DOI: 10.11817/j.issn.1672-7207.2017.11.015

共晶组织对2E12铝合金热变形行为及组织演变的影响

陈宇强[1], 2,宋文炜1,潘素平3,刘文辉1, 2,唐昌平1, 2

(1. 湖南科技大学 高温耐磨材料及制备技术湖南省国防技术重点实验室,湖南 湘潭,411201;

2. 湖南科技大学 难加工材料高效精密加工湖南省重点实验室,湖南 湘潭,411201;

3. 中南大学 高等研究中心,湖南 长沙,410083)

摘要:采用不同热处理方法制备过饱和固溶体(1号合金)和富含共晶组织(2号合金)这2种具有典型组织特征的2E12合金。结合热模拟实验和显微组织观察,针对2种合金铸锭在变形温度为340~490 ℃、应变速率为0.001~10 s-1下的变形行为以及组织演变特征进行研究。研究结果表明:在0.001~0.1 s-1的应变速率下,2号合金具有较高的峰值应力;在10 s-1的应变速率下,1号合金具有较高的峰值应力;1号合金在热变形过程中的主要失效形式表现为三叉晶界的失稳开裂;2号合金在340 ℃/10 s-1变形时的主要失效形式为晶界共晶组织的碎化;在490 ℃/ 0.001 s-1变形时的主要失效形式为晶界共晶组织的熔化开裂;在相同变形条件下,1号合金更容易发生动态再结晶且晶粒更细小;弥散分布的T相粒子可以促进合金均匀变形并且细化晶粒。

关键词:2E12铝合金;热变形;共晶组织

中图分类号:TG146.2 文献标志码:A 文章编号:1672-7207(2017)11-2949-10

Effect of eutectics on hot deformation behaviors and microstructure evolutions of 2E12 aluminum alloy

CHEN Yuqiang1, 2, SONG Wenwei1, PAN Suping3, LIU Wenhui1, 2, TANG Changping1, 2

(1. Key Lab of High Temperature Wear Resistant Materials Preparation Technology of Hunan Province,

Hunan University of Science and Technology, Xiangtan 411201, China;

2. Hunan Provincial Key Laboratory of High Efficiency and Precision Machining of Difficult-to-cut Material,

Hunan University of Science and Technology, Xiangtan 411201, China;

3. Advanced Research Center, Central South University, Changsha 410083, China)

Abstract: Two kinds of alloys whose microstructures were featured with supersaturated solid solution (alloy 1) and enriched with eutectics (alloy 2) were prepared by different heat-treatment methods, respectively. By combining isothermal hot compression test with microstructure observation, the hot deformation behaviors and microstructure evolution of both alloys were studied at temperature range of 340-490 ℃ and strain rate range of 0.001-10 s-1. The results show that alloy 2 possesses a higher peak-stress value deformed at 0.001-0.1 s-1, while alloy 1 possesses a higher peak-stress value deformed at 10 s-1. The main failure mode of alloy 1 is cracking at triple grain boundaries (GBs). When deformed at 340 ℃/10 s-1, the main failure modes of alloy 2 is the fracture of eutectics at GBs. When deformed at 490 ℃/0.001 s-1, the main failure modes of alloy 2 is the cracking caused by eutectic melting. The dynamic recrystallization takes place easier in alloy 1 and thus makes a smaller grain size. The dispersively distributed T-phase particles promote the homogeneous deformation of alloy and also refine grain size.

