Al-Mg-Mn-Sc-Zr合金板材搅拌摩擦焊和氩弧焊焊接接头的对比

来源期刊:中国有色金属学报(英文版)2011年第8期

论文作者:何振波 彭勇宜 尹志民 雷学锋

文章页码:1685 - 1691

关键词:Al-Mg-Mn-Sc-Zr合金; 搅拌摩擦焊; 氩弧焊; 焊接接头

Key words:Al-Mg-Mn-Sc-Zr; friction stir welding; tungsten inert gas; welded joints

摘 要:研究Al-Mg-Mn-Sc-Zr合金的焊接工艺和焊接接头组织和性能。采用搅拌摩擦焊(FSW)和氩弧焊(TIG)2种焊接工艺对该合金的热轧和冷轧-退火2种使用态板材进行焊接。采用比较研究的方法测定和研究焊接接头的力学性能和显微组织,利用光学显微镜和透射电子显微镜研究焊缝的显微组织和力学性能之间的关系。结果表明,与基材相比,Al-Mg-Mn-Sc-Zr合金的热轧和冷轧-退火板材的FSW和TIG焊接接头的强度均下降,但FSW焊接系数高于TIG焊接系数。这是因为FSW焊接接头焊核区亚结构强化的丧失和Al3(Sc, Zr)的析出强化作用的极少量丧失,而TIG焊焊接接头的软化主要原因是其形变强化的完全丧失和Al3(Sc, Zr)的析出强化作用的大部分丧失,且搅拌摩擦焊焊核区晶粒比TIG焊的焊缝区晶粒更细小。

Abstract:

In order to study the welding process, microstructure and properties of Al-Mg-Mn-Sc-Zr alloy, comparative methods of friction stir welding (FSW) and tungsten inert gas (TIG) were applied to the two conditions of this alloy, namely hot rolled plate and cold rolled-annealed plate. The relationships between microstructures and properties of the welded joints were investigated by means of optical microscopy and transmission electron microscopy. Compared with the base metal, the strength of FSW and TIG welded joints decreased, and the FSW welding coefficients were higher than the TIG welding coefficients. The loss of substructure strengthening and a very little loss of precipitation strengthening of Al3(Sc, Zr) cause the decreased strength of FSW welded joint. But for the TIG welded joint, the disappearance of both the strain hardening and most precipitation strengthening effect of Al3(Sc, Zr) particles contributed to its softening. At the same time, the grains in weld nugget zone of FSW welded joints were finer than those in the molten zone of TIG welded joints.

HE Zhen-bo1, 2, PENG Yong-yi3, YIN Zhi-min1, LEI Xue-feng1

1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Northeast Light Alloy Co. Ltd., Harbin 150060, China;

3. School of Physics Science and Technology, Central South University, Changsha 410083, China;

Received 20 September 2010; accepted 14 December 2010

Abstract: In order to study the welding process, microstructure and properties of Al-Mg-Mn-Sc-Zr alloy, comparative methods of friction stir welding (FSW) and tungsten inert gas (TIG) were applied to the two conditions of this alloy, namely hot rolled plate and cold rolled-annealed plate. The relationships between microstructures and properties of the welded joints were investigated by means of optical microscopy and transmission electron microscopy. Compared with the base metal, the strength of FSW and TIG welded joints decreased, and the FSW welding coefficients were higher than the TIG welding coefficients. The loss of substructure strengthening and a very little loss of precipitation strengthening of Al3(Sc, Zr) cause the decreased strength of FSW welded joint. But for the TIG welded joint, the disappearance of both the strain hardening and most precipitation strengthening effect of Al3(Sc, Zr) particles contributed to its softening. At the same time, the grains in weld nugget zone of FSW welded joints were finer than those in the molten zone of TIG welded joints.

