DOI:10.19476/j.ysxb.1004.0609.2018.06.06

工艺参数对双辊薄带铸轧中心层偏析影响

张德全,许志强,安仲健,杜凤山,魏洁平

(燕山大学 国家冷轧板带装备及工艺工程技术研究中心,秦皇岛 066004)

摘 要:双辊薄带铸轧过程中工艺参数对中心层偏析有重大影响,针对双辊薄带铸轧机的特点,利用多相流技术建立完全耦合溶质场、流场、温度场的数学模型,对铸轧熔池中液相-液固两相-固相同时存在的复杂凝固过程进行模拟仿真,研究分析铸轧熔池中Mg、Si元素溶质场与流场分布特征,对比研究不同工艺参数(浇铸温度、辊缝宽度)对铸轧薄带中心层偏析的影响规律,并结合铝合金6061的铸轧实验对结论进行验证。

关键词:双辊薄带铸轧;中心线偏析;流场;Kiss点高度

文章编号:1004-0609(2018)-06-1128-08 中图分类号:TG233.6 文献标志码:A

双辊薄带铸轧(Twin-roll strip casting)属于近终型薄带材生产工艺之一,其有效地促进了现代冶金工业的转型发展[1]。偏析是在轧制过程中比较常见的现象,中心层偏析属于宏观偏析种类之一,其对铸轧薄带的质量和力学性能产生恶劣影响[2],严重时薄带会出现中心分层现象[3],尤其对铝带材料的性能影响较重[4]。溶质元素在固液两相中溶解度不同以及固液两相中的溶质输运是产生中心层偏析的根本原因,但其如何影响中心层偏析以及其影响效果目前尚不清楚[5],目前薄带连铸过程中宏观偏析的数值模拟较多,但双辊薄带铸轧过程中的数值模拟往往是脱离溶质场孤立地研究熔池内的流场分布。由于浇铸与凝固同步进行,浇铸过程中的动量、温度差以及浓度差引起的对流会影响铸轧带坯的组织和成分,因此在分析熔池的溶质场以及中心偏析时,必须将流场与温度场、溶质场耦合建立适用于双辊薄带铸轧的数学模型[6]。

1 多场耦合数学模型的构建

1.1 研究方法及基本假设

铸轧熔池内同时存在液相、固相以及固液两相区,在Kiss点以上主要为金属液的凝固以及坯壳生长,Kiss点以下金属液已经完全凝固,主要发生带坯的固态轧制。中心层偏析的产生除了与温度场有关,更与熔池内部流场相关。铸轧力通过凝固坯壳对流场的影响与熔池内金属液自身流动相比影响较小故而忽略,熔池区域统一处理为广义流体,忽略轧制力对熔池内部流场的影响,采用该方法对熔池内溶质场求解更加符合实际[7]。

考虑到几何模型的对称性以及熔池内复杂的物理现象,为了简化数值模拟模型铸轧熔池区域需作如下假设。

1) 由实际三维结构简化为二维轴对称模型;

2) 熔池内金属液视为不可压缩Newton流体;

3) 凝固过程遵循局部组分平衡;

4) 忽略铸轧辊面以及薄带热变形,带坯与铸轧辊表面无滑移;

5) 熔池内金属液的流动视为湍流运动[8];

6) 熔池中液面认为水平固定,忽略液面的波动[9];