Key words: 2E12 aluminum alloy; hot deformation; eutectic

出于经济性和安全性的考虑,大型飞机必须采用大尺寸结构件进行组装以减少铆接带来的增重和焊接所造成的强度损失[1]。作为重要的航空结构材料,大型铝材的生产加工是目前制约中国航空工业快速发展的主要瓶颈[1]。因此,针对大型航空铝材的生产加工问题开展研究具有重要意义[2]。2E12铝合金是在美国2524合金基础上通过成分优化和工艺改进后自主研发的一种新型国产航空铝合金[1, 3]。其板材具有优良的断裂韧性和卓越的抗疲劳损伤性能,是国产大飞机的机身蒙皮和机翼壁板的首选材料[4]。热加工是2E12铝合金生产的关键环节[5-6],因此,2E12合金在热加工过程中的变形行为以及组织演变规律一直是研究人员关注的重点[7]。黄裕金等[8]对2E12合金热变形行为进行研究,其研究结果表明应变速率和变形温度对2E12合金的流变应力影响显著,流变应力随着温度的升高而降低,随着应变速率的增大而增大。此外,合金中存在的细小第2相会阻碍位错的运动,从而抑制合金的动态回复行为。杜凤山等[9]对2E12铝合金铸锭的均匀化和热加工工艺进行了研究,其结果表明合金在高温均匀化过程中容易出现过烧现象,并会对合金的热变形行为造成明显影响。综上所述,合金的初始态的组织特征对于其热变形行为有着显著影响[10-13],特别是在2E12合金铸锭中,共晶组织的溶解速率对均匀化温度十分敏感[4, 9],其在低温下溶解十分缓慢而在高温下溶解较为迅速。工业上通常采取高温长时间的均匀化处理来消除合金中的共晶组织。但是,由于大型铸锭控温难,为避免出现过烧现象,大型2E12合金铸锭通常在较低温度下进行均匀化处理,因此,合金中不可避免地残留有部分共晶组织。然而,人们对共晶组织对2E12合金热变形有何影响尚不清楚[8-10]。为此,本文作者通过不同的热处理方法获得完全不含共晶组织和富含共晶组织2种微结构特征的2E12合金铸锭,并利用Gleeble-1500热模拟实验机对2种合金的热变形行为进行研究,分析共晶组织对合金热变形行为以及组织演变规律的影响。

1 实验材料与方法

实验所用的2E12合金铸锭由西南铝业(集团)有限责任公司提供。铸锭采用常规的模铸方法获得,铸锭长×宽×高为400 mm×1 620 mm×2 500 mm。合金的化学成分为Al-4.21Cu-1.41Mg-0.58Mn-0.08Fe- 0.06Si(质量分数,%)。

在铸锭中间部位选取长×宽×高为15 mm×15 mm×10 mm的长方体作为实验试样。将试样置于马弗炉中进行热处理获得2种不同初始组织状态特征的合金,其制备方法如表1所示。

利用Gleeble-1500对2种不同初始组织的合金分别进行热压缩变形试验。实验选取340,390,440和490 ℃这4个变形温度以及0.001,0.01,0.1,1和10 s-1这5个应变速率。为减小试样与挤压杆之间摩擦力对应力状态的影响,试样两端涂上75%(质量分数)石墨+20%机油+5%硝酸三甲苯脂做润滑剂。当压缩实验完成后,将样品迅速水冷到室温以保留热变形时的组织。

表1 2种不同组织特征2E12合金的制备方法

Table 1 Preparation methods of 2E12 alloys with different microstructures

为更直观地观察合金变形后的形貌特征,在变形前,对试样表面进行抛光处理。采用FEI Sirion 200场发射扫描电镜(SEM)观察变形后合金的表面形貌特征,进而分析合金的变形机理。此外,利用JSM- 5600LV型场发射型SEM配带的EBSD探测系统对合金的晶粒形貌进行分析。利用TecnaiG2 F20透射电镜(TEM)对合金变形后的位错等亚结构进行观察。TEM试样在 MIT-II型双喷电解仪上制备,双喷液采用25%(体积分数)硝酸+75%甲醇混合溶液,电压为15~20 V,工作电流控制在50~100 mA,采用液氮冷却至-25 ℃左右。

2 结果与分析

2.1 合金初始态的组织特征

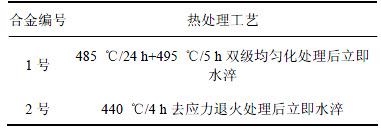

图1所示为2种合金的背散射电子(back scattered electron, BSE)形貌照片。从图1可以看出:1号合金没有明显的共晶组织,仅保留有很少量的难熔第2相粒子[4](图1(a))。这说明经双级均匀化处理后,合金中的共晶组织已经充分溶解,大部分合金元素溶入基体中,此时合金处于高度的过饱和状态[11-13]。与1号合金完全不同,2号合金沿晶界连续分布着众多粗大的骨骼状共晶组织(图1(b))。通过观察可以发现,这些共晶组织由黑色、灰色和白色这3种颜色的第2相组成。根据文献[14-15]可知这种共晶组织为α(Al)+ θ(Al2Cu)+S(Al2CuMg)三元共晶。