Key words: Al-Mg-Mn-Sc-Zr; friction stir welding; tungsten inert gas; welded joints

1 Introduction

Friction stir welding (FSW) was invented and patented by the Welding Institute (TWI) in UK in 1991 as a green solid-state joining technique. Compared with the conventional fusion welding techniques, FSW has several advantages, such as no filler metal or cover gas, no smoke or dust. Additionally, FSW does not bring welding defects, such as hot cracks and porosity [1-2]. In recent years, the application of FSW has been a research focus. Up to now, FSW has been successfully applied to the welding of magnesium alloy, copper alloy, steel, composite materials and dissimilar materials [3-8], especially widely applied to the welding of 2×××(Al-Cu) series and 7×××(Al-Zn) series aluminum alloys that have poor fusion welding performance [9-14]. Despite the widespread growth of FSW as a commercial joining process, the development and evolution of the microstructure at welded joint, the relationship between microstructure and properties of joint is not well understood.

Al-Mg-Mn alloy containing trace Sc and Zr with medium strength is a new light-weight structural material used in aerospace and aviation application. Hot rolled plate and cold rolled-annealed plate are the two common conditions of delivery. Compared with conventional Al-Mg-Mn alloy, the yield strength of Al-Mg-Mn-Sc-Zr alloy increases by 60% [15-16]. In this study, 6 mm- thick hot-rolled plate and 2 mm-thick cold rolled- annealed Al-Mg-Mn-Sc-Zr alloy were investigated to study the effect of FSW and tungsten inert gas (TIG) welding process on the microstructure and mechanical properties of welded joints and to provide theoretical and experimental basis for the application of FSW process and Al-Mg-Mn-Sc-Zr alloy.

2 Experimental

The chemical composition of the studied alloy plate was 5.8%Mg, 0.4%Mn, 0.25%Sc, 0.1%Zr and balance Al (mass fraction). This alloy had two conditions of delivery, 6 mm-thick hot rolled plate and 2 mm-thick cold rolled-annealed plate annealed at 350 °C for 1 h.

Single side FSW was carried out along the rolling direction of plate at China FSW center authorized by TWI, and the shape of welding pin was truncated cone. TIG welding was conducted along the rolling direction of plate at China Aerospace Research Institute of Materials & Processing Technology. The welding wire for TIG welding was Al-Mg-Sc-Zr alloy with diameter of 3 mm, the flow rate of argon shield was 14 L/min, the welding voltage and current were 14 V and 250 A, respectively, and the speed of welding was 6 mm/s. The tensile samples of base and welded joints were intercepted along the transverse direction of plates. The test of tensile properties were measured on a CSS-44100 electron tensile testing machine according to GB228-87 and the tensile velocity was 2 mm/min. The Vickers microhardness of the welded joints were measured on a 401MVD Vickers microhardness tester on the transverse section of the welded joints. The metallurgical microstructure of specimens was researched on a POLYVER-MET optical microscope (OM). Thin foils for transmission electron microscopy (TEM) were prepared by MTP-Ⅱ twin-jet polishing with an electrolyte solution consisted of 30% HNO3 and 70% methanol (volume fraction) below -20 °C. The foils were observed on a TECNAI G2 20 transmission electron microscope.

3 Results

3.1 Microhardness of welded joints

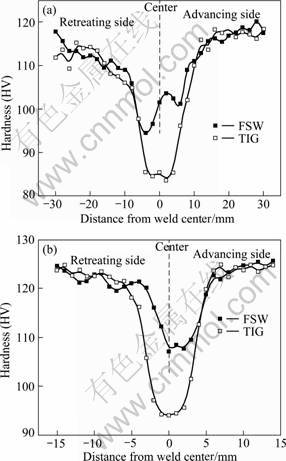

For the two conditions of Al-Mg-Mn-Sc-Zr alloy plates, the microhardness values of FSW and TIG welded joints are shown in Fig. 1.

For hot-rolled plate and cold rolled-annealed plate, the microhardness distributions of both FSW welded and TIG welded joint are approximately symmetrical. As for FSW welded joints, it is obvious that the symmetry of hot-rolled plate is inferior to that of cold rolled-annealed plate, which is caused by the difference of microstructure at the retreating side and the advancing side of the weld nugget zone (WNZ). The central microhardness values of FSW and TIG welded joints are the lowest, and softening occurs in the center of the joints. As the distance from the center of welded seam increases, the microhardness of the welded joints increases gradually to the microhardness of the base metal. For hot-rolled plate and cold rolled-annealed plate, the microhardness at FSW weld center is higher than that at TIG weld center, and the microhardness values at both FSW and TIG weld center of cold-rolled annealed, plate are a little higher than the hot-rolled plates. In general, the yield strength of aluminum alloy is almost directly proportional to its hardness [17]. The distribution of microhardness is consistent with the result that tensile samples of FSW all broke at the weld center.

