DOI:10.19476/j.ysxb.1004.0609.2017.07.04

2124合金淬火后的室温停留效应

景慧博,柏振海,罗兵辉,尹 远,高 阳

(中南大学 材料科学与工程学院,长沙 410083)

摘 要:为了探明2124合金的淬火后室温停留效应对合金力学性能的影响并找到应对措施,运用拉伸试验、硬度试验、电导率测试、DSC测试、XRD实验、EDS、TEM实验手段对2124合金淬火后室温停留不同时间的力学性能、相变过程及显微组织进行分析。结果表明:合金淬火后室温停留降低2124合金随后185 ℃人工时效的峰值强度,屈服强度最大降低60 MPa,伸长率略有升高,但低于1.5%;室温停留阶段合金内部析出物为GPB区,并且位错密度降低;室温停留24 h后185 ℃人工时效阶段主要强化相S相的析出激活能由淬火后直接时效的56.8 kJ/mol上升至72.7 kJ/mol,室温停留阶段位错密度的降低抑制了S相的非均匀析出是导致S相析出激活能升高的原因之一;在淬火后对材料进行3%冷变形即可消除室温停留对2124合金强度、硬度带来的不利影响。

关键词:2124合金;力学性能;淬火后室温停留;S相

文章编号:1004-0609(2017)-07-1344-08 中图分类号:TG135.5 文献标志码:A

2124合金为美铝公司在20世纪70年代在2024合金的基础上研发的新一代2X24合金,已在航天航空领域取得广泛应用[1-3]。2124合金为Al-Cu-Mg合金,属于高强可热处理强化型铝合金,国内外对其析出相与析出序列开展了大量的研究[4-6],并在2124合金的固溶、时效及形变热处理方面取得大量成果[2, 7]。2124合金的人工时效进程通常分为两个阶段[8]:一是起始时候的快速硬化阶段;二是随后缓慢升至时效峰值的缓慢硬化阶段。目前第一阶段的产生原因仍存在争议,第二阶段即峰时效阶段通常认为是S′或S相析出强化所致(由于S′相与S相结构十分相似且强化效果相同,所以统称为S相[9]),但S相的先析相及不均匀析出序列目前尚未有定论。在工厂的实际生产中,合金淬火后到入炉人工时效前,由于生产工艺及实际条件限制,往往需要在室温停留较长时间,在室温停留阶段的2124合金可发生自然时效,所以预期会对随后的人工时效产生影响。目前对于2124合金尚未有这方面的报道,本文作者运用多种实验手段对2124合金淬火后的室温停留效应进行了研究,并希望找到消除淬火后室温停留对合金力学性能不利影响的方法。

1 实验

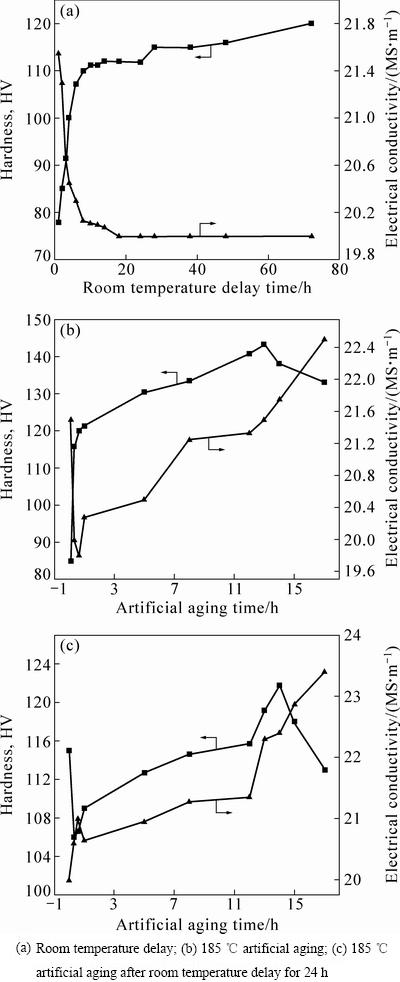

实验材料选用由西南铝业(集团)有限责任公司提供2124合金板材,合金的成分如表1所列。

表1 2124合金的分析成分

Table 1 Chemical composition of 2124 alloy (mass fraction, %)

