软锰矿与硫化铋矿交互焙烧过程的热力学分析

张传福,夏楚平,王志坚,湛菁,邬建辉

(中南大学 冶金与环境学院,湖南 长沙,410083)

摘要:提出利用软锰矿与低品位硫化铋矿交互焙烧反应可同时进行氧化锰的硫酸化焙烧和硫化铋的氧化焙烧2个焙烧过程从而实现二氧化硫的零排放的新工艺。首先从热力学角度并通过热重分析等手段在理论上论证新工艺的可行性。然后进行焙烧试验,研究物料配比n(MnO2)/n(S)对硫转化率及固硫率的影响。研究结果表明:软锰矿在交互焙烧过程中氧化锰转化成硫酸锰的固硫率非常高。当固定焙烧温度为923 K、焙烧时间为2 h和n(MnO2)/n(S)≥1.6时,固硫率大于99%,其硫转化率高达94%。原矿中铋在焙烧产物中主要以Bi2O3和Bi28O32(SO4)10形态存在,其他硫化物物相消失,表明在交互焙烧过程中硫化铋充分转化成氧化物。

关键词:硫化铋矿;交互焙烧;软锰矿;固硫

中图分类号:TF046.2 文献标志码:A 文章编号:1672-7207(2013)10-3984-07

Thermodynamic analysis of interactive roasting process of bismuth sulfide ore and pyrolusite

ZHANG Chuanfu, XIA Chuping, WANG Zhijian, ZHAN Jing, WU Jianhui

(School of Metallurgy and Environment, Central South University, Changsha 410083, China)

Abstract: The new method of interactive roasting with bismuth sulfide ore and pyrolusite was put forward, which consists of two simultaneous processes: sulphating roasting of manganese oxide and oxidizing roasting of bismuth sulfide to achieve zero emissions of sulfur dioxide. Firstly the feasibility was demonstrated theoretically through thermodynamics analysis and thermogravimetry. Then roasting experiments were carried out, and then effect of the material ratio n(MnO2)/n(S) on sulfur conversion ratio and sulfur-retained ratio was studied. The result shows that sulfur-retained ratio of pyrolusite by process of manganese oxide into manganese sulfate is very high. When roasting temperature is 923 K, roasting time is 2 h, and n(MnO2)/n(S)≥1.6, the sulfur-retained ratio reaches about 99% or more, and the sulfur conversion rate reaches 94%. The bismuth in raw ore mainly converts into the form of Bi2O3 and Bi28O32(SO4)10, and other sulfide phases disappear, which shows that oxidizing roasting of sulfide is enough.