2.2 合金的流变应力

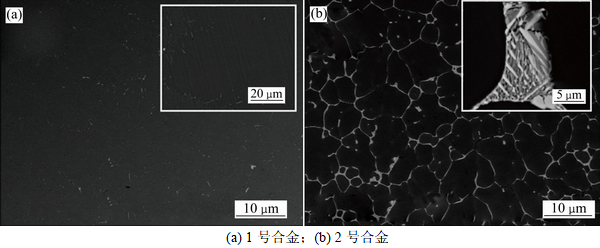

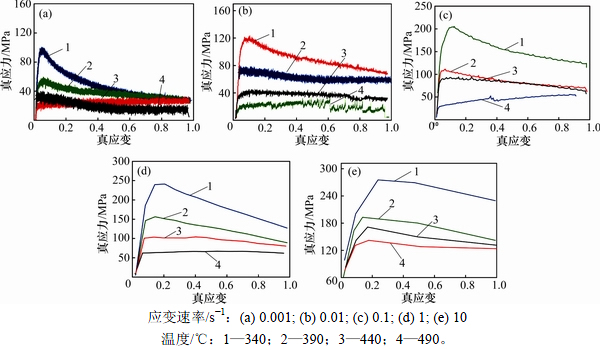

图2和图3所示分别为不同应变速率条件下1号合金、2号合金在340,390,440和490 ℃热压缩变形条件下的真应力-真应变曲线。

通过观察可以发现,在同一变形条件下,随着真应变的增加,2号合金的真应力均呈现先急剧增大,达到峰值后逐渐降低的趋势(图3)。这说明该合金在所有变形条件下均显示出明显的动态软化特征[16-17]。1号合金在340,390,440 ℃时的真应力曲线特征与2号合金的相似(图2)。但在490 ℃变形条件下,其动态软化特征不明显。尤其当应变速率低于1 s-1时,随着应变量增加,1号合金的真应力甚至持续增大。这说明合金在此变形条件下存在一定的加工硬化现象。

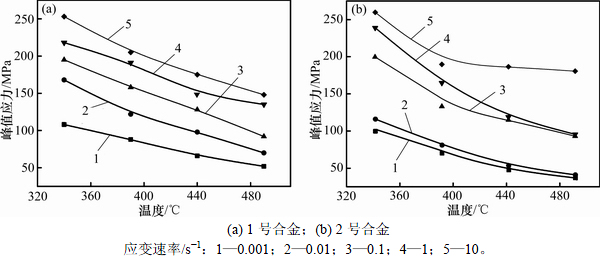

图4所示为2种合金在不同变形条件下的峰值应力。由图4可知:在实验所施加的变形条件下,2种合金的真应力-真应变曲线变化规律基本相同,即在相同的应变速率下,合金的真应力随着变形温度的升高而减小;在同一变形温度下,合金的真应力随着应变速率的增大而增大。在较低的应变速率下(0.001≤ ≤0.1 s-1),1号合金的峰值应力更高;而在较高的应变速率下(

≤0.1 s-1),1号合金的峰值应力更高;而在较高的应变速率下( 10 s-1),2号合金峰值应力较高。

10 s-1),2号合金峰值应力较高。

图1 合金的BSE形貌照片

Fig. 1 BSE images of alloy

图2 1号合金在不同应变速率下的真应力-真应变曲线

Fig. 2 Flow stress-true strain curves of alloy 1 deformed at different strain rates

图3 2号合金在不同应变速率下的真应力-真应变曲线

Fig. 3 Flow stress-true strain curves of alloy 2 deformed at different strain rates