拉伸试样每组取3个平行试样,拉伸试样尺寸及拉伸实验规程分别遵照GB6397—86和GB228—87进行。在CSS 44100电子万能实验机上进行拉伸力学性能测试,拉伸速率为2 mm/min,室温下拉伸。硬度试验在HV-10B小负荷维氏硬度计上进行,载荷为5 N,保载时间15 s,每个试样至少测验5个点后取平均值以保证数据真实可靠。试样在箱式电阻炉中进行固溶处理,固溶温度为495 ℃,固溶时间为1 h;固溶完成后迅速取出在室温(RT)水中淬火,淬火转移时间不超过3 s;淬火后在室温停留不同时间进行人工时效,室温停留与人工时效均在电热鼓风干燥箱中进行,室温停留温度设为25 ℃,人工时效温度为185 ℃。拉伸试验、硬度试验、电导率测试试验、XRD、DSC试验所用样品均在处理完成后立刻测量,TEM试验所用试样在等待间隔均放入液氮中保存以保证在此阶段无组织变化产生。

电导率(electrical conductivity,简称EC)测量方法按照GB/T12966—1991标准规定进行, 测量仪器为数字金属电导率测量仪(D60K),测量误差为±2%,试样温度保持25 ℃,每个试样测5个点取平均值。DSC测试在耐驰Netzsch同步热分析仪(STA449C)上进行,加热时通Ar气保护。位错密度测量根据Williamson-Hall方法进行[10],即

。其中:ε为微观应变,d为微晶尺寸,B为衍射峰半高宽,K为常数0.9,θ为布拉格角,λ为0.154 nm,通过线性拟合方式求出ε与d,代入公式

。其中:ε为微观应变,d为微晶尺寸,B为衍射峰半高宽,K为常数0.9,θ为布拉格角,λ为0.154 nm,通过线性拟合方式求出ε与d,代入公式 [11]。其中:ρ为位错密度;b为Al的柏氏矢量长度,即0.286 nm[12]。XRD测量仪器为Bruker D8 Discover型X射线衍射仪。TEM试验样品经机械减薄至80 μm后,冲剪为3 mm的小圆片然后进行双喷处理,电压为15~20 V,电解液为25%硝酸+75%(体积分数)甲醇。观测用透射电镜型号为TECNAL-200型,加速电压为200 kV。

[11]。其中:ρ为位错密度;b为Al的柏氏矢量长度,即0.286 nm[12]。XRD测量仪器为Bruker D8 Discover型X射线衍射仪。TEM试验样品经机械减薄至80 μm后,冲剪为3 mm的小圆片然后进行双喷处理,电压为15~20 V,电解液为25%硝酸+75%(体积分数)甲醇。观测用透射电镜型号为TECNAL-200型,加速电压为200 kV。

2 实验结果

2.1 合金的力学性能

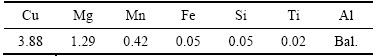

图1所示为将2124合金在固溶淬火后室温停留不同时间对其随后在185 ℃时效13 h后(以下简称为室温停留)试样的力学性能的影响。从图1可以看出,室温停留会使人工时效后材料的屈服强度最大降低60 MPa,断裂强度最大降低50 MPa,且室温停留2 h的时间内,对随后时效试样的屈服及断裂强度影响最为显著,在室温停留2~12 h的时间内,随后时效试样的屈服及断裂强度缓慢降低;伸长率则略有升高,从4.3%缓慢上升至5.5%。

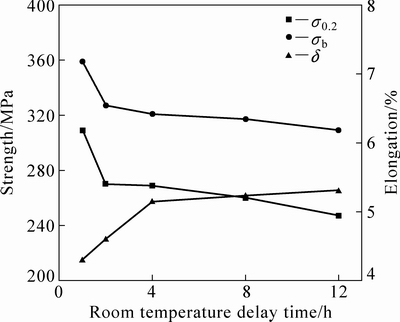

图2所示为2124合金不同热处理条件下硬度与电导率随室温停留时间的变化,根据图2(a)所示,2124合金在室温停留时,在前10个小时内硬度由淬火后的77.5HV上升到110HV,之后缓慢上升到115HV左右保持恒定,电导率则在前10 h内迅速降低,随后维持在20 MS/m。