Key words: bismuth sulfide; interactive roasting; pyrolusite; sulfur-retained

铋资源是我国最宝贵的优势资源之一,储量约占世界75%[1]。铋以其安全无毒的特性,正逐渐取代镉、锑、汞、铅等有毒元素广泛应用于医药、冶金添加剂、易熔合金、超导材料、化妆品以及核能源等诸多领域[2]。国内对于硫化铋精矿通常采用沉淀熔炼、混合熔炼及湿法氧化浸出工艺。湿法氧化浸出工艺要求采用防腐设备[3],且浸出过程浸出渣过滤和洗涤困难[4],不利于生产的正常进行。火法炼铋主要采用沉淀熔炼工艺[5],是目前铋的主要生产方法。但目前绝大部分火法冶炼厂生产规模小,工艺及设备落后,总体质量不高。生产方式主要采用反射炉或回转窑等设备,绝大部分厂家不具备二氧化硫回收能力,每年向大气中排放大量的低浓度含硫烟气(主要含SO2),对环境造成极大污染,另外铁屑消耗大、能耗高,这些问题制约着铋冶炼工业的稳定持续性发展,因此,SO2烟气的治理及成本控制成了亟待解决的关键问题。当前冶金行业针对SO2烟气污染问题主要有2种解决方案:一是利用含硫烟气制酸,而工业实践表明,制酸相关技术设备所需投资很大,只有在生产规模较大,设备先进的条件下才是经济可行的;二是直接在焙烧过程中进行固硫,防止硫以二氧化硫形式逸出。根据目前国内绝大多数提铋厂家规模小,技术水平落后等特点,第二种方案更加科学可行,当前这方面相关研究主要有利用石灰[6],软锰矿在焙烧过程中固硫[7]以及硫化铋精矿低温碱性熔炼[8]等工艺。软锰矿或化学二氧化锰是一种很好的固硫剂[9-10],利用其强氧化性和硫化矿的还原性,早在20世纪70年代就已经发展了硫化矿物(如黄铁矿[11-12]、闪锌矿[13]、黄铜矿)与软锰矿的联合浸出工艺[14]。近年来又有人将软锰矿与硫化矿(主要为辉钼矿[15] 、黄铁矿)进行共同焙烧,在焙烧过程中利用软锰矿吸收负二价S或还原性气体SO2,并生成MnSO4,该工艺取得了较好的效果,有效消除了硫化矿焙烧过程中SO2烟气问题。为解决目前铋传统冶炼主要存在的普遍而突出的低浓度SO2污染问题,结合我国提铋厂家的生产实际情况特点,在两矿湿法和两矿干法的相关研究基础上,本文作者提出利用软锰矿与硫化铋矿进行交互焙烧新工艺研究思路,利用软锰矿在硫化铋矿焙烧过程中进行固硫,并为下一步浸出工艺提供更加易于处理的氧化铋矿。并通过热力学计算及热重-差热分析方法研究硫化铋矿、软锰矿以及软锰矿和硫化铋矿混合焙烧的特性,论证了交互焙烧工艺的可行性,最后考察了不同软锰矿的量对硫化铋矿焙烧过程固硫率及硫转化率的影响。

1 硫化铋矿与软锰矿交互焙烧新工艺的提出

Bi2S3在空气中于958 K开始分解,氧化分解(Bi2S3(s)+9/2O2(g)=Bi2O3(s)+3SO2(g), (T)=0.234T- 1 307.92,kJ/mol)时放出大量的热,反应平衡常数非常大,反应能在短时间内迅速完成。在高温条件下此气-固反应过程主要由气体扩散控制,即取决于氧气和二氧化硫通过硫化铋表面生成的氧化铋膜向相反方向的扩散速率。当温度大于873 K时,氧化铋膜变得疏松多孔,易于气体的传输,且温度越高,氧化膜越疏松,越有利于硫化铋的氧化焙烧。

(T)=0.234T- 1 307.92,kJ/mol)时放出大量的热,反应平衡常数非常大,反应能在短时间内迅速完成。在高温条件下此气-固反应过程主要由气体扩散控制,即取决于氧气和二氧化硫通过硫化铋表面生成的氧化铋膜向相反方向的扩散速率。当温度大于873 K时,氧化铋膜变得疏松多孔,易于气体的传输,且温度越高,氧化膜越疏松,越有利于硫化铋的氧化焙烧。

软锰矿来源广且价格低廉,疏松多孔且疏水,能很好地均匀分散于硫化铋矿中,二者混合研磨过程中能使得铋矿分布更加均匀和疏松,这样更有利于气体的扩散和传输,并增大有效反应面积和反应活性中心,从而促进焙烧反应的进行;软锰矿的主要成分MnO2氧化性极强,能吸收焙烧过程产生的SO2并生成稳定的硫酸锰,在达到固硫作用的同时直接或间接促进了硫化铋矿的氧化分解。该工艺不仅能有效消除传统火法提铋SO2烟气的污染,同时实现软锰矿资源的综合利用。