7) 熔池凝固组织全部视为柱状晶,凝固坯壳以柱状晶形式沿与热传递相反<001>方向生长,不考虑间隙生成;同时固态相变潜热远小于凝固潜热,故忽略固态相变潜热。

1.2 几何模型及边界条件的确定

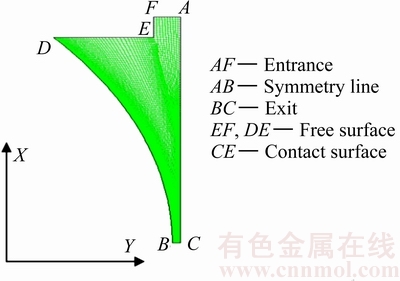

熔池计算区域如图1所示,边界条件如下。

1) 入口(Entrance—AF)边界条件

布流器入口AF采用Velocity-inlet条件,浇铸速度vin根据出入口质量守恒来计算。由于出坯速度恒定,因此入口速度为根据出口速度变化的恒定值[10]。

2) 对称 (Symmtry—AB)边界条件

由于几何对称性其热边界条件设置为无热量传递。

3) 铸轧辊(Contact surface—CD)壁面边界条件

根据铸轧带坯与铸轧辊面无滑移的假设,凝固带坯沿辊面切向方向运动,紊流动能及耗散率均为0。

4) 出口(Exit—BC)边界条件

出口处铝液流动状态充分发展,除压力外的各个变量沿轧制方向的梯度值为零,且与时间无关,瞬态计算过程中每一时刻都是充分发展的。

图1 铸轧熔池计算区域及边界条件

Fig. 1 Calculation area and boundary conditions of roll casting molten pool

2 数值模拟与结果分析

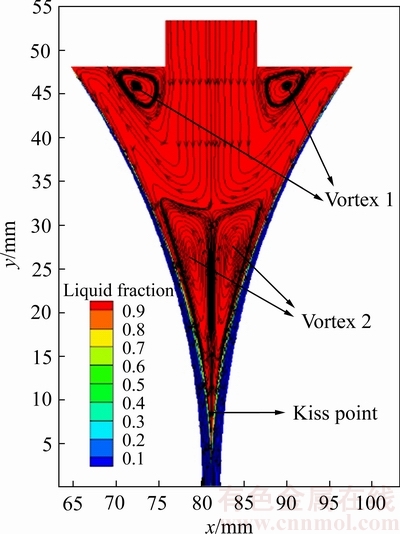

以双辊铸轧设备熔池区域为研究对象研究不同工艺参数(辊缝宽度、熔池温度)对熔池内金属液流动、溶质输运以及薄带宽度方向合金元素中心层偏析的影响,计算分析的实验方案如表1和表2所列。

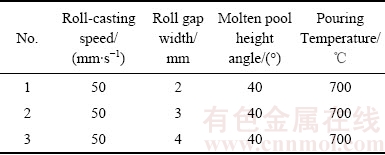

表1 不同辊缝宽度下数值模拟实验方案

Table 1 Numerical simulation experiments under different gap widths

表2 不同浇铸温度下数值模拟实验方案

Table 2 Numerical simulation experiments under different pouring temperature

2.1 铸轧熔池流场与溶质场特征

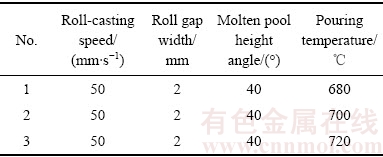

由于铝合金液凝固过程存在选分结晶现象,加之铝液流动造成的对流扩散,Mg、Si元素在铸轧熔池内的分布极度不均匀。铸轧熔池内流场、溶质场分布特征如下:

铸轧熔池区域流场分布如图2所示,熔池主要存在2个涡流区(Vortex zone)[11],Vortex 1靠近自由液面,其主要影响铝液的滞留时间和液面波动,释放推送至熔池表面铝液部分潜热,另一方面将铝液推送至铸轧辊面进一步对流换流形成初始坯壳;Vortex 2的形成主要是铝液凝固造成黏度增大以及铸轧辊的轧制作用造成的,Vortex 2呈细长楔形并且尖部深入到Kiss point附近区域。Vortex 2不仅影响熔池固液两相区所占比例,而且能使偏聚在Kiss point附近富溶质铝液返回到熔池进行混合再分配。涡流的存在不仅可以促使富含溶质的铝液返回到熔池中进行再混合均匀化,另一方面该涡流的存在还能够以较大的速度冲击枝晶臂,以及芯部较高的温度能熔断枝晶,这两方面都有利于增加形核率,促使Kiss点区域温度场均匀化从而有助于芯部等轴晶的形成[12]。