3.2 Fracture and mechanical properties of welded joints

The FSW welded joints of hot-rolled plate and cold rolled-annealed plate broke at the center of the welded joint, but their TIG welded joints broke at the fusion-line. Part of tensile samples of FSW and TIG welded joints and their fracture position are shown in Fig. 2.

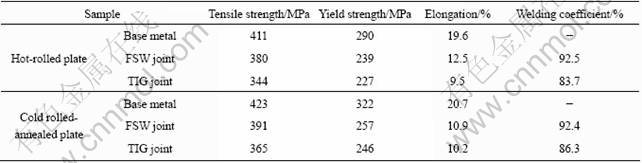

The tensile mechanical properties of the base metal and welded joints are listed in Table 1.

Fig. 1 Microhardness of welded joints: (a) Hot rolled plate; (b) Cold rolled-annealed plate

Fig. 2 Photos of welded joints for tensile samples and their fracture positions: (a) 2 mm thick, FSW; (b) 6 mm thick, FSW; (c) 2 mm thick, TIG; (d) 6mm thick, TIG

Table 1 Tensile mechanical properties of base metal and welded joints

For the hot-rolled plate and cold rolled-annealed plate, the tensile strength, yield strength, elongation and welding coefficient of FSW welded joint are higher than those of TIG welded joint. For the TIG welding process, the properties of cold rolled-annealed plate are better than those of the hot-rolled plate. As for the FSW, the strength of cold rolled-annealed plate is higher than that of the hot-rolled plate. The FSW welding process can improve the mechanical properties.

3.3 Microstructure

3.3.1 OM images of base metal

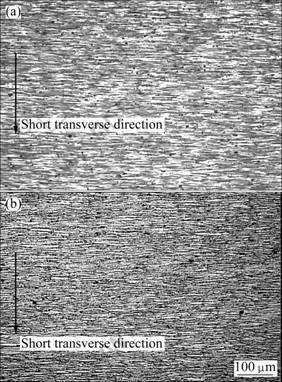

The OM images of hot-rolled plate and cold rolled-annealed plate are shown in Fig. 3. Both the two plates exhibit fibrous microstructures, and the fibrous metallographic microstructure of the 2 mm-thick cold rolled-annealed plate is longer than that of the hot-rolled plate.

Fig. 3 OM images of transverse section: (a) Hot-rolled plate; (b) Cold rolled-annealed plate

3.3.2 OM images of welded joints

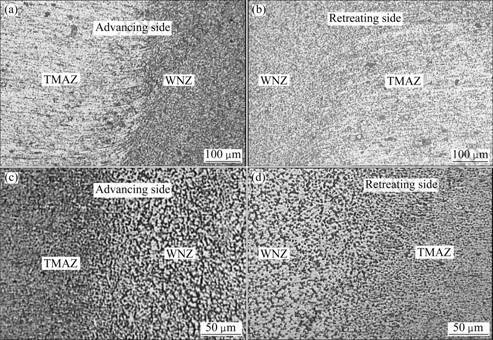

The WNZ and thermo-mechanically affected zone (TMAZ) of two kinds of welded joints are shown in Fig. 4. As shown in Fig. 4, the microstructures of WNZ in both the hot-rolled plate and cold rolled-annealed plate were crushed by the strong stirring effect of the rotating pin. Because of the high temperature at WNZ, dynamic recrystallization took place, small and uniform equiaxed grains emerged at WNZ. A great deal of small recrystallized grains also appeared in TMAZ. TMAZ experienced weaker heating effect than WNZ, but stronger than the heat affected zone. Owing to the effect of thermal cycling, besides bended plastic deformation occurred in the fibrous microstructures, dynamic recovery and partial recrystallization took place at TMAZ. There is an evident difference at the boundary between WNZ and TMAZ at advancing side and retreating side. The boundary at advancing side is obvious, but the boundary at retreating side is vague. This can be explained by the following reasons, the relative rate between rotating pin and base metal reached a peak in advancing side and it was the lowest in the retreating side. The strain degree and rate were greater in the advancing side, and the distortion of fibrous microstructure in the advancing side is more severe than that in the retreating side [18], which brought the asymmetry of microhardness distribution.