2 硫化铋与软锰矿交互焙烧热力学分析

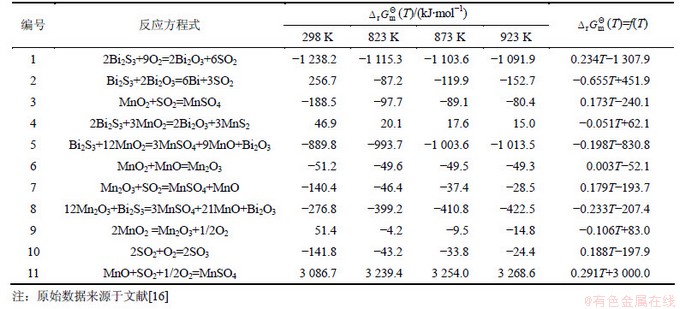

硫化铋矿与软锰矿的交互焙烧过程实质上主要涉及以下两大反应:Bi2S3 和其他金属硫化物的氧化(氧化剂为氧气或MnO2)和MnO2的分解、还原(还原剂为SO2或金属硫化物)。铋和锰涉及的主要反应及其热力学计算结果如表1所示。由表1可知:反应⑴的自由能在298~923 K温度范围内均为很负,说明硫化铋的氧化分解能彻底进行,反应(2)说明控制一定条件焙烧过程直接获得铋是可行的。从反应(3)和(7)可以看出:理论上软锰矿及其分解产物Mn2O3均能够吸收二氧化硫并转化为MnSO4,反应基本上不可逆,且焙烧温度越低,自由能越负,反应趋势越大;随着反应(3)和(7)的进行,实际上反应(1)和(2)产生的二氧化硫被不断消耗掉, 逐渐下降,根据热力学反应平衡原理,反应(3)和(7)的进行能间接地促进硫化铋的氧化焙烧,这两点是软锰矿在交互焙烧过程中实现固硫作用的主要理论基础,说明该工艺在热力学理论上是可行的。反应(5)和(8)说明理论上软锰矿或Mn2O3作为氧化剂直接将硫化铋氧化成为氧化铋并生成MnSO4同样是可能的。

逐渐下降,根据热力学反应平衡原理,反应(3)和(7)的进行能间接地促进硫化铋的氧化焙烧,这两点是软锰矿在交互焙烧过程中实现固硫作用的主要理论基础,说明该工艺在热力学理论上是可行的。反应(5)和(8)说明理论上软锰矿或Mn2O3作为氧化剂直接将硫化铋氧化成为氧化铋并生成MnSO4同样是可能的。

基于上述表达式,采用先进热力学计算软件FactSage 6.2计算作图得到Bi-Mn-S-O四元系在不同温度条件下的优势区域图,如图1所示。

表1 交互焙烧体系可能发生的反应及自由能

Table 1 Possible reactions and their free energy in roasting system

图1 不同温度条件下Bi-Mn-S-O系优势区域图

Fig. 1 Bi-Mn-S-O system pourbaix diagram at different temperatures

由图1可知:(1) 存在Bi2O3与MnSO4共存的优势区域,因此从热力学角度说明交互焙烧新工艺理论上是可行的。(2) (Bi2O3+MnSO4)优势区域所对应的平衡氧分压很小,平衡氧压范围p(O2)=(10-12~10-5)×101.325 kPa,这说明在较高温度条件下,硫化铋的氧化趋势很大,对氧化气氛的要求较低,故在自然通风(p(O2)约为2×104 Pa)或鼓入空气的条件下,就能持续为交互焙烧提供足够的氧气使其达到平衡;同一优势区域内SO2平衡分压随氧平衡分压增大而下降。(3) 温度升高,(Bi2O3+MnSO4)优势区域往右上方向偏移,所对应的平衡氧分压和平衡SO2分压均增大,而一定条件下反应体系平衡SO2分压越低,固硫效果越好,因此低温更利于固硫。但同时应考虑反应的实际进行程度,温度过低,不利于气体的扩散和传质,从而降低反应速率,因此,焙烧温度应结合实际焙烧效果进行综合考虑。