图1 室温停留时间对2124合金185 ℃峰时效后(13 h)力学性能的影响

Fig. 1 Effects of room temperature delay time on mechanical properties of 2124 alloy under peak aging (13 h) at 185 ℃

在淬火后立即进行人工时效过程中,2124合金硬度上升阶段分为两段(图2(b)):在人工时效开始的前40 min内硬度迅速由淬火态的85HV升高到120HV,在人工时效40 min至13 h的时间内,材料硬度缓慢上升至峰值145HV,继续延长时效时间,材料进入过时效状态,硬度值随时效时间缓慢下降,所以2124合金在185 ℃下时效,其峰值时间为13 h,峰值硬度为145HV;电导率的变化分为两个阶段,从开始时效至时效40 min后电导率迅速由淬火态的21.6 MS/m降到最低19.8 Ms/m,在时效40 min后电导率开始升高,电导率的升高也可以分为两个阶段,在40 min至12 h的时间内,电导率缓慢升高,12 h之后电导率升高速率明显增大,直至材料处于过时效状态。

在固溶水淬后室温放置24 h后再进行人工时效,其时效动力学发生了较为显著的变化,开始时效时硬度值出现下降现象,随后的人工时效阶段整体硬度值偏低,峰值时效时硬度125Hv较人工时效的峰值硬度145Hv下降20Hv,峰值时效时间由13 h延长至14 h。电导率从室温停留24 h后的20 Ms/m开始缓慢上升,在12~17 h内迅速升高,且此阶段电导率绝对值高于淬火后直接185 ℃人工时效时的电导率。

图2 2124铝合金495 ℃固溶1 h再水淬后在不同热处理过程中电导率与硬度随时效时间的变化

Fig. 2 Changes of electrical conductivity and hardness of quenched 2124 alloy during different heat-treatments

2.2 DSC测试结果

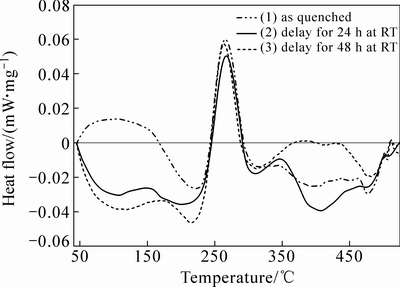

图3所示为2124合金在不同热处理状态下的DSC测试结果。加热速率均为10 K/min,图3中曲线1、2、3分别代表淬火态、室温停留24及48 h后测得的DSC曲线。结合文献数据[13-14],图3中不同处理条件下2124合金的DSC测试中的峰代表的相的变化如下:温度在50~150 ℃之间的吸热峰,代表GPB区的形成,在150~250 ℃之间的放热峰代表GPB区的溶解,可以看到在原本GPB区溶解区之间出现小峰,多数研究者认为这是由于GPBⅡ区的形成与溶解导致的;随后在250~320 ℃出现的吸热峰代表S相的形成,随后320~500 ℃的放热峰代表S相的溶解,最后的小峰代表其他相的形成与溶解。对于曲线2和3,其与曲线1存在一点不同,在开始阶段GPB区的形成峰消失了,直接出现一个溶解峰,代表GPB区的溶解,在150~200 ℃之间有一个较弱的凸起,这是GPBⅡ区的形成引起的,随后的吸热峰是GPB及GPBⅡ区的继续溶解峰;曲线2与3的不同之处在于,曲线3开始阶段溶解峰面积要更大,表明有更多的GPB区溶解。对比3条曲线S相的形成峰可以看出,曲线1的峰要更大,表明有更多的S相形成。

图3 2124铝合金不同热处理状态下的DSC测试结果

Fig. 3 DSC results of 2124 alloy under different heat-treatments

2.3 位错密度测试

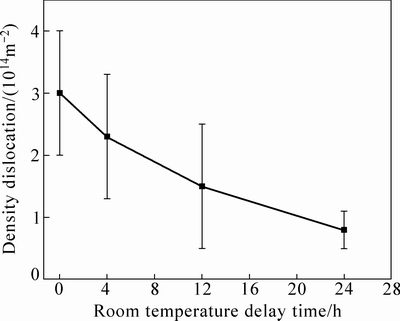

图4所示为2124合金淬火后室温停留阶段组织内部位错密度的变化,根据测得的XRD数据,运用前述Williamson-Hall方法测得的位错密度,结果表明合金中位错密度随室温停留时间延长而降低。淬火后极短时间内的位错密度在3.0×1014 m-2,室温停留24 h后,组织内部位错的密度降低至0.8×1014 m-2。

