计划项目(2015BAB12B01);国家重点研发计划(2017YFC0602901);国家自然科学基金资助项目(41672298)(Project(2015BAB12B01) supported by National Science and Technology Pillar Program during the “Twelfth Five-Year” Period; Project (2017YFC0602901) supported by the National Key Research and Development Program of China; Project(41672298) supported by the National Natural Science Foundation of China)

通信作者:胡建华,博士,教授,从事高效安全采矿技术与岩土工程的稳定性分析研究;E-mail:hujh21@126.com