图2 铸轧熔池液相分数及流线

Fig. 2 Liquid fraction and streamline of roll casting molten pool

2.2 浇铸温度对中心层偏析的影响

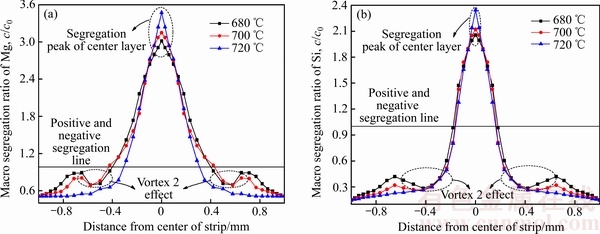

合金元素的宏观偏析比定义为各部位局部浓度与初始浓度之比即c/c0,且c/c0>1称为正偏析,c/c0<1称为负偏析[13]。不同浇铸温度下薄带厚度方向Mg、Si元素宏观偏析比分布如图3所示,Mg、Si元素含量由铸轧薄带边部向中心线区域逐渐增高,且越靠近芯部Mg、Si元素含量增长越快,并在中心线处达到最大值时形成正偏析尖峰,这主要是由于各部位材料凝固时间和位置不同造成的,越靠近中心线区域铝液中合金元素含量也就越高。浇铸温度由680 ℃上升至700 ℃时Mg、Si元素中心线位置偏析比尖峰值基本不变,但继续上升至720 ℃时中心线处Mg、Si元素的宏观偏析比值变化较大,分别达到了3.37和2.34。3种浇铸条件下Si元素正偏析区域尺寸均为0.32 mm,占铸轧带坯带坯厚度方向16%,680 ℃和700 ℃浇铸温度下Mg元素正偏析尺寸基本相同,但是720 ℃浇铸温度条件下Mg元素正偏析尺寸由0.84 mm减小至0.72 mm。

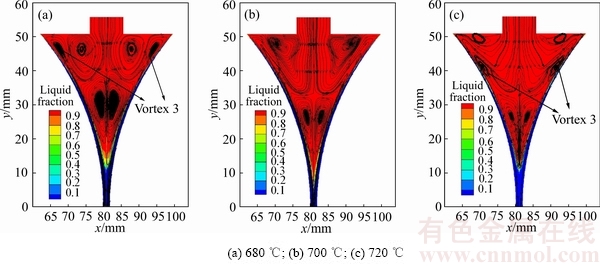

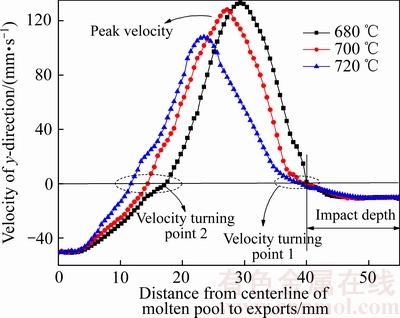

由图4和5可以看出,随着浇铸温度的升高,Vortex 1逐渐向熔池液面移动并且涡流区域范围减小,而入口铝液冲击深度保持17.5 mm左右不变,Vortex 1的退化导致铝液进入熔池后大部分直接冲向辊面,不利于铝液的散热和凝固;Vortex 2回流区速度拐点2下降了5.3 mm,峰值速度也下降了25.3 mm/s,Vortex 2的变化对Kiss点区域的搅拌强度降低,高浓度铝液得不到新鲜铝液的有效稀释从而加重中心层偏析。720 ℃浇铸条件下Vortex 3下移并最终与Vortex 2相连导致了流动通道消失(Disappearance of flow passage),从而无低浓度金属液在Vortex 2与Vortex 3之间冲击高浓度铝液,Vortex 2 effect消失后偏析曲线由边部呈现持续上升趋势。