图4 2124淬火后合金中位错密度随室温停留时间变化

Fig. 4 Change of dislocations density in 2124 alloy with the delaying time at room temperature delay after quenching

2.4 TEM测试

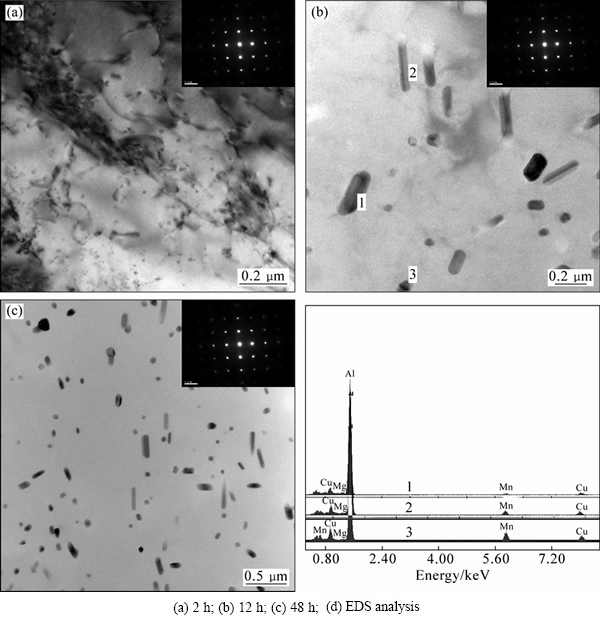

图5所示为2124合金室温停留不同时间后的TEM明场像,在图中只能观察到短棒状的粒子,对这些粒子的EDS分析如图5(d)所示,这些粒子均为含Al、Cu、Mn的相,成分接近,可认为是同一种相,即成分为Al20Cu2Mn3的T相,形成于均匀化阶段[15]。在衍射斑点中没有观测到第二相的衍射斑点,但在基体斑点间出现的微弱附加晕斑表明了GPB区的存在[16]。