结合图1和表1,在0~1 000 K温度范围内,焙烧过程中Bi2S3的氧化(氧化剂为O2或MnO2和Mn2O3)及软锰矿(MnO2)的还原(还原剂为二氧化硫或硫化铋)两大主要反应的标准吉布斯自由能均很负,所获热力学推动力很大,反应能进行地非常彻底,实际过程主要取决于强化动力学因素。交互焙烧是一个气-固多相反应,在高温下一般为气体扩散速率控制,即取决于氧气和二氧化硫在焙烧物料中的传递速率,影响其传递速率的主要因素为温度、气体流速、两矿接触界面性质、矿物粒度、反应时间等,这些因素是具体工艺实验须重点考虑的条件。对于软锰矿的固硫作用,物料配比(软锰矿对硫化铋矿的过量系数)则是其主要影响因素。(Bi2O3+MnSO4)优势区域所对应的平衡氧分压很小,高温下硫化铋的氧化对氧化气氛要求不高,因此交互焙烧首先考虑直接向炉内鼓入空气。

3 硫化铋矿与软锰矿在热重分析过程中的交互反应

采用热分析仪(型号为SDT Q600 V8.0 Build 95)在空气气氛中,以283 K/min的升温速率对硫化铋矿(取自湖南郴州某硫化铋矿,其中w(Bi)=25.95%,w(S)=27.50%)、软锰矿及硫化铋矿+软锰矿(w(MnO2)=38.92%,n(MnO2):n(S)=1:1)进行热重差示扫描量热分析,其结果如图2~4所示。

图2 硫化铋矿的热重差示扫描量热分析曲线

Fig. 2 Thermogravimetric and differential scanning calorimetry curves for bismuth

图3 软锰矿的热重差示扫描量热分析曲线

Fig. 3 Thermogravimetric and differential scanning calorimetry curves for pyrolusite

图4 硫化铋矿和软锰矿(n(MnO2):n(S)=1:1)的热重差示扫描量热分析曲线

Fig. 4 Thermogravimetric and differential scanning calorimetry curves for mixture of bismuth sulfide ore and pyrolusite(n(MnO2):n(S)=1:1)

由图2可看出:硫化铋矿样品在313~1 273 K时一直处于质量损失状态。在313~473 K,热重曲线有所下降,质量损失过程主要由硫化铋矿物中少量水分、灰分或者有机浮选药剂的挥发或分解引起;在473~723 K,硫化铋矿热重曲线无变化,对应DSC曲线无明显吸热或放热峰;在723~1 023 K,热重曲线急剧下降,对应DSC曲线出现明显的放热峰,这主要是由于复杂硫化铋矿中Bi2S3以及其他硫化矿物开始氧化分解并逐渐加剧,释放出大量的二氧化硫,导致样品质量急剧减少;在1 023~1 123 K样品质量基本不变,此时硫化铋矿正好完全氧化分解;当温度大于1 123 K时,由于部分金属硫酸盐的分解,样品质量有所减少,对应DSC曲线出现吸热峰。

从图3可看出:随着温度升高,软锰矿样品质量不断减少。在283~763 K,热重曲线有所下降,对应DSC曲线有较小吸热峰存在,这是由于该过程中样品中少量水分,有机物等杂质的分解挥发导致质量减少,且说明其中杂质量较多;当温度升至803~1 073 K时,热重曲线下降明显,对应DSC曲线有明显的吸热峰,这主要是由于MnO2的分解造成,放出氧气并生成Mn2O3;温度升高,三氧化二锰继续分解为四氧化三锰,但热重曲线变化不大。

由图4可看出:在283~693 K,热重曲线下降,对应DSC曲线出现较小吸热峰,但不明显,结合图2和图3,质量损失主要是由于硫化铋矿和软锰矿中水分、有机质、灰分等的分解和挥发造成;而在693~973 K,热重曲线明显上升,对应DSC曲线出现明显的放热峰,样品的质量迅速增加,对比相同温度区间条件下的图2和图3,可推断这是因为硫化铋矿和其他金属硫化物氧化分解释放出的二氧化硫气体,绝大部分被MnO2吸收,由于硫化物的氧化焙烧吸收了氧,同时产生的二氧化硫又被MnO2很快吸收并生成更稳定的硫酸锰,大大减少或避免了MnO2的分解,因此质量增加,这与后面交互焙烧试验焙烧产物质量增加是吻合的;当1 023~1 173 K时,由于生成的硫酸锰大量分解导致样品质量减小,对应DSC曲线出现吸热峰;1 173 K后分解基本完全,样品质量不变。