During the welding process, the temperature at TIG weld center was much higher than that at FSW weld nugget zone, the temperature at TIG weld center was higher than the melting point of the alloy, the metal of TIG welded joints melted, and the microstructure of TIG welded joint changed greatly. The OM images of TIG welded joint are shown in Fig. 5. Figures 5(a) and (d) show that the weld center of hot-rolled plate and cold rolled-annealed plate exhibit cast structure, and the grain size of TIG weld center is larger than that of FSW weld center. For the TIG welded joints of hot-rolled plate, there are a few short feathery or pine tree structures (Fig. 5(a)), the boundary of semi-molten zone and heat affected zone (HAZ) is obvious (Fig. 5(b)), and there is a very thin layer of equiaxed grains between the semi-fused zone and the HAZ, the equiaxed grains are smaller than the grains of semi-fused zone and HAZ (Fig. 5(c)).

Fig. 4 OM images of FSW welded joints: (a) Advancing side, hot-rolled plate; (b) Retreating side, hot-rolled plate; (c) Advancing side, cold rolled-annealed plate; (d) Retreating side, cold rolled-annealed plate

Fig. 5 OM images of TIG welded joints: (a)-(c) Hot-rolled plate; (d) Cold rolled-annealed plate

3.3.3 TEM images of welded joints

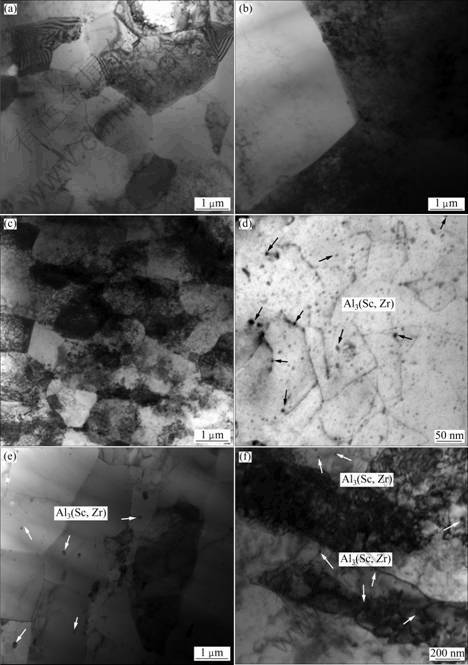

Figure 6 shows the TEM images of FSW and TIG welded joints of the hot-rolled plate and cold rolled-annealed plate.

The grains at WNZ of hot-rolled plate and cold rolled-annealed plate were crushed into fine equiaxed grains with diameter of 1-3 μm, as shown in Figs. 6(a) and (c)) [19-20]. Because recovery and recrystallization occurred in some grains, there were some subgrain structures containing Al3(Sc, Zr) particles that were coherent with Al matrix (Fig. 6(d)). But few Al3(Sc, Zr) particles and coarse cast grain structures can be found at the molten pool in TIG welded joint of hot-rolled plate, and the grain diameter was about 10 μm (Fig. 6(b)). The HAZ of hot-rolled plate still kept lath-shaped grain structure of the base metal; however, the dislocation density in this zone was low because of recovery, hence it contained much subgrain structure, recrystalline grains and Al3(Sc, Zr) particles (Fig. 6(e)). Al3(Sc, Zr) particles can be found in the WNZ, TMAZ of FSW and HAZ of TIG, and the grain structure of TMAZ of FSW were lath-shaped, and the Al3(Sc, Zr) particles in this zone were always covered by high-density tangled dislocations (Figs. 6(d) and (f)).