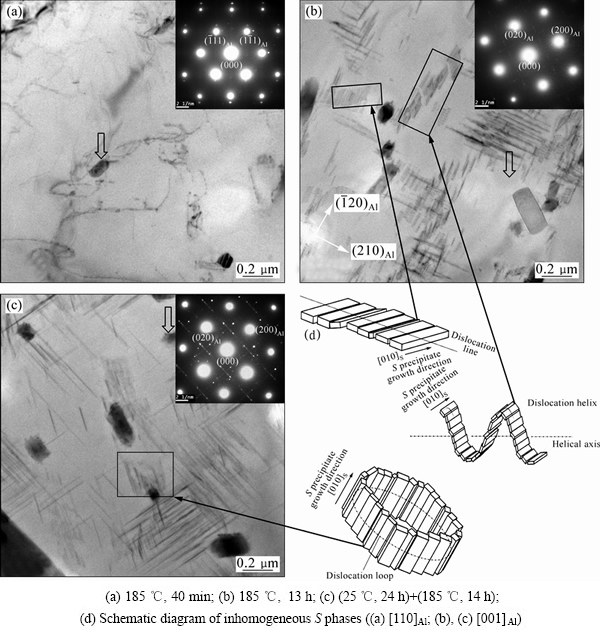

图6所示为2124合金在不同热处理条件下的TEM像。在图6中可看到有两种类型的析出相,一类为短棒状的粗大析出相(如图中箭头所示),结合图5分析,这些短棒状的析出相为T相。第二种为在平面上呈针状,衬度较暗的析出相,结合衍射斑点分析可以确定为S相。图6(a)为185 ℃时效40 min后的微观组织图,图中除了T相外,未能明显看到有S相出现,但可观察到在185 ℃时效40 min后仍有大量的位错存在。尽管在TEM明场像中看不到有析出相的存在,但在衍射斑点图中却能够发现除了铝基体的衍射斑点外还存在一些较小、微弱的衍射斑点;可以确定是S相的衍射斑点,所以,在185 ℃时效40 min后即有S相形成,但是在此阶段S相十分细小,在TEM明场像下观测不到,且只能形成十分微弱的衍射斑点。图6(b)、(c)所示分别为2124合金在185 ℃时效及室温停留24 h后再在185 ℃时效状态。在这两种状态的组织内可观察到两种形态的S相,一类为呈垂直交叉状分布的S相,另一类为呈团簇状分布的S相,此类S相更加细小(如图6(b)白色方框内所示);结合图6(d)中S相非均匀形成示意图[5]与这两类S相的分布形态可看出,垂直交叉分布状的S相与铝基体呈[100]Al//[100]S,[021]Al//[010] S,[012]Al//[001] S位向关系[8][8],均匀形成于基体内部;细小、密集团簇状的S相是依靠淬火后保留的位错环或者位错螺旋不均匀形核长大的。对比图6(b)、图6(c)中S相的形貌,在图6(b)中交叉分布的S相要更加细小一些;图6(b)内存在较多团簇状S,而在图6(c)内此类S相的量很少。

图5 2124合金淬火后室温停留不同时间的TEM明场像

Fig. 5 TEM bright field images of 2124 alloy under room temperature delay for different time([001]Al)

图6 2124合金经过不同热处理后TEM明场像及对应的衍射斑点图

Fig. 6 TEM bright field image and diffraction spots of 2124 alloy under different heat-treatments

3 分析与讨论

结合图3及DSC分析,在2124合金的室温停留阶段,主要发生的组织变化为GPB区的析出,由于GPB区的强化机理在于其与位错强烈的交互作用,阻碍位错的移动[17],所以强化材料;GPB区为Cu、Mg原子团,其形成后既纯化了基体(即消除了固溶强化效果)同时又由于其与基体保持共格关系而产生严重的晶格畸变,对自由电子的散射作用增加从而使电导率不断下降[4]。实验证明,此阶段晶体内部存在的空位及位错对电导率不产生影响[18],所以可不考虑位错密度带来的电导率变化。GPBⅡ区与GPB区结构类似,也与基体保持共格关系,所以即使GPBⅡ区析出,电导率也无大的变化[4]。结合图2电导率及图3的DSC分析,在185 ℃人工时效的前40 min内,析出的产物主要为GPB区,与室温停留18 h后相比,其硬度与电导率都十分接近,但由于温度升高,使得时效动力学大大加速,很快便完成了室温停留24 h才能完成的第二相析出,故在此阶段硬度值迅速升高而电导率降低。185 ℃人工时效40 min至峰时效阶段电导率逐渐上升,在这一阶段内发生的组织变化主要为S相的析出。S相与基体保持半共格关系,对晶格的畸变作用减小,其析出既消耗了大量的溶质原子,又使GPB区的数量减少,所以电导率在其析出期间不断上升[4]。185 ℃人工时效13 h后硬度下降,而电导率保持上升,证明在这一阶段,S相不断的粗化聚集,为一个Ostward熟化过程。综上,2124合金在人工时效的过程中,其析出产物先后为SSS→GPB→GPBⅡ→S;由图6(b)、(c)中观察结果可以看到,在人工时效前预先在室温停留24 h的样品中主要强化相S相的数量较少,较为粗大,对晶格畸变的作用更低,所以电导率曲线整体高于直接人工时效状态的电导率。

在时效中S相的形成激活能可以运用式(1)所示Kissinger法来计算[19]:

(1)

(1)

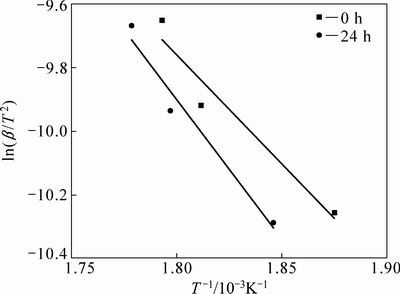

式中:β为加热速率;T为DSC峰值温度;EK为析出激活能;R为摩尔气体常数;C为积分常数。根据DSC测试中不同的加热速率(β=10、15、20 K/min)及S相形成峰所对应的峰值温度,如表2所列,其激活能的Kissinger法拟合如图7所示。根据拟合结果,可求得在淬火后直接时效的样品其S相的析出激活能为56.8 kJ/mol,而淬火后室温停留24 h后,S相的析出激活能为72.7 kJ/mol,相对于直接淬火态增加了28%,这表明淬火后的室温停留导致S相的形成更加困难。