综上所述,交互焙烧过程中软锰矿中的MnO2转化为MnSO4和硫化铋矿中的Bi2S3转化为Bi2O3的效率非常高,这验证了上述热力学分析的正确性。

4 交互焙烧试验

4.1 实验原料

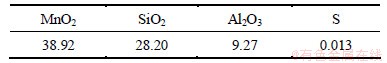

实验原料为湖南郴州某复杂低品位硫化铋矿、软锰矿。表2所示为硫化铋矿的主要化学成分,其中Bi,Fe和S含量较高;原铋矿中Bi主要以Bi2S3的物相形态存在,同时共存的其他主要物相为FeS2和CuFeS2,硫化铋矿属于复杂低品位型硫化矿。软锰矿平均粒度小于75 μm,其主要化学成分如表3所示,其中S含量很低。

表2 复杂低品位硫化铋矿主要成分(质量分数)

Table 2 Main compositions of complex low-grade bismuth sulfide ore %

表3 软锰矿主要成分(质量分数)

Table 3 Main compositions of pyrolusite %

4.2 实验方法

按配比n(MnO2)/n(S)称取一定量干燥的软锰矿和硫化铋矿(二者合计100 g左右),充分混合后置于气氛炉中,开动鼓风机向炉内鼓入空气,鼓风1 h待气流稳定后开始升温至设定温度,达到预定反应时间后取出焙砂。通过化学分析得到焙烧产物中硫和硫酸锰的含量。其中,固硫率R1按下式计算:

(1)

(1)

式中:m2为焙砂质量,g;w2为焙砂S的质量分数;m1为混矿总质量,g;w1为混矿S的质量分数。

原混矿中S转化为MnSO4的转化率R2按下式计算:

(2)

(2)

式中:m3表示所得焙砂中MnSO4含量,g;m4表示MnSO4中对应的硫含量,g,m4=0.212 m3。

5 试验结果与讨论

5.1 物料配比n(MnO2)/n(S)对固硫率及硫转化率的影响

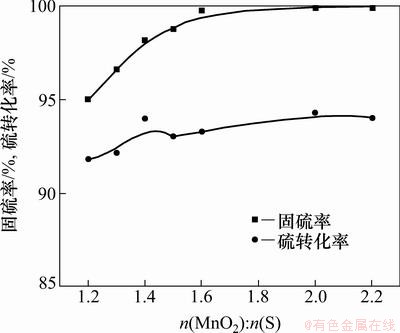

焙烧试验研究了物料配比n(MnO2)/n(S)对交互焙烧过程软锰矿的固硫作用及生成相应硫酸锰所得硫转化率的影响。结果如图5所示,其中选定焙烧温度为923 K,焙烧时间为2 h,通风量为140 L/h。

图5 配比n(MnO2)/n(S)对硫转化率和固硫率影响

Fig. 5 Effect of n(MnO2)/n(S) on S conversion ratio and sulfur-retained ratio

从图5可看出,软锰矿在焙烧过程中的固硫效果非常明显,当配比n(MnO2)/n(S)=1.2时,固硫率即达95%;固硫率随配比的增大而增大,当n(MnO2)/n(S)≥1.6时,固硫率达99%以上。同时,硫化铋矿中的硫转化为硫酸锰形式存在的转化率非常高,当n(MnO2)/n(S)=1.4时,达到94.04%,之后趋于稳定。通过进一步系统地优化焙烧工艺条件,如温度、时间、配比、矿物粒度、混料方式、通风量等,可在较低软锰矿用量条件下获得更佳的固硫和硫转化效果。

5.2 焙烧产物的物相分析

图6所示为焙烧温度为923 K,时间为2 h,n(MnO2)/n(S)=1.4,通风量为140 L/h实验条件下的焙烧产物的XRD谱。

由图6可看出:原矿中Bi2S3主要转化为Bi2O3和Bi28O32(SO4)10;原矿中FeS2主要转化为Fe2O3;MnO2在焙烧过程中顺利生成MnSO4,过量的MnO2主要以Mn2O3存在,同时发现有MnS生成,其余的主要为SiO2和CuO等。