Fig. 6 TEM images of FSW and TIG welded joints: (a) WNZ of hot-rolled plate, FSW; (b) Molten pool of hot-rolled plate, TIG; (c), (d)WNZ of cold rolled-annealed plate, FSW; (e) HAZ of hot-rolled plate, TIG; (f) TMAZ of cold rolled-annealed plate, FSW

4 Analysis and discussion

4.1 Strengthening mechanism of Al-Mg-Mn-Sc-Zr alloy

The base metal is the solid solution of Al-Mg-Mn- Sc-Zr alloy. Its strengthening mechanism includes the solution strengthening of Mg, substructure strengthening and precipitation strengthening of second Al3(Sc, Zr) and fine grain strengthening of Sc and Zr. For the strength and hardness of 5××× aluminum alloys, previous studies showed that the contribution of Mg solution strengthening and substructure strengthening, precipitation strengthening of second Al3(Sc, Zr) are nearly equal to and the contributions of these three strengthening mechanism are all about 100 MPa. The contribution of fine grain strengthening is less, about 25 MPa [21-22]. The change of any kind of these strengthening mechanisms all can lead to the change of strength and hardness of welded joint.

4.2 Effect of welding process on properties of welded joints

Studies show that no inclusions or precipitates containing Mg were detected in welded joints and Mg content in FSW or TIG welded joints was not lower than that in base metal, and Mg solid solution was not affected by FSW and TIG processes [23]. There are fine and dispersed Al3(Sc, Zr) particles in the FSW nugget zone. At a high temperature, Al3(Sc, Zr) particles exhibit good stability. They do not coarsen and keep coherent with Al matrix, consequently can still pin dislocations and grain boundaries strongly. Even the temperature rises to 500 °C, the average radius r and volume faction f of Al3(Sc, Zr) particles hardly change. When the temperature is 550 °C, 50% Al3(Sc, Zr) particles dissolve, dislocations bypass the Al3(Sc, Zr) particles in conformity with Orowan mechanism; as the precipitation-hardening of Al3(Sc, Zr) particles is proportional to f 1/2r -1, the precipitation-hardening of Al3(Sc, Zr) particles decreases [23]. During the FSW, the temperatures of WNZ, TMAZ and HAZ are 500-530 °C, 480-500 °C and 450-490 °C, respectively [24]. The time of thermal cycling is very short in the process of FSW, therefore, only a very small part of Al3(Sc, Zr) particles in WNZ dissolve. The radius and density of Al3(Sc, Zr) particles in WNZ are almost the same as those in base metal [23, 25]. Only recovery and partial recrystallization occur in WNZ. But during the TIG, the temperature at molten pool is higher than 550 °C, and the alloy in this zone experiences meltage. The TIG welded seam exhibits cast structure, many Al3(Sc, Zr) particles in this zone dissolve, and their precipitation strength effect becomes weaker. Therefore, for the FSW welded joint, the decrease of its strength is due to the loss of substructure strengthening related to recrystallization and a very little loss of precipitation strength of Al3(Sc, Zr). The TIG welded joint experiences meltage, which results in its softening, the strain hardening disappears entirely and most of precipitation strengthening of second Al3(Sc, Zr) also disappears. Hence, the grains in WNZ of FSW are finer than those in the welded seam of TIG, and the hardness of TIG welded seam is lower than that of FSW nugget.

A post-weld annealing treatment on FSW and TIG joints at 300 °C was carried out by CABELLO et al [23]. Their experiments showed that post-weld annealing treatment can improve the strength of TIG welded joint greatly, and TIG welded joint can reach almost the same strength as the base metal. But the post-weld annealing treatment had almost no effect on improving the mechanical properties of FSW welded joint. It can be seen that the re-precipitation of Al3(Sc, Zr) particles has a great impact on the mechanical properties, and the effect of the grain structure is secondary. Therefore, from industrial practical application, FSW is a very competitive welding process, and its welded joints do not need a post-weld heat treatment. This welding process can save massive energy, and also avoid the welding defect that fusion welding brings.

5 Conclusions

1) For each condition of Al-Mg-Mn-Sc-Zr alloy, namely thick hot rolled plate and cold rolled-annealed plate, the tensile strength, elongation and welding coefficient of FSW welded joints are higher than those of TIG welded joints. Compared with base metal, the strengths of FSW and TIG welded joints both decrease. For the TIG welding process, the properties of cold rolled-annealed plate are better than those of hot-rolled plate. The FSW welding process can bring better mechanical properties.