图4 合金在不同变形条件下的峰值应力

Fig. 4 Peak stress values of alloys under different deformation conditions

2.3 失效行为分析

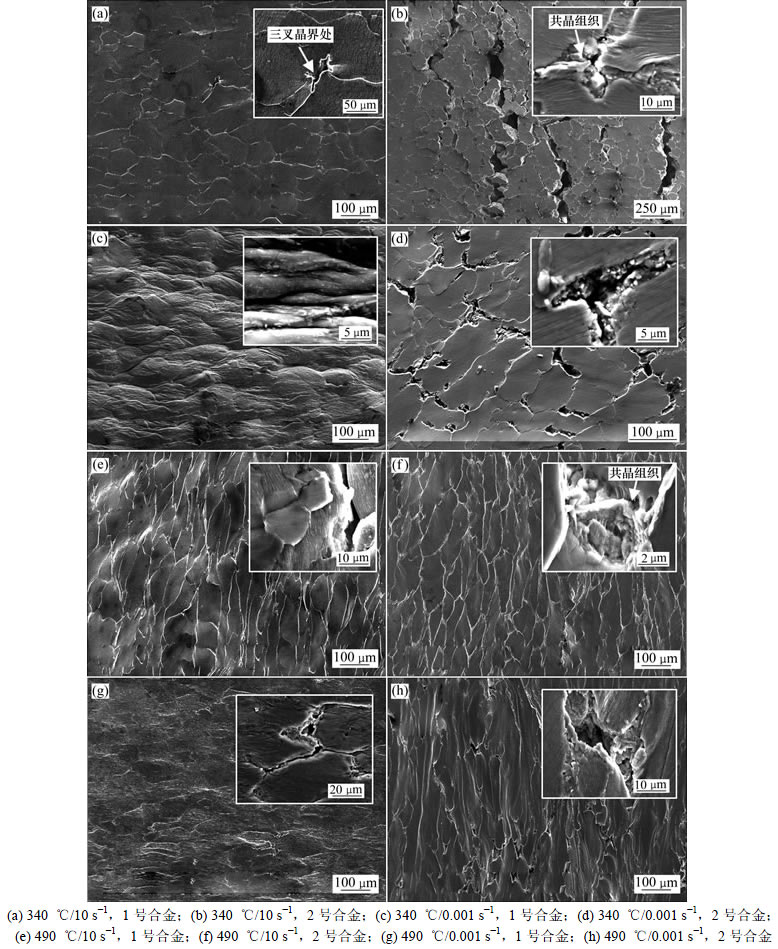

图5所示为2种合金在不同变形条件下压缩变形60%后的表面形貌。从图5可以看出:在340 ℃/10 s-1变形条件下,2种合金都存在一定程度的变形失稳现象。其中,1号合金的变形失稳主要集中在三叉晶界处,并且在部分三叉晶界处出现少量微裂纹(图5(a))。2号合金的变形失稳非常严重,出现大量沿晶裂纹(图5(b))。经观察发现,2号合金的沿晶裂纹主要源于晶界处共晶组织的破碎。在340 ℃/0.001 s-1变形条件下,1号合金表面整体上凹凸不平,局部区域出现严重的扭曲(图5(c))。这说明在该变形条件下,合金晶内发生显著的变形。2号合金在该变形条件下的表面较为平整,但合金晶界处的共晶组织发生明显的破碎并形成大量孔洞,部分孔洞彼此连接成型细小的裂纹(图5(d))。在490 ℃/10 s-1变形条件下,1号合金表面形貌展现出明显的流变特征,但部分晶界(特别是三叉晶界)发生明显的开裂现象(图5(e))。在2号合金中,晶界处共晶组织发生了严重的熔化现象(图5(f))。在490 ℃/0.001 s-1变形条件下, 1号合金三叉晶界处出现了明显的开裂现象(图5(g)),而2号合金的晶界已经完全弱化,合金显示出一定的粘流变形特征(图5(h))[18-20]。

2.4 合金的变形机理

在抛光处理后,试样表面的局部区域不可避免地会留有一些非常平直的划痕。在合金变形过程中,这些划痕会根据合金的变形特征而发生变化。因此,通过观察变形后合金表面划痕的形貌特征,可以对合金的变形机制进行分析。

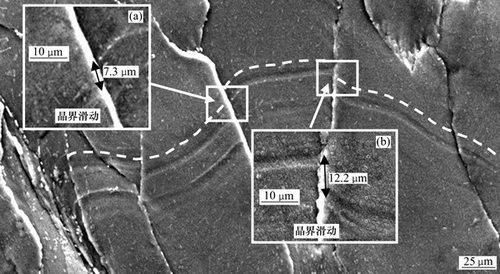

图6所示为1号合金在340 ℃/10 s-1 条件下压缩变形20%后的表面SEM形貌照片。由图6可知:合金表面存在2条平行的划痕并且划痕在晶粒内部时发生非常严重的扭曲。这说明在该变形条件下合金晶内变形十分显著。此外,经观察发现,划痕在穿过图6(a)和图6(b)所示的2处晶界时分别发生7.3 μm和12.2 μm的错动。这表明在此变形条件下,1号合金发生明显的晶界滑移。