图6 交互焙烧产物焙烧的物相分析

Fig. 6 XRD pattern of calcine from co-roasting

首先,Bi2O3 与MnSO4的顺利共同生成,从实验角度验证了图1热力学理论分析的正确性,亦即证明了本工艺的可行性。Bi2S3和FeS2等主要金属硫化物物相均已不存在,结合图5,绝大部分硫顺利转化为易于回收的硫酸锰,说明氧化焙烧充分。相对于Bi2S3,Bi2O3可直接酸浸出,解决了传统湿法提铋过程中须使用强氧化剂氧化浸出所带来的一系列固有缺陷和问题,生成的Bi28O32(SO4)10也易溶于酸,为下一步湿法提铋提供了更易于处理的含铋物料。不足之处是焙砂中有少量MnS生成以及少部分过量的MnO2和Mn2O3存在,这给Mn的回收带来一定困难。对本条件所得焙砂经物相成分分析,得到焙砂中S的所有存在形态及含量,并得到焙烧过程中S的平衡结果,如表4所示。

综合图5和图6,进一步验证了热力学及热重等理论分析的正确性。

表4 硫在焙烧过程中的平衡(质量分数)

Table 4 Main compositions of original ore %

6 结论

(1) 提出低品位硫化铋矿与软锰矿交互焙烧新工艺,同时进行氧化锰的硫酸化焙烧和硫化铋的氧化焙烧2个焙烧过程并能实现二氧化硫的零排放。

(2) 计算绘制了Bi-Mn-S-O系化学位相图并进行了热重-差热分析实验,为硫化铋矿与软锰矿交互焙烧新工艺提供了一定的理论基础。

(3) 进行了交互焙烧试验研究,确定了最佳实验条件。当固定焙烧温度923 K、焙烧时间2 h、n(MnO2)/n(S)≥1.6时,固硫率大于99%;其硫转化率高达94%。

参考文献:

[1] 王淑玲. 中国铋资源形势与对策[J]. 中国金属通报, 2009(48): 39-41.

WANG Shuling. Situation and strategies of bismuth of China[J]. China Metal Bulletin, 2009(48): 39-41.

[2] 魏洪洁. 铅阳极泥中锑铋分离提取的研究[D]. 沈阳: 东北大学材料与冶金学院, 2009: 6-9.

WEI Hongjie. Study on recovery process for stibium and bismuth from Pb anode slime[D]. Shenyang: Northeastern University. School of Materials and Metallurgy, 2009: 6-9.

[3] Maslova S G, Gulevitskaya I A, Epshtein L A. Separation of Bismuth and copper from complex ore according to combination flow sheet[J]. Obogashch Rud, 1976, 21(6): 35-38.

[4] Corneille E K. Hydrometallurgical extraction of copper and bismuth from a complex Ore[J]. Ind Miner Minerallurgie, 1977(3): 204-212.

[5] 汪立果. 铋冶金[M]. 北京: 冶金工业出版社, 1986: 17-95.

WANG Liguo. Bismuth metallurgy[M]. Beijing: Metallurgical Industry Press, 1986: 17-95.

[6] 徐盛明. 难处理银金精矿的无污染冶金新工艺及其应用基础研究[D]. 长沙: 中南大学冶金科学与工程学院, 1996: 1-11.

XU Shengming. Basic Study on pollution-free process and its application for intractable silver gold concentrates[D]. Changsha: Central South University. School of Metallurgical Science and Engineering, 1996: 1-11.

[7] 李春, 何良惠, 李升章, 等. 软锰矿与黄铁矿共同焙烧制备硫酸锰的研究[J]. 化学世界, 2000, 13(2): 66-69.

LI Chun, HE Lianghui, LI Shengzhang, et al. The preparation of manganese sulfate by the common roasting of pyrolusite and pyrite[J]. Chemistry World, 2000, 13(2): 66-69.