表2 Kissinger法测得的S相的析出激活能

Table 2 Activation energies of S phases obtained by Kissinger method

在室温停留阶段另一个组织的变化是位错密度的降低。根据图4可知,室温停留24 h后,合金中位错密度降低至直接淬火态位错密度的1/3。考虑到S相在位错位置的不均性形核(见图6,图中可明确地看出借助位错形核长大的S相占人工时效峰时效阶段S相的很大一部分),所以这种位错密度的降低是导致随后人工时效阶段S相减少的原因之一,即在185 ℃时效峰值阶段S相十分依赖在位错处的非均匀析出。由于室温停留导致位错密度显著降低,致使S相更多的依靠GPB及GPBⅡ区转化而成,所以S相数量减少,尺寸增加,而在淬火后直接185 ℃时效过程中,根据图6(a)所示在时效开始初期S相就已形核析出,根据文献报道[5],在位错处S相更容易形核,所以不经过室温停留的合金其峰时效状态时,S相的数量较多,尺寸较小。

图7 S相析出的Kissinger法拟合曲线

Fig. 7 Fitting curves of Kissinger equation for S phases precipitation

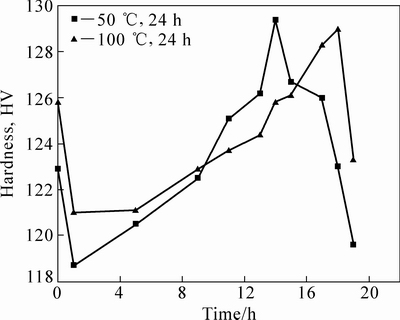

由图2可看出,室温停留后,185 ℃人工时效峰时效时间推迟了1 h,为了充分说明这一变化,同时对比S相的均匀形成与非均匀形成,设计了另外两个双级时效。图8所示为将试样先分别在50 ℃和100 ℃时效24 h后再进行185 ℃人工时效的时效-硬度曲线,这两条曲线在185 ℃时效初期都出现了一个硬度下降的现象,而根据预处理的不同,185 ℃时效的峰值时间分别变化为14及18 h。根据DSC测量结果及文献研究结果[20],在50 ℃和100 ℃时效24 h后S相不能够形成,只能形成GPB区,合金中位错密度也都降低到了非常低的水平。时效初期硬度值的降低是由于有部分GPB区发生溶解而非转化为S相,由于预处理后位错密度显著降低,所以S相的非均匀形核受到抑制,致使185 ℃时效峰值时间被延迟。由于GPB区形成符合典型的JMA方程,所以50 ℃和100 ℃时效24 h预处理后合金内的组织区别在于50 ℃处理后GPB区的尺寸较小,GPB区的间隔较近,在随后转化为S相过程中,溶质原子迁移的距离较近,所以峰时效时间大大先于100 ℃预处理的样品。

图8 2124铝合金经不同预处理后185 ℃时效的硬度变化曲线

Fig. 8 185 ℃ artificial aging curves of 2124 alloy under different pre-treatments

根据上述分析可以推出,若需要抑制室温停留对强度、硬度带来的不利影响,需要在淬火后的组织中保持一定的位错密度。图9所示为在淬火后室温停留24 h,随后进行3%预变形,然后进行185 ℃人工时效的维氏硬度和电导率随人工时效时间的变化曲线。由图9可以看出,由于预变形,在材料内部引入大量的位错,所以极大地促进了S相的析出,不仅提高了峰时效时的硬度而且缩短了峰时效时间。

图9 3%预变形对2124铝合金室温停留效应的消除效果

Fig. 9 Effects of 3% pre-deformation on effect of room temperature delay on 2124 alloy

4 结论

1) 2124铝合金在固溶淬火后、185 ℃人工时效之前进行室温停留会显著降低其峰时效状态的强度,屈服强度最大降低60 MPa;随室温停留时间的延长,185 ℃人工时效13 h(对应此温度的峰值时效时间)后的强度值先迅速降低,然后缓慢到达最低值,伸长率略有升高,不超过1.5%。