2) The WNZ of FSW and the molten zone of TIG are the weakest zone of the welded joints. For the FSW welded joint, the main reasons that lead to the decrease of its strength are the loss of substructure strengthening related to recrystallization and a very few loss of precipitation strength of Al3(Sc, Zr). As for the softening of TIG welded joint, owing to the process of meltage, the strain hardening disappears entirely and most precipitation strengthening of the second Al3(Sc, Zr) disappears.

References

[1] HEURTIER P, JONES M J, DESRAYAUD C, DRIVER J H, MONTHEILLET F, ALLEHAUX D. Mechanical and thermal modelling of friction stir welding [J]. Journal of Materials Processing Technology, 2006, 171(3): 348-357.

[2] KNIPSTROM K E, PEKKARI B. Friction stir welding process goes commercial [J]. Welding Journal, 1997, 76(9): 55-57.

[3] ESPARZA J A, DVIS W C, E TRILLO A, MURR L E. Friction stir welding of magnesium alloy AZ31B [J]. Journal of Materials Science Letters, 2002, 21(12): 917-920.

[4] MERAN C. The joint properties of brass plates by friction stir welding [J]. Materials and Design, 2006, 27(9): 719-726.

[5] LEITAO C, LEAL R M, RODRIGUES D M, LOUREIRO A, VILACA P. Mechanical behaviour of similar and dissimilar AA5182-H111 and AA6016-T4 thin friction stir welds [J]. Materials and Design, 2009, 30(1): 101-108.

[6] SATOY S, YAMANOI H, KOKAWA H, FURUHARA T. Microstructural evolution of ultrahigh carbon steel during friction stir welding [J]. Scripta Materialia, 2007, 57(6): 557-560.

[7] KWON Y J, SHIGEMATSU I, SAITO N. Dissimilar friction stir welding between magnesium and aluminum alloys [J]. Materials Letters, 2008, 62(23): 3827-3829.

[8] CHRISTIAN B F, MURRAY W M, MIKE C. Evolution of microstructure and mechanical properties in naturally aged 7050 and 7075 Al friction stir welds [J]. Materials Science and Engineering A, 2010, 527(9): 2233-2240.

[9] LI Y, TRILLO E A, MURR L E. Friction-stir welding of aluminum alloy 2024 to silver [J]. Journal of Materials Science Letters, 2000, 19(12): 1047-1051.

[10] PEEL M, STEUWER A, PREUSS M, WITHERS P J. Microstructure, mechanical properties and residual stresses as a function of welding speed in aluminium AA5083 friction stir welds [J]. Acta Materialia, 2003, 51(16): 4791-4801.

[11] GENEVOIS C, DESCHAMPS A, DENQUIN A, DOISNEAU-COOTTIGNIES B. Quantitative investigation of precipitation and mechanical behaviour for AA2024 friction stir welds [J]. Acta Mater, 2005, 53(8): 2447-2458.

[12] RHODES C G, MAHONEY M W, SPURLING R A, BAMPTON C. Effect of friction stir welding on microstructure of 7075 aluminum [J]. Scripta Materialia, 1997, 36(1): 69-75.

[13] MAHONEY M W, RHODES C G, FLINTOFF J G, SPURLING, BINGEL R A. Properties of friction stir welded 7075-T651 aluminum [J]. Metallurgical and Materials Transaction A, 1998, 29(7): 1955-1964.

[14] CAVALIERE P, CABIBBO M, PANELLA F, SQUILLACE A. 2198 Al-Li plates joined by friction stir welding: Mechanical and microstructural behavior [J]. Materials and Design, 2009, 30(9): 3622-3631.

[15] YIN Zhi-min, PAN Qing-lin, ZHANG Yong-hong. Effect of trace Sc and Zr on the microstructure and mechanical properties of Al-Mg based alloys [J]. Materials Science and Engineering A, 2000, 280(1): 151-155.

[16] MILMAN Y V, LOTSKO D V, SIRKO O L. ‘Sc effect’ of improving mechanical properties in Aluminium alloys [J]. Materials Science Forum, 2000, 331(3): 1107-1112.