图3 不同浇铸温度下薄带厚度方向Mg、Si元素分布

Fig. 3 Mg(a) and Si(b) element distribution in thickness direction of strip at different pouring temperatures

图4 不同浇铸温度下熔池液相分数及流线

Fig. 4 Liquid fraction and streamline of molten pool at different pouring temperatures

图5 不同浇铸温度下熔池中心线速度分布

Fig. 5 Linear velocity distribution in molten pool center at different pouring temperatures

2.3 辊缝宽度对中心层偏析的影响

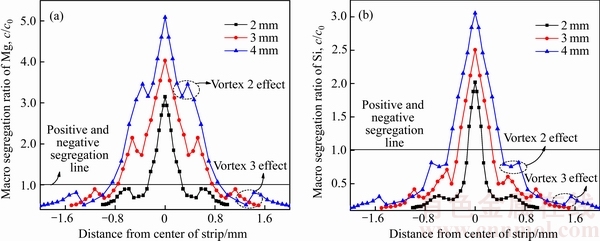

不同辊缝宽度下薄带厚度方向Mg、Si元素含量分布如图6所示,随着辊缝由2 mm增大至4 mm,Mg、Si元素在中心线处宏观偏析比分别由3.14、2.02上升至5.08、3.05,中心层偏析加重。

一方面根据凝固凝壳平面长大平方根定律可知凝固时间与坯壳厚度呈平方关系,因此随着辊缝宽度增大,凝固时间激增从而凝固速率降低,在较低的凝固速率条件下固液界面析出的溶质元素在铝液对流作用下被冲刷带入熔池芯部与新鲜铝液再混合从而使边部溶质元素含量维持在较低值。另一方面溶质元素在辊缝出口处质量守恒必须满足式(1),在辊缝宽度增大条件下进入熔池溶质含量上升,而铸轧薄带边部溶质元素含量基本不变且保持较低值,因此熔池辊缝越宽越

会有较多的溶质聚集在芯部,中心层偏析程度越严重。

(1)

(1)