2) 室温停留24 h后S相的析出激活能由淬火后直接时效态的56.8 kJ/mol上升至72.7 kJ/mol。室温停留阶段位错密度的降低抑制了S相的非均匀析出。S相的均匀析出慢于其依靠位错析出,在25、50、100 ℃停留24 h后185 ℃人工时效时其峰值时效时间分别推迟至14、14和18 h。

3) 在淬火并室温停留后对材料进行3%冷变形可在一定程度上消除室温停留对2124合金强硬度带来的不利影响。

REFERENCES

[1] 李成侣, 潘清林, 刘晓艳, 何运斌, 李文斌. 2124 合金的均匀化热处理[J]. 中国有色金属学报, 2010, 20(2): 209-216.

LI Cheng-lü, PAN Qing-lin, LIU Xiao-yan, HE Yun-bin, LI Wen-bin. Homogenizing heat treatment of 2124 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(2): 209-216.

[2] 湛利华, 李炎光, 黄明辉. 应力作用下2124 合金蠕变时效的组织与性能[J]. 中南大学学报(自然科学版), 2012, 43(3): 926-931.

ZHAN Li-hua, LI Yan-guang, HUANG Ming-hui. Microstructures and properties of 2124 alloy creep ageing under stress[J]. Journal of Central South University (Science and Technology), 2012, 43(3): 926-931.

[3] 郭加林, 尹志民, 沈 凯, 彭小芒, 王 华. 使役条件下热暴露对2124-T851 合金显微组织与性能的影响[J]. 中南大学学报(自然科学版), 2009, 40(4): 921-925.

GUO Jia-lin, YIN Zhi-min, SHEN Kai, PENG Xiao-mang, WANG Hua. Effect of thermal exposure during application on microstructure and mechanical properties of 2124-T851 aluminum alloy[J]. Journal of Central South University (Science and Technology), 2009, 40(4): 921-925.

[4] HAN Cheng Shih, NEW-J1N HO, HUANG J C. Precipitation behaviors in AI-Cu-Mg and 2024 aluminum alloys[J]. Metallurgical and Materials Transactions A, 1995, 27: 1996-2479.

[5] FENG Z Q, YANG Y Q, HUANG B, LUO X, LI M H, HAN M, FU M S. Variant selection and the strengthening effect of S precipitates at dislocations in Al-Cu-Mg alloy[J]. Acta Materialia, 2011, 59(6): 2412-2422.

[6] KOVARIK L, COURT S A, FRASER H L, MILLS M J. GPB zones and composite GPB/GPBII zones in Al-Cu-Mg alloys[J]. Acta Materialia, 2008, 56(17): 4804-4815.

[7] 王昌臻, 潘清林, 何运斌, 邹 亮, 尹志民, 聂 波, 何振波. 2124 铝合金热轧厚板的热处理制度[J]. 中南大学学报(自然科学版), 2007, 38(3): 386-393.

WANG Chang-zhen, PAN Qing-lin, HE Yun-bin, ZOU Liang, YIN Zhi-min, NIE Bo, HE Zhen-bo. Heat treatment of thick hot-rolled plate of 2124 alloy[J]. Journal of Central South University (Science and Technology), 2007, 38(3): 386-393.

[8] WANG S C, STARINK M J, GAO N. Precipitation hardening in Al-Cu-Mg alloys revisited[J]. Scripta Materialia, 2006, 54 (2): 287-291.

[9] STYLES M J, MARCEAU R K W, BASTOW T J, BRAND H E A, GIBSON M A, HUTCHINSON C R. The competition between metastable and equilibrium S (Al2CuMg) phase during the decomposition of Al Cu Mg alloys[J]. Acta Materialia, 2015, 98: 64-80.

[10] WILLIAMSON G K, HALL W H. X-ray line broadening from filed aluminum and wolfram[J]. Acta Mater, 1953, 1(1): 22-31.

[11] ZHAO Y H, LIAO X Z, JIN Z, VALIEV R Z, ZHU Y T. Microstructures and mechanical properties of ultrafine grained 7075 Al alloy processed by ECAP and their evolutions during annealing[J]. Acta Mater, 2004, 52(15): 4589-4599.