[17] YUTAKA S S, KOKAWA H. Distribution of tensile property and microstructure in friction stir weld of 6063 aluminum [J]. Metallurgical and Materials Transactions A, 2001, 32(12): 3023-3031.

[18] ZHANG Hua, LIN San-bao, WU Lin, FENG Ji-cai. The weld nugget formation of friction stir welded AZ31 magnesium alloy and its affecting factors [J]. Journal of Aeronaut Mater, 2004, 24(6): 6-10. (in Chinese)

[19] CHRISTIAN B F, ALBERT R K, DAVID C D, DAVID N S. Microstructure and mechanical properties of a 5754 aluminum alloy modified by Sc and Zr additions [J]. Materials Science and Engineering A, 2002, 338(1): 8-16.

[20] CAVALIERE P, CABIBBO M. Effect of Sc and Zr additions on the microstructure and fatigue properties of AA6106 produced by equal-channel-angular-pressing [J]. Materials Characterization, 2008, 59: 197-203.

[21] KENDIG K L, MIRACLE D B. Strengthening mechanism of Al-Mg-Sc-Zr alloy [J]. Acta Mater, 2002, 50(16): 4165-4175.

[22] LAPASSET G, GIRARD Y, CAMPAGNAC M H, BOIVIN D. Investigation of the microstructure and properties of a friction stir welded Al-Mg-Sc alloy [J]. Materials Science Forum, 2003, 426(4): 2987-2992.

[23] CABELLO M A, R?CKERT G, HUNEAU B, SAUVAGE X, MARYA S. Comparison of TIG welded and friction stir welded Al-4.5Mg-0.26Sc alloy [J]. Journal of Materials Processing Technology, 2008, 197(1-3): 337-343.

[24] CHANG W S, BANG H S, JUNG S B, YEON Y M, KIM H J, LEE W B. Joint properties and thermal behaviors of friction stir welded age hardenable 6061Al alloy [J]. Materials Science Forum, 2003, 426(4): 2953-2958.

[25] SAUVAGE X, D?D? A, CABELLO MU?OZ A, HUNEAU B. Precipitate stability and recrystallisation in the weld nuggets of friction stir welded Al-Mg-Si and Al-Mg-Sc alloys [J]. Materials Science and Engineering A, 2008, 491(1-2): 364-371.

何振波1, 2, 彭勇宜3, 尹志民1, 雷学锋1

1. 中南大学 材料科学与工程学院,长沙 410083;2. 东北轻合金有限责任公司,哈尔滨 150060;

3. 中南大学 物理科学与技术学院,长沙 410083

摘 要:研究Al-Mg-Mn-Sc-Zr合金的焊接工艺和焊接接头组织和性能。采用搅拌摩擦焊(FSW)和氩弧焊(TIG)2种焊接工艺对该合金的热轧和冷轧-退火2种使用态板材进行焊接。采用比较研究的方法测定和研究焊接接头的力学性能和显微组织,利用光学显微镜和透射电子显微镜研究焊缝的显微组织和力学性能之间的关系。结果表明,与基材相比,Al-Mg-Mn-Sc-Zr合金的热轧和冷轧-退火板材的FSW和TIG焊接接头的强度均下降,但FSW焊接系数高于TIG焊接系数。这是因为FSW焊接接头焊核区亚结构强化的丧失和Al3(Sc, Zr)的析出强化作用的极少量丧失,而TIG焊焊接接头的软化主要原因是其形变强化的完全丧失和Al3(Sc, Zr)的析出强化作用的大部分丧失,且搅拌摩擦焊焊核区晶粒比TIG焊的焊缝区晶粒更细小。

关键词: Al-Mg-Mn-Sc-Zr合金; 搅拌摩擦焊; 氩弧焊; 焊接接头

(Edited by FANG Jing-hua)

Foundation item: Project (MKPT-2005-16ZD) supported by the National Key Scientific and Technological Project of China; Project supported by the Postdoctoral Science Foundation of Central South University, China

Corresponding author: YIN Zhi-min; Tel: +86-731-88830262; E-mail: zmyin@163.com;

PENG Yong-yi; Tel: +86-13973183149; E-mail: pengyongyi@126.com

DOI: 10.1016/S1003-6326(11)60915-1