式中:l为熔池辊缝宽度,mm;vin为入口浇铸速度,mm/s;vout为出口速度,即轧制速度,mm/s;d为浇铸入口尺寸,mm。

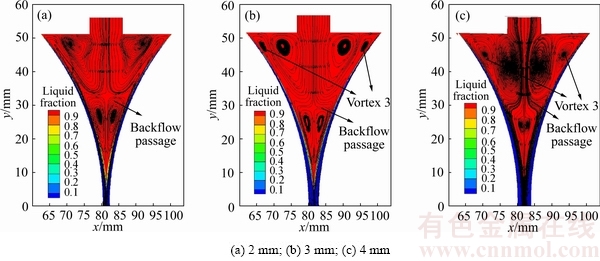

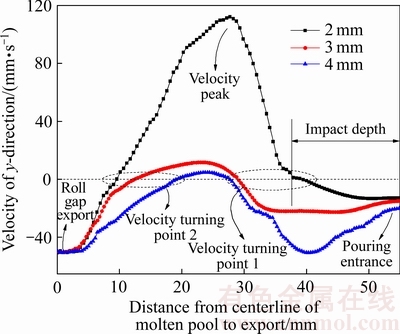

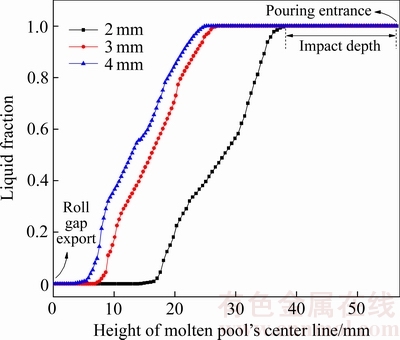

在相同布流器尺寸和轧制速度条件下,随着辊缝由2 mm扩大至4 mm,根据出入口质量守恒入口速度由10 mm/s扩大至20 mm/s。由图7和图8可知,随着入口速度由10 mm/s上升至15 mm/s时入口冲击深度(Impact depth)增加了10.2 mm,而辊缝宽度由3 mm升至4 mm时冲击深度(Impact depth)基本改变,冲击深度增加能够将新鲜铝液尽可能带入熔池底端冲击高浓度回流铝液起到稀释作用,同时带动较多的铝液随之流动,降低了卷渣的可能性,便于夹杂物和高浓度铝液上浮。凝固初期靠近辊面的自然对流引起较强的涡流Vortex 1,其能够将凝固前沿的溶质带入熔池内部起到稀释作用。随着入口速度升高回流Vortex 1水平方向逐渐向熔池中心线方向靠近,竖直高度逐渐降低向远离液面位置移动,同时涡流区域范围逐渐增大,初始坯壳附近开始形成Vortex 3,并且随着辊缝增大Vortex 3回流区域范围也逐渐增大。涡流Vortex 1位置的改变不利于初始坯壳固液界面处析出溶质元素通过对流冲刷进入熔池,边部溶质元素升高速度加快,而Vortex 3的出现能够形成Vortex 3抑制合金元素的持续上升。

图6 不同辊缝下薄带厚度方向Mg、Si元素分布

Fig. 6 Mg(a) and Si(b) element distribution in thickness direction of strip under different roll gaps

图7 辊缝不同时熔池液相分数以及流线

Fig. 7 Liquid phase fraction and streamline under different roll gaps

伴随着Vortex 1位置的改变,Vortex 2的位置基本没有太大变化,但是Vortex 2区域范围急剧减小,由图8可以看出,随着辊缝由2 mm升至3 mm涡流2在中心线上的速度锐减,搅动强度降低。辊缝为4 mm时铝液回流区Vortex 2同上方涡流之间的联系被截断(Disappearance of back flow passage),部分注入熔池的铝液未经过出口处回流区冷却也未被推送至初始接触区进行冷却而直接被卷向熔池出口。

当辊缝较大时,较多的铝液未经过Vortex 1对流换热冷却,也未被推送至液面受到初始接触条件冷却因而Kiss点位置大幅度降低(见图9),辊缝由2 mm升至3mm时Kiss点位置下降了7.02 mm,而辊缝继续上升至4 mm时Kiss位置只下降了3.40 mm,但是辊缝3 mm和4mm时Mg、Si元素中心偏析差异却较大, 因此辊缝较大时Kiss点位置对中心偏析的影响减小。

图8 辊缝不同时熔池中心线速

Fig. 8 Centerline velocity of molten pool under different roll gaps

图9 辊缝不同时熔池中心线液相分数

Fig. 9 Liquid fraction of molten pool under different roll gaps

由图8可以看出中心线上两个速度拐点之间的速度峰值现象逐渐消失,Vortex 2造成的速度拐点之间尺寸也由28.2 mm锐减至8.6 mm,Kiss点附近高浓度铝液的搅拌效果减弱,无法将偏聚的中心线处的高浓度铝液带回熔池进行再分配,最终随两侧坯壳的焊合而封闭在中心线处加重中心偏析。

3 实验验证

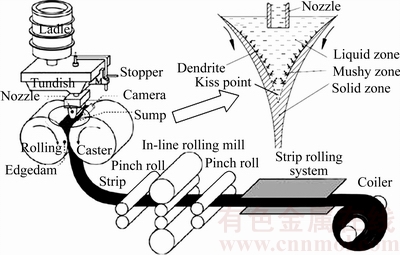

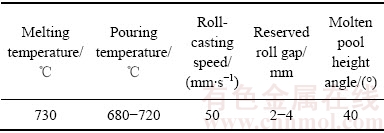

本实验中通过双辊铸轧设备来验证铸轧6061铝合金薄带的可行性(见图10、11),参照6061铝合金的铸造工艺参数特性,经过多次反复的实验并在实验过程中对实验参数进行分析,初步确定了在现有实验室双辊铸轧设备轧制能力下铸轧6061铝合金薄带的合理工艺参数[14](见表3),成功轧制的6061铝合金薄带。