[8] 肖剑飞. 硫化铋精矿低温碱性熔炼新工艺研究[D]. 长沙: 中南大学冶金科学与工程学院, 2009: 1-11.

XIAO Jianfei. Study on a new process for alkaline smelting bismuth sulfide concentrate at low temperature[D]. Changsha: Central South University. School of Metallurgical Science and Engineering, 2009: 1-11.

[9] 韩效钊, 朱艳芳, 姚卫堂, 等. 软锰矿吸收二氧化硫制备硫酸锰(Ⅰ)[J]. 矿冶工程, 2003, 23(2): 53-55.

HAN Xiaozhao, ZHU Yanfang, YAO Weitang, et al. Preparation of manganese sulfate from pyrolusite by absorbing sulfur dioxide (Ⅰ)[J]. Mining and Metallurgical Engineering, 2003, 23(2): 53-55.

[10] 符剑刚, 毛耀清, 钟宏. 软锰矿湿法脱硫工艺的研究[J]. 中国锰业, 2003, 21(1): 19-22.

FU Jiangang, MAO Yaoqing, ZHONG Hong. Study on wet desulfurization process by pyrolusite[J]. China’s Manganese Industry, 2003, 21(1): 19-22.

[11] 覃文胜. 软锰矿与黄铁矿在硫酸介质中的浸出[J]. 矿冶工程, 1993, 13(4): 52-56.

QIN Wensheng. The leaching of pyrolusite and pyrite in sulfuric acid medium[J]. Mining and Metallurgical Engineering, 1993, 13(4): 52-56.

[12] 袁明亮, 梅贤功, 庄剑鸣. 软锰矿两矿法选择性浸出[J]. 中国有色金属学报, 1996, 6(3): 22-25.

YUAN Mingliang, MEI Xiangong, ZHUANG Jianming. Selective leaching of manganese dioxide ore with two ore method[J]. The Chinese Journal of Nonferrous Metals, 1996, 6(3): 22-25.

[13] 唐尚文. 用闪锌矿(方铅矿)精矿催化还原软锰矿制取硫酸锰[J]. 无机盐工业, 2005, 37(6): 46-49.

TANG Shangwen. The preparation of manganese sulfate from manganese dioxide/oceanic manganesenodule ore by catalytic reduction with refined zincblende/plumbag ore[J]. Inorganic Chemicals Industry, 2005, 37(6): 46-49.

[14] 郭慧贞, 粟海锋. 两矿湿法制取工业硫酸锰的研究[J]. 广西化工, 1991(3): 2-7.

GUO Huizhen, LI Haifeng. The study for the preparation of industrial manganese sulfate by two ore wet[J]. Guangxi Chemical, 1991(3): 2-7.

[15] 符剑刚, 钟宏, 吴江丽, 等. 软锰矿在辉钼矿焙烧过程中的固硫作用[J]. 中南大学学报: 自然科学版, 2005, 36(6): 995-999.

FU Jiangang, ZHONG Hong, WU Jiangli, et al. Sulfur-retained in roasting process of molybdenite concentrate by pyrolusite[J]. Journal of Central South University: Science and Technology, 2005, 36(6): 995-999.

[16] 叶大仑. 实用无机物热力学数据库手册[M]. 北京: 冶金工业出版社, 2002: 200-221, 937-943, 1427-1429.

YE Dalun. Practical Thermodynamics data hand book of inorganic substances[M]. Beijing: Metallurgical Industry Press, 2002: 200-221, 937-943, 1427-1429.

(编辑 杨幼平)

收稿日期:2012-12-16;修回日期:2013-03-04

基金项目:湖南省科学技术厅科技计划重点项目(2010SK2010);国家高技术研究发展计划(“863”计划)项目(2011AA061002)

通信作者:王志坚(1970-),男,湖南涟源人,博士研究生,教授级高工,从事有色金属清洁冶金新技术研究;电话:0731-88836048;E-mail:wzj21836@163.com