图5 合金试样在不同变形条件下压缩变形60%后的表面形貌

Fig. 5 Surface morphologies of alloys after 60% deformation

图6 1号合金在340 ℃/10 s-1条件下压缩变形20%后的表面SEM形貌照片

Fig. 6 SEM surface morphology of alloy 1 deformed at 340 ℃/10 s-1

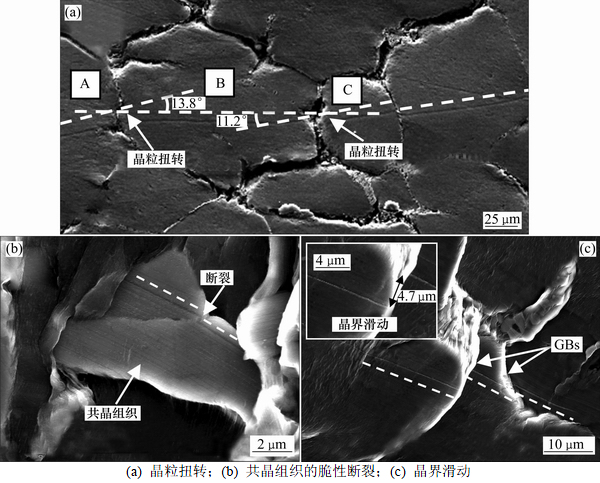

图7(a)所示为2号合金在340 ℃/10 s-1条件下压缩变形20%后的SEM表面形貌照片。由图7(a)可知:试样表面在水平方向有1条清晰的划痕;该划痕在穿过A和B这2个晶粒之间的晶界时发生约13.8°的偏转,在穿过B和C这2个晶粒之间的晶界时也发生约11.2°的偏转。这说明合金在变形时,晶粒之间发生了明显的相对转动。划痕在穿过晶粒内部时仍然保持非常平直,这说明在该变形条件下,2号合金晶内变形并不明显。

图7(b)所示为2号合金在变形后发生破碎的共晶组织的SEM形貌照片。经观察发现,共晶组织表面保留有细小的划痕。这些划痕仅在共晶组织的断裂处发生明显的错动而其他区域仍保持完全平直,这说明共晶组织在破碎前完全没有发生塑性变形,其断裂属于完全脆性断裂。此外,2号合金在该变形条件下也可以观测到大量晶界滑移的特征,如图7(c)所示。

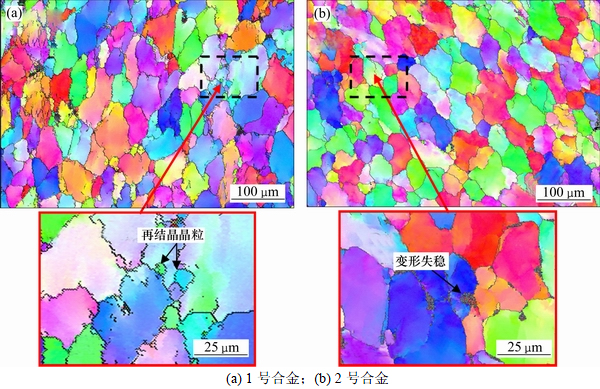

图8所示为2种不同微结构特征的合金在440 ℃/0.001 s-1条件下压缩变形20%后EBSD形貌照片。由图8(a)可知:在1号合金的晶界处出现细小的等轴晶粒,表明合金在该变形条件下出现动态再结晶现象。由图8(b)可知:2号合金在该变形条件下的再结晶特征不明显,且在局部晶界出现了一定程度的变形失稳。