图10 双辊薄带铸轧机照片[15]

Fig. 10 Photo of twin roll strip rolling machine[15]

图11 双辊薄带铸轧工艺流程示意图[16]

Fig. 11 Process flow diagram of twin roll strip continuous casting[16]

表3 6061铝合金薄带铸轧实验工艺参数

Table 3 Strip roll casting experiment process parameters of 6061 aluminum alloy

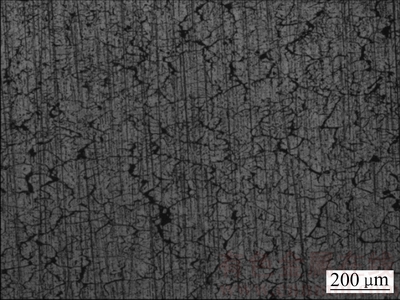

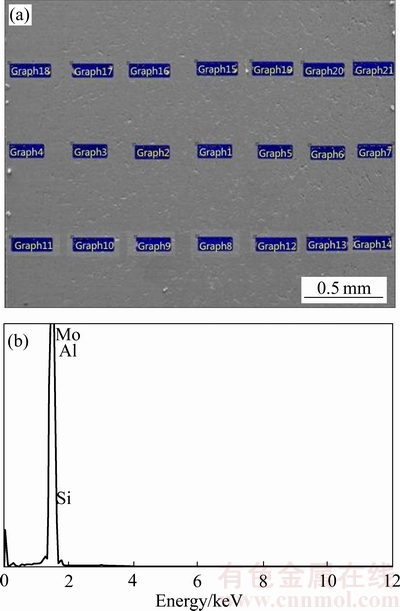

为验证所构建数学模型的正确性,需要将带宽方向溶质元素的分布检测值与数值仿真模拟值进行对比,本实验采用断面取点扫描的方式检测合金元素含量。图12、13所示为实验结果的金相组织图和元素扫描图。

图12 铸轧薄带的显微组织

Fig. 12 Cast-rolling strip microstructure

图13 检测点分布以及EDS扫描结果

Fig. 13 Distribution of check points(a) and EDS scan result(b)

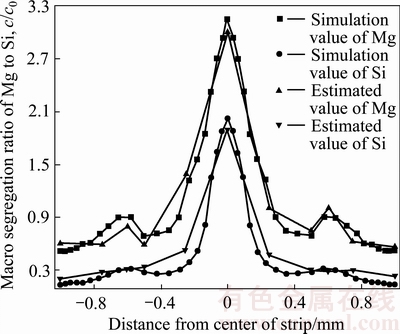

图14所示为相同工艺参数下铸轧薄带厚度方向溶质元素宏观偏析比的模拟结果和实际检测结果,模拟结果与实际检测得到的宏观偏析比分布极为相似,在薄带中心部位出现较为明显的正偏析尖峰,中心线两侧也存在由于回流漩涡造成的成分偏低区域。

同时图14也表明数值模拟结果与实测结果存在一定的差异,一方面中心位置合金元素含量实测值比模拟值较小,这主要是合金元素在熔炼、铸轧过程中部分合金元素氧化成为熔渣减少了合金元素的实际含量;另一方面模拟结果显示中心正偏析尺寸比实际检测尺寸要大,Mg、Si元素上升速率相对较慢,这表明实际上尽管凝固末期熔池区域在Kiss点附近Vortex 2的对流对用已经很微弱,但是在铸轧辊的轧制作用下Kiss点附近糊状区高浓度铝液仍会有一定的流动,从而迫使Kiss点附近部分高浓度铝液回流返回熔池,降低了合金元素含量上升速率。