[12] SEIDMAN D N, MARQUIS E A, DUNAND D C. Precipitation strengthening at ambient and elevated temperatures of heat-treatable Al(Sc) alloys[J]. Acta Mater, 2002, 50(16): 4021-4035.

[13] HERSENT E, DRIVER J H, PIOT D. Modelling differential scanning calorimetry curves of precipitation in Al-Cu-Mg[J]. Scripta Materialia, 2010, 62(7): 455-457.

[14] STARINK M J, WANG Shuncai. Comments on “Modelling differential scanning calorimetry curves of precipitation in Al-Cu-Mg”[J]. Scripta Materialia, 2010, 62(9): 720-723.

[15] SHEN Zhen-ju, LIU Chun-hui, DING Qing-qing, WANG Shuang-bao, ZHANG Zhao-yong. The structure determination of Al20Cu2Mn3 by near atomic resolution chemical mapping[J]. Journal of Alloys and Compounds, 2014, 601: 25-30.

[16] 任杰克, 陈志国, 黄裕金, 张纪帅, 魏 祥, 方 亮. 新型热机械处理对2E12铝合金显微组织与性能的影响[J]. 中国有色金属学报, 2014, 24(3): 643-650.

REN Jie-ke, CHEN Zhi-guo, HUANG Yu-jin, ZHANG Ji-shuai, WEI Xiang, FANG Liang. Effect of new thermo-mechanical treatment on microstructure and properties of 2E12 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(3): 643-650.

[17] STARINK M J, GAO J L Y. The origins of room temperature hardening of Al-Cu-Mg alloys[J]. Materials Science and Engineering A, 2004, 387/389: 222-226.

[18] GUYOT P, COTTIGNIES L. Precipitation kinetics, mechanical strength and electrical conductivity of AlZnMgCu alloys[J]. Acta Materialia, 1996, 44(10): 4161-4167.

[19] GHOSH K S, GAO N. Determination of kinetic parameters from calorimetric study of solid state reactions in 7150 Al-Zn-Mg alloy[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(6): 1199-1209.

[20] 刘延斌, 刘志义, 李云涛, 邓才智. 时效对2524铝合金热稳定性的影响[J]. 材料研究学报, 2007, 21(6): 585-588.

LIU Yan-bin , LIU Zhi-yi, LI Yun-tao, DENG Cai-zhi. Effect of aging process on thermal stability of 2524 aluminum alloy[J]. Chinese Journal of Materials Research, 2007, 21(6): 585-588.

Effect of room temperature delay on quenched 2124 alloy

JING Hui-bo, BAI Zhen-hai, LUO Bing-hui, YIN Yuan, GAO Yang

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: To figure out the effects and reason of room temperature delay of 2124 alloy, and to find a countermeasure, mechanical property tester, hardness and electrical conductivity tests, DSC, XRD, EDS and TEM tests were used to analyze the mechanical property, phase transformation and microstructure of 2124 alloy. The result indicates that, the room temperature delay significantly reduces the intensity of 2124 alloy under followed peak aging at 185 ℃ whose σ0.2 can reduce up to 60 MPa, while the increase of elongation rate is lower than 1.5%. GPB forms during the room temperature delay, meanwhile, the density of dislocation decreases. The activation energy of S phase, the main strengthening phase of 2124 alloy under peak aging at 185 ℃, increases from 56.8 kJ/mol of alloy as-quenched to 72.7 kJ/mol of alloy as-delayed for 24 h at room temperature. The decrease of the density of dislocation, which restrains the inhomogeneous formation of S phase, is one of the reasons which result in this increase. 3% pre-deformation can eliminate the side effect of room temperature delay on 2124 alloy.

Key words: 2124 alloy; mechanical property; room temperature delay; S phase

Foundation item: Project(JPPT-125-GJGG-08-01) supported by the Military Industry Cooperative Program

Received date: 2016-06-28; Accepted date: 2016-10-21

Corresponding author: LUO Bing-hui; Tel: +86-731-88830333; E-mail: lbh@csu.edu.cn

(编辑 龙怀中)

基金项目:军工配套科研项目(JPPT-125-GJGG-08-01)

收稿日期:2016-06-28;修订日期:2016-10-21

通信作者:罗兵辉,教授,博士;电话:0731-88830333;E-mail:lbh@csu.edu.cn