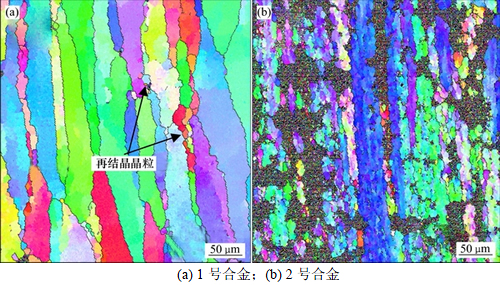

图9所示为合金在440 ℃/0.001 s-1条件下压缩变形60%后的EBSD形貌照片。由图9可知:随着变形量的继续增加,合金的晶粒在垂直于压缩方向上被逐渐拉长;在1号合金中,仍然可以观测到明显的再结晶晶粒(图9(a)),但是,2号合金的再结晶行为并不明显(图9(b))。

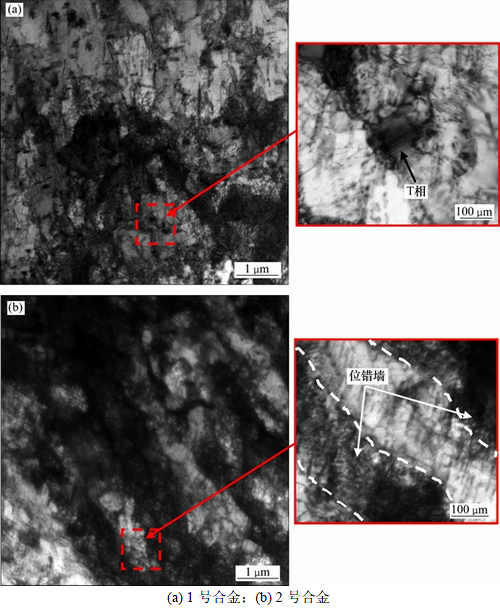

图10所示为2种合金在340 ℃/10 s-1条件下压缩变形60%后的TEM形貌照片。在1号合金中弥散分布着大量尺寸为200~500 nm的细小第2相粒子。合金中的位错缠绕在这些第2相粒子周围,形成高密度的位错网(图10(a))。根据文献[12, 18-20]可知,1号合金中的这些弥散第2相是T相,主要在合金均匀化过程中形成。一般认为,T相粒子对位错滑移有明显的阻碍作用,可以在一定程度上对合金起到弥散强化作用。由于2号合金仅进行了较低温度退火而没有经过均匀化处理,因此,晶内的T相粒子很少。因为缺少T相粒子的阻碍作用,位错可以在合金基体中进行长程滑移,从而在晶内局部区域形成高密度的位错墙[13](图10(b))。

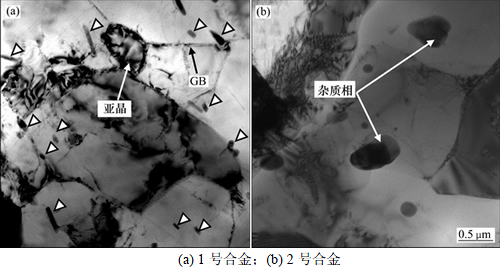

图11所示为2种合金在490 ℃/0.001 s-1条件下压缩变形60%后的TEM形貌照片。由图11可知:与 340 ℃/10 s-1的变形条件相比,2种合金在490 ℃/0.001 s-1变形条件下的位错密度明显减少并且出现大量亚晶,这说明合金发生明显的动态回复。在1号合金中,亚晶的尺寸非常小(图11(a))。这主要是因为合金晶内有大量弥散分布的T相粒子,这些T相粒子对晶界有明显的钉扎作用,从而抑制了晶界的迁移。在2号合金中,T相粒子的数量很少,晶内仅有少量由共晶组织破碎所产生的粗大第2相粒子(图11(b))。由于缺乏大量弥散T相粒子的钉扎作用,合金晶界的迁移较为容易,因此,2号合金的亚晶尺寸较大。根据上述分析可知:1号合金在340~440 ℃之间变形时的再结晶行为并不明显,因此,其动态软化主要是由动态回复引起的。相比于1号合金,2号合金更容易发生再结晶,因此,其动态软化特征也更加明显。此外,对比图11(a)和(b)可知:1号合金在490 ℃低应变速率下变形时之所以出现加工硬化行为(见图2),主要是因为T相粒子对晶界的钉扎作用在一定程度上抵消了合金的动态回复和再结晶所产生的软化作用。