图14 薄带厚度方向Mg、Si元素偏析比模拟结果与实测值

Fig. 14 Simulation results and measured values of Mg and Si segregation ratio in strip's thickness direction

4 结论

1) 不同浇铸温度下,Mg、Si正偏析尖峰均出现在薄带中心线处,但浇铸温度由680 ℃上升至700 ℃时Mg、Si元素中心线位置偏析比尖峰值基本不变,但继续上升至720 ℃时中心线处Mg、Si元素的宏观偏析比值变化较大。

2) 随着辊缝由2 mm增大至4 mm,Mg、Si元素在中心线处宏观偏析比分别由3.14、2.02上升至5.08、3.05,中心层偏析加重。

3) 通过将相同工艺参数下铸轧薄带厚度方向中心层偏析模拟值与实测值对比发现,两者之间的趋势基本一致,但由于数值模拟过程中忽略了铸轧辊的轧制力作用,因而中心线位置处模拟值比实测值偏高。

REFERENCES

[1] ZAPISKALOV N. Comparison of continuous strip casting with conventional technology[J]. ISIJ International, 2003, 43(8): 1115-1127.

[2] BIROL Y, GEBZE K. Centerline segregation in a twin-roll cast AA8011 alloy[J]. Aluminium, 1998, 77(5): 318-321.

[3] HADAZADEH A, WELL M A. Inverse and centerline segregation formation in twin roll cast AZ31 magnesium alloy[J]. Materials Science & Technology, 2015: 1715-1726.

[4] 徐国栋, 小森重喜, 石洪志. 宝钢连铸板坯中心偏析改进[C]// 中国金属学会. 2001中国钢铁年会论文集. 下卷. 北京: 冶金工业出版社, 2001: 816-817.

XU Guo-dong, XIAO Sen-chong-xi, SHI Hong-zhi. Continuous casting slab center segregation improvement of Baosteel[C]// The Chinese Society for Metals. 2001 China’s Steel Conference Proceedings. Book Two. Beijing: Metallurgical Industry Press, 2001: 816-817.

[5] 张兴中, 廖 鹏, 王明林. 双辊薄带连铸技术状况的调查分析[J]. 钢铁, 2010, 45(3): 13-17.

ZHANG Xing-zhong, LIAO Peng, WANG Ming-lin. Investigation on development of twin roll cast strip[J]. Iron and Steel, 2010, 45(3): 13-17.

[6] 杜凤山, 吕 征, 黄华贵, 许志强, 安仲健. 双辊薄带铸轧中心线偏析机理与实验研究[J]. 中国有色金属学报, 2015, 25(10): 2739-2744.

DU Feng-shan, Lü Zheng, HUANG Hua-gui, XU Zhi-qiang, AN Zhong-jian. Mechanism and experimental research on centerline segregation of twin-roll strip casting[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(10): 2739-2744.

[7] 孟哲儒. 振动对双辊薄带铸轧流场温度场影响的研究[D]. 秦皇岛: 燕山大学, 2014.

MENG Zhe-ru. Effect of vibration on twin-roll strip roll casting's flow field and temperature field[D]. Qinhuangdao: Yanshan University, 2014.

[8] GUTHRIE R I L, TAVARES R P. Mathematical and physical modeling of steel flow and solidification in twin-roll/horizontal belt thin-strip casting machines[J]. Applied Mathematical –Modeling, 1998, 22(11): 851-872.

[9] ABOUTALEBI M R, HASAN M, GUTHRIE R I L. Coupled turbulent flow, heat, and solute transport in continuous casting processes[J]. Metallurgical and Materials Transactions B, 1995, 26(4): 731-744.