图7 2号合金在340 ℃/10 s-1条件下压缩变形20%后的表面SEM形貌

Fig. 7 SEM surface morphologies of alloy 2 deformed 20% at 340 ℃/10 s-1

图8 合金在440 ℃/0.001 s-1条件下压缩变形20%后的EBSD形貌照片

Fig. 8 EBSD-derived IPF maps of alloys deformed 20% at 440 ℃/0.001 s-1

图9 合金在440 ℃/0.001 s-1条件下压缩变形60%后的EBSD形貌照片

Fig. 9 EBSD-derived IPF maps of alloys deformed 60% at 440 ℃/0.001 s-1

图10 合金在340 ℃/10 s-1条件下压缩变形60%后的TEM形貌照片

Fig. 10 TEM images of alloys deformed 60% at 340 ℃/10 s-1

图11合金在490 ℃/0.001 s-1条件下压缩变形60%后的TEM形貌照片

Fig.11 TEM images of alloys deformed 60% at 440 ℃/0.001 s-1

3 结论

1) 在0.001~0.1 s-1的应变速率下,过饱和固溶体合金的峰值应力更大,而在10 s-1的应变速率下,富含共晶组织合金则拥有较大的峰值应力。

2) 在340~490 ℃温度范围内,变形温度对合金的热变形行为影响显著。过饱和固溶体合金在340 ℃和490 ℃热变形时三叉晶界容易出现开裂。富含共晶组织合金在340 ℃热变形时晶界共晶组织发生严重破碎并形成大量沿晶裂纹,在490 ℃变形时共晶组织出现明显的熔化现象。

3) 在340 ℃/10 s-1条件下压缩变形20%后,过饱和固溶体合金晶内严重变形并且出现一定的晶界滑移,富含共晶组织合金的变形方式主要包括晶粒扭转和晶界滑移。

4) 在合金中弥散分布的T相粒子一方面可以抑制高密度位错墙的产生,有利于合金变形均匀,另一方面可以钉扎亚晶界,有利于细化晶粒。

参考文献:

[1] 曹春晓. 一代材料技术, 一代大型飞机[J]. 航空学报, 2008, 29(3): 701-706.

CAO Chunxiao. One generation of material technology, one generation of large aircraft[J]. Acta Aeronautica et Astronautica Sinica, 2008, 29(3): 701-706.

[2] CHEN Y Q, PAN S P, ZHOU M Z, et al. Effects of inclusions, grain boundaries and grain orientations on the fatigue crack initiation and propagation behavior of 2524-T3 Al alloy[J]. Materials Science and Engineering A, 2013, 580(15): 150-158.

[3] 管琪, 刘慧丛, 朱立群, 等. 2524铝合金包铝层在模拟油箱积水环境中结垢及其对腐蚀行为的影响[J]. 材料工程, 2013, 5: 11-15.

GUAN Qi, LIU Huicong, ZHU Liqun, et al. Scaling of 2524 aluminum alloy with cladding in simulated fuel tank water environment and influence to corrosion behavior[J]. Journal of Materials Engineering, 2013, 5: 11-15.

[4] CHEN Y Q, YI D Q, JIANG Y, et al. Concurrent formation of two different type precipitation-free zones during the initial stage of homogenization[J]. Philosophical Magazine, 2013, 93(18): 2269-2278.

[5] 谢俊峰, 朱有利, 黄元林, 等. 2A12与2A11铝合金超声波焊接工艺与组织研究[J]. 材料工程, 2015, 43(3): 54-59.

XIE Junfeng, ZHU Youli, HUANG Yuanlin, et al. Researches on process and microstructure of 2A12 and 2A11 aluminum ultrasonic welds[J]. Journal of Materials Engineering, 2015, 43(3): 54-59.

[6] SUN Z C, YIN J L, YANG H. Microstructure evolution and microhardness of 7075 aluminum alloy during heat treatment by considering hot deformation history[J]. Advanced Materials Research, 2013, 699: 851-858.

[7] LIN Y C, XIA Y C, CHEN X M, et al. Constitutive descriptions for hot compressed 2124-T851 aluminum alloy over a wide range of temperature and strain rate[J]. Computational Materials Science, 2010, 50(1): 227-233.

[8] 黄裕金, 陈志国, 舒军, 等. 2E12铝合金的高温塑性变形流变应力行为[J]. 中国有色金属学报, 2010, 20(11): 2094-2100.