[10] LI Q, ZHANG Y K, LIU L G, ZHANG P, ZHANG Y, FANG Y. Effect of casting parameters on the freezing point position of the 304 stainless steel during twin-roll strip casting process by numerical simulation[J]. Journal of Materials Science, 2012, 47(9): 3953-3960.

[11] 司开田. 1235 合金铸轧带材中心层偏析机制的研究及其预防措施[J]. 轻合金加工技术, 2007, 35(10): 5-6.

SI Kai-tian. Research on segregation and its mechanism of 1235alloy cast-rolling stock and its preventive measures[J]. Light Alloy Fabrication Technology, 2007, 35(10): 5-6.

[12] ZHAO H, LI P, HE L. Coupled analysis of temperature and flow during twin-roll casting of magnesium alloy strip[J]. Journal of Materials Processing Technology, 2011, 211(6): 1197-1202.

[13] JING Cai-liang, TIAN Zhi-hong, WANG Xin-hua. A simple micro-segregation model for steel billet[J]. Journal of Iron and Steel Research, 2013, 25(6): 18-23.

[14] 王 娜, 周志敏, 路贵民, 赵大志. 工艺条件对6061铝合金近液相线铸造微观组织的影响[J]. 特种铸造及有色合金, 2009, 29(6): 508-511.

WANG Na, ZHOU Zhi-min, LU Gui-min, ZHAO Da-zhi. Effect of technological conditions on 6061 aluminum alloy near liquidus casting microstructure[J]. Special Casting & Nonferrous Alloys, 2009, 29(6): 508-511.

[15] 杜凤山, 许志强, 路鹏程, 张 沛. 振动式双辊薄带铸轧机: 中国, CN101181719A[P]. 2008-05-21.

DU Feng-shan, XU Zhi-qiang, LU Peng-cheng, ZHANG Pei. Vibrating twin-rolls strip rolling machine: China, CN101181719A[P]. 2008-05-21.

[16] LEE D S, LEE J S, KANG T. Robust molten steel level control in a strip-casting process[J]. ISIJ International, 2005, 45(8): 1165-1172.

Effect of process parameters on centerline segregation of twin-roll strip casting

ZHANG De-quan, XU Zhi-qiang, AN Zhong-jian, DU Feng-shan, WEI Jie-ping

(National Engineering Research Center for Equipment and Technology of Cold Strip Rolling, Yanshan University, Qinhuangdao 066004, China)

Abstract: The technical parameters of twin-roll strip casting have significant impact on the centerline segregation. The mathematical model in completely coupled temperature field, flow field and solute field was established by using multiphase flow technology for the characteristics of twin-roll strip casting mill. The solidification process of simultaneous existence of liquid phase, liquid-solid-phase and solid phase in molten pool was simulated based on the coupled mathematical model. The distribution characteristics of Mg and Si solute field and flow field in the molten pool were studied by the simulation results, and the influence of different technical parameters (the width of the roll seam and casting temperature) on the centerline segregation of the thin strip was studied. The research conclusion was verified by the casting and rolling experiments of the aluminum alloy 6061.

Key words: twin-roll strip casting; centerline segregation; flow field; Kiss point height

Foundation item: Project(51374184) supported by the National Natural Science Foundation of China; Project (E2013203342) supported by the National Natural Science Foundation of Hebei Province—Joint Steel Research Fund Project, China; Project(E2017203043) supported by the Key Project of National Natural Science Foundation of Hebei Province, China

Received date: 2017-03-17; Accepted date: 2017-06-07

Corresponding author: XU Zhi-qiang; Tel: +86-13930357680; E-mail: xzq@ysu.edu.cn

(编辑 王超)

基金项目:国家自然科学基金资助项目(51374184);河北省自然科学基金—钢铁联合研究基金资助项目(E2013203342);河北省自然科学基金重点资助项目(E2017203043)

收稿日期:2017-03-17;修订日期:2017-06-07

通信作者:许志强,教授,博士;电话:13930357680;E-mail: xzq@ysu.edu.cn