HUANG Yujin, CHEN Zhiguo, SHU Jun, et al. Flow stress behavior of 2E12 aluminum alloy during hot plastic deformation at high temperature[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(11): 2094-2100.

[9] 杜凤山, 邓少奎, 闫亮, 等. 2E12铝合金过烧温度及高温塑性研究[J].材料工程, 2008, 7: 18-21.

DU Fengshan, DENG Shaokui, YAN Liang, et al. Study on overheat temperature of ingot and high temperature plasticity of 2E12 aluminum alloy[J]. Journal of Materials Engineering, 2008, 7: 18-21.

[10] 黄裕金, 陈志国. 2E12铝合金热变形过程中的动态软化机制[J]. 机械工程材料, 2011, 35(11): 22-27.

HUANG Yujin, CHEN Zhiguo. Dynamic softening mechanism of 2E12 aluminum alloy during hot deformation[J]. Materials for Mechanical Engineering, 2011, 35(11): 22-27.

[11] NIKULIN I, KIPELOVA A, MALOPHEYEV S, et al. Effect of second phase particles on grain refinement during equal-channel angular pressing of an Al-Mg-Mn alloy[J]. Acta Materialia, 2012, 60(2): 487-497.

[12] CHEN Y Q, YI D Q, JIANG Y, et al. Twinning and orientation relationships of T-phase precipitates in an Al matrix[J]. Journal of Materials Science, 2013, 48(8): 3225-3231.

[13] PAUL H, MAURICE C, DRIVER J H, et al. Application of orientation imaging to the study of substructural development in cold deformed Al-0.3%Mn single crystal of {110}<112> orientation[J]. IOP Conference Series: Materials Science and Engineering, 2010, 7: 012024.

[14] 陈宇强, 潘素平, 刘文辉, 等. 析出相对Al-Cu-Mg合金蠕变行为的影响[J]. 中国有色金属学报, 2015, 25(4): 900-909.

CHEN Yuqiang, PAN Suping, LIU Wenhui, et al. Effect of precipitates on creep behaviors of Al-Cu-Mg alloy[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(4): 900-909.

[15] 陈宇强, 易丹青, 潘素平, 等. 蠕变温度对Al-Cu-Mg合金晶内S′相析出过程的影响[J]. 稀有金属材料与工程, 2011, 40(1): 63-68.

CHEN Yuqiang, YI Danqing, PAN Suping, et al. Effects of creep temperatures on the precipitation of S′ phases in Al-Cu-Mg alloys[J]. Rare Metal Materials and Engineering, 2011, 40(1): 63-68.

[16] 周坚, 潘清林, 张志野, 等. 7B50 铝合金热变形组织演变[J]. 材料热处理技术, 2012, 41(2): 20-24.

ZHOU Jian, PAN Qinglin, ZHANG Zhiye, et al. Microstructure evolution of 7B50 alloy during hot deformation[J]. Material and Heat Treatment, 2012, 41(2): 20-24.

[17] 肖罡, 李落星, 叶拓. 基于材料参数修正的6013铝合金热变形本构模型优化[J]. 中国有色金属学报, 2014, 24(6): 1393-1400.

XIAO Gang, LI Luoxing, YE Tuo. Optimization of constitutive equation during hot deformation of 6013 aluminum alloy based on modified material parameters[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(6): 1393-1400.

[18] CHEN Z W, CHEN P, LI S S. Effect of Ce addition on microstructure of Al20Cu2Mn3 twin phase in an Al-Cu-Mn casting alloy[J]. Materials Science and Engineering A, 2012, 532(15): 606-609.

[19] SHEN Z J, LIU C H, DING Q Q, et al. The structure determination of Al20Cu2Mn3 by near atomic resolution chemical mapping[J]. Journal of Alloys and Compounds, 2014, 601(15): 25-30.

(编辑 伍锦花)

收稿日期:2016-12-24;修回日期:2017-02-08

基金项目(Foundation item):国家自然科学基金资助项目(51405153,51475162) (Projects(51405153, 51475162) supported by the National Natural Science Foundation of China)

通信作者:陈宇强,博士,讲师,从事高性能铝合金材料研究;E-mail: yqchen1